Job interviews are not easy. If you want to apply for...

Sealing seams in a panel house can be done in several ways. The choice of a specific technology depends on the condition of the building and the goals set. Our company provides a full range of services related to the repair of interpanel seams, namely:

Opening and cleaning the seam;

Removing the remnants of the old sealant from the facade;

Filling the seam with mounting foam;

Laying insulation "Vilaterm";

Covering the insulated seam with mastic.

|

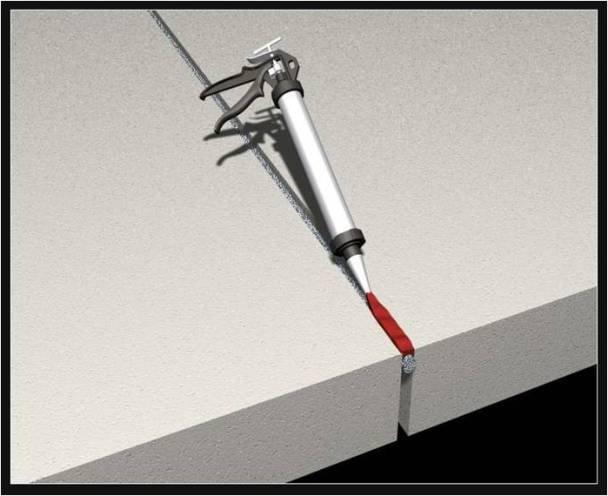

See the technology of work:

|

Sealing "closed" joints of external wall panels vulcanizing sealants using polyurethane polyurethane foam or without the use of mounting foam. |

|

Sealing joints of the "closed" type with vulcanizing mastics / sealants is carried out on the basis of Vilaterm polyethylene foam gaskets installed in the joint "dry". If necessary, voids can be foamed with Illbruck PRO 70 mounting foam. Filling the mouth of the joint with mastic is done with a spatula. With a large opening of the joint, the mastic is applied with a stop on the panel of the outer walls up to 3 cm. |

|

|

The temperature is not lower than -20°C in the absence of precipitation. The thickness of the applied sealant layer is at least 3 mm. |

|

|

Vulcanizing mastic / sealant: Akatamast, Oksiplast, Elastosil, Sazilast. |

|

|

The spatula is universal. |

The final price for the performance of work will depend on the number of linear meters on which the sealing should be carried out. You can find out the exact cost of the work thanks to the free measurer call service, with the help of a telephone consultation or by calculating it yourself using this price list:

|

Name of works |

Unit measurements |

Price, rub.) |

|

1. Primary sealing of the seam with insulation |

||

|

2. Secondary sealing |

||

|

3. "Warm joint" (opening or drilling holes in the concrete joint, foaming, sealing) |

||

|

4. Sealing stained-glass windows, skylights |

||

|

5. Sealing window joints |

||

|

6. Sealing seams of metal roofing |

||

|

7. Sealing the visors |

||

|

8. Sealing the technical floor slabs (without replacing the roof deck) |

||

|

9. Sealing of technical floor slabs (with replacement of roof decking) |

1. ZhSK "Serpukhov". Sealing joints 3,200 running meters

2. Sealing 5,050 linear meters - "Warm seam"

3. Sealing "Warm seam without opening" - 7 750 m.

You leave a request

Is free

In 15 minutes

We contact you

Is free

On the day when

appointed

meeting

We inspect the work site, take measurements

Is free

In 2 hours

after meeting

We provide you with an estimate for high-altitude work

Is free

Next

day

We conclude an agreement

Prepayment

within the stipulated

terms

We carry out all works "turnkey"

final settlement

You receive fully completed high-rise work on time and within

the price agreed in the contract.

Our company guarantees the repair of panel joints in accordance with all technical instructions adopted in the Russian Federation. In their repair and construction activities, specialists are guided by the main regulatory documents, such as:

SN 420-71 "Building codes and rules for sealing interpanel seams";

VSN 19-95 "Instruction on the technology of sealing butt joints of panels of external walls of residential buildings";

VSN 40-96 "Instruction for the performance of work on sealing the joints of external walls and window blocks";

TR 94.10-99 "Technical regulations for work on sealing joints of external enclosing structures";

TR 94.07-99 "Technical regulations for work on sealing joints of external enclosing structures";

44-03 TK ( routing) "Sealing the joints of external enclosing structures";

VSN-119-75 "Instructions for sealing joints during the repair of prefabricated buildings";

TR 95.07-99 "Technological regulations for sealing joints of external enclosing structures";

VSN 170-80 "Instruction Sealing vertical and horizontal joints of panels of external walls of the series"; P44/16

VSN 17-94 "Instruction on mechanized technology of thermal insulation of joints of external wall panels of residential buildings with phenol-formaldehyde foam".

Following these standards, the company has developed its own methods for performing external sealing of joints, thanks to which our customers have been receiving a high-quality and fast solution for the insulation of expansion joints for more than 10 years. Experienced industrial climbers that work in the state, use the latest equipment and construction facilities - those advantages that make it possible to call the group of companies OOO "Diamand" a leader in its industry. Convince yourself of this too!

Fast erection, low-cost apartments - all this explains the growth in construction panel houses. The fact that such buildings give a "good" shrinkage people know firsthand. New settlers are in no hurry to make renovations in their apartments, realizing that it is necessary to wait a certain period (at least three years) after the completion of the construction of the house.

What is a panel building made of? The "raw material" basis of construction is reinforced concrete slabs. If during their production all technological processes are sustained (composition of the material, drying and pressing conditions), then in general a solid and reliable house should be obtained. The structural integrity and strength of the boards can be compromised if the material was not dried well enough under factory conditions. This is one of the reasons for the formation of cracks in a panel house. The second reason is sediment. panel house.

The main technological feature of the concrete structure is the presence of seams. Poor tightness of the seams causes uncomfortable living in the apartment. “It blows from all cracks” - one often hears from residents of panel houses. Dampness and high humidity in the room lead to the formation and spread of fungus and mold, which negatively affects the health of households. The solution to this problem is the insulation of interpanel seams. The work is carried out using various building materials: mastic, sealant, mounting foam and others.

Should I open the seam? Before answering this question, it is necessary to check the condition of the docking area. For these purposes, use a climbing hammer with a sharp tip. Using a tool, the seam is checked for strength. They strike and the result is used to judge the state of docking. If the seam is broken into pieces, then an opening and complete sealing is required. When working with concreted joints, it is recommended to use a chipper.

If earlier they used tow or rubber for these purposes, today builders more often work with materials such as dowels, cement mortar, and hydrophilic rubber swelling cord. Here are a few reasons why such sealing cannot be considered high-quality and complete:

Fully fill interpanel seams and voids is capable, perhaps, only mounting foam. It evenly spreads over the surface of the walls and leaves no “sins”. Together with it, a sealant is also used (we have already talked about this, revealing the topic of how to insulate interpanel seams).

Panel housing construction replaced brick housing in the middle of the 20th century. Panel housing allows you to build in a short time and inexpensive housing at cost. In a panel house, expansion joints are necessary between the panels so that the building does not collapse during settlement. The expansion joint is the empty space between the panels that allows the house to move and remain stable. Sealing joints in prefabricated houses is necessary to eliminate heat leaks and waterproofing the panel facade. Reinforced concrete panels must be produced in accordance with approved GOSTs in a certified production. If all the technological processes of manufacturing boards, according to the marking, such as the composition of the board material, pressing and drying conditions, are maintained, then, in principle, high-quality housing can be obtained as a result. In this case, the plate can withstand the necessary load in a multi-storey building. If a panel house is being built in a geo-movable place, the slabs must withstand the additional load that occurs when the house settles.

Interpanel seams- this is an empty space at the joints between the exterior panels of the house, the so-called expansion joints, which are necessary for the thermal seasonal expansion-compression of the panels and to ensure the stability of the building during settlement. Insulation of interpanel seams and waterproofing of panel joints are necessary for panel buildings of all series.

Complex sealing of the seams of a panel house includes insulation of the entire interpanel cavity (filling with polyurethane foam and vilaterm laying) and waterproofing the panel joint (application of sealing rubber mastic).

In most panel houses of the 20th century series, the seams between the panels were insulated with tow and sealed with cement mortar. But the cement mortar is not deformable and allows moisture to pass through, as a result, water and ice destroy the interpanel seam.

According to another technology, in some series of houses, rubber and metal profiles with rubber bands were used to seal the seams. Rubber on the profile bar, under the influence of the building's settlement, moisture, ice and temperature changes, quickly cracks and shrinks. And after a short time, it no longer adheres tightly to the walls of the panel seam, so that water freely flows into the seam from the outside, and cold air freely circulates inside the seam. Metal profiles are more decorative elements than thermal or hydroprotection.

Many people, after buying an apartment in a new panel house, wait three years and only after that make repairs. During the precipitation in the panel house, cracks are formed absolutely unpredictably. If the house is built in winter, this imposes additional risks. The panels at the factory do not have time to dry, often they dry on the way to the construction site. Water inside the panels turns into ice and destroys the structural integrity and strength of the slab.

In any panel houses, sealing of seams is necessary. In concrete structures, seams are indispensable. Seams in monolithic houses are caused by the need for breaks in concreting. In panel buildings, seams connect the panels. Therefore, the seams in concrete houses must be given priority. Seams in building structures are stress concentrators and have an unpleasant property to diverge. Panel joints should only be sealed with elastic materials. A rigid material with good adhesion to concrete will crack over time due to the inevitable shrinkage of the concrete.

All voids between the panels must be filled, and the joint between the panels must be sealed. The tighter the interpanel seam is sealed, the warmer it will be in the house. The highest quality seam sealing is produced using technology

"Tight seam".

Previously, during the construction of panel houses, the interpanel seam was filled with tow or rubber. In modern construction, the seams are sealed in different ways, depending on the series of the house. For example apply:

- Swellable cords made of hydrophilic rubber,

- Profiles (dowels)

- Cement mortar

The quality of such sealing cannot be high and absolutely does not fulfill its functions for the following reasons:

- The gaps between the plates are different.

- There are internal chips and cracks between the plates.

- Poor performance of work even with such unacceptable technologies.

The joints between the panels are not even, and water and wind get into them, contributing to the further destruction of the panel. When the house settles, the gaps between the plates become larger, and problems crawl out. Very often it is impossible to understand where the water flows from and from which cracks the wind blows.

It is necessary to eliminate the causes of these problems. It is impossible to completely close the seam from the side of the apartment. This can partially solve the problem of keeping warm on short period time. The seam can only be completely sealed from the outside. From the inside, access to the interpanel joint is impossible due to the horizontal ceiling and floor slab. If a low-quality panel cracks on the first or last floors, this leads to huge heat losses, since the violation of the tightness of the outer floors contributes to additional air extraction. If the slabs are destroyed on the technical floor or in the basement, then except for the owners of apartments on the top and first floors, no one feels this in full.

Khrushchev houses are called houses, the construction of which began during the reign of N. S. Khrushchev, from 1956 to 1964. It is worth noting that in the capital their construction continued until 1972, and in some areas - until the mid-80s. Houses with a height of 5 floors were originally built of brick, but due to the high cost of materials, in the early 1960s it was decided to build buildings from panel blocks. The disadvantages of Khrushchev include a small area. For example, the kitchen area does not reach 6 m2, and the bedroom does not exceed 9. The ceiling height reaches 2.5 m. In winter, heat is not retained in such apartments, but in summer, on the contrary, it is very hot. There is no attic, like a garbage chute, in such houses. Elevators are also not provided. The toilet and bathroom are located in the same room. However, among all the shortcomings, it is worth highlighting the main advantage: an attractive price, a convenient location of houses, since they were located in areas of the city where the infrastructure was sufficiently developed, not far from metro stations.

As the name implies, houses that were designed at a time when the General Secretary of the Central Committee of the CPSU Leonid Brezhnev was in power (1964 - early 1980s). Brezhnevka has high ceilings - 2.65 m. There is an elevator and a garbage chute. One of the disadvantages is the poor thermal insulation of the walls, but on this moment in such buildings, major repairs are carried out, correcting all the shortcomings.

There are several series of panel houses on the real estate market. The most prestigious among them are series 137. Spacious apartments, up to 70 m2, large kitchens, reaching 9 sq.m. The middle class includes series 600.11 and 606. The kitchens in such houses are 2 squares smaller than the rooms in the houses of the 137 series, and the area of the apartments themselves is about 65 sq.m. The economy version of panel houses are houses of the 504 series and "ships". The premises in the apartments were narrowed by 1.5 times, the kitchens were reduced to 6.3 m2. The windows are high and there are no window sills.

Block buildings are often confused with panel buildings, however, they have a difference. If in the panel one each wall is a separate panel, then in the block one the walls are made up of several separate blocks. In addition, in both types of houses, twin window frames are of poor quality. One of the main drawbacks is poor-quality plaster, and uneven ceilings at the joints of the floors are constantly deformed, forming cracks in the plaster. This defect can also be found in Brezhnevka. Among the advantages - affordable redevelopment. If desired, you can not only expand the window and door openings, but also change the area of rooms, bathrooms, toilets, kitchens.

erection monolithic houses begins with the preparation of the formwork, and a ready-made concrete solution is brought to the construction site. It is worth noting that when building monolithic houses, they do not do “wet” work (plaster and putty). The absence of seams can significantly increase heat saving and sound insulation. Innovative technologies and modern insulation help to reduce the volume and weight of the structure, while increasing the quality of operation in cold weather. As a result of the reduction in mass, the need for an overly powerful foundation is lost. Thus, the material consumption and the cost of laying the foundation are reduced. It is impossible not to say about the shrinkage of the building, which is simply absent in monolithic ones. Therefore, immediately after putting the house into operation, repairs can begin in the new apartment. There is an opinion that monolithic houses are unsuitable for habitation. It is justified on the fact that solid walls do not let air through. If we take into account the ecology, then it's time for everyone to move closer to the forest, to cozy wooden houses. As for the monolith, modern materials and the latest technologies make it possible to build buildings that are completely safe for housing.

The options for custom home projects are endless. Depending on the ideas of the designers, the amount invested in the construction, the construction of real masterpieces is possible. The walls between the apartments are also built of brick. Such houses are very warm, however, and not everyone can afford apartments in such a house. The factor that determines the cost of an apartment in an individual house is its location and infrastructure. To increase heat and sound insulation in houses, high-quality triple-glazed windows with 3-glazing are mounted.

One of the most common types of buildings these days. The frame is made monolithic, and the outer walls are made of brick. These are the most earthquake and flood resistant buildings. Inter-apartment partitions are load-bearing, but inside the apartment you can make any layout. Thermal insulation is increased due to high-quality insulation in several layers. The service life of such houses is about 100 years, and with the timely repair of the roof and facade, it increases.

The choice of a method for sealing panel joints for houses of various series primarily depends on the technological features of the erected building and the design of wall panels. Besides, important point is the economic feasibility of using the chosen method of sealing joints in each case.

One of the best is the sealing of seams using the "Dense Seam" technology. The essence of this technology is the complete filling (insulation) of the seam, followed by waterproofing of the joints. All work is carried out using environmentally friendly materials, such as Vilaterm polyurethane sealant, Macroflex sealant and Oksiplast mastic. Depending on the specific series of the house, the technology of waterproofing the joints in each case has its own characteristics.

The design feature of the houses of the KOPE series is the use of double sandwich panels during their installation, inside of which there is a void. Since the panels are not airtight, they do not retain heat well, and damp cold air from the street easily penetrates into the apartments. Sealing the interpanel seams with mounting foam in this case is very expensive and does not give the desired result, since the sealant simply spreads over the voids in the panels and does not hold the seams. For high-quality sealing of the seams, the Vilaterm sealant is used, which directly fills the joint between the panels, and, accordingly, the entire wall is insulated. At the same time, imperfections and structural gaps in sandwich panels are eliminated along the way.

In panel houses of the p.44, p.44t series or houses of the "Soviet panel", problems arise mainly due to chips in the panels and large joints through which moisture seeps and cold air passes. In these houses, it is usually quite cold, condensation collects on the walls, and it is very drafty under the ceiling and at floor level. In this case, the “Warm joint” technology is excellent for sealing panel joints, and if the distance between the plates is very small and it is not possible to lay “Vilaterm”, then the joints in this case are well foamed and covered with sealant. Without access to moisture, air and direct sun rays, polyurethane foam serves for a very long time and reliably.

Unlike panel houses in monolithic-brick structures, the main problem arises when joining brickwork and monolithic ceilings, as well as at the junction of double-glazed windows on glazed loggias. These joints are not enough just to foam and plaster, they need good sealing of the window seams, which will reliably protect the rooms from the penetration of cold air and moisture.

Very often, before sealing the seams, it is necessary to repair the facade.

We will make high-quality seam sealing for you!

At least 50 percent of the housing stock is made up of apartment buildings that were built using panel technology. She provided housing for many in need.

The main problem of such buildings is the leakage of joints, which are formed by structural elements. This indicates that in some cases the need for sealing joints in a panel house is especially acute. Thanks to these procedures, it is possible to reduce energy consumption, get rid of mold, and also improve the microclimate in the premises of the house.

Seam sealing was relatively recently considered not such an important task, which is why little attention was paid to this issue. Most construction organizations used traditional glass wool or tow to carry out these works; at best, rubber-based seals were used. Then the seam was filled with a mixture made of sand and cement. At the last stage, the surface was covered with bitumen-based mastic. Due to the fact that any building structure shrinks during operation, the sealing of the seams is broken, even a very slight displacement of the panels in relation to each other contributes to a change in the initial joint geometry. Moisture gets into the seam, which contributes to destruction cement mortar, opens up space for external influences: precipitation and winds. The sealing of joints after such phenomena can, of course, be carried out in the manner described above, however, there will be no guarantee of durability. Depending on the state of the joints between adjacent panels, today it is customary to use several methods.

Sealing the seams should be done after the master manages to determine the state of the groove. Thus, if the concrete or cement filling is not badly damaged, then cosmetic repairs are carried out. This access method acts as the most budgetary, but it does not guarantee efficiency. If the main area of the seam remains in good condition, but has some defects, then repair work is carried out according to a technology that involves partial opening of the seam at the original level. The best, but very expensive option is the sealing of joints using a technology called "warm seam". It should be mentioned that sealing cannot be performed from inside the room. If such works were produced, then they cannot be called high-quality. All such manipulations should be carried out exclusively from the side of the facade of the building.

However, when repairing an apartment, it is possible to fill open joints using mortar and insulating material. This will achieve a certain effect, but the situation will not change radically. Among other things, sealing of interpanel joints must be carried out over the entire height, otherwise there will be no guarantee that water that has entered between the panels will not destroy the already repaired surface. For this reason, it is preferable to cooperate with neighbors, it will be cheaper and more reliable due to the amount of work being done. The cost is affected by the need to attract climbers to carry out these manipulations on multi-storey buildings. It must be taken into account that the use of lifting towers and other devices is often not possible.

Sealing of interpanel seams can be made without opening. This option is considered the most inexpensive. It should only be used when the joint coating is in perfect condition. Initially, an analysis of the state of the seam is carried out, with the help of a spatula it is necessary to remove the layer of old mastic or resin. If the cement on the base is reliable, then to save money, you can limit yourself to a cosmetic finish. However, sealing panel joints using this technology is not correct. After the seam has been cleaned, it must be treated with a deep penetration primer, it is preferable to use a composition that has fungicidal additives. If there is a need, then the disturbed places can be repaired with a solution. Then the entire surface must be treated with a water-repellent mastic. In order for the seams to be sealed in a panel house, one- or two-component compositions can be used, the choice will be up to the customer. A number of experts advise the use of two-component compositions based on polyurethane.

For the reason that the sealing of the seams of the house can only be done qualitatively from the outside, it is necessary to prepare the components of the mixture well, which are stirred with a mixer. The sealant is applied to the seams with a spatula, the width of the tool is selected depending on the dimensions. It is recommended to seal the front edges of the panels with masking tape, which is removed after processing with mastic. This allows you to get a more aesthetic surface.

Seam sealing wooden house can be made with a partial opening of the seam. If some part of the coating is broken or there is confidence that there is no sealing material behind the screed layer, then the sealing is carried out using a technology that involves the removal of the cement coating. If, according to this principle, a small part of the seam is opened, holes must be drilled every twenty-five centimeters. You need to use a drill for this. After the voids are filled with mounting foam, for which it is preferable to use a special gun, which will reduce material consumption. After the foam has hardened, its protruding parts must be removed. The seam is treated with a primer, hidden areas and holes are plastered. The final step is the processing of the seam with mastic.

The best way to deal with leaky seams is in a way called "warm seam". The cost will be higher, but the quality of the work will be at its best. Let's consider it in more detail.

The best way to deal with leaky seams is in a way called "warm seam". The cost will be higher, but the quality of the work will be at its best. Let's consider it in more detail.

Manipulations must begin with opening the seam along the entire length, the sealant must be removed, and the edges of the panels, if necessary, restored. The surface must be treated with a primer. The seam must be sealed with foam, given its ability to expand. After the foam begins to increase, you need to lay a sealant made of foamed polyethylene on top. This will prevent foam from escaping. This seal is produced in the form of hollow tubes, however, solid ones can also be purchased. The dimensions of this material should be more than the width of the seam by fifteen centimeters. In place of its installation is carried out using a spatula, the element must be pressed into the layer of mounting foam. Care must be taken during installation to avoid damage to the material. In this case, tape can also be used to seal the seams. This technology is considered today the most effective and modern. Its use allows you to heat-insulate the seam, making it waterproof, which will provide reliable protection of the home from the effects of external negative factors, and increase the operational life of the building. Sealing in multi-storey buildings should only be carried out with the help of professional support.

You can experiment with sealing joints only at the level of 1-2 floors, having the ability to mount sustainable scaffolding. In other cases, it is reasonable to entrust these manipulations to industrial climbers. After all, it will be very difficult to physically carry out such work, even with the appropriate equipment, without professional experience. In addition, it is very dangerous, and at least the result of the work carried out on your own may not suit you, because you do not know about the subtleties and basic rules that should be followed.

A variety of construction technologies is associated with the search for opportunities to reduce costs. Moreover, it is desirable to reduce the cost of work and the time of their implementation. That is why it has become widespread panel construction. In pursuit of deadlines, little attention was paid to the quality of such buildings. In this regard, the issue of warming the butt joints between the plates is quite acute.

Concrete panels themselves are a source of cold. Increased heat transfer occurs through concrete, which leads to significant heat losses in the apartment. But this is half the trouble. The thin point of such construction are interpanel seams. Although the seams are insulated at the frame installation stage, this is not enough. There are several reasons for the problem:

These and many other circumstances force us to resort to re-sealing.

Insulating materials not only prevent the formation of cold bridges. They contribute to the fastening of the structure, which has a positive effect on its durability. In this case, minor displacements and deformations can be avoided.

Protection against the penetration of dampness and cold reduces their detrimental effect on the frame. In this case, the service life is extended. Education is also excluded:

1. A common method of insulation is the complete sealing of the seam. During the construction process, this is achieved by embedding with mortar.

Plastic solutions are used in the work. They penetrate deep into the cavities of the structure, filling the voids. The aggregate for such materials should be sufficiently fine. As it is used:

Currently, manufacturers of cement mixtures produce special insulating compositions. They include foam balls. Thanks to them, concrete contributes to the retention of heat flow.

There are also special mixtures with air particles. Air bubbles keep heat in, preventing it from seeping out. At the same time, the cold cannot get inside.

The last two types of products can be:

The first option is more convenient in terms of the correct ratio of components. The second one is cheaper and allows you to adjust the workability and some properties depending on the working conditions.

Greater confidence in the insulation abilities will give the use of expanded polystyrene concrete to fill the seams. It differs from conventional mixtures with the addition of insulating elements by GOST manufacturing standards.

2. With a large distance between the seams, you can use soft warming fibers. The most affordable option would be to use mineral wool. It is characterized by:

Warming with the help of this material consists in pressing parts of the mat into the area of non-integrity of the structures.

The disadvantages of insulation will be:

It is much safer to use stone wool. As a heater for a residential building, it is better to choose a basalt composition. She:

Installation of such a heater does not take much time. No additional adhesive structures are needed. The fiber is mounted by surprise. However, it is not necessary to overfill the seam with material. In the case of a tight fit, the fibers will not provide the necessary thermal protection.

3. The use of polyurethane based sealant is common for small joints. The consumption of this heater is quite large, and its cost is considerable.

This technology provides the following methods of insulation:

The first option is less expensive. In this case, the nozzle of the sprayer is placed in the joint cavity and the gap is foamed with the material.

In the second case, the seam between the plates is expanded with the help of special tools. Foaming occurs in excess. During the expansion process, the foam should stick out. After curing, the excess material is cut off.

4. Vilaterma tubes are specially designed for insulation of interpanel space. The product is a solid or hollow polyethylene foam cylinder.

The advantage of this type of insulation is the simultaneous protection against moisture. The properties of the product will not allow moisture to penetrate into the seam. In addition, polyethylene seals are quite elastic and remain so even when temperatures change. This parameter will ensure the durability of the work, even when compressing parts of the house.

insulation apartment building outside is most effective. But there may be difficulties associated with high-altitude work.

If it is not difficult to seal the joints of the first floor panels, then serious problems can arise with the fifth.

There are three ways to solve this situation:

Installation of supporting structures is possible only with a small height of the building. Scaffolding can be used with self-insulation of interpanel seams. You can rent them in any city.

The convenience of the approach lies in the possibility of covering a large width. In addition, there is always a place to place tools and materials for sealing.

The use of a tower is a more costly way. This method is mainly used when part of the structure diverges. With local weakening, the amount of work is immediately visible, most often it is small.

The tower allows you to work at an impressive height. But the range of work in this case is small. There is not enough space in the cradle to accommodate inventory, which creates additional problems.

Use is rational for long-term work in one place. These are the cases:

Appeal to climbers is necessary in case of repair of high-rise structures. Organizations engaged in such work must provide a certificate assuring the client that they have complied with all regulations. Insulating seams in panel houses at height is dangerous work, and before starting it, you should make sure that the employees are competent.

Often, mountaineering does not provide for sealing the seams specifically, but for work on continuous insulation. In this case, a closed system is obtained that does not let the cold into the room.

Work is carried out on a cleaned and leveled surface. Plate-type insulation materials with a high coefficient of strength.

In no case should the junction of the insulation elements be allowed to fall on the junction of the plates. With such a deficiency, cold bridges are inevitably formed. Insulating elements should cover the joints, protecting them from the movement of air masses.

Spend interior work you can on your own. Therefore, many apartment residents and office owners prefer this option.

Insulation of joints is facilitated:

Before insulating interpanel seams, it is necessary to dismantle the protective layers of the joint. Often it is putty and plaster. You can also encounter previous insulation.

In no case should new work be carried out without deleting old materials. This attitude can lead to decay of the previous components, which will render the repair unusable.

The service life of previously used heaters could expire. They may be unsuitable for service or may not meet the requirements of this process at all.

After removal of interfering components, it is necessary to remove from the surface:

This amount of work will protect against destruction of the coating in the future.

If the cavity between the plates is through, it must be monolithic with fastening compounds. It is best to do this with a cement-sand mortar. He:

The main problem with working with such defects is the ingress of moisture. You can fight this with the help of waterproofing mastics.

You can apply the material using:

After setting, the substance forms a waterproof elastic barrier. A thin layer of spraying provides a minimum consumption of sealing material. The advantage is the high tensile strength. With minor deformations of the building, there is a guarantee that the coating will remain intact.

In the case of a small space between the plates, sealing with sealants and further gluing with insulating tape is used. The material is a strip of soft insulation on an adhesive base. Its use allows you to avoid a multi-level process of work.

In any case of insulation, it is necessary to observe the complexity of measures. Subject to seal:

Only technologically proper conduct work will provide optimally comfortable living conditions. At the same time, the level of costs will be reduced, in comparison with partial operations, for the formation of a warm apartment.