Our expert is the head physician of the sanatorium Olga Bogush. Traditionally to the resorts ...

The wooden house is distinguished by its beauty on the outside and a pleasant atmosphere on the inside. But making your home perfect is impossible without such structures as windows. Before you install them, you need to understand what material is best for this. For more than one year, people have been actively using plastic windows. They go well with wood, while allowing you to reduce heat loss, increase sound insulation and give the structure a finished look. It is also worth paying attention to that. how is going

Before buying PVC windows, you need to decide what they are made of. Such information will allow you to perform high-quality installation of plastic structures. So, the main elements of PVC windows remain:

And here is what wooden window shutters look like, and how they can be installed. can see

Even when choosing a PVC window, you should pay attention to the size. According to the standard for plastic windows, the size of the window structure will be 1200x1200 mm.

The process of installing PVC windows in a wooden house presupposes strict adherence to technology. The first step is to carefully make all measurements. First, determine the distance from the floor to the windowsill. This will require taking into account the height of the person. The resulting distance is equal to 80 or 90 cm. When taking measurements, it is necessary to take into account the comfortable indentation to the window. The windowsill should be higher than the dining or writing table. When everything became clear with the location of the window sill, it is worth moving on to the inset of the openings. They will be 5 cm below the windowsill.This distance must be ensured for polyurethane foam... It is also worth paying attention to how you can produce

Cut the opening using a level. Using a plumb line, mark the vertical marks. The upper limit is determined taking into account the height of the structure. PVC frames suggest an increase in the opening by 14 cm above the window structure. The width of the opening should also be 12 cm larger than the horse.

When the preparation of openings and casing is completed, then you can proceed to the installation of double-glazed windows. In this case, one basic rule should be taken into account - it is impossible to drill through the frame, as this can violate the tightness and thermal insulation. It is best to use special mounts for this. It is possible to simplify the installation work by dismantling the sash from the frame. Thus, it is possible to facilitate the construction.

It may also be useful for you to learn more about which material should be used.

On the video how to install a plastic window in a wooden house:

The process of mounting the frame is carried out using a level. This will make it possible to get it the correct fit. After installing the frame, you can proceed to fixing the slopes. In this case, do not forget about the gaps for the polyurethane foam. When the frame has already been installed, you can pick up a gun with polyurethane foam and walk it along the perimeter of the opening.

Carrying out work on the installation of PVC windows in a wooden house, it is necessary to take into account the following features:

After the installation of the plastic window is over, it is necessary to ensure that the built-in structure has an attractive appearance. For these purposes, you will have to complete the finishing, which includes the installation of slopes.

They can be either plastic or wooden. Consider the process of installing PVC panels:

But how the insulation of a plastic window for the winter is carried out will help to understand this

On the video design of a plastic window in a wooden house:

If you decide to use wooden slopes, then you will get an attractive design of PVC windows. But when choosing a material, make sure that it is favorably combined with the appearance of the whole house. In a wooden house, slopes from a wooden lining look great. This design option is in great demand today and for the following reasons:

But how to regulate plastic windows, and what tool is needed, this will help to understand

The process of installing the lining is not difficult, so even an inexperienced person can cope with such work.

To do this, you just need to follow the following sequence of actions:

After installation, it is important to understand and how to do this work with your own hands.

You can buy a PVC window today at a price of 3000 -6500 rubles per piece. But professionals can install a window at a price of 800 rubles per m2.

The popularity of PVC windows is growing every year. And this is not surprising, because such structures have a presentable appearance, long service life and excellent noise and heat insulation properties. Even windows installed in a wooden house will be favorably combined with the construction and will perfectly fulfill their tasks.

Plastic windows can be installed in any kind of structure: stone, concrete, wood. But installation in a structure made of wood requires more attention, since wood is prone to shrinkage due to drying out. Wood that dries up turns into the strongest press, capable of deforming the window block. As a result, the window structure ceases to function correctly and may squint. Let's consider how to avoid such a situation and install windows without errors. Let's dwell on the specifics of the PVC window structure, its strengths and weaknesses.

PVC windows are PVC window constructions. This material is a chemical synthetics based on petroleum ethylene, chlorine. This polymer is resistant to various influences and serves for a long time... Window structures made of the specified material are resistant to:

PVC for window constructions is a tough and durable material. The strength of the polymer is several times higher than the strength of wooden structures and can withstand drops of one hundred degrees - from fifty degrees below zero to fifty degrees above zero.

Polyvinyl chloride consists of the following components:

The material serves for a very long time, manufacturers give a twenty-year guarantee, but it is still impossible to make sure whether this is so. The service life of the first installed windows has not yet passed. The assertions that even in fifty years the windows will not lose their properties are possibly real. But window seals fail much faster. As practice shows, they need to be changed every eight to ten years. In general, the service life of a seal depends on the temperature of each specific location.

Among the advantages of plastic structures are the following:

Supporters and opponents of plastic windows argue over the safety of these structures for health. Those who argue about the unsafeness of structures for human health argue this by the presence of lead in the basis of raw materials. But lead in windows is completely safe, besides, most manufacturers have replaced this material with others. The fact that PVC window structures are quite economical and environmentally friendly is confirmed by certificates:

In some countries, the government pays money to residents who have installed plastic structures for their personal contribution and concern for conserving natural resources.

Opponents of plastic structures argue that over time, plastic takes on an unaesthetic appearance, as it turns yellow and fade. But at present, the technologies for the production of plastic windows have improved and the color is not lost under the influence of natural forces.

In the event of a fire inside the room, window structures of this type will "hold back" the fire, since the plastic structure has high thermal insulation capabilities.

There is a huge variety of plastic windows in the construction segment. They are different in many parameters: shape, size, number of doors, opening options, types of double-glazed windows, types of profiles. Currently, manufacturers provide windows with various kinds of decoration, varying degrees of transparency.

By the number of sashes, the windows are divided into one, two and three-sash. The option chosen depends on the location of the localization, the size of the structures and the individual characteristics of the dwelling. For a small window, it will be convenient to have one sash. For typical apartments, it is recommended to install a pair of windows.

With regard to opening windows, the following options are distinguished:

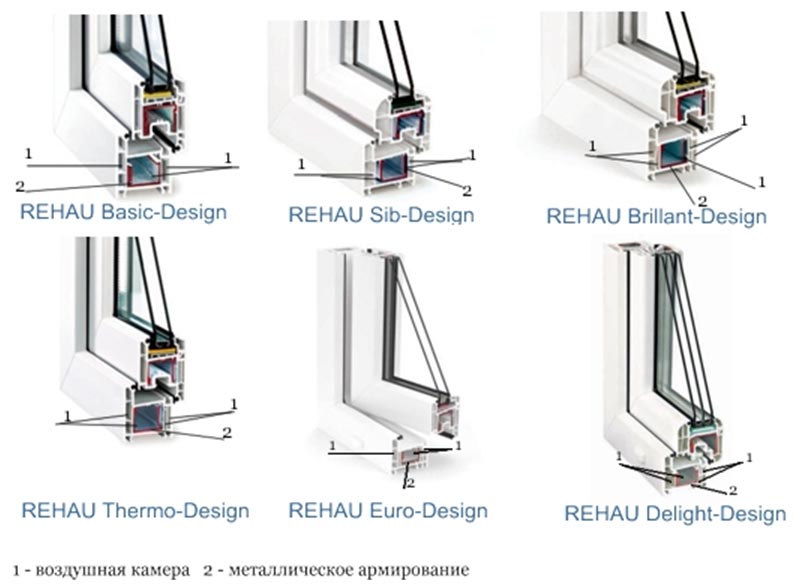

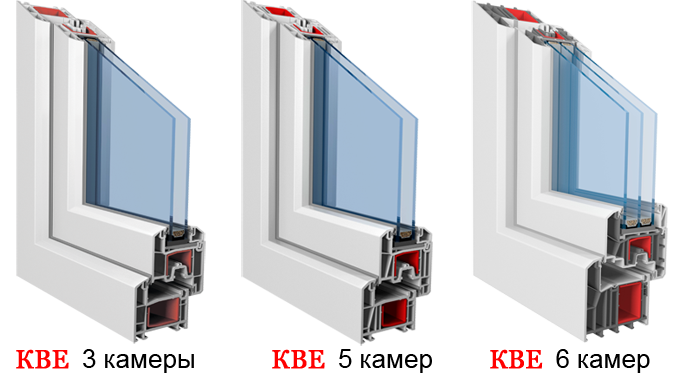

Its operational capabilities depend on the characteristics of the profile. PVC itself has low thermal conductivity, but chambers with air inside the structure help to retain heat several times better. The thermal conductivity of the window and the air temperature in the dwelling depend on the number of chambers. There are from three to seven cameras.

Three-chamber windows are installed in rooms that do not require heating: farm buildings, sheds.

As for the six and seven-chamber windows, they do not perform their functions better than four or five-chamber windows, so there is no point in overpaying for the construction.

As for the marking of profiles with letters, there are types: A, B and C. Type "A" is used in dwellings. "B" and "C" are recommended for use in factories or warehouses.

The glazing of the structure itself can be made using two, three or four sheets of glass. They are fixed at the required distance from one another and form chambers.

Double-glazed windows can be one, two and three-chamber. This point can be confusing when buying a window. It should be clarified which cameras are meant, in the frames themselves or in the double-glazed windows.

With the installation of plastic windows in wooden walls, you will have to study the theory of the issue in order to do everything right. Some people think that it is impossible to install plastic windows in old wooden type buildings. But in fact, no, it can be done in any type of premises. You can install windows yourself, provided that you have a minimum knowledge of the building blocks. The main thing is to take into account the peculiarities of wood as a material and take into account the fact that the wooden frame of the house can also sag.

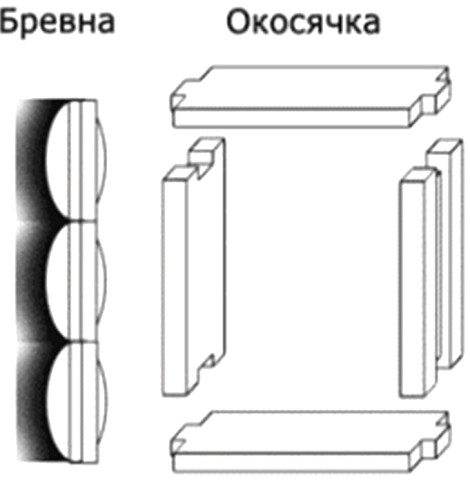

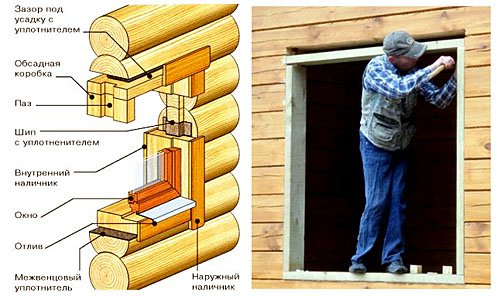

After the windows for wooden house, it is necessary to become familiar with the technology of "okosyachki". This technique is aimed at preventing deformation of window structures, regardless of the selected material.

As statistics show, a wooden house shrinks up to thirty-five centimeters. Depending on the basis of the structure, twelve months after the construction of the house, it sinks in any case, this is a natural process. The maximum error will be provided that the house is erected from rounded timber, the minimum - from glued timber. An ordinary timber can sag by thirty to forty centimeters. This is taken into account as a factor capable of deforming window structures. Deformation can manifest itself in the impossibility or difficulty in opening and closing the window.

Builders advise not to install plastic structures in new homes until it has shrunk. But experience shows that old structures can also deform windows. But what to do, isn't it impossible to install plastic metal structures in wooden houses? In fact, experienced builders have developed installation technology that will allow PVC windows to be used to their full potential.

For the successful implementation of installation work, it is important to plan and carry out competent preparatory work, they consist of the following actions:

At the preparatory stage, a decision is made on the shape of the window, the number of sashes, in what color it will be and in how many packages.

When all decisions have been made, insulating glass units are ordered according to the requirements.

Okosyachka is the next stage in the installation of a metal-plastic structure.

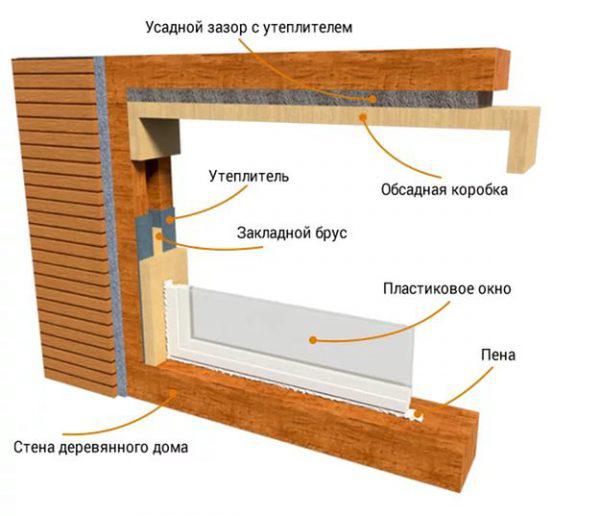

It is possible to finally install the window structure in a wooden structure after preparing the window. This is a structure made of wooden beams, aimed at supporting weight. load-bearing walls and does not allow the window to deform. The required size of the bar is ten by fifteen centimeters. Using a chisel, connecting grooves are made on these bars, about five centimeters wide. Longitudinal cuts are made using a chainsaw. All manipulations are controlled by the building level.

Plastic structures are inserted into the prepared jigging system and fixed with fasteners. The order of installation work is as follows:

A window, installed specially in a wall made of wooden material, performs several important tasks:

Experienced builders insist on installing a window, even when installing plastic windows in an old wooden house. They argue that this measure is simply necessary. A structure made of wood all the time, to one degree or another, changes its size - it swells during rain, and dries up during heat.

The most important process is the process of installing plastic structures in their designated place. To do this, it is advisable to prepare in advance the entire tool that will be needed in the process of mounting the structure:

Naturally, during the work, you will need other tools. Ideally, this work should be done with a partner who can feed the tool, hold the structure as needed.

Installing plastic elements is a challenging type of construction activity. If you are installing plastic windows yourself, take into account all the recommendations of specialists.

It is not easy to calculate the dimensions correctly, it is a very difficult process, which is best entrusted to a professional from a window workshop. Recently appeared online calculator plastic structures, allowing you to find out the exact cost. It is very comfortable. Various filters are presented on the sites:

The cost of window structures is influenced by the number of sashes, the choice of additional fittings, additional functions of the glass unit, the color of the profile.

To imagine how the installation of plastic metal structures in wooden houses takes place in practice, watch the video. In fact, you can install windows on your own, for this you need to take into account the specifics and features of this method and follow the recommendations of specialists.

Windows made of strong and durable plastic can be found today not only in stone, but also in wooden buildings.

However, their installation in a wooden wall differs significantly from installation in stone structures. The reason for this is the significant shrinkage of the wood during the drying period.

For raw material, it can reach 6-8% (1.2-1.6 cm per 1 meter of log height).

The drying wood turns into a powerful press that easily deforms the window block. The leaves do not open after such an impact, and the frame is strongly warped.

It turns out that a high-quality installation of plastic windows in a wooden house is not possible - you ask? No, it is quite real, but only with the observance of special technology. We will consider it in our article.

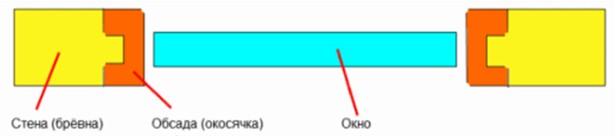

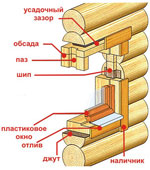

In order to exclude the pressure of the wall on the window block, the craftsmen invented special "skids", popularly known as jibs or casing. The idea of this technology is very simple: a vertical ridge-ledge is made on the end part of the logs of the window opening with a chainsaw.

A window carriage is put on it - a wooden beam with a vertical groove cut out in it. There is no rigid connection with screws or nails between the opening and the gun carriage. As a result, due to the sliding tongue-and-groove connection, we get a frame that moves freely along with the drying wall.

Thanks to this original solution, the destructive forces of the frame deformation do not act on the plastic window installed in the casing.

Okosyachka performs several important functions in a wooden wall:

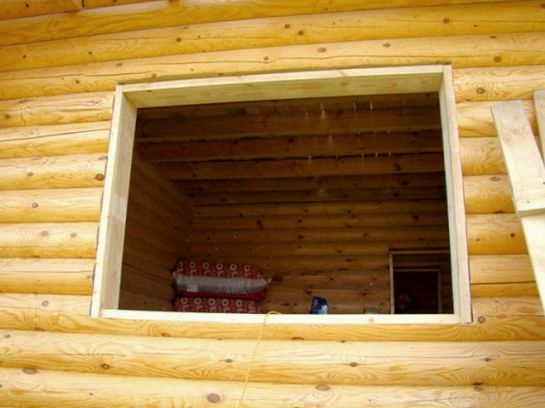

Now let's take a closer look at how to install plastic windows in a wooden house with our own hands using a casing box.

Cutting the ridge at the ends of the window opening must be taken very responsibly, having completed the markup using a level. Any deviation from the vertical and any inaccuracies in the ridge-groove joint will adversely affect the operation of the jig, disrupting its free movement along the wall.

Having made the ridged cuts, you can start making window carriages. These are wooden planed bars with a section of 150x100 mm. At their ends, it is necessary to make cutouts 5x5 cm in size for inserting horizontal jumpers (board 150x50 mm with two spikes at the ends).

When making a casing box, keep in mind that its assembled height should be 7-8 cm less than the height of the window opening.If you make a casing without such a gap, then the upper rims, when the wall shrinks, will press on the box, deforming it.

In order to correctly insert a plastic window in a wooden house, you need to adhere to the sequence of operations established by experienced craftsmen.

First you need to overlay the crests of the window opening with tow and fix it with a stapler or small nails. This is necessary to insulate the joint and eliminate squeaks. After that, the lower lintel of the window is placed in the window opening. Then carriages (side bars of the casing box) are stuffed onto the ridges. The second jumper is inserted into the upper cut of the carriage and lowered to a horizontal position. Having assembled the box, it must be carefully fastened with self-tapping screws so that they do not go out into the ridges of the log house. Otherwise, the siege will not "work", because the screws will prevent it from sliding along the wall.

All the cracks remaining in the window opening after the installation of the window is tightly clogged with tow. Further, according to the standard technology, the installation of a plastic window is carried out with all the accompanying operations to ensure the protection of the junction area with the casing from moisture, heat loss and noise penetration.

The gap between the window and the wall of the log house is filled with thin boards wrapped in rolled tow. As the walls shrink, they are knocked out one by one. To do this, the upper platband (it is attached only to the window) is removed and, removing the unnecessary "compensation" board, put it back in place.

The finishing of a plastic window in a wooden house is no different from the decorative cladding of a conventional frame. It is highly desirable to order not standard white plastic windows, but covered with a special film that imitates the color and texture of natural wood. They will look natural against the background of a chopped wall. Having completed the insulation and sealing of the joints, the window block with a window from the inside and outside is sheathed with a wooden platband.

Until now, we talked about the installation of plastic window blocks in new log cabins.... But is such a technology needed if it comes about an old wooden house?

Experienced craftsmen say that a box is needed here. The fact is that any log house, even after 5 years of shrinkage and shrinkage, does not stop changing its size. Wood is a living, porous material. Therefore, when it rains outside, the log and timber swell. During a hot summer, the opposite process takes place and even an old hundred-year-old log house loses a few centimeters from its previous "wet" height.

It should be noted that the old window frame is absolutely unsuitable for the role of a window, since it cannot slide along the surface of the wall, compensating for its shrinkage.

Therefore, the owner has two options:

Concluding our review, let's say that installing a plastic window into a wooden wall is not a very difficult process. With an accurate and attentive attitude to the matter, it can be performed with high quality on your own, without involving from the "expensive" masters.

We sometimes receive additional questions, which cannot always be answered within the framework of the comments. We will answer such questions further and give options for solving a specific problem.

Good day!

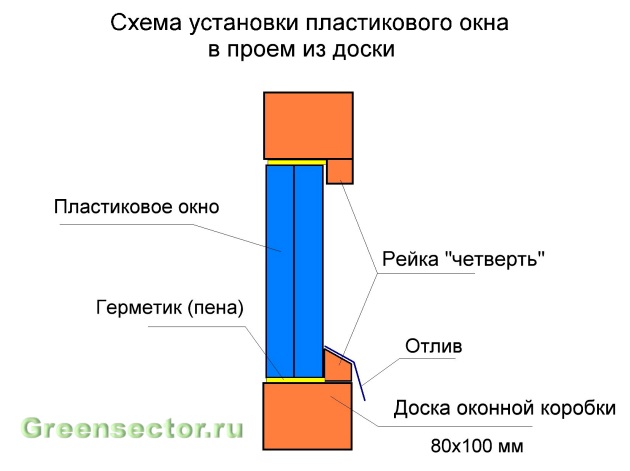

With the installation of a plastic window in a log house, it is clear, but how is a plastic window installed in a house on a pediment, in which an opening for a window is made from an 80x100mm board?

This installation option is not difficult. Just before installation, it is advisable to attach an antiseptic rail 20x20 mm along the contour of your box (it will act as a quarter, protecting the polyurethane foam sealant from solar radiation). If you have already made a quarter in the board, then there is no need to put the rail.

We put the plastic window on the spacers (to create a gap into which the foam will blow). After that, carefully go through the entire circuit with a sealant. You can additionally secure the window to the opening using metal mounting plates. However, foam alone will hold the window securely.

It has not receded from the outer edge of the window block, but the house is old, the window block is level and somewhere in some places a 50 mm board goes out into the street, and now it is cold. What can be done?

The best option is to take out the window block and install it in the opening with a quarter margin as shown in the previous diagram.

An acceptable option is to make a strapping of a thick board around the window block outside the wall so that quarters are obtained that cover the junction of the window block with the wall from blowing. Seal all leaks and gaps with foam or tow.

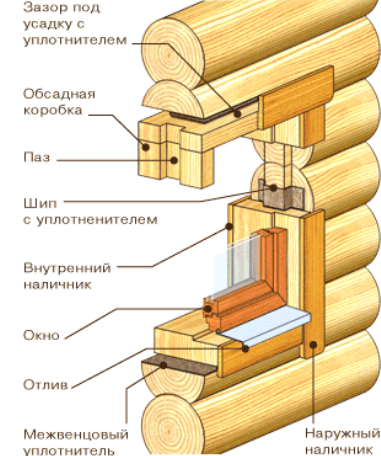

Installation of plastic windows in wooden houses has its own characteristics, in contrast to installation in a conventional panel house, the technology of which is described in the main section of this site. For example, openings of log (squared) houses, as a rule, do not have quarters. But the most important difference is that in the first few years after construction (does not apply to frame-panel) wooden houses tend to shrink as a result of the drying out of the wall material (logs, beams). And this factor cannot be neglected, because a plastic window installed in the usual way (into a bare opening) in the first year will be crushed and deformed by the overlying crowns. As you know, in the first two years (the most active period of wood drying) after building a house, the amount of wall shrinkage per 1 meter of height can be:

There are other more frightening figures regarding the shrinkage of log cabins: 10-15% of the original height. At one of the construction forums, I somehow saw this information: from the original wall height of 2.3 m, 2 meters remained after shrinkage. In general, the amount of shrinkage depends on several factors:

Log houses made of ordinary logs sit most strongly, then rounded logs, timber (2 times less than a conventional log), profiled timber, glued timber (about 10 times less than a log) go to the smaller side.

Even if the house survived, i.e. has been in operation for more than 5 years, experts still recommend taking into account the possibility of vertical movement of walls when installing windows and doors as a result of seasonal changes in humidity and air temperature. Figuratively speaking, a wooden house is a more lively structure compared to urban buildings made of stone and concrete. Therefore, the installation of plastic windows in such cases is not carried out in the opening itself, but in a special wooden box, which acts as a connecting link between the window and the wall. This box is called differently: siege, salary, deck, okosyachka. For the purposes of this article, we will use the term siege .

First, let's figure out how the siege works and what is the point of using it.

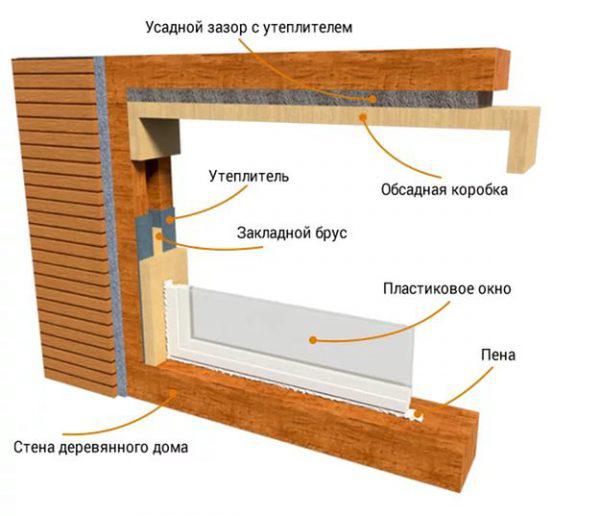

As you can see from the picture (click to enlarge the picture), the cage is an ordinary window box made of four, sometimes three (sides and top) thick boards, installed inside the opening. The meaning of this design is that it is independent of the vertical movements of the wall and moves freely in the opening, since it is not attached to the logs (timber) with either nails, or self-tapping screws, or other fasteners, but is held with the help of grooves in the side posts planted on the spikes at the ends of the logs. Even foam is not used to seal the gaps around the casing - only tow, jute (linen) and other soft insulation. Please note: a large gap is specially left above the casing, the size of which is designed for the maximum possible shrinkage of the logs (bar). During the first years after the construction of the house, this expansion gap will gradually decrease to a minimum, but the upper log (bar) of the opening, if correctly calculated, will not press down or deform the casing. Thus, the shrinkage of the house will not in any way affect the size and shape of the casing, and, accordingly, will not damage the plastic window inside it.

If you decide to install plastic windows in an old wooden house, which has long gone through the shrinkage process, then, disassembling the window blocks, you will probably notice: they are made according to the same principle as the casing construction described here, i.e. are not nailed to the logs of the opening, but are fixed in it using a simple "groove-tenon" system on the sides. This suggests that the technology of installing windows and doors in the casing was invented a very long time ago, and is used with success to this day. We will not invent anything new and will go the same way.

There are several ways to install casing:

We will use the last option - in the deck, since it determines the maximum strength and stability of the opening, because the casing not only protects the window from shrinkage of the walls, but also ensures the stability of the wall in the place where the opening is cut.

In short, the sequence of our actions will be as follows:

We use foam only inside the casing. We insulate the gaps around it with traditional tow. For the next 5 years (if the house is freshly built), we have to periodically remove the platbands and re-caulk the upper gap above the casing, gradually reducing the amount of insulation inserted there. Only after the house has completely shrunk, the gaps around the casing, if desired, can be sealed with foam from the outside.

Before cutting out, we mark the window opening using a level, because the plastic window will be installed strictly according to the level in all planes, therefore, the cage should also be installed in the opening as accurately as possible according to the level initially. The lower crown in the opening must be sawed off, as shown in the figure, to get a flat horizontal platform.

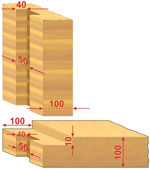

The dimensions of the opening are determined based on the dimensions of the plastic window, the thickness of the casing bars and the size of the required clearances. I propose to take the thickness of the bars 100 mm.

Opening width ( W opening) will be equal to the width of the plastic window frame ( W frame) plus 40 mm (two lateral gaps of 20 mm to the right and to the left of the frame) plus 200 mm (thickness of two side posts of the casing 100 mm each) + 30 mm (thickness of the insulation on the sides of the casing and correction for unevenness of the side walls of the opening) minus 50 mm (the ends of the spikes recessed into the grooves of the racks at the ends of the logs are 25 mm on the right and left):

W opening = W frame + 220 (mm)Opening height ( H opening) will be equal to the height of the plastic window frame ( H frame) plus 30 mm (clearance under the frame) plus 20 mm (clearance above the frame) plus 180 mm (thickness of two casing crossbars, 100 mm each, minus two docking grooves, 10 mm each) + 15 mm (thickness of insulation under the casing and correction for irregularities bottom edge of the opening) plus the upper shrinkage gap ( H homestead):

H opening = H frames + H shrinkage + 245 (mm).The size of the shrinkage gap ( H homesteads) is not easy to determine, since the amount of shrinkage at home, as mentioned above, depends on many factors. If, for example, we roughly calculate, taking everything to the maximum, then for a window of a standard height of 1400 mm (plus the thickness of the casing crossbars, plus mounting gaps of ~ 245 mm) at 15% shrinkage, the upper gap will be 24.5 cm - a huge hole , the height of which, most likely, will end up being unnecessarily large. To simplify the task and avoid mistakes, you should not rack your brains over GOSTs that regulate the shrinkage values of building materials of various tree species, comparing this with local climatic conditions, etc. You can do it easier, namely:

So, we calculated the size of the opening, marked it out and cut it out. Now you need to cut a thorn at the ends of the logs (timber) on the sides of the opening. The spike is also marked with a level in the center of the log (bar). The size of the spike is 40x40 mm. We sew the side and lower parts of the opening with linen or jute using a stapler.

First, it is necessary to decide on the width of the casing bars: it should either be equal to the wall thickness, or be slightly larger, so that later, when installing the outer casing, they (casing) fit tightly without hindrance on the casing, and not on the wall. Secondly, for the manufacture of the casing, it is necessary to take a well-dried material, otherwise the assembled structure itself will be deformed soon when it dries.

First, we cut out the upper (top) and lower (window sill) crossbeams, making them 30 mm shorter than the opening width (excluding thorns). At the ends of the top and the window sill, cut a groove for a thorn 50 mm wide and 40 mm deep. Also, at the ends of both crossbars, we make small indentations of 10 mm for joining the crossbars with the side posts.

We make the side posts with a height exceeding the height of the plastic window frame by 70 mm. On the reverse sides of the racks, using a circular saw, we cut out a groove for a spike 50 mm wide and 40 mm deep.

We begin the installation of the casing in the opening from the lower crossbeam (window sill). Then a top is put into the opening, under which we alternately substitute the side racks, placing them on the spikes with grooves. We fasten the casing elements together with self-tapping screws and coat the joints with a sealant. We caulk the gaps around the casing with ordinary tow. We plug the upper shrinkage gap with a roller of tow, wrapped in flax (jute). Now you can start installing the window.

We install the plastic window by aligning it with the front edge of the casing or slightly deepening it into the house. Bring the window inward by a third of the wall thickness, as is done in a panel or brick house, there is no need here due to the lower thermal conductivity of wood (lower freezing depth). Moreover, with a small thickness of the walls of a wooden house, by deepening the window into the opening, we will have to cut the already narrow window sill.

If you calculated the dimensions of the opening and casing as described above, then the mounting gaps around the window frame should be 20 mm at the sides, 20 mm at the top and 30 mm at the bottom (we make the lower gap larger so that later it will be possible to insert a plastic window sill under the frame, the thickness of which is 20 mm).

It is more convenient to fasten the frame to the casing using self-tapping screws 6x100 or 6x120 mm in size, placing them in the same way as when fastening with anchors. We drill holes in the frame with a 6 mm drill. It is dangerous to use self-tapping screws longer than 120 mm because they will pass through the casing and screw into the logs (timber), which is unacceptable.

Provided that all the preparatory work was done using a level, the window frame should stand exactly along the casing, i.e. the leading edge of the casing should be parallel to the plane of the window, without noticeable distortions.

Before foaming the gap between the window and the casing, it is necessary to decide with what material we will waterproof the assembly seam from the street side. As you know, the two main enemies of foam are sunlight and water. If from sun rays we can simply close the installation seam with platbands or strips, then the situation with waterproofing is more complicated, because it must meet two main conditions: do not let water through and at the same time do not prevent moisture vapor from escaping from the inside to the outside. Well, and, of course, waterproofing must be resistant to long-term weathering. All these conditions are met by materials such as, waterproofing vapor-permeable tape and a special sealant.

Sealant "STIZ-A"- one-component vapor-permeable acrylic sealant of white color for sealing the outer layer - characterized by good adhesion to the main building materials: plastic, concrete, polymer concrete, foam concrete, plaster, brick and wood, including. It is also resistant to UV radiation, atmospheric precipitation, temperature deformation and can be applied even at temperatures as low as -20 degrees. The only drawback of this material is that it is difficult to find it in small containers, and it makes sense to buy a whole bucket when you install a lot of windows. If you choose "STIZ-A" as external waterproofing, then the procedure will be as follows: first we foame the window, then, after complete drying, we cut off the foam sticking out from the outside and after that we apply the sealant to the cut using a spatula.

Waterproofing vapor-permeable tape(self-adhesive butyl rubber tape, consisting of a vapor diffusion membrane with an adhesive sealant on one or both sides) is sold in rolls of different widths. In our case, a tape with a width of 70 mm is suitable. Using this tape as a waterproofing tape, orient it correctly when gluing. You can determine this by blowing into it from one side and the other (do not forget to remove the paper first). Since there is a membrane inside the tape, air passage is possible only in one direction. The side from which it is impossible to "blow" the tape is the outside (street) side. The sequence of actions (first the tape, then the foam or first the foam, then the tape) does not really matter, but it must be taken into account that the foam, expanding upon drying, not only pulls the tape with a bubble (it will interfere later when installing the platbands), but in general it can tear it off the window or casing. Therefore, if you first of all stick the tape, then immediately screw the platbands or rigid strips on top of it, and only then foamed. Or foaming first, wait for the foam to dry completely (24 hours), cut off its excess and straightaway In order not to expose the foam cut for prolonged weathering, stick the tape.

Pre-compressed self-expanding sealing tape (similar to foam rubber), impregnated with a special compound, thanks to which it is waterproof and vapor-permeable. Delivered in a compressed state, rolled into rollers. If you opt for a tape, then buy one that expands more than 30 mm. PSUL will have to be glued not to the outer side of the frame profile, but to the end next to the front edge. This should be done after fixing the frame in the opening, but before foaming. Of course, it is more convenient to glue the PSUL frame over before installation, when it lies on the floor, but then the installation will have to be performed at an accelerated pace, because after a few minutes the tape will expand and interfere with work. Foam the assembly seam only after the PSUL has fully expanded and covers the assembly gap. But here the same problem is quite possible as with waterproofing tape: foam expanding when drying can squeeze the PSUL outward. This can be avoided by pressing the PSUL from the street side with platbands or strips.

On the inside, the foam should also not remain open in order to exclude moisture from the room air from entering it. For the device of internal vapor barrier, you can apply vapor barrier tape, which has already been described in the main section of this site, or use an acrylic sealant SAZILAST-11("STIZ-B").

It is glued to the end of the frame with a thin adhesive strip until foaming. Immediately after foaming, the protective paper is removed from the wide adhesive strip and the tape is adhered to the casing. Until the foam under the tape has hardened, it is advisable to immediately install the window sill and screw the starting profile to the edges of the frame, otherwise the tape "inflated" with foam will interfere later.

It is applied to the hardened foam, more precisely, to its cut. In this case, it is no longer necessary to rush to install the window sills and the starting profile, as when using tape. Nothing prevents you from doing this later, when it is convenient.

The interior decoration of a window in a wooden house (window sills, slopes) is not much different from the decoration in a panel or brick house. It is even a little simpler here: you do not need to drill holes to install slopes - we fix everything with self-tapping screws into the tree (into the casing). Also, it is not required to additionally insulate the slopes from the inside with foam or other material. To play it safe, it is enough to foam the inner surface of the casing with a narrow strip next to the assembly seam before installing the slopes. This will be enough, because the tree does not freeze as deeply as concrete or brick.

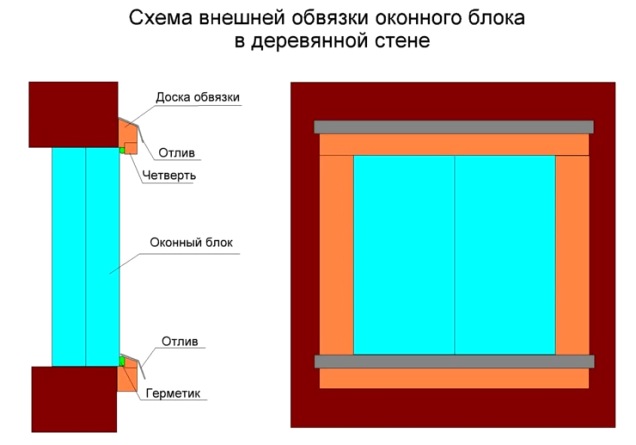

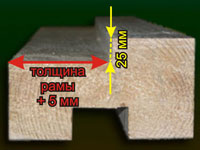

This method of installing a window allows you to save on slopes and window sills, gain time and achieve more, in my opinion, an aesthetic effect, but this will require a good woodworking machine to evenly cut the so-called reverse quarter on the casing elements, into which the plastic window will be installed. ...

What is a reverse quarter can be easily understood from the figure. This is the recess into which the window frame will be installed from the street side. The depth of the quarter is 25 mm. The width is 3-5 mm larger than the frame thickness, for example: for a 5-chamber VEKA, the profile thickness is 70 mm, therefore the width of the reverse quarter should be 73-75 mm. It is important to accurately calculate the size of the casing and window, carefully assemble the casing and install the casing in the opening exactly according to the level - the inner gap should have the shape of a regular rectangle, and all the edges of the outer edge should be located in the same plane without skewing. In order not to be mistaken in the dimensions, it is better to first make and install the casing, and only then accurately measure and order a plastic window on site.

Consider how the reverse quarter casing window will be installed.

Let's say that the cage is already installed in the opening. The size of the plastic window is made in such a way that it turns out to be slightly larger than the "clearance" of the casing, or rather: 14 mm wider and the same height. Such a window will not enter the casing from the inside, but it will easily enter the opposite quarter from the street side. In this case, the edges of the frame will "hide" behind a quarter of 7 mm on each side (it is no longer possible - the hinges of the sash will interfere), and an assembly gap will remain around the frame, which will later be filled with foam. The frame is attached to the casing with self-tapping screws, as described above. We use a D-shaped door seal to ensure a beautiful sealed connection of the frame and casing from the room side. We glue it before installing the frame with the glue side on the edge of the quarter. When attaching the frame, we press it tightly to the quarter, squeezing the seal, and screw in the self-tapping screws, fixing the window in this position. The installed window is foamed from the street. Then, after the foam dries, its excess is cut off, the seam is sealed with a waterproofing tape or sealed with STIZ-A sealant, platbands are installed.

Of course, since we are giving up interior decoration casing with any additional elements, then they must refine it, i.e. give it a look that matches interior design premises.

First of all, you need to give the lower crossbar the shape of a window sill so that with its inner edge it protrudes slightly from the wall and is slightly wider than the opening.

Second, we make the "dawn" of the inner surfaces of the racks and apex, i.e. we abandon the primitive rectangular (in section) shape of these elements and cut out a large chamfer, simulating the turn of the slopes.

Next, we process the inner surface of the casing elements. There are many possible options: texture, color - the choice is yours. You can simply sand the surface and varnish it. You can paint the wood in the desired color to match the casing surface with the color of the window and / or the color of the walls.

There is also, in my opinion, an interesting but more expensive option - to brush the surface, i.e. processed semi-antique.

Artificial aging of wood for antiques is now very popular in various design styles. The essence of the brushing technology is to remove soft fibers from the wood surface using a metal brush (along the fibers), while the surface turns from smooth to embossed. After giving the embossed texture, the wood is cleaned from pile and fibers, then the final gloss is given. You can immediately varnish the wood, but the "aged" wood will look much more impressive after processing with a stain of the color you need. However, there is an even more effective way of painting - patting - creating a contrast between dark wood pores and a lighter surface. This is achieved using paint of the desired color: the entire front surface of the casing is covered with it, and then the top layer is removed with a cloth until the paint has time to dry. The final stage of artificial aging is varnishing. It is applied in two or three layers. You can then rub the surface with a soft cloth to add gloss.

Is it possible to install plastic windows in a wooden house? What are the criteria for choosing a profile, fittings and a double-glazed window? How to install windows and how to maintain them during operation? In my article I will try to answer these and some other questions.

In my opinion, wooden frames have no advantages over plastic ones, except for a more respectable appearance.

This argument for wood is also pretty dubious. The metal-plastic frames, pasted over at the factory with a textured film, very faithfully depict wood, while they are devoid of all its disadvantages.

What exactly are modern wooden frames losing to plastic ones?

Before discussing how to install a window, let's decide on its choice.

In multi-apartment wooden buildings built during the USSR, standard wooden window blocks made of wood, produced in accordance with GOST 11214-86, were used. The dimensions of the window units are easy to find in the text of the document. For the convenience of the reader, I will present them here:

| Height / width, mm | 510 | 870 | 1170 | 1320 | 1470 | 1770 | 2070 |

| 560 | + | + | |||||

| 860 | + | + | + | + | |||

| 1160 | + | + | + | + | |||

| 1460 | + | + | + | + | + | + | + |

| 1760 | + | + | + |

When choosing the number of sashes, it is worth remembering a simple rule: the width of the opening sash should not exceed 70-80 centimeters. Otherwise, under the weight of the glass unit, it will inevitably sag in one or two years of operation and will rub over the frame.

Another instruction is related to the position of the opening sash. In a tricuspid window, it should be in the middle; alternatively, you can choose a window with two opening sashes at the edges and one blind in the middle. Such a window block device will give you the opportunity to wash the glass of blind sashes from the outside, without putting yourself in danger of falling out of the window.

In my opinion, the choice of profile has a minimal effect on the performance of windows. All profiles currently offered on the Russian market are made of high-quality polyvinyl chloride, UV-resistant, low and high temperatures... The days when cheap Chinese plastic turned yellow and became fragile a couple of years after installation are long gone: no one needs problems with customers.

The only any weighty argument that can be cited in favor of expensive profiles from German manufacturers (primarily the widely advertised KBE and Rehau) is their somewhat higher rigidity, the ability to withstand significant bending stress without deformation. However, rigidity is important only in very specific conditions - with a large area and under conditions of significant wind loads.

By the way: two panoramic windows in my attic (13 square meters each) are assembled on an inexpensive Chinese Hauteck profile. They perfectly tolerate the strong winter winds characteristic of Sevastopol. With strong gusts of wind, only slight vibration of the glazing is noticeable.

When choosing a profile for a region with cold winters, you should pay attention to the number of isolated air chambers in it. The more there are, the less heat will be lost through the window frames due to air convection.

In my opinion, Siegenia-Aubi fittings are the most reliable. After a thoughtful study of the reviews, I opted for it and never regretted my choice. In addition to this manufacturer, Roto, Maco and Winkhaus fittings deserve flattering reviews.

When choosing a set of fittings, you should pay attention to several points related to its functionality:

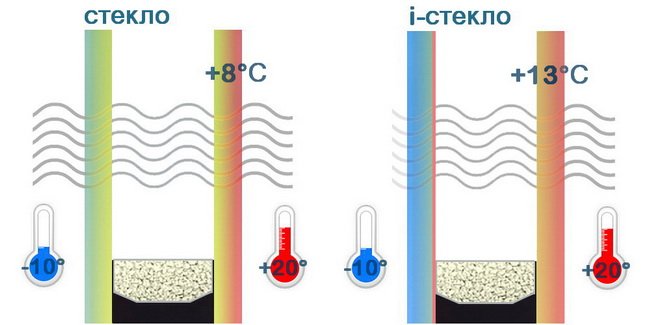

The answer depends on the climatic zone in which you live:

![]()

One of the glasses in it is supplied with a thin (only a few molecules thick) multilayer metal sputtering that reflects light in the infrared part of the spectrum (corresponding to thermal radiation).

What it gives:

Here are a couple of curious facts related to its direct functions:

In addition: triple glazing is one and a half times heavier than double, which means a greater load on the profile and faster sagging of the opening sashes.

Light-shielding glazing has limited transmission to light in the visible part of the spectrum. It is popular in regions with long sunny summers. A light-protective glass unit will also come in handy in a room with panoramic glazing on the south side of the house.

Mirror glass differs from light-shielding glass in that its translucency changes depending on the direction of light transmission. Simply put, you can see the street from the house, but you can't see the interior of the house from the street.

Don't flatter yourself: mirrored glazing is impenetrable to view from the street only as long as it is lighter on it than in the house. In the evening, when the lights are on, the picture changes.

Soundproof glass unit combines several glasses different thickness(usually 4 and 6 mm). The thickness of the spacers separating the glasses in the package also varies. Thanks to this structure, the glazing dampens sound in the widest possible frequency spectrum.

Now - about how to insert a plastic window in a wooden house.

The installation technology is very different from the order of installation of a window block in a brick or panel house. The differences are due to the fact that wooden structures do not have constant dimensions and geometry:

Hence, the basic rules for installing windows follow:

If there is no opening in the wall, the order of installing the window is as follows:

The lower edge of the opening in a log structure should not fall on the top of the crown, but in its middle. Agree that installing a window sill on a round log is quite problematic.

Hint: correct installation of the window block is possible only if there is a gap of 1.5 - 2 centimeters between it and the casing. Foam mounting allows the joint to compensate for slight deformation of walls and casing due to fluctuations in temperature and humidity.

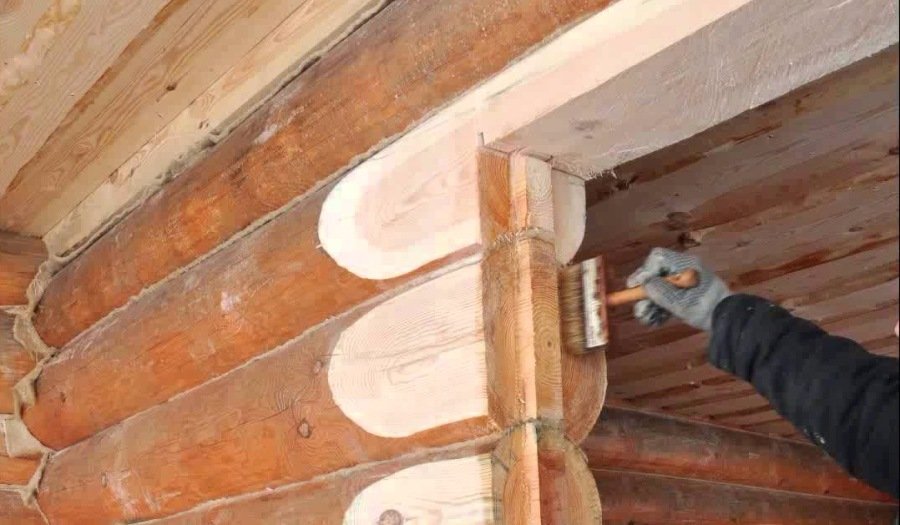

Replacing windows with plastic ones in a wooden house is carried out, as a rule, without replacing the window: only the window block changes. If the planting is in good condition, it is enough to grind it with a grinder with a petal wheel and re-treat it with a protective impregnation with an antiseptic.

With a large wall thickness, the slopes of the opening need additional finishing. As a rule, they are covered with a wide board or are assembled from a wooden lining.

Everything is very simple. Maintenance is required only for the rubber seal, and then only twice a year: it is lubricated along the entire length with a special silicone grease or ... ordinary castor oil, which can be bought at any pharmacy. The lubricant will prevent the rubber from drying out and cracking.

Also: do not forget to set the pressure rollers to the summer position in the spring and to the winter position in the fall. The seal pressed in the warm season with excessive force will quickly lose its original shape, and in winter it will see through from under the sash.

The adjusting screw responsible for changing the vertical position of the sash is located in the lower hinge. The head of the screw is for a hexagon; You can find a universal wrench with a set of hex keys at any bike store.

Another screw in the lower hinge is located horizontally, on the side of the sash. Its rotation will eliminate the skew or bring the sash closer to the frame from the side of the lock. The latter is necessary in the case when the pressure rollers in severe frosts ceased to cling to the counterparts of the lock due to a change in the linear dimensions of the sash.

Easy. To do this, it is enough to buy a window clamp-comb. The cost of this simple device is only 100 - 150 rubles.

Window retainer - comb.

Its self-installation will not cause you any problems:

Yes, it's not difficult:

How to insert a glass unit into a frame? It's also very simple:

In the opening sash, the pads must be installed under the glass unit from the side of the hinges, as well as between the top of the package and the side profile from the side of the lock. They are needed in order to eliminate skewing and relieve the profile of the bottom of the sash.

Hint: in its absence, you can use a regular hammer with a bar or thick plywood spacer.

For obvious reasons, in this case, it is impossible to install a radiator in the window sill niche - it simply does not exist. But the problem has several other solutions:

I hope that my simple recommendations will help the dear reader in choosing and installing windows in his own home. As usual, Additional materials can be found in the video in this article. I would be grateful for your comments and additions. Good luck, comrades!

September 22, 2016If you want to express gratitude, add clarification or objection, ask the author something - add a comment or say thank you!