DEGREES OF COMPARISON OF ADJECTIVES In English, as in Russian, ...

fundamentally changed low-rise housing construction. Canadian frame housing technology is a special case of panel housing technology that has moved from mass panel housing construction to the individual sector and is made of wood, the predominant building material. This technology has put on stream the production and construction of comfortable and affordable houses for people.

The term "Canadian technology" has been used in construction practice in Russia for a long time. At the end of the last century, the construction of frame-panel houses for the construction of summer cottages became popular. Dachas were called Finnish houses and were built from wooden panels with wall insulation from mineral wool and foam. The ease of erection of structures and the speed of erection in 3 months were liked by the Russian consumer. There was an interest in improving construction technology and expanding the properties of insulation with the speed of building houses. In the USA much earlier than in Canada put on stream frame houses, and our technology was called "Canadian".

The first Canadian houses in Russia were built from components produced locally. A frame was mounted on the finished foundation, a roof was mounted on the frame, and the space of the house was gradually filled with walls and partitions. In the 21st century, the technology of frame housing construction is very different from that used at the beginning of this century. Eighty percent of building elements are manufactured in-line. Further progress in panel housing construction led to the fact that the frame of the house is assembled on the site from ready-made blocks. The Canadian house is combined at the request of the customer from ready-made panels, like a Lego constructor.

Since 2000, the RNR company, under the official license of the Canadian Housing Association, began manufacturing frame houses using equipment purchased in 2001. Since then, the company has built hundreds of frame houses using Canadian technology, and created thousands of kits for the construction of frame houses. The company's factories in the Rostov region and the Moscow region are loaded with orders for 2-3 months in advance. The products of these plants are I-beams, pre-assembled wall panels, truss systems for roofs of houses and basic sets of frame houses. The company sells OSB boards to European manufacturers and distributors.

The RNR company uses its know-how idea, an I-beam to make a load-bearing frame. Such a beam has strength to loads, the weight is 20% lower. This reduces the load on the foundation, increases the speed of installation and simplifies the technology of building a house (no heavy special equipment is needed for installation). With the help of the use of an I-beam, two and three-story houses are erected.

The company owns a procurement complex and a complex for primary wood processing. Blanks of parts for the manufacture of houses are dried in drying chambers, flame retardant and antiseptic impregnation, which increases the service life of products.

The quality of manufacturing frame houses is ensured by an organized system for creating projects. RNR plants are equipped with design and quality control systems. Calculation of structures and drawings is carried out according to the standards of 2010 computer programs and gives a 3D image model of the house. Individual projects are developed or standard changes are carried out in a short time.

Mechanics, engineers and builders control the operation of the equipment. The level of automation of production processes is high, which minimizes human errors in the production process. Moisture resistant OSB boards are used for the outer cladding, and plywood or OSB slabs are used for the inner cladding. Outside, the panels are finished to look like natural stone, brick, siding or other materials. It is also possible to plaster the house outside.

A feature of frame houses is their thermal insulation qualities and low costs for heating the house. The frame house heats up quickly and slowly releases heat. Heating is provided by air ducts, through which warm air from a heat pump or other heat producer enters each room and heats up in a matter of minutes. Each room of the house receives as much heat energy as the person living in it requires. In the same way frame house behaves in the heat, only through the air ducts the air cooled by the air conditioner enters the rooms.

Both the manufacturer and the consumer benefit from the production of frame houses.

The manufacturer of frame houses receives:

The consumer acquires:

Additional resistance to external damage is added by the use of external finishes. Exterior finish option - with the use of reinforcing mesh, on top of which the outer layer is attached finishing materials. Finishing the house with brick or natural stone adds strength and stability to the walls.

The RNR company, in addition to modern equipment for the production of houses prepares production personnel and assemblers for the assembly of frame houses. Preparation is carried out for our own production and construction, and for third-party construction organizations. The company uses the Canadian system of personnel training. In addition, periodically the company's masters are trained to improve their skills and master new tools in Canada.

Quality control in the company begins from the moment of receiving an order for a house, then at the stages of production and construction. Each project is assigned a quality manager who controls the stages of the house passing through the production chain and the stages of building construction.

These measures allow the company "PHP" to confidently give a guarantee to buyers of products for many years.

Technologies for assembling frame houses are being improved, and processes are being removed and minimized. Typical panel assembly operations are carried out in factories.

The construction of light, warm, reliable and inexpensive buildings is offered by the frame technology known for more than five hundred years. It was widely used first in Scandinavia and northern Europe, and then moved to the USA and Canada.

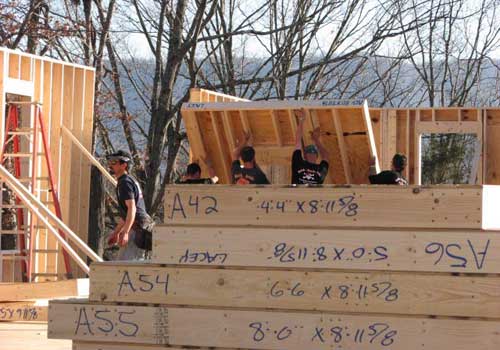

The frame of a house under construction using conventional construction technology

On the post-Soviet space such cottages are often called "Canadian" or "Finnish", because the first companies that entered our market were from these countries. Today, domestic factories are also successfully operating, manufacturing individual elements for prefabricated structures and completely ready-to-install house kits.

Frame houses are manufactured in industrial conditions using two main technologies:

In the first case, the manufactured elements are not interconnected and are separate parts that are assembled into one unit directly on the site. For each construction stage, the plant produces a certain set of such parts. So, for the skeleton of the house, they make supports and floor beams, roof trusses. For the construction of walls - OSB slabs, which, after mounting on the frame, are insulated from the inside of the building. Recently, sandwich panels with already provided insulation inside have earned great popularity. Their use significantly reduces construction time.

Unlike the classical one, the panel production technology makes it possible to produce from the factory not individual parts of the designer, but almost completely finished houses, assembled literally floor by floor. The wall panel does not consist of small "sandwiches" like bricks - it is delivered as a whole, with windows, door frames already provided and installed in it, special channels for laying communications, and even with exterior finishes. The inner side of such panels is covered with drywall and does not require additional alignment for finishing decoration - wallpapering, painting or plastering.

High-quality assembly of the frame in production

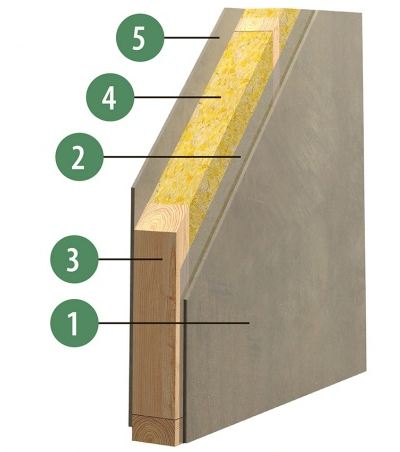

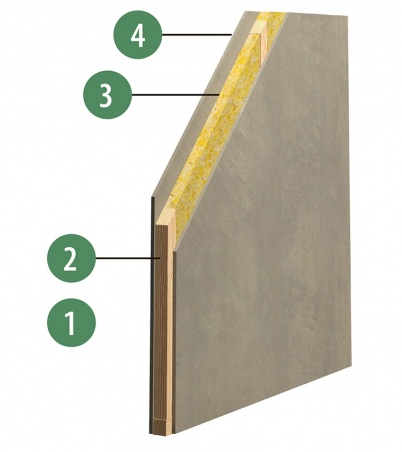

The wall panels of a prefabricated panel house are a multi-layer structure, and the content of each layer depends on the manufacturer. In order to comply with the minimum necessary physical characteristics of such a structure, the internal walls are produced according to the type of all the same “sandwiches”, where basalt or other insulation is located between two gypsum boards or gypsum boards. For the outer wall, a vapor barrier film is added on its inner side between the insulation and the gypsum board, and on the outer side, an OSB sheet and additional insulation made of expanded polystyrene.

At the factory, they create a drawing of the future house, the panels are all numbered

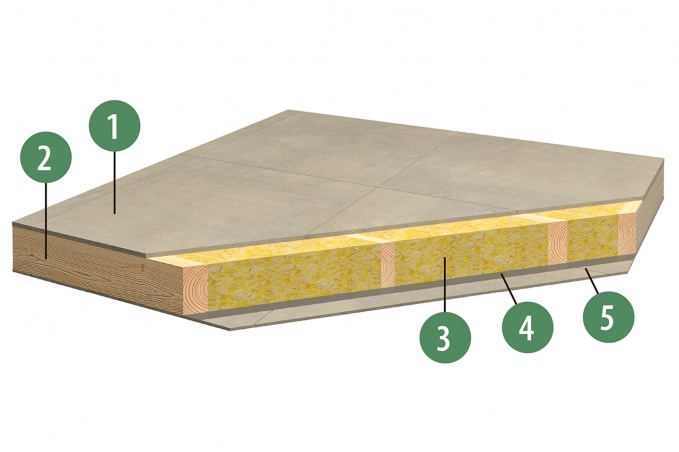

The floors of the house are approximately the same, but instead of drywall - cement-bonded particle board. The plinth element is additionally protected by a vapor barrier film. Ribs made of planed wood of different thickness act as a support and base.

The assembly of the factory interfloor frame ceiling takes little time. It is always exactly the right size.

All supporting elements, wall panels and floor slabs are made according to a specific drawing for a specific building, and together they are called a house kit. Different manufacturers are distinguished from each other not so much by the scheme for manufacturing the details of a finished house, but by the materials used. The design part also plays a key role: a good company has not only an extensive catalog of standard layout options offered, but also a service for the production of houses according to individual projects.

The traditional option of building from sandwich panels has one very attractive advantage - a low price. Firstly, due to the simplicity of the parts used themselves, and secondly, due to the ability to save on professional installation and do everything yourself. For the construction of such a structure, neither serious tools nor equipment are required. But knowledge and skills will still be needed - otherwise there is a risk of nullifying all the advantages of a frame cottage.

Illiterate assembly is the main reason for complaints about the shortcomings of "Canadian" houses. Inaccurately fitted panels, gaps between them, curvature, loose fit lead to drafts and, of course, cold in the rooms. And visually, such structures look like card structures, they look flimsy and unreliable. Therefore, those who seek to build a fortress, albeit lightweight, choose house kits.

Benefits of factory assembly:

When choosing a company to build your home, pay attention to the technology, the quality of lumber and raw materials, the timing of manufacturing and installation, as well as the composition of the proposed kits. The average cost on the market is 15-18 thousand rubles per square meter.

P profile construction company"Individual house" is the sale, transportation, as well as the construction of low-rise buildings from prefabricated house kits:

Here, we will tell you in detail about the factory house kit from the 5th generation TAMAK panels, which are manufactured according to Austrian technology based on modern, reliable, environmentally friendly and high-quality materials.

Widely popular in private construction are frame- panel houses factory-made, built according to Austrian, Finnish, German technology. This is primarily due to their energy efficiency, minimum construction time, year-round installation and durability.The price of a house set is fixed by the Tamak house set manufacturer.

| Factory house kits Tamak frame-panel type is made only from high quality materials: | ||

|

|

|

Components in production wall panels and floor slabs are cement, wood shavings, so this building material belongs to the category of environmentally friendly panels. This type of plate has an abbreviated name. In addition to these components, the composition of the board includes special binder additives that provide the necessary homogeneous mixing of the cement mixture and chips, as well as strength properties. Thanks to additives, the plate is resistant to high humidity, which means that fungus and mold never form on its surface. Panels are manufactured to exacting standards. Constant control over the technological process does not allow defects in the manufacture of DSP, so frame house kits are always of a consistently high quality level.

Frame-panel houses of the 5th generation, built using DSP, carry a high degree of thermal efficiency and durability. The walls of houses made of panels of the latest generation slowly give off heat even when severe frosts up to -50 degrees. This aspect allows you to significantly save on heating and air conditioning at home. A house built from 5th generation factory panels using Tamak technology can be heated with electricity without worrying about high electricity consumption.

The liquid glass included in the CSP makes the house completely fireproof.

The design features of frame house kits allow the construction of a house, depending on the project and area, within 90-120 days completely "turnkey". Houses based on TAMAK technology assumes a high degree of factory readiness of the house and, accordingly, shortest cycle time directly on the construction site.

The production of frame-panel houses at the factory eliminates the occurrence of construction errors at the construction site. A very important fact is that the storage of materials, the assembly of critical components and structures of the house take place in the workshop under ideal temperature and humidity conditions that are not available on the construction site. The construction of walls takes approximately 4-5 days. Due to the relatively low specific gravity of the panels, frame-type houses do not require the manufacture of a complex massive base, it is enough to use a shallow strip foundation. Houses of this type do not shrink and therefore you can immediately proceed to interior and exterior decoration.

High durability of houses from frame house sets - more than 75 years without external and internal finishing.

The structure of the surface of the panels is even on both sides, which makes it possible to carry out interior finishing work without their preliminary preparation, immediately after the installation of the roof and communications.

Frame-panel technology "TAMAK" assumes a high degree of factory readiness of the house and, accordingly, the shortest cycle of work directly on the construction site.

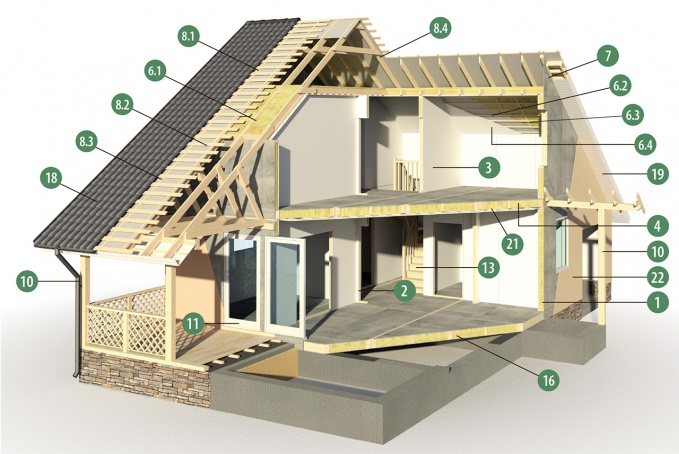

A complete description of the basic delivery package for a prefabricated house constructed from large-sized panels (up to 12 m long).

5. Attic floor slabs (if provided by the project).

6. Attic ceiling disassembled:

6.1. Non-combustible insulation with a total thickness of 200 mm.

6.2. Vapor barrier film.

6.3. Clamping rails.

6.4. Attic ceiling lining.

7. Cold gables.

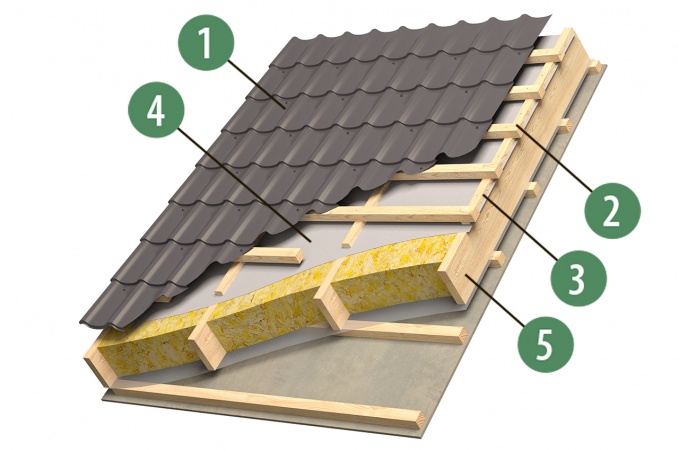

8. Roof structure:

8.1. Lathing under a metal tile.

8.2. Clamping plate for diffusion film.

8.3. diffusion film.

8.4. Rafters and wooden girders.

9. Portals.

10. Wooden structures of balconies, terraces and porches.

11. Window blocks (optional):

11.1. Plastic windows with two-chamber double-glazed windows / wooden euro-windows TAMAK.

11.2. Plastic window sill / wooden window sill TAMAK.

11.3. Internal extensions from GVLV sheets.

11.4. External metal drains - optional.

12. Insulated metal outer door - optional.

13. Internal stairs without risers, spruce - optional.

14. Set of connecting parts.

15. Support beam (antiseptic) with a section of 47x150 mm.

16. Basement slabs manufactured by TAMAK - option.

17. Electrical equipment - optional.

18. Roofing - optional.

19. Hemming of cornices - optional.

20. Ventilation channels - optional.

21. Filing plasterboard ceilings.

22. TAMAK facade: elastic plaster, sealant, joint filler - optional.

Note:

Other exterior finishes available

| More about the composition of the factory house kit: | |

OUTDOOR factory WALL PANELS Tamak |

|

|

Panel thickness 168 mm or 219 mm

|

INTERIOR WALL PANELS |

|

|

Panel thickness 168 mm

|

INTERNAL PARTITION PANELS |

|

|

Panel thickness 68 mm (94 mm)

|

INTERFLOOR AND ATTIC FLOOR PANELS |

|

|

Panel thickness 227 mm

|

Finished PANELS (plate) |

|

|

Panel thickness 227 mm

|

ROOF STRUCTURE |

|

|

1. Metal tile / cement-sand tile (not included.) Roof insulation - 200 mm (250mm, 300mm) |