Denis Valentinovich Manturov Minister of Industry and Trade of the Russian ...

The presence of even a small area can allow you to make a canopy from corrugated board with your own hands. The simplicity of the design, the availability of materials and the possibility of self-assembly allow us to speak not only about the functionality of such a structure, but also about the economic benefits.

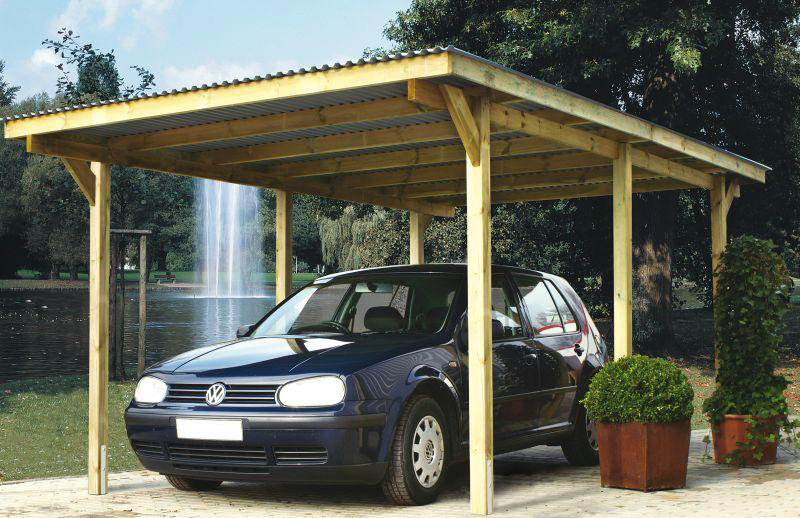

Most often, a corrugated canopy is made in order to shelter the car from the scorching sun and rain, but such a canopy can serve as a secluded place for arranging a gazebo.

Before proceeding to the stage of direct construction of the frame and base, it is necessary to choose the location of the structure, its type and purpose.

Stationary canopies have a solid, non-separable structure and reliable supports. Mobile awnings are used when protection from wind and sun is needed temporarily. This category includes greenhouses and summer cottages. The main requirement for mobile sheds is a strong frame that is resistant to strong gusts of wind.

According to their functional purpose, hinged structures are divided into recreational and household ones. Recreational awnings provide protection from wind, sun and rain, are erected over swimming pools, benches, playgrounds. Household sheds are able to protect the car from direct sun rays or bad weather, serve as a summer kitchen, are used to store inventory.

Awnings can be detached or attached. The latter form a single structure with the building. The canopy is attached with one side to the wall of the building, and the other - to special supports. Detached sheds - separate buildings of various shapes, with arched and pyramidal, domed and arched, gable and gable roofs.

For the construction of supports, brick and natural stone, wood, forged metal and metal profiles can be used. For the manufacture of the roof, corrugated board or polycarbonate is most often used.

Back to the table of contents

The frame for the canopy must be made of metal pipes and corners, they can withstand a large weight of corrugated sheets.

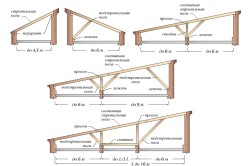

It is simple and cost-effective to use a metal profile for the construction of a canopy. In this case, the material is used both for the supporting structure in the form of metal pipes and for the roof. and the wall thickness of the pipes depends on the loads. You can use a metal profile made of aluminum, copper, galvanized steel.

Required tools:

In most cases, do-it-yourself installation of a canopy from corrugated board does not imply the arrangement of a drainage groove, therefore the installation is performed in blocks of three sheets, laid in a certain way. From two sheets connected to each other, the first row is assembled from the bottom. A sheet is attached to them, the first in the second row. The resulting block is fixed parallel to the cornice. Next, the next block is attached, and so on until the entire roof is covered.

In the process of installing the rafters, it is necessary to make them in such a way that the roof of the canopy is larger than the area between the supports. Further, at the edges, visors should form, from which rainwater will flow. For drainage of water, a gutter can be formed around the canopy.

Remember that the profile iron used for the metal roof is a rather slippery material. Working with him, you must follow all safety measures.

Not all car owners have the option to build a garage. And how, in this case, to keep your iron horse, how to protect it from rain and snow? In this case, you can build a canopy from corrugated board. To create such a simple structure is strong enough for anyone who has at least a little skills in construction. And what difficulties may arise when doing this work? What should be considered when creating a canopy on your site using corrugated board? About everything about it and there will be a speech in the article.

Sheds made of corrugated board can be very different. The material lends itself quite well to processing, which allows you to perform various designs with it. The most common types of canopy from a profiled sheet are the following:

What option to choose a canopy from corrugated board for the yard of your house is up to you. Each type has its own pros and cons. The positive aspects of the single-pitched version include the simplicity of the design. But there are also disadvantages. The slight slope of the slope will prevent snow and rainwater from leaving quickly. But if you make the roof steeper, then the wind load increases. Besides, high roof will poorly protect the car or other things under the canopy from rain.

A beautiful arched version will reliably protect against precipitation. But in this case, it will be difficult to do everything right. This design requires certain skills. In addition, for its construction, you will need additional equipment. Therefore, an arched canopy made of corrugated board, as a rule, is ordered from companies specializing in this field.

A do-it-yourself canopy made of corrugated board is a completely realizable project. At the first stage of its implementation, you need to choose the right material. And what may be needed in order to make a canopy from a profiled sheet? What materials and tools do you need?

Shed sheds are erected using the following:

If we talk about tools, then everything also depends on the material used. As already mentioned, to work with metal, you will definitely need welding. For wood, the usual carpenter's kit will suffice.

The device of a corrugated canopy depends on the type you choose. The simplest option, which is easy to calculate, would be a one-pitched one. To build the structure correctly, you need to make a drawing. And for this, everything should be carefully calculated.

In order for the roof over your car to be reliable and effectively protect it, you should decide on the following parameters:

It is not difficult to calculate all these parameters. It is enough just to make measurements. After that, a drawing of the future canopy is made from corrugated board. It is best to sketch everything on paper with dimensions and angles. In this case, it will not be difficult to carry out the installation correctly.

After the calculation of the canopy from the corrugated board has been made and the drawing has been drawn up, you can start construction work. All the elements used do not weigh much, so installation can be done alone. But in order to speed up the work and eliminate injuries, it is better to call assistants. A team of three is the best option, according to most construction specialists.

A do-it-yourself shed made of corrugated board is erected in the following sequence:

At the final stage, or rather even before the installation of the corrugated board, all metal elements of the canopy must be painted or coated with an anti-corrosion agent. If we are talking about wooden structures, then they are also pre-treated with special impregnations, which will protect the material from bugs, mold, sun and fire. Without such additional processing, your canopy will not last long.

On this, the construction is considered complete. To make it convenient to place the car under a canopy made of corrugated board, you can make a concrete floor. If funds are not enough, then it is enough to pour a layer of gravel.

A canopy made of corrugated board, built in a country house or the territory of a suburban area, can become not only a shelter for a car from the adverse effects of atmospheric precipitation and phenomena, but also an excellent place for outdoor recreation for the whole family. A do-it-yourself canopy made of corrugated board is an excellent playground for children, which will be reliably protected from the burning rays of the sun and sudden rain. Installation of a corrugated canopy does not require the construction of massive capital walls. For construction, it is enough to build a light frame from a metal profile or a wooden bar.

Most often, a corrugated canopy is made in order to shelter the car from the scorching sun and rain, but such a canopy can serve as a secluded place for arranging a gazebo.

Depending on the design of the site, you can build a canopy of any design. There are a large number of designs, the main among which are the following:

The most common and simplest design is the single-slope design. Its construction will not take much time and will not require a large amount of building materials. In addition to the canopy, you can make a visor from corrugated board above the entrance to a house or other structure. Installation of the visor will make the design of the facade of the house more original.

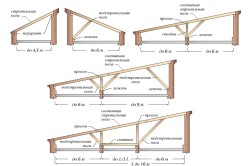

Among all the varieties of canopy structures, a single-slope structure is the simplest. The roof of such a structure is a plane that is located at a slight slope. This design of the roof allows to some extent reduce the mechanical loads exerted on it by snow. The presence of a slight slope of the roof organizes high-quality drainage in case of precipitation.

The angle of inclination of the roof when creating a shed structure is limited to a small range of values. If the slope is too steep, the roof ceases to perform its protective function. Precipitation falling on such a plane, under the influence of the wind, will be thrown onto the site under a canopy. A single-pitched structure with a large angle of inclination of the roof is subjected to a stronger wind load, which requires a significant strengthening of the structure of the structure.

After installing the supporting racks, they begin to fasten the longitudinal beams and girders. When installing the girders, self-tapping screws or electric arc welding are used to secure them. After the installation work, the structure is primed and painted. Then the installation of the corrugated board is carried out. Having laid a sheet of material, it is screwed to the frame with self-tapping screws. Laying the corrugated board should be started from the bottom row.

Gable structures are most often erected in regions characterized by snowy winters, which leads to heavy loads on the roof of the structure. The roof of a gable structure is formed by two planes located at a certain angle to each other. Using a gable roof allows you to cover a larger area than a pitched roof. However, the supporting structure of a gable roof is much more complicated due to the need to create a ridge assembly.

Also, due to the longer length of the slopes, it is more difficult to complete the frame itself. The girders, which are the support for the corrugated board, must be mounted in the form of trusses, since the bearing capacity of the beam structure in the presence of a large span is not enough. If it is necessary to cover a large area, a multi-slope canopy can be constructed, which structurally is a series of sequentially installed gable canopies, combined with each other. A device of this design provides for the installation of a ridge assembly in the upper part and a drainage system in the lower part of the structure.

Arched canopies are characterized by a smooth, arched roof bend with a certain radius. The disadvantage of this design is the complexity of the installation work.

Back to the table of contents

Installation of this type of structure can be carried out by anyone who has the simplest skills in working with tools, as well as basic knowledge in the construction field.

When planning the construction of a canopy, at the initial stage, you should tackle the selection of material for the construction of the frame. Ideally, the selection of material should be carried out according to the results of the strength calculations performed. Performing such calculations requires certain knowledge and qualifications from the builder. When building a lean-to structure with a small area, the cross-section of the metal profile can be selected approximately, without complicated mathematical calculations... In this case, you should choose a metal profile with a certain margin of safety. The best option is to use a 40x60 rectangular pipe for construction.

After choosing the material for the installation work, you should start preparing the site for the construction of the structure. For this purpose, the selected area is cleared of debris and topsoil, then leveled.

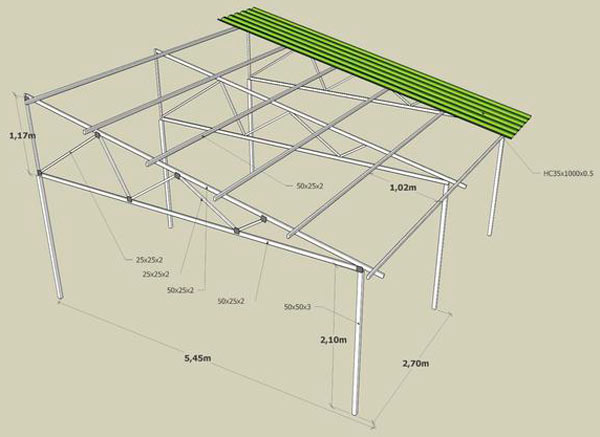

Having prepared the site for construction, proceed to the installation of racks. The bearing racks should be installed at a distance of 1 m from each other. It is necessary to install racks in a columnar foundation. The depth of the foundation must be below the level of soil freezing. For the construction of the foundation, pits are prepared in the places where the bearing racks are installed. At the bottom of the pits, pillows are made of compacted rubble. A polyethylene film or roofing felt is installed along the perimeter of the pits, which act as waterproofing. After preparing the pits, bearing racks will be placed in them, which are poured with concrete. The length of the racks should correspond to the slope of the canopy under construction.

A place to relax in the fresh air is necessary for both adults and children. It is in such a place that a pleasant evening coolness will help relieve fatigue after an exhausting heat, and children can swing on a swing or play in a sandbox even during the day, being reliably protected from the burning sun or a sudden summer shower.

Corrugated canopy with curved timber support beams

At the same time, for a comfortable stay and protection from the weather, massive capital walls are not needed and a light canopy made of profiled sheet is quite suitable.

When planning the installation of a canopy made of corrugated board, you need to decide on its design and once again weigh the pros and cons of the material chosen as its cover. Having opted for a metal profiled sheet with a bright elegant polymer coating, you will never regret your decision.

In recent years, polycarbonate awnings have become quite popular. But compared to this material, corrugated canopies, the price of which is almost the same, have a number of advantages. The profiled sheet is almost as light as polycarbonate, and allows you to create air-weightless structures that harmoniously fit into the overall style of the suburban area.

Canopies made of corrugated board - photo of canopies made of profiled steel and polycarbonate

A canopy in the yard made of corrugated board will never seem too bulky and inappropriate. At the same time, a huge range of colors of protective and decorative coatings of the profiled sheet will allow you to choose a material that will preserve the style unity of the architectural composition of the entire building.

Profiled sheeting is distinguished from polycarbonate by very high strength and resistance to ultraviolet radiation. A roof for a canopy made of corrugated board will never need to be replaced after even a very strong hail and will not burn out after 10-15 years, retaining the original brightness of colors and an attractive appearance for almost the entire service life.

The canopies made of corrugated board will not only easily fit into any design of a suburban area or a private mansion, they will make the facade of a private house even more respectable and noble and add solidity to an office building.

Gable canopy over the porch made of corrugated board

Most often, three main structures of canopies are used - these are arched, gable and single-slope canopies made of profiled sheet, the price of which increases in proportion to the complexity of the structure. The easiest to manufacture are single-pitched sheds. They can be either freestanding or leaning on one side against the wall of the building.

Sheds made of profiled sheet - photo of a structure with trusses, reinforced with stiffeners

A gable canopy made of corrugated board is simple in design and its manufacture does not require special knowledge and skills. The main thing is to take care of a sufficiently large slope of its cover, which will not allow the snow mass to linger on the surface of the canopy, overloading its light frame.

Gable canopies made of profiled sheet are more difficult to manufacture. They are usually built to cover large areas, which is why it is necessary to take measures to strengthen the structure of the frames of such awnings. This can be achieved without increasing the section of the metal profiles to which the profiled sheet is attached. For this, metal trusses are made with stiffening ribs, which allow you to distribute the load acting on the canopy structure without concentrating it in one place.

An arched canopy made of corrugated board of all three types is the most complex. This is due to the fact that the purlins of the upper part of the frame, on which the profiled sheet is directly attached, must be bent with a certain radius. Such an operation is almost impossible to perform without special equipment, therefore, it is unlikely that it will be possible to make an arched canopy from a profiled sheet with your own hands.

Arched canopies made of corrugated board, photo of semi-arched and arched canopies

If you do not take into account the complexity of arched structures, making a canopy from corrugated board with your own hands is quite simple. After all, it is not for nothing that such canopies, according to the building classification, belong to easy-to-build structures.

Before making a canopy from corrugated board, choose a place for its construction and prepare the site. Then the support posts are installed and poured with concrete mixture. Since they are subject to an exclusively vertical load, a 60x40 mm metal profile is usually sufficient for their manufacture. If you are going to build a very large canopy, then for reliability you can take a profile of 80x80 and even 100x100 mm.

The number of racks is determined based on the distance between them 1.0 m, and their location along the entire perimeter of the canopy (except for structures resting on one side of the wall of the building). In addition, do not forget about the logs - as a rule, you need two rows of logs from a metal profile for a canopy, with a section of 60x40 or 60x60 mm.

One-sided permanent canopy made of profiled sheet with wooden uprights and support on the wall of the house

Racks for a canopy made of profiled sheet must be installed in a hole, with a depth greater than the depth of freezing of the soil in your area. After that, you need to fill them with concrete and wait one to two weeks for the concrete to gain strength.

Some builders consider such measures to be superfluous, since the windage at the shed is small. However, for the sake of reliability, I still recommend spending a little time on a good foundation. This will help you stay out of trouble in high wind storms. In addition, many people subsequently make full-fledged walls of corrugated board near the canopy - and if the supports are securely fixed, you can do this without any problems. For the same reason, I recommend welding the logs, and not screwing them on.

The direct manufacture of canopies from corrugated board begins with the frame. The design of the trusses and the cross-section of their metal profiles depend on the area of the canopy and the angle of its inclination. It is these parameters that determine the possible snow load. The choice of the brand of corrugated board also depends on the slope angle of the canopy: the smaller this angle, the greater the bearing capacity should be, and, consequently, the height of the profile wave. Usually they use professional flooring НС35 or НС44, which can withstand heavy loads and provide good drainage.

Having mounted the horizontal trusses on the support posts of the canopy, you can proceed to the fastening of the profiled sheet. Attach it directly to the metal profile of the purlins or trusses using roofing screws, matched to the color of the coating. Such self-tapping screws always have a special rubber gasket, which ensures a tight connection at the point where they are screwed. For reliable fastening, 7-8 self-tapping screws per 1 m2 of the canopy surface are quite enough.

Now you know how to build a canopy from corrugated board yourself. A simple canopy for a gazebo or a car can be easily built in two days: one day you will spend on pouring the supports and another day on creating a frame and direct installation of sheets.

However, if it seems to you that you cannot cope on your own, then you can always contact a specialized company that will take over the manufacture and installation of the canopy. At the same time, the cost of a canopy made of corrugated board will be relatively small - it can be roughly determined at the rate of 2500 rubles per 1 m2. This is at least twice as much as you spend on self-production a canopy from a professional sheet, but at the same time you will save your time and effort.