In this article, we will look at how to download product information from your...

| WALLS: | |

| aerated concrete Ytong (600x250x400mm): | |

| 40.94 m³ x 4440 rubles/m³ | 181774 rub. |

| block adhesive: | |

| 33 pack. x 290 rubles/pack (25 kg) | 9570 rub. |

| Ytong U-aerocrete blocks (500x375x250mm): | |

| 26 pcs. x 400 rubles / piece | 10400 rub. |

| masonry reinforcement Ø10 AIII: | |

| 0.09 t x 37500 rub/ton | 3375 rub. |

| bar fittings Ø12 AIII: | |

| 0.25 t x 37500 rub/ton | 9375 rub. |

| concrete M200: | |

| 1.6 m³ x 4200 rub/m³ | 6720 rub. |

| mineral wool (Rockwool): | |

| 0.1 m³ x 3700 rub/m³ | 370 rub. |

| extruded polystyrene Penoplex 35: | |

| 0.3 m³ x 5100 rub/m³ | 510 rub. |

| PVC siding (3660x230mm): | |

| 101 pcs. x 437 rub./pc. | 44137 rub. |

| bars (40x25mm): | |

| 0.2 m³ x 6500 rub/m³ | 1300 rub. |

| wood protection impregnation: | |

| 9 l x 75 rubles/liter | 675 rub. |

| TOTAL: on the walls | 268206 rub. |

| FOUNDATION: | |

| sand: | |

| 3.8 m³ x 850 rubles/m³ | 3230 rub. |

| concrete blocks FBS 24-4-6: | |

| 33 pcs. x 3135 rub./pc. | 103455 rub. |

| masonry mortar: | |

| 1.2 m³ x 2700 rub/m³ | 3240 rub. |

| concrete M200: | |

| 14.9 m³ x 4200 rub/m³ | 62580 rub. |

| armature D10-12 AIII: | |

| 0.7 t x 37500 rub/ton | 26250 rub. |

| pine board for formwork: | |

| 0.5 m³ x 6500 rub/m³ | 3250 rub. |

| roofing material RKK-350: | |

| 3 rolls x 315 rubles/roll (10m²) | 945 rub. |

| TOTAL: on the foundation | 202950 rub. |

| COVERS: | |

| pine beams 100x50; 150x100: | |

| 1.4 m³ x 7000 rub/m³ | 9800 rub. |

| Knauf drywall boards (2500x1200x10): | |

| 12 pcs. x 260 rub./pc. | 3120 rub. |

| metal profile with fasteners: | |

| 100.1 line meters x 52 rubles / line meters | 5205 rub. |

| mineral wool (Rockwool): | |

| 8.6 m³ x 3700 rub/m³ | 31820 rub. |

| : | |

| 83 m² x 68 rubles/m² | 5644 rub. |

| polyethylene vapor barrier film: | |

| 83 m² x 11 rubles/m² | 913 rub. |

| plywood FK 1525x1525x18: | |

| 0.6 m³ x 19000 rub/m³ | 11400 rub. |

| subfloor board: | |

| 0.7 m³ x 6500 rub/m³ | 4550 rub. |

| TOTAL: by floors | 72452 rub. |

| ROOF: | |

| wooden beams (150x50mm): | |

| 1.6 m³ x 7000 rub/m³ | 11200 rub. |

| wood protection impregnation: | |

| 24 l x 75 rubles/liter | 1800 rub. |

| waterproofing film (Tyvek Soft): | |

| 94 m² x 68 rubles/m² | 6392 rub. |

| corrugated board SINS 35–1000: | |

| 89 m² x 347 rubles/m² | 30883 rub. |

| self-tapping screws with washer EPDM 4.8x35: | |

| 3 pack. x 550 rubles / pack (250 pcs.) | 1650 rub. |

| skate profile (2000mm): | |

| 5 pieces. x 563 rub./pc. | 2815 rub. |

| lathing board 100x25mm: | |

| 0.6 m³ x 7000 rub/m³ | 4200 rub. |

10:0,0,0,220;0,290,220,220;290,290,220,0;290,0,0,0|5:165,165,0,220;0,165,95,95;165,290,144,144|1134:214,144|1334:140,31;140,106|2255:0,124|2155:63,0;63,220;205,220|2422:290,47;290,90|1934:205,-20

RUB 664,098.0

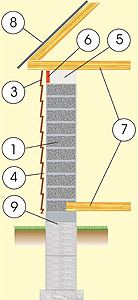

Only for the Moscow region!

Do you want to know how much it costs to build your house and choose contractors?

Place an express application and get offers from professional builders!

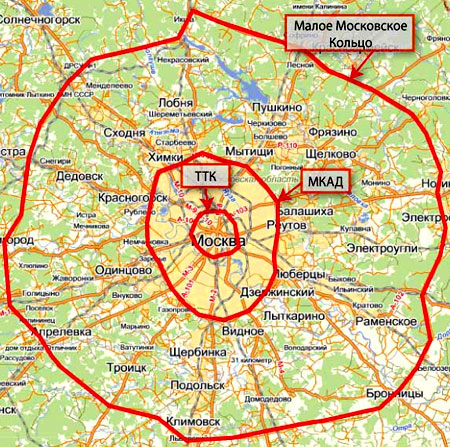

An example of a layout of 8x6 m for calculation |

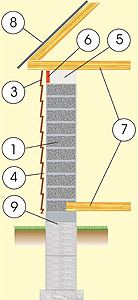

Structural scheme |

|

|

1.

Gas silicate block d=400mm; 2. Vinyl siding; 4. Air gap d=20-50mm; 5. Reinforced concrete screed h=200mm; 6. Extrusion insulation d=30-50mm; 7. Floor beams d=150-250mm; 8. Roof made of corrugated board; 9. Foundation tape block h=1.8m; |

|

When installing aerated concrete block walls, it is necessary to link many restrictions and technological issues, otherwise, instead of reducing the cost of thermal insulation, you can get very cold, wet, and sometimes emergency walls.

The construction of the wall structure is carried out in an approximate way:

Due to the fact that PVC siding varies greatly in size with changes in temperature, it is necessary to use a loose fit of vinyl sheets.

It is important to know that a PVC siding profile can function for quite a long time and have a beautiful exterior, only if the installation rules are strictly observed.

PVC siding does not spread fire, is resistant to impact, chemical, weather aggression, does not rot.

The vinyl profile in case of fire only slowly melts, igniting when heated to more than 390 ° C (moreover, the tree is already at 230-260 ° C), quickly extinguishing when the source of the flame is removed, and the amount of carcinogenic emissions is no more significant than when smoldering wooden structures.

Today, PVC siding dealers (Gentek, Ortho, Snowbird, AltaProfil, FineBer, Mitten, Vytec, Holzplast, Tecos, Docke, Varitek, Georgia Pacific, Nordside) are announcing a wide range of colors and shades to give every home a unique look.

Typical aspects of installing plastic siding:

Reinforced concrete blocks are a classic building component, which makes it possible to make the foundation of a cottage in a short time.

When performing a block foundation on solid and dry subbases, it is permissible to lay concrete blocks directly on the sand-leveled base of the construction site.

Reinforced concrete blocks are produced in the following types: "FBV" - with a cutout, "FBS" - solid, "FBP" - hollow. Typically, building blocks are made with a vertical size of up to 650 mm, the horizontal size varies within 0.9-2.4 m (FBS-9 - FBS-24), the transverse size is 0.3-0.4-0.5-0.6 m.

The use of one or another type of FBS block follows from the section of the load-bearing walls of the house. For individual construction, a reinforced concrete block width of 0.30 or 0.40 m is acceptable. The thickness of prefabricated block foundations can be narrower than the facade masonry of the cottage walls, since they have a much greater load capacity.

In order to expand the area on which the base of the foundation rests, in order to thereby reduce further movements of the continental layer, FBS - blocks should be mounted on pre-prepared FL blocks.

For lands with low groundwater rise, it is possible to install foundation blocks without reinforcing them, however, a concrete screed 100-200 mm high with a reinforcing mesh should be arranged above and below them.

Today, the foundation of prefabricated FBS-elements, in terms of a range of essential parameters, among which: resistance to subbase subbase and cost, is inferior to its counterpart - a monoconcrete foundation.

The practice of buying heavy blocks to complete the foundation is usually motivated by the all-season work or tight deadlines.

When the characteristics of the soil are unknown, for peace of mind, instead of ready-made pillows, perform a single reinforced concrete screed.

In suburban construction, wooden-beamed floors are traditionally in demand, due to the availability and ease of installation.

Since ancient times, coniferous trees have been used for beams: larch, spruce, pine, with a moisture content of 14 percent. It should be noted that the most durable lag is a beam with a sectional proportion of seven to five, for example, 0.14x0.10 m.

When calculating lumber for flooring, it is necessary to be guided by calculations that correlate the dimensions of the beam from the length of the span between the supports and the load; or you can start from the simplified rule that the height of the beam should be about 0.042 of the floor length, and the thickness should be 50 ÷ 100 mm, with a load of 150 kgf / sq.m and a laying step of lag 50 - 100 cm.

For a suitable replacement of bars of a given size, boards fastened with screws can be used, while maintaining the total size.

Some rules for installing a wooden beam floor:

The covering of the last floor is thermally insulated with the implementation of a vapor-tight membrane under the insulation, the basement floor is insulated with the placement of a vapor-tight layer above the insulation, and the interfloor ceiling is not insulated.

If the problem of the load capacity of wooden interlevel ceilings is mainly solved by an ordinary increment in the size of the lag and their number, then with fire protection and acoustic insulation the situation looks more complicated.

A possible method for improving the fire-retardant and acoustic properties of wooden floors is as follows:

Roofing material is mounted on a solid frame, made up of rafters and sheathing.

In the construction of private housing construction, a two- or three-span system is traditionally designed with medium load-bearing walls and inclined roof trusses.

The supporting ends of the rafter legs are placed on a Mauerlat beam measuring 100x100-150x150 mm; the distance between the rafters is usually set within 600-900 mm with a rafter size of 50x150-100x150 mm.

The main advantages of a corrugated roof, in comparison with a metal tile, are expressed in the speed of installation and low price.

The corrugated material is trapezoid-shaped stamped iron sheets with a polymeric color coating, which are produced under the brands, for example, HC44, H60, H57, MP-35, H44, C-21, B-45, HC18, HC35, where the numbers determine the height wave profile.

For roofing purposes, corrugated board with a profile span of at least 2 cm is used to create the required rigidity and save battens. The working angle to the roof horizon is assumed to be at least 8 degrees.

Standard installation procedure for profiled steel corrugated sheets:

Here we will help you figure out how much it costs to build your dream home.

The article provides an algorithm for calculating the approximate cost of construction brick house(prices of 2016), as well as a calculator for calculating the cost of a frame house.

Ready-made project for calculating the total cost of the house

It will depend on many factors:

Since there are many factors affecting the final cost of the site, there is no need to talk about any specific figure. For reference, let's take the average cost of a plot of six acres, located at a distance of 70-100 km from the Moscow Ring Road - 20-30 thousand dollars.

If you got a plot in an open field, without communications connected to it and a leveled surface, then the corresponding costs will be significant. They will include:

In the event that the site already had an owner who prepared it for construction, the cost of land development will be minimal.

There are several approaches when choosing and buying a residential building project:

First of all, it is necessary to determine the type of foundation being built. There are several of them today:

Each of these types of foundation has its own characteristics, advantages and disadvantages. Accordingly, their prices will also differ.

A columnar foundation is an engineering structure represented by pillars buried to a calculated depth, the upper part of which is interconnected by rand beams.

The cost of the columnar foundation will be up to 15% of the total cost of construction.

A strip foundation is an engineering structure represented by monolithic concrete or reinforced concrete blocks, which are located at the base of all the supporting structures of the planned house.

Scheme of pouring a strip foundation

Scheme of pouring a strip foundation The cost of a strip foundation is, as a rule, from 30% of the cost of the entire house.

The slab foundation is a monolithic concrete or reinforced concrete slab laid under the entire base of the building. The cost of a slab foundation can be approximately calculated at the rate of 2000 r / m2 (with a slab thickness of 25 cm).

The pile foundation consists of a system of deepened piles interconnected by rand beams. The construction of a pile foundation requires the involvement of special equipment, a large number of workers, and therefore is the most expensive of all types of foundations.

First of all, you need to decide for yourself what kind of house you plan to build:

Peculiarities wooden house are environmentally friendly and economical. Wooden house erected quickly and at the lowest cost. Since wood is a fairly light material, you can save on the foundation and get by with columnar instead of tape. The walls of a wooden house, made of timber, allow air to pass through, i.e. the house “breathes”.

A wooden house heats up quickly and retains heat well, and the resinous aroma of the room has a beneficial effect on nervous system person. Such houses can be used not only for suburban construction, but also for permanent residence.

A wooden house is built from glued laminated timber or. The advantage of a solid bar is its ideal roundness and evenness of the surface, which allows you to fit the logs as tightly as possible on top of each other.

The advantage of glued laminated timber is its cost-effectiveness, resistance to ignition, lack of deformation and cracking. The wall, made of glued beams, practically does not shrink.

Brick houses make up more than 70% of all private buildings.

Their main advantage is durability and a small daily temperature fluctuation inside the house. However, such a house, unlike a wooden one, will be distinguished by a high price, longer heating and will require exterior decoration.

It will also not work to save on the foundation, because brick is a rather heavy material, and the columnar foundation will not withstand it. If a one-story house can be built on a strip foundation, then a two-story house requires a slab foundation.

Reinforcement of the slab foundation for pouring

Reinforcement of the slab foundation for pouring Private house, made of foam blocks, in terms of its characteristics is not inferior to brick, but has a number of advantages over it. The use of foam blocks instead of bricks facilitates the construction of the building. The porous structure of foam blocks improves the thermal insulation characteristics of the walls. In addition, the use of foam blocks instead of bricks can significantly reduce the cost of construction.

Foam blocks for the construction of the same number of walls will require less, and their price is lower.

Recently, the construction of monolithic blocks has been widely developed. Its advantages: relative ease of construction (20% lighter than brick), good heat and sound insulation, the possibility of seamless wall construction. The disadvantage is the high cost of construction.

Foam block house project

Foam block house project And, finally, attached to the wooden frame of the house. Their advantage is: low price, speed of construction, ease of construction, good thermal insulation properties. Disadvantages - low structural strength, as well as fragility (2-3 times less than that of a brick house).

Everyone is free. For suburban construction are increasingly preferred frame technologies, and in most cases they are built of brick. That is why we will dwell in more detail on the cost of building frame and brick houses.

How much does a house project cost? We have absolutely free, when ordering construction work!

-Type of foundation- Depending on the total weight of the house, various foundation designs are used. The heavier the structure, the more massive the foundation should be. Accordingly, more material will go into its construction, which will increase the cost of the house. .

-Type of foam blocks -cost of a house from foam blocks depends on the size of the stones, their properties and characteristics.

- Floor material- it can be a reinforced concrete monolith or wooden beams. The choice between concrete and wood is always yours.

- Type of roof covering- tiles or elastic roofing materials. In addition, you should decide on the drainage system and insulation.

-Facade- an estimate for the construction of a house is drawn up taking into account what materials and methods of their installation will be used for the facade. The presence and thickness of insulation is also taken into account.

-Interior decoration- the calculation is carried out taking into account materials for the construction of internal partitions (foam block, drywall or brick), as well as for finishing walls and ceilings.

-Engineering facilities- the price includes the cost of materials for the installation of power supply, water supply and gas supply.

-Installation of windows and doors- the final cost depends on the number of windows and doors, as well as on the type of materials used for their manufacture.

ATTENTION! Our site is for informational purposes only and is not a public offer determined by the provisions of Article 437 of the Civil Code of the Russian Federation. Pay attention to the date of updating the price lists. For exact information on the cost of services, call: 8-495-744-86-85; 8-926-906-93-66

Our construction calculator will calculate how much it costs to build a house. Based on the results, an estimate is made for the construction of a house. If you don't know how to build a house for a million - use our calculator and you will see that the cost of building a house can be no more than 1 million rubles.