From internal pipelines, drains are transported by external ...

Modern plumbing equipment makes the installation process of communication systems less time consuming. More recently, manufacturers of such products presented another novelty - stainless corrugated pipe. Based on this material, it is possible to create gas supply, water supply and heating systems. Durable and flexible material is very popular among craftsmen.

For the first time, a corrugated stainless pipe for water supply was used by Japanese experts. Gradually, products conquered the European market.

Among salient features plumbing corrugated pipes stainless steel can be called:

The manufacturing process for corrugated stainless steel tubular products is fully automated. The absence of a human factor provides high precision performing basic technological operations.

The most reliable are Japanese-made products. But the ratio of price and quality meets the goods of companies from Latvia.

The production of stainless pipes for water supply consists of several main stages:

The depressions and protrusions may have different parameters, since each manufacturer produces products in accordance with their Technical Specifications and Standards. It is worth noting that this does not affect the quality of tubular products.

Comparing corrugated pipes for water supply with similar products from other materials, one can note the great superiority of corrugated pipes.

This is due to the main advantages of the material:

Corrugated stainless steel pipes are used to assemble water pipes. In some cases, it is possible to install material for gas supply and as an adapter in heating systems.

Fittings for connecting corrugated water pipes must exactly correspond to the list recommended by the manufacturer of corrugated pipe products. Purchasing cheaper connection elements can cause an emergency.

The installation of a corrugated steel pipe system is carried out similarly to pipe products from other materials. However, the flexibility of the corrugated pipe makes the installation process easier and faster.

Installation of the pipeline is carried out in a certain sequence:

For any technical product, there are certain rules for installation and operation. Perform these steps with a corrugated pipe in accordance with the following requirements:

Information regarding electric-welded steel products is specified in GOST 10705-80. The same document describes the requirements that corrugated products must meet for communication systems, including water and gas.

Product quality is determined by the results of the tests to which selected samples of manufactured products are subjected.

The quality of the seam is checked by additional testing with hydraulic pressure.

The chemical composition of steel is regulated by GOST 22536.0.

Annealed stainless steel corrugated pipe is produced in accordance with paragraphs GOST 9941-81. They contain information regarding heat-deformed seamless products.

The main regulatory document in this area is the ISO 10806 standard adopted by the International Organization for Standardization in 2003.

High quality stainless steel corrugated water pipe is produced by several companies:

Corrugated stainless steel pipe allows installation work on pipelines several times faster. Therefore, specialists in this field need to study in more detail the properties of stainless steel pipes for water supply, in order to use them for various communication systems.

Today, every home has a wide variety of communication systems. The most important is centralized and sewage water supply. For this, numerous varieties of pipes are used.

In past years, heavy massive pipes made of cast iron were used for heating. But progress does not stand still, the material has also changed, from which pipes for sewage and water supply began to be made.

Cast iron pipes completely replaced lightweight modern designs. Various types of alloys were used to make such pipes, but they quickly rusted and collapsed. They were replaced by corrugated culverts and sewers.

These parts are lightweight, made of several types of material, and have excellent properties.

Corrugated parts, made of stainless steel, in most cases are used for mounting ventilation pipes. They protect electrical wiring, sewer and plumbing systems. The price of such pipes is quite high. They withstand surges in temperature and high pressure.

Corrugated parts, made of stainless steel, in most cases are used for mounting ventilation pipes. They protect electrical wiring, sewer and plumbing systems. The price of such pipes is quite high. They withstand surges in temperature and high pressure.

PVC corrugated pipes apply much more often. They are characterized by increased strength, their price is quite affordable. In addition, such PVC products are not deformed and can be operated for many years in the sewage system.

To protect the wires, a corrugated pipe made of PVC is mainly used. The price of such products is low, and the part is highly practical.

A disadvantage of corrugated PVC pipes is their easy ignition.

Water supply and sewerage systems made of corrugated stainless pipes have a lot of positive qualities when compared with ordinary metal water pipes.

In the manufacture of such corrugated elements, high quality stainless steel having the appropriate chemical composition is used. Thanks to this, such material acquires several positive characteristics:

When the wall thickness of the corrugated pipe reaches 0.3 mm, it can be mounted in places of high fluid pressure. Therefore, it has found wide application in heating, sewage and water supply systems.

Installation of stainless sewer corrugated products is much easier due to the flexibility of the material. The price of such work is available to anyone.

Corrugated stainless materials resistant tolerate high temperatures. They have low thermal deformation, therefore, the line does not bend, unlike polypropylene communications. They are often used for laying sewer systems.

Such a product easy to process. It is easily cut with any hand tool. You can use a grinder or other tool.

The plant produces stainless corrugated pipe in long coils. This makes it possible to reduce the number of joints when laying the line. No brass fittings required.

Their important difference is the presence of a large number of stiffeners. All ordinary models have a smooth surface, they can be laid only at a specific distance.

In a corrugated part, the stiffeners resemble folds that allow it to bend in any direction at any angle.

In a corrugated part, the stiffeners resemble folds that allow it to bend in any direction at any angle.

This product is manufactured using a special technology for the remelting of material. It turns out a high-strength design with great endurance. The part can bend regardless of the angle of bend, which is very important when laying sewers.

One of the positive qualities of this corrugated water pipe, is the application of welding. The corrugation is bent in any direction, and the length of the bay is enough to equip the water supply in any working area.

To further strengthen the corrugation, carry out its reinforcement. To improve the strength properties of a corrugated pipe, it is made of several materials.

If you want the water pipe laid in your house or land to exist without repair for many years, you can advise using corrugated pipes. As a result, you get a reliable and very durable design.

16 September 2015  Alexei

Alexei

A modern person prefers to live and work in comfortable conditions. Gone are the days when water had to be carried in buckets from the nearest well, and it was necessary to heat the dwelling by heating the stove several times a day. Now everything is much simpler - there are central communication systems. They supply drinking water, gas, electricity, without which life would be completely uncomfortable and gray.

But the materials that are used in the process of organizing such systems also undergo changes. Heavy cast-iron radiators were replaced by lighter and more modern ones, the same goes for pipes. The alloys used earlier for production are short-lived and susceptible to corrosion, so they were replaced by corrugated culverts. They are much lighter than their predecessors, are delivered in coils and are made of stainless steel, which has excellent characteristics.

Such products are available in shells of various colors, which allows them to harmoniously fit into the color scheme of the room. They are produced and used for a short time, therefore, as everything new is not cheap.

This aspect somewhat restrains the use of corrugated culverts in water supply systems. But at the same time, such products are in great demand in heating and especially in the arrangement of warm water floors:

A new product on the market, made of high-alloy steel SUS 304, which contains 18% chromium and 8% nickel in combination with a small amount of carbon, has clear advantages over similar materials. The presence of such components makes the product suitable for both domestic and industrial use.

In addition, they are distinguished by such qualities as:

The manufacture of corrugated water pipes is as follows. A product of certain sizes is molded from a steel tape. TIG welding is used to connect the seam. The quality of this process is evaluated by a laser check, while its seam should not be more than 1.6 times thicker than the walls of the pipe for the water supply.

After that proceed to the formation of the corrugation. In the step between the rings and their size there may be insignificant differences in the products of various manufacturers. However, this does not affect the quality of the product itself. The last stage of production is heat treatment, due to which the product becomes flexible. It consists in heating the product to 1150 ° C and then cooling it to 200 ° C.

If you compare these products with similar ones, only made from other materials, you can see that they significantly exceed almost all obsolete models. Corrosion-proof corrugated pipes for water have a lot of advantages and practically have no shortcomings. Among the positive qualities noted:

Of the drawbacks of corrugated stainless steel culverts for water supply, only one is cost. Yes, while these products have a rather high price, but at the same time they are one of the best, so the choice is often in their favor.

The use of stainless steel pipes for water supply is designed for long periods, but only if the following conditions are met:

Of course, these are far from all the criteria that should be considered when choosing corrugated stainless steel pipes for water supply; they can be continued. But still, each consumer must decide for himself what products he needs to install a water supply or heating system.

Buying any product, I want it to be inexpensive, but at the same time, quality and could serve for a long time. Quality is all the more important if you purchase corrugated stainless steel pipes for water supply. After all, this will determine whether there will be leaks and breakthroughs. To help you navigate a large assortment of pipes, consider a few popular manufacturers of these products.

Compare popular manufacturers:

The most popular in the domestic market are corrugated pipes made in Korea, but they do not belong to cheap goods and are not available to everyone. Cheaper is the products of domestic manufacturers, of course, it is somewhat inferior in quality, but still finds its consumer. Compare the pipes produced in these two countries. Let's start with domestic products - these are pipes of the Neptun IWS brand. It is made of high alloy steel, supplied from Korea and has unique qualities:

The scope of such stainless corrugated pipes for water supply extends not only to residential premises, but can also be used for production purposes, for example, in automatic fire extinguishing systems.

In addition, the organization of the production of fittings for corrugated pipes and the products themselves in their country made it possible to make a lower price, which means the product becomes interesting for a wide range of consumers. The cost of a meter of such a pipe is about $ 2.

Korean products are supplied to the domestic market under the brand name Kofulso. These pipes are made of stainless steel and can have an internal diameter of 15 to 50 mm. They are widely used.

Watch a video about Kofulso brand products:

Fittings for corrugated pipes of this brand are highly reliable and durable, easy to install, resistant to mechanical stress and able to work in a wide temperature range. The cost of pipes of this brand is about $ 3 per linear meter, which is 50% higher than that of domestic products.

We specified the characteristics of the pipes of only two manufacturers. And if you do not go into details, then they are almost the same, but the price is different and quite noticeable. Therefore, you have to choose taking into account financial opportunities.

Add to bookmarks

Conventional steel pipelines, previously universally used for laying water pipes, heating systems and various other utilities, had a number of drawbacks, the most important of which was susceptibility to corrosion. That is why steel pipes had to be replaced every 10-15 years. In addition, metal oxidation products deposited on the inner walls sharply worsened the quality of drinking water and reduced the pipe throughput diameter. All this has led to the fact that modern water supply systems are increasingly using stainless steel pipe as structural elements.

Stainless steel pipes are not only able to last without replacement for at least 400 years, but also provide high hygiene when in contact with drinking water.

Stainless steel is an alloy containing at least 13% chromium in its composition. Such steel is corrosion resistant in a conventional or slightly aggressive environment. If the chromium content increases to 17%, then such a metal resists corrosion even in 50% nitric acid.

Stainless steel is ideal for installation of water supply and heating systems.

Stainless steel is corrosion resistant in a normal or slightly aggressive environment.

And this is understandable, because it is not only able to serve without replacement for at least 400 years, but also provides high hygiene in contact with drinking water. Due to the indifferent attitude to acids and alkalis and excellent mechanical strength, stainless steel pipelines are the best option for use in food, chemical and pharmaceutical industries.

Despite the higher cost of raw materials, the costs of laying heating and water pipelines from stainless steel are ultimately comparable to the costs of completing pipelines from another material, given the absence of costs for maintenance and minimum layout time when applying the crimping system.

When the composition of the aqueous medium is normalized, the foci of rust are inhibited and subsequently the material is still resistant to rust.

Strictly speaking, even stainless steel is capable of oxidizing if the chlorine content in the drinking water transported through the water supply lines exceeds permissible limits. In this case, foci of rust form on the inner surface of the pipes. However, with the normalization of the composition of the aquatic environment, these areas are inhibited and subsequently the material, as before, resists rust. For prophylaxis, sections of water pipes through which a concentrated chlorine solution is supplied to disinfect water supply systems should be washed periodically in order to neutralize the harmful effects of chlorine.

It was invented at the end of the last century, and, due to its high functional properties, it is widely applicable in various utilities, both domestic and industrial (water pipelines, technical cold or hot water supply, and especially water heated floor systems, gas distribution systems and equipment, water fire extinguishing, etc.). The advantages of corrugated products, even compared to a conventional stainless steel pipe, are undeniable:

All these qualities make it possible to assert that a flexible stainless pipe is a revolutionary invention for heating and water supply systems.

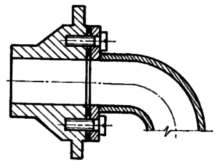

During the technical installation of stainless steel pipe structures, individual elements are connected into a single network by welding, using special flange joints or crimping.

The connection of stainless pipes by welding has its own subtleties and requires special equipment and highly qualified specialists. Welding with stainless metal can be carried out in an inert gas using tungsten electrodes. But more commonly used plasma welding methods using a directed flow of a plasma arc.

Flange connection is used mainly if the system needs periodic maintenance and replacement of individual parts.

However, welding is not always possible when laying pipelines. In addition, when laying a domestic water supply system, it can be difficult to find workers of suitable qualifications. Less time-consuming is a threadless flange or threaded fitting connection using special structural parts - couplings, flanges or fittings. The flange connection allows you to assemble the pipes through the use of fasteners (bolts or studs), and is a pair of rings with holes between which the sealing element is laid. This installation method is used mainly if the system needs periodic maintenance and replacement of individual parts. Also when using flange connection Pipes can not be ignored and its shortcomings: a rather large metal consumption, an increase in the size of the nozzles and a decrease in tightness under temperature fluctuations and force effects.

When using fittings, for tightness of the connection of the individual components of the water supply, the kit uses a special silicone gasket, which is clamped by a ring when screwing the union nut. Such a connection is mobile and, if necessary, makes it possible to dismantle the system without deformation of individual parts. It is not recommended for use on large-diameter pipelines, since it cannot provide sufficient strength for connecting parts, but household water systems are often assembled using this method.

In this article we will try to analyze in which cases a water-supply steel pipe can be used, what are the advantages and disadvantages of this material for creating a water supply, and are there any alternatives to it.

Steel pipes have been used for water supply, to say the least, for a long time. In order not to lie - from the very beginning of the use of pressure water pipes and special pumps to increase water pressure. Now, with the abundance of much more modern materials, it would seem that the material has outlived itself. Right?

But no. Steel water pipe occupies a significant part of the racks in any building materials supermarket and is still used today.

Since it is being sold, it means that it obviously has some advantages compared to its competitors, right?

Steel pipes can be used primarily where the pipeline is subject to noticeable external mechanical stress. If you need to lay a pipe under your feet in the corridor, steel will be the best choice. From the point of view of strength, of course, since this material is full of flaws in other areas.

If the pipeline has to transport water under very high pressure, a steel pipe will also be the best choice.

For example, immediately after the booster pump during its operation, the pipeline is immediately subjected to two extremely adverse effects:

A steel water pipe is not the cheapest material for creating water pipes. But one of the cheapest. We must not forget that for water supply they often use not what is cheaper to buy, but what is already on the farm.

A bay or a bundle of polypropylene was hardly lying in someone's basement, but a few meters of a half-inch steel pipe was easy.

If an arbitrary shape fitting is sometimes necessary to look for, then ordinary cast-iron corners or tees are a heap in any general store.

This is important when water pipes, steel or from other materials, are recessed into the screed or plastered. The use of a material that expands greatly upon heating will quickly lead to cracking.

Unfortunately, not everything with traditional material is so cloudless.

Yes, the steel is rusting. This is especially true for cold water pipelines; the combination of constant moisture due to the appearance with atmospheric oxygen is fatal.

Water pipe steel on cold water eventually grows inside. Clearance can catastrophically decrease over several years of operation of the water supply system.

To assemble a water pipe from steel is not at all what to tighten a few union nuts on the fittings of metal-plastic or to weld together the pieces of polypropylene with a small soldering iron. You will need to either involve a welder, or manually cut into thread pipes. And this requires a lot of effort and a special tool.

Oh, hard work ...

How much the pipes weigh - the owner of the water supply does not care until the moment when they have to be transported and unloaded.

Of course, in the first place among the shortcomings is susceptibility to rust. Who needs plumbing, which in a few years will certainly become worthless? If a few decades ago there simply were no reasonable cost alternatives, then now why put up with this shortcoming?

Tip: immediately after the installation of the water supply from steel pipes, making sure that there are no leaks, prime and paint the pipe. Later, this is likely to prevent condensation on the pipe with cold water.

Fortunately, it is not so difficult and expensive to protect steel from corrosion. A simple steel pipe has alternatives that preserve its mechanical strength and at the same time lack the main disadvantage.

Galvanized pipes for water supply are made of a simple steel pipe by electrochemical spraying of zinc on the inner and outer surfaces.

This solves two problems at once:

Galvanized pipes are much more expensive than steel pipes, but they are a much more robust solution for water supply. The service life of galvanized pipes, if it is limited, then a period quite comparable with the duration of human life.

Tip: the thread on the galvanized pipe exposes the steel under the anti-corrosion coating. In general, galvanization does not need paint, but the thread must be painted, otherwise it will quickly rust.

Stainless steel water pipes are an excellent choice for those cases when you need special reliability. Without regard to the price. This is a wonderful material, the water supply from which is made on the principle of "shot and forgot." If he ever needs repairs, he will most likely come down to cleaning the filters and removing bits of scale.

In order not to convince the reader that he will find the happiness of his life in the stainless steel water supply system, we still mention the drawbacks.

As we see, stainless steel water pipes as a material for water supply are good, but far from ideal.

If, for some reason, it is intended to use only metal water pipes to create a water supply system, then of the materials suitable for this, copper and cast iron should also be mentioned.

If metal water pipes are not a fetish for you, then the modern market will offer you a lot of much more convenient to use and install modern materials:

To connect steel pipes and any of their options - be it a galvanized water pipe or stainless steel, there are only two ways.

Tip: if you want to use stainless steel pipes for water, think about inviting an electric welder.

The most common propane welding torches do not give enough hot flame for comfortable stainless steel welding. Threads on it do not manually cut.

On steel and galvanized pipes, threads are cut manually if necessary. If there is a lathe within reach - even better. Having made pipes and bends with threads of the required length, you will make the assembly of the water supply system much more comfortable.

Diameters of steel water pipes are traditionally more often denoted by inches. Moreover, in order to calculate the exact inner or outer diameter in millimeters, it’s not enough just to multiply the number of inches by 25.4. If we see 1/2 inch metal water pipes in the store, it only means that a cylindrical pipe can be cut on this pipe pipe thread of that diameter.

Along with inches and sellers and specialists, mention may also be made of the diameter of the pipe in the familiar metric system. In this case, the inner diameter of the pipe is taken; External varies with wall thickness.

According to GOST 3262-75, gas pipes according to wall thickness are divided into:

In millimeters, the wall thickness varies depending on the diameter of the pipe. If, with an inner diameter of the pipe of 25 millimeters, a wall thickness of 4 mm will make the pipe refer to reinforced, then for a hundredth pipe, a wall of four millimeters means belonging to light pipes.

If there are no special requirements for the ability of the water supply to withstand extreme pressure or, conversely, for the weight of the material (which does not fit well with the choice of steel), ordinary pipes should be preferred. Reinforced, in addition to more weight and greater cost, it is much more difficult to cook with gas.

Threading them with a familiar tool may also not work: their inner diameter is standard, but their outer one is bigger! If a stainless water pipe with a large wall thickness is processed, then at least hang yourself ...

On the other hand, light pipes with their thin walls were originally intended for gas pipelines with welded joints. It is obvious that corrosion will destroy a thin pipe faster. In addition, pipes with thin walls are frankly fragile.

Even with a slight voltage water pipe (and they are often mounted due to the characteristics of the material, at least a little, but a stretch) after a couple of years, the thread may simply break off. What this is fraught with in an apartment building - I think, no need to explain.

Of all the steel pipes, our choice in terms of consumer characteristics is the galvanized water pipe. Although, we repeat, in our time steel has excellent alternatives.