From internal pipelines, drains are transported by external ...

The construction calculator allows you to calculate the amount of building materials necessary for you: crushed stone, sand, asphalt, soil, peat. It is extremely easy to use - by entering the source data, online you get the amount of material that you need to complete the work.

for instance You decided to spend a good road to the summer cottage. What material is needed for this is known: sand, gravel and asphalt. But how much to order? To do this, it is not necessary to go to a construction company for a consultation, you can use the calculator on our website. So, the future road should be 150m long, 4 meters wide, for the thickness of the sand layer we take, say, 5 cm: we believe that the area is 150 (d.) X4 (w) \u003d 600m2. Fill the values \u200b\u200bin the empty fields, click calculate, we get: the required volume of sand is 30m3 or 46.5 tons. We do the same actions with rubble and asphalt.

Another option of our calculator is the calculation of the preparation of concrete mix. In the first field, select the concrete brand (concrete class for compression), and in the second field enter the required volume. For example, to prepare 10 m3 of concrete mix M 200, 3 000 kg of cement, 7 140 kg of building sand and 11 560 kg of crushed stone will be needed. You can purchase all these materials and much more at Baytek Building

In addition, when choosing the converter of quantities, you can translate weighted quantities into volumetric ones and vice versa, which is quite convenient if you need to know how much is in 1m.cub. tons of this or that material.

The most requested materials during construction are cement, sand and gravel. Therefore, to calculate their estimated consumption is required constantly. A person facing such a need for the first time, when searching for information about this on the Internet, is faced with furious formulas. In fact, everything is much simpler.

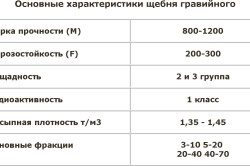

There are factors that can significantly affect the calculations. They are associated with the features of the rubble itself. Directly in the calculations, they are taken into account by design firms and large construction companies that make up large-scale estimates. It is enough for a private developer to know the potential causes of errors to avoid them.

The last indicator (compaction ratio) is 1.3 by default. In fact, it shows how much it will be possible to ram the crushed stone with a vibrating plate or roller.

The value of the specific gravity or bulk density of crushed stone is indicated in the certificate for the goods. In its absence, you need to focus on the average for this type of indicators. The bulk density is significantly less than true, since it is calculated without taking into account the cavities between the grains of stone.

Everything is very simple. First you need to determine how much gravel will be needed per cubic meter. It is known that the layer thickness should be at least 20 cm. Thus, the required volume is obtained according to a formula familiar from childhood: we multiply the latitude by the length and height, that is, in this case 1 m x 1 m x 0.2 m \u003d 0.2 m 3.

The result must be multiplied by specific gravity crushed stone and the same compaction coefficient. In our case, 0.2 m 3 x 1.47 t (for granite crushed stone) x 1.3 \u003d 0.382 m 3. This is a material consumption for one cubic meter of foundation. Multiply this value by total area foundation. So you know the exact amount of crushed stone that will be needed to create the entire structure.

You can find out the required amount of crushed stone for the construction of the road using the same formula. There will be only one difference in the formula - the layer thickness. It will take only 15 cm, which means that the volume will be 0.15 m 3. Accordingly, the costs will be 0.15 m 3 x 1.47 tons (for the same gravel) x 1.3 \u003d 2.87 m 3.

The error in the calculations is minimal. Therefore, this formula is preferred by builders and developers to calculate the amount of necessary materials for medium-sized objects.

Crushed stone is one of the most commonly used materials in construction. Depending on the grain size obtained by crushing boulders, it is divided into several fractions, each of which has its own application.

Small grains of small fractions are part of concrete and concrete products. Larger grains are used during the laying of the foundations of buildings and when laying roads. Well, the largest pieces of crushed stone are used exclusively on the railway to create a ballast layer under the sleepers.

In the company "" you can order crushed stone of any type and in any volume you need. Our specialists will quickly take an application for work and deliver the goods to anywhere in Krasnoyarsk and the nearest settlements in the shortest possible time.

Often our customers face the same problem: to determine the amount of crushed stone they need, they try to calculate the amount of material that is already in stock. The problem is that all the rubble, as a rule, is piled up in a heap, so this is not so easy to do.

How to determine the amount of rubble in a heap lying on a flat surface? To do this, resort to the school curriculum in geometry. So, the crushed stone, usually takes the form of a "hill" or a pyramid with a rounded base, and therefore, we will call it a cone. You can find out the volume of this geometric figure by the formula:

![]()

Where V is the volume of the figure, R is the radius of its base, and H is the height of the cone. The number " pi"Is a constant value equal to 3.14.

So, for the calculations, it remains only to measure the height of the heap and find its radius. And if there shouldn’t be any problems with the first, then finding the second parameter is quite difficult. But you can easily measure the circumference of the base, and already with its help find the necessary value by the formula:

Where R is the radius of the base and C is the circumference.

After all the necessary measurements, it remains only to slightly change the formula and substitute the necessary values \u200b\u200binto it.

![]()

Tell me, please, how many bags of gravel will be needed to fill a site measuring 3x3 meters, if the thickness of the embankment should be 20 cm? Thanks.

Manufacturers usually release ordinary crushed stone in bulk, but decorative crushed stone, as a rule, is packed in bags of 50 or 25 kg, depending on the particle size of the fraction. Very small fractions of 1-5 mm are packed in 50 kg bags, and fractions of 5-40 mm in 25-kg bags. These types of decorative gravel are used to solve various technical and design problems: laying paving slabs, arranging paths in landscape design, and decorating rooms and facades.

In order to accurately calculate the amount of crushed stone needed to solve a particular problem, it is necessary to know the volume of the embankment and the volumetric (or bulk) weight of the used fraction of the material. This parameter is indicated in the quality certificate.

For an accurate calculation of the required amount of crushed stone, in addition to the volume of the embankment, it is necessary to know the volume fraction weight

If this value is unknown, the average indicator can be used for calculations. Volume weight decorative crushed stone of a fraction of 5-40 mm is 1300-1600 kg / cubic meter,

in the calculations we use the average value of –1500 kg / cubic meter.

Dividing the volume by weight, we determine that 1 ton of material occupies a volume of 0.67 cubic meters, and 25 kg of crushed stone from a packaging bag will occupy a volume of 0.017 cubic meters.

Knowing the dimensions of the site for filling and the thickness of the embankment, we calculate its volume:

V \u003d length x width x thickness \u003d 1.8 cubic meters

So, we need 1.8 cubic meters of crushed stone, which is:

Thus, the estimated number of gravel bags for filling a given site is 106 bags, but it is recommended to buy it with a margin of 5-10%, which means you will need 110-115 bags of 25 kg each.

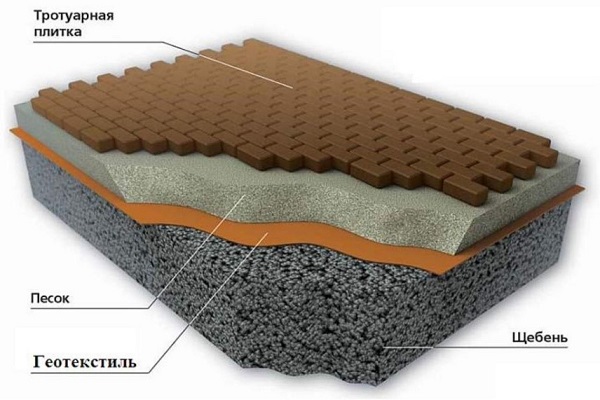

When filling garden paths and creating other elements of landscape design in the soil, make a notch to the thickness of the embankment, lay the geotextile insulation layer on the bottom, fix the edges of the future embankment with a special tape only then crushed stone is covered with an even layer, as shown in the video:

Thanks to these measures, gravel will not sink in the soil, weeds will not grow through it, and the embankment will last for many years.

In modern construction it is very difficult to do without such important material as crushed stone. Its use is necessary in the construction of both ordinary residential buildings and public buildings. In addition to the construction of buildings, gravel with various sizes of fractions is actively used to create a new pavement surface, as well as during the implementation of landscape design projects. The properties of the structure being built and the quality of the created pavement, as well as parameters such as reliability, durability, wear resistance and strength of the structures created, directly depend on how correctly and correctly the calculations of the quantity and type of this building material were made.

To calculate the required amount of crushed stone, you need to know its specific gravity. Contact your supplier for this information.

Having knowledge of how to calculate the volume of crushed stone, it is possible to competently draw up budget documentation, calculating exactly the cost of the necessary material. With such information, it is possible to draw up a schedule of construction work in a short time, ensuring timely delivery of the material in the required quantity. In addition, a correct and competent calculation of the required volume of crushed stone or gravel will allow you to calculate in advance the total cost of all work and materials for the construction of a particular structure.

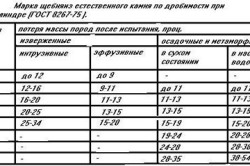

By the type of its origin, such a product as crushed stone is a building or even decorative material of non-metallic origin. It is used in repair and construction works as an independent product for the implementation of construction tasks or as a material included in the list of ingredients for mortars when creating a variety of reinforced concrete products, elements or structures. The classification of this material is carried out depending on such factors as the origin or place of its extraction, and depending on the types of minerals.

The main thing, when calculating the volume of crushed stone, it must be remembered that its consumption and quantity are parameters that directly depend on the type, average size of its fractions, their shape, direct use according to the type and technical instructions that speak about acceptable operating conditions for a particular type of material .

In the place where raw materials are extracted, crushed stone can be divided into only three main groups, such as:

All existing types are characterized by such parameters as high strength properties, increased resistance to wear during operation, to low temperatures. Suppliers of minerals of this type are simply obliged to indicate for each batch of products the level of frost resistance corresponding to its quality. This is a very important parameter, because it is able to influence such properties of the material as its density, the cross section of its faces and the average dimensions of the mineral fractions.

Consumption rates of one or another type of crushed stone are quantities that are directly dependent on all individual parameters of the material, on the type and size of each of its fractions. Before undertaking volume calculations to solve a particular problem, one should inquire about what type of material is, how its surfaces were processed, what sizes its particles have, how many cycles of processing bulk material has passed (2 or 3), before getting ready-to-use status.

In the process of making the most accurate calculations of the volume of material, one should take into account the presence of other bulk additives in it. And if any, then their technical parameters should not be overlooked.

Back to the table of contents

In the process of preparing for the start of construction of facilities, which will subsequently be used for various purposes, it is settlement activities that play a special role. Calculations begin with measurements of the future facility, with a detailed study of existing documentation, determining the conditions under which the finished facility will be operated. The project documents must certainly contain data on what parameters the future structure will have, its specific gravity, and also such a value as the compaction coefficient. For the production of works, various grades of crushed stone, types of material by origin, minerals that are most suitable for solving certain problems depending on the grain size and basic properties can be applied.

So, for example, it is necessary to take into account that dolomite minerals have a weight of 1 cubic meter in 1.5 tons. Well, the crushed stone created from granite weighs much more, and the weight of its cubic meter per 1000 kg exceeds the weight of the dolomite material and is 1.6 tons per 1 m³.

There are significant differences in the calculations associated with different values \u200b\u200bof the compaction coefficient.

So, for example, to create an embankment during the implementation of landscape design projects during road works, this ratio is 1.3. This value is calculated both for mechanical ramming and for ramming using a roller.

Proper selection of the most suitable material by type of origin can also affect the quality of building concrete, which is used to create the foundation as a material for preparatory work. So, to create a pillow under the foundation, gravel rubble with a grain size of not more than 4 cm is considered the most preferable. In the composition of concrete, gravel is aggregate, which increases the durability of the structures created several times, their strength, minimizes shrinkage and creep of the composition. It is worth noting that the addition of crushed stone to the solution will reduce the consumption of rather expensive concrete.

In addition, the shape of the fractions of the material exerts its influence on the pouring technology and, therefore, on the consumption of material. So, flat stones or fractions of a needle-shaped shape significantly increase the consumption of material and at the same time reduce the frost resistance and strength of the finished structures. For this reason, round-shaped minerals with a high level of strength and frost resistance are most preferred for construction work.