Coffee is not just a drink for a long time, but an integral part of our life. Without...

In the store you can buy wooden window structures, PVC windows and aluminum profiles. Each of the materials has its own characteristics that can satisfy any customer requirements. But if we are talking about a window for a summer residence, then a wooden frame would be the most suitable option. Such a wooden window frame can be made with the necessary materials and tools, as well as with the observance of technology. Work must be carried out carefully and accurately so that all geometric dimensions are clearly observed. The window will last a long time.

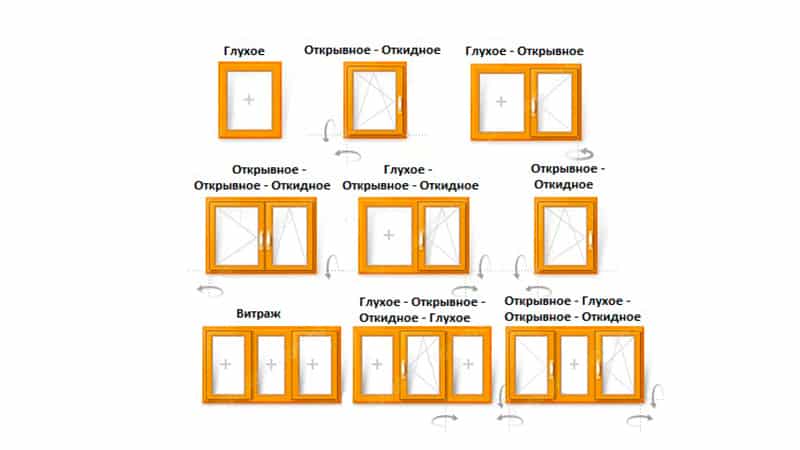

Structurally, a wooden frame can be made in several modifications:

At the same time, in option 1, it is possible to provide a window that will perform the functions of ventilation more efficiently than a sash.

The wooden frame can be made from any type of wood. It all depends on personal preferences, skills in wood processing. Oak is considered the strongest and most durable breed. However, it is quite difficult to process and is an expensive material. Among other species that are most often used for the manufacture of wooden frames, birch, ash, pine, and larch are known.

In order for a wooden frame to be strong and reliable, it is not necessary to take solid bars or boards. Glued laminated timber is quite a suitable material. It is made in such a way that it does not shrink during operation. This indicates greater reliability and durability of this material.

As an alternative to wood, plywood sheets are used to make a wooden window frame. It has sufficient strength and reliability, which allows its use as a starting material.

The wooden frame can be assembled using the following tools:

Back to index

Before the wooden frame is assembled, it is necessary to treat the bars with a special antiseptic composition. Thanks to this, the frame will last longer, as the wood will be protected from the formation of fungi and moisture penetration.

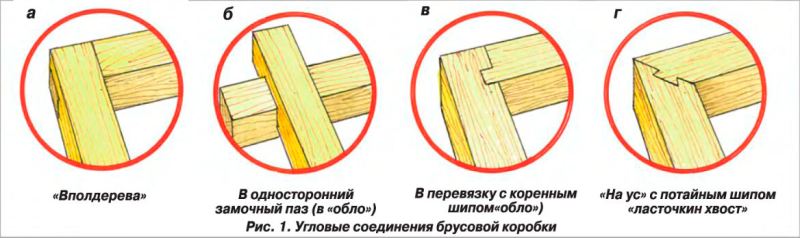

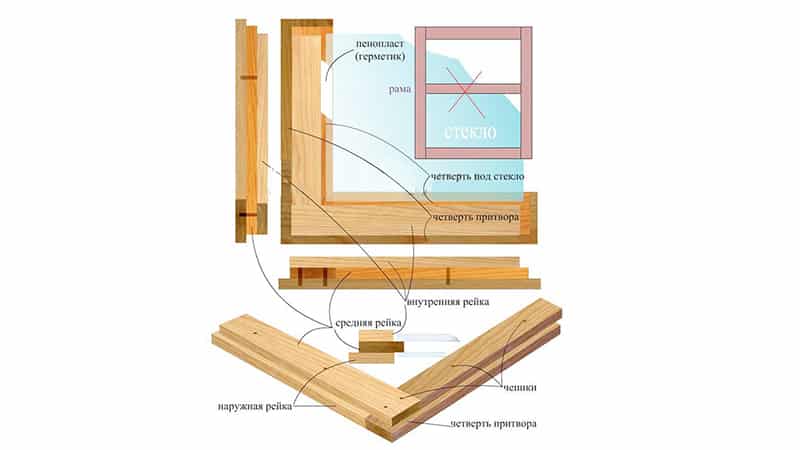

Making a frame with your own hands begins with a box. In a board measuring 50x150 mm, a slot is made in such a way that a configuration in the form of the letter "G" is formed. This will ensure the impermeability of the window. Next, you should divide it into 4 identical parts. They are fastened together by means of a thorn-groove connection. That is, a groove is sawn on one of the parts, and a spike is sawn on the other. These 2 connection elements must be carefully sized so that the spike fits into the groove without gaps, tightly. This will ensure secure fastening.

The groove is made using a circular saw, which is used to make cuts. And the excess is removed with a chisel and a hammer. The spike can be made both with a hand saw and with a circular saw, with a certain skill. The grooves must be made on the frame parts, which are located vertically. On the horizontal - a spike is cut out.

After pre-assembly of the elements of the box, it is disassembled. Carpentry glue is carefully applied to the fastening parts. Then they are connected, strictly observing geometric angle at 90°. You can control this with a square.

After that, metal corners are inserted at the end corners. They will provide the box with additional rigidity. Further work can be carried out only after the glue has completely dried.

The window wooden frame is made of timber with a section of 50x50 mm. A profile should be cut out of it according to the design of the window. It will differ depending on the size and dimensions of the glasses that will be inserted further, the width of the glazing bead. Wherein dimensions frames should be such that when it is inserted into the box, a gap of 1-2 mm is preserved. The profile is performed using an electric or manual planer. The resulting notches should be sanded with a machine or sandpaper.

The blanks of the wooden frame are fastened together in the same way as a box, that is, a tenon-groove connection is used. For reliability and rigidity glued. On the outer part, metal corners can be screwed in the corners, which, in addition to decorative purposes, will increase the rigidity of the structure.

After that, the wooden frame and box can be stained and varnished, if there is a desire to preserve and emphasize the texture of wood, or painted. Hinges are screwed on the window frame and the box, which serve as the connection of these parts to each other. After inserting the glass, the frame can be hung on the prepared hinges.

Wooden windows have always been popular due to such positive properties of wood as: high heat-saving characteristics, environmental friendliness and durability.

One of the advantages is also that the production wooden windows do-it-yourself task is quite feasible even for a non-professional.

Of course, now they use metal-plastic windows more, which are cheaper and also have their undeniable advantages, but still, wooden windows are a classic and they will always be popular.

The most popular material for the manufacture of a wooden window box in our latitudes is pine. It is distinguished by availability, low price and practicality. In terms of material characteristics, pine is superior to oak, but it is more expensive and therefore, for the first time, it is better to stop at pine windows.

Process of creation

The main requirements for the board are as follows. Firstly, it must be well dried, and secondly, it must not have knots and deformations. These conditions are important, since the box will experience the main loads, so its strength should not be in doubt.

Do-it-yourself wooden window manufacturing technology involves the use of glued laminated timber to make the box. In this case, the box has the most durable design. Glued laminated timber is a compilation of individual boards in packages and gluing them along the plane. Boards in our case will be made of pine.

The size of the board is taken 15 * 5 cm. They are interconnected by gluing. Then four holes are drilled and wooden pins are inserted into them. Such a connection will provide structural rigidity. In the opening, the box is installed motionless, using self-tapping screws and dowels, and then, the gaps between the opening and the box are blown out mounting foam.

It is necessary to dwell briefly on the tool that will be needed to make the window.

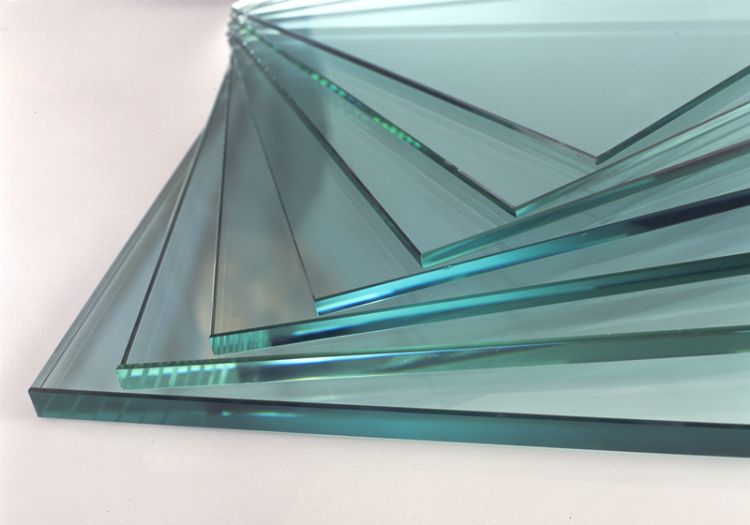

If the window will be made for a dacha in which you do not live in the autumn-winter period, it will be enough to confine yourself to a thin double-glazed window.

window frames

Useful information:

Pay attention to inexpensive windows made of Krasnaya Gorka wood: a frame made of two-layer glued laminated timber (pine) 57x60 mm, single-chamber double-glazed window.

If you decide to carry out the manufacture of wooden windows with double-glazed windows, then you need to start with the design of the window frame. The minimum timber that you will need in order to make a frame should be 6 * 4 cm in size and will depend on the thickness of the window.

The profile for one window pane should have two rectangular folds, and a window with two panes should have one more. Frame production begins with careful processing of timber. Then, with the help of a thickness gauge, we make all the markings, after which we begin the installation of folds (grooves).

The manufacture of folds is carried out so that when the frame is already assembled, they are in the same plane. Otherwise, the glass will be weakly sealed. In general, the dimensions of the grooves depend on the thickness of the glass and the type of seal.

Note!

If putty is used as a seal, then the folds have a smaller width than when using glazing beads.

It must be remembered that strongly narrowed folds will let the wind through. The width of the strapping beam also affects the thickness of the grooves.

The window frame is assembled in such a way that the spikes fit snugly into the grooves. For a tighter connection, a spike must be installed. To do this, you must first drill a hole according to the diameter of the spike and grease it with glue.

In addition, at the end of the frame boards, to improve the connection, you can use a key. Its appearance will resemble a double dovetail. To do this, on each of the connected ends, a hole in the form of a trapezoid is made, into which a key is then inserted. Before completing the assembly, the joints are smeared with glue, and after assembly, the remaining glue must be cleaned with a knife. In the manufacture of a window with a sash, the installation of fittings will be added to the above works.

To prevent the window from blowing through, you need to carefully fit the glass to the size of the frame. To do this, you need to cut it with a diamond glass cutter. Before work, for safety, you need to wear goggles to prevent glass chips from getting into the eye and mittens, so as not to cut your hands. Glass cutting is carried out with a ruler, which should exceed the length of the glass. After we have drawn a line with a glass cutter, we move the glass to the edge of the table and, using pressure, break off the excess part. The glass should break off according to the cut.

Anyone who has an idea about how to make wooden windows should know how to correctly insert a window into a frame. To begin with, let's try on the cut glass by inserting it into the frame. If the glass is cut correctly, then we take it out and begin to prepare the folds.

To do this, they need to apply sealant and insert the glass into the frame. We fix the glass with the help of the top glazing bead and fix it with a thin carnation. When using a larger glazing bead, you can use self-tapping screws to attach it to the frame.

In the manufacture of windows, which consist of two halves, another bar is installed in the center, with the same grooves. One half of the window is made with a thinner frame and attached to the main one with hinges. In addition, a handle is attached to such a frame, and a groove is also cut out for the closing mechanism.

double wooden window

Vents in wooden windows are an integral part and come in several types: mortise, split and sliding. The latter represent a rather complex mechanism and it is difficult to perform them on their own. The first option is made together with the window frame and here you need maximum accuracy.

The best option for window vents in wooden windows are split, which are made separately from the window, and then, finished, are inserted into the frame.

Note!

In the manufacture of a split window, the use of any special fasteners and special skills in execution is not required.

The manufacturing technology of such vents differs slightly from the order of mounting the window itself, only for smaller sizes. The difference lies in the mounting of the opening mechanism, which usually consists of hinges, and the attachment of additional fittings, in the form of a handle with a closing device.

After completing all the work, the manufacturing technology involves lubricating the window surfaces with an antiseptic. After that, the window is placed in the opening and fastened in the grooves. Then we fix it with self-tapping screws that pass through the box and fasten them to concrete. Holes in concrete are most often made using a mounting gun.

After we fixed the window, we blow out the cracks with sealant. You need to wait for it to dry, and then plaster the sealing points. The work is completed by mounting the ebb and the window sill. Thus, it can be seen that making a wooden window with your own hands is not an impossible task, and this distinguishes them favorably from metal-plastic windows.

Modern windows are distinguished by an enviable variety of materials, colors and shapes. Various manufacturers offer frames made of plastic, aluminum, wood. Thanks to new equipment and tools, the windows are airtight, durable and practical, as they do not require special care.

Plastic windows

However, there is such a huge choice and a negative point: the cost of purchased windows is quite high.

That is why many craftsmen are increasingly wondering how to make a window frame with their own hands.

Indeed, in order to glaze a small greenhouse, a veranda in a country house or a balcony, an ordinary wooden structure is enough, which will protect from dust and wind.

Before you start carpentry work, be sure to stock up on all the necessary tools or materials.

Do-it-yourself homemade wooden frames will require completely dried or glued wood for manufacturing. Options are also possible when wood is replaced by ordinary plywood.

As for the carpentry tool, for a start it is quite possible to get by with the most elementary and simple things:

In addition to wood, timber or plywood, of course, you will need glass, wood glue, metal corners, and a drawing of the future window. If you chose boards as the main material, it is best to purchase them with a section of 50 by 150 mm. The "golden section" of a bar for a future window is a bar of 50 by 50 mm.

If everything is ready, then you can start making wooden frames with your own hands.

carpentry tool

Glued timber is a reliable, durable and lightweight material. It is not easily deformed and is often used in construction.

An ordinary beam is also suitable for a frame, only the likelihood that such a frame will lose its shape under the influence of precipitation and temperature is much higher.

Although do not forget that wooden structures can be treated with a special protective compound.

Window frame manufacturing technology includes:

We make our own windows

Since the factory frames have a rather complex profile, it is very problematic to repeat it at home. This will require not only a professional tool, but also special equipment. Acquiring all this for the manufacture of a simple design does not make sense. That is why simple craftsmen invented their own way of creating a profile for a window frame: fastening plywood strips.

For such a plywood frame, four strips are enough, from which a rectangle is then fastened. To make the desired profile, several rectangles are assembled together, made from plywood strips of different widths. This is the technology for manufacturing window frames.

Do not forget the common rule: it is better to measure several times than to spoil once. If you are new to this matter, then be sure to double-check your measurements several times.

Thus, the result of the efforts will be a puff timber of the required configuration.

Using this method, both a regular, blank frame and a window with two or three glasses are made. A frame with one glass is easy to make from eight plywood strips forming two rectangles. P the strips of the second layer should be of a smaller width: this will make it possible to subsequently fix the glass on the frame.

We fasten the handle

Finished parts are connected using self-tapping screws. For structures with several glasses, it is better to coat all parts with wood glue. Then such a frame will serve its owner for more than one year.

Despite the abundance of advice, the question of how to make wooden window frames yourself, each self-taught carpenter can decide on his own. After all, it is not in vain that they say that each product remembers the hands of its master and often lasts much longer than a thing bought in a regular store.

The advantages of plastic windows over wooden ones are considered quite obvious today. But ease of manufacture and installation does not mean quality and comfort.

Spared from the ability to breathe, plastic double-glazed windows often create conditions that are unfavorable to health. In addition, suffocating air does not become cleaner even after ventilation of rooms with double-glazed windows.

Wooden windows, in turn, also have a number of disadvantages, the most important of which is exposure to moisture. But with proper care, a wooden window can serve for a long time and, due to its environmental friendliness and the ability to breathe, will allow residents of a wooden or other house to stay in a more pleasant state.

Wooden windows have an important advantage - environmental friendliness and naturalness.

How can you make a quality wooden window with your own hands? To do this, you need to follow a simple plan, as well as have some skills in working with woodworking tools. Making windows of the simplest kind has a memorable step-by-step character.

Before making a new wooden window, it is worth preparing a number of tools, including a screwdriver and a drill, a hammer with a set of chisels and chisels, as well as an electric planer. If there are no ready-made glasses for the window, then you will also have to get a glass cutter. Additionally, rulers and other small devices will be needed.

From the materials you should take the wood itself, self-tapping screws, window hinges, as well as a sheet of glass.

The main task of the wizard at the first preparatory stage is to create a drawing. Sketches or drawings should contain clear dimensions for each element of the window.

When they are created, it is usually done to scale, respecting all relative distances. An improperly designed scheme can lead to a waste of materials or premature destruction of the window.

When buying lumber, it’s worth everything to buy them with a margin so that it’s enough. If you plan to make more than one window, then it is better to make one sampler and then proceed from the amount of materials that actually went into making one window with your own hands.

Wooden blanks for wooden window parts should be made from wood that is best suited for this. Pine wood is often used for windows, as they are easy to process and sufficiently resistant to moisture. Often oak materials are also used.

lumber requirements:

Individual parts and blanks are manufactured according to the drawing. This must be done using conventional cutting tools - a jigsaw, a saw. It is better to grind already finished parts.

In some cases, glued beams can also be used instead of solid wood. Their main feature is that, due to the glued structure, the beams from many layers remain quite stable and do not deform for a long time.

The basic size of the raw material for creating a box of a conventional wooden window is a board with a section of 150 by 50 millimeters. The box consists of four boards, which are interconnected with the help of grooves and spikes made with a cutter or chisels. They are made dense in such a way that they fit into each other quite rigidly. In this case, all 4 parts of the box must be connected to each other strictly perpendicular.

The strength of the finished structure depends on the strength of the connection.

In order for the tongue-and-groove connection to gain greater strength, it is stitched through with a wooden rod, under which a separate hole is drilled.

The finished base of the wooden window is installed in the window opening, and the gaps between the box and the walls are foamed with mounting foam. It is worth noting that too large gaps between the walls and the box cannot be sealed with foam alone, since a foam layer of more than 5 centimeters can deform the box. Therefore, it is desirable to make a window opening of the optimal size with a margin of up to 5 centimeters.

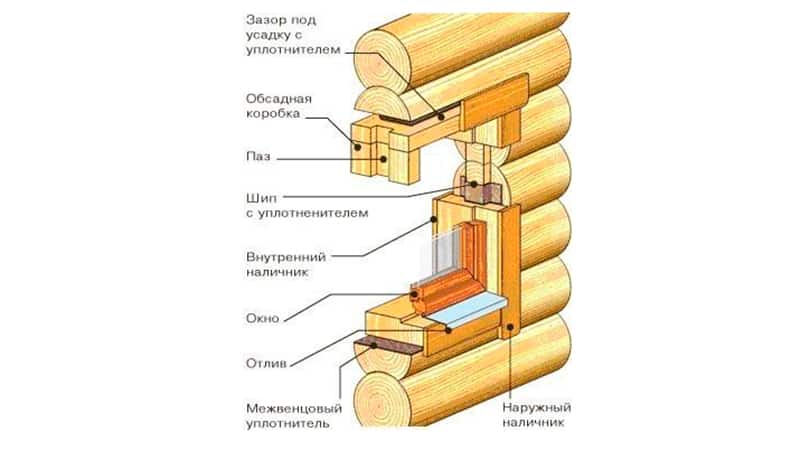

In the case of a wooden building and walls made of beams or wooden log cabins, a pigtail is also used, the production of which has its own characteristics.

Before you make a frame, you need to determine the base material for it. Window frames are made of beams with a section of 50 by 50 millimeters. The manufacture of window frames provides for one of two processing options - you can make both 1-glass and 2-glass profiles, which have 2 or 3 grooves, respectively (one for each glass insert and one for the box).

The grooves, as a rule, have a recess for glass sheets 10 millimeters high and 14 millimeters wide. The glazing bead, which will fix the glass, has a width of 10 millimeters (calculated on glass with a thickness of 4 millimeters). The groove for the box is a little larger and has a section of 15 by 20 millimeters.

Making wooden windows with your own hands is generally a simple process, just like assembling the most complex part of them (the frame). First, wooden window frames are assembled in the same way as a box was assembled. Their elements are connected using spikes and grooves, which are glued with glue.

Sometimes the frames are additionally fastened with metal corners (using self-tapping screws). Although the corners give additional strength to the structure, they negatively affect their static appearance.

Even if all the dimensions of a do-it-yourself wooden window, frames and openings for glass are known in advance, the glass still needs to be measured before cutting. This is important to know in fact, since a deviation of even 1 millimeter can cause the window to blow through.

If you accurately measure and cut the glass, then this will ensure a sufficiently high density of its connection with the base of the frame.

Working as a glass cutter requires skill and experience.

To cut glass, a glass cutter is used, the technique of working with which also needs to be mastered. If you don’t have the skills to work with glass cutting, then it’s better to ask a specialist about it or purchase glass of the right size in a store where it can immediately be cut to the specified measurements.

The edges of the glass are quite sharp, and therefore they need to be processed with sandpaper.

If glass is processed independently, then it is very important to adhere to safety precautions, the instructions for which have several important points. First, you need to use special gloves with rubber pads, since even the smallest pieces of glass can injure your hands. Secondly, it is desirable to protect the face with a mask, as well as glasses.

Before cutting the main sheet, make a few preliminary cuts to determine the optimum pressure on the glass cutter.

When cutting glass, you need to press it with optimal force. If you do not press it, then a poor-quality cut will lead to the appearance of chips on it. Otherwise, applying excessive force will cause the glass itself to crack, which will not only damage the glass, but also lead to injury and cuts.

When cutting, the glass cutter is carried out along a ruler, which can be made from almost any material. As a ruler, you can also use a regular bar.

After cutting, the glass is placed in the window frame, fixed with glazing beads. Sealant is applied to the wood first.

A window made of wood is mounted on a box. For this, self-tapping screws or window hinges are used. After that, the window sill is installed.

The simplest do-it-yourself window will provide the house with warmth and comfort, and will also be inexpensive.

If necessary, several such windows can be made and installed in a box from the outside and inside. Thus, it is easy to provide additional insulation for the winter.

With your own hands, you can create almost any device or element of the house that will become a reason for joy. After all, even a wooden window can not only replace plastic double-glazed window, but also to become a good test for the aptitude of a novice carpenter.

Modern windows for the most part are double-glazed windows, consisting of prefabricated panels. These windows are easy to use, but they also have some drawbacks. So, for example, if one of the glasses is accidentally broken, it will not be easy to replace it, especially if it has a non-standard size. In addition, companies that produce double-glazed windows often close, and many models, when it comes time for glass replacement, are discontinued.

For those who are interested in how to make wood windows yourself, photos and detailed instructions posted on this page will be very useful. The photo shown below shows a real home-made double-glazed window, the manufacture of which does not require any special skills or significant financial investments. If glass breaks in such a double-glazed window, a replacement can be easily found at any hardware store, and if condensation collects between the glasses, it will be enough to change the sealant and replenish the desiccant.

Double-glazed windows with an air gap not filled with any noble gas, due to the circulation of air flows between the glasses, suffer significant convective losses. Noble gases have a large mass, which significantly slows down diffusion. But on the other hand, gas tends to be lost as the glass pack ages, and in a bag filled with air, you can add a desiccant and change the sealant without special tools.

The most common material from which wooden window frames are made is pine, which today is considered the most practical, inexpensive and affordable wood. A reasonable substitute for pine wood is oak wood, but for craftsmen making wooden windows for the first time in their lives, it is still better to choose less expensive tree species. Wooden beams for wooden windows must be dried in accordance with all the rules, and in addition, they must not have any branches, cracks or other damage. It is important to remember that the boxes, when they are fixed in the window opening, take on the main mechanical load. If glued laminated timber is used for the manufacture of all elements, then its strength will be sufficient to withstand deforming loads.

Tools for the job that will be needed

If, for example, a 150x50 mm board is used to make a box, then in the blanks for it you will need to make a groove 15 mm deep in the form of the letter G. For the block, you will need to make four blanks, and then connect them with glue (best of all, carpentry) , and additionally drill holes in the right places and insert a three-centimeter wooden rod, which will provide immobility and the necessary rigidity to the connection at a right angle.

The finished box is fixedly fixed in the prepared window opening. To do this, drill holes in the wall, drive in dowels and fix the finished structure with self-tapping screws. If gaps remain between the finished block and the walls, they must be sealed with building foam. It should be remembered that the installation of the box does not take into account the mobility that it can acquire during temperature changes.

The main feature of the project presented here is the window sash, which expands the glass and provides free space for the sealant and the wooden glazing beads that hold the glass.

For those who are going to make windows with their own hands from wood, the drawings presented on this page show how to make a frame for ten millimeter glazing beads that will securely hold four millimeter glass. The gap between the glasses is about 1 cm, while the metal parts that burst them are not used. It should be borne in mind that a seal for wooden windows, the width of which is equal to the width of the glass, will not be the most the best option for this design: it is better if the cross section of the seal is equal to the section of the groove.

Making a window box

The best sealant will be a material that does not suffer from exposure sun rays. Often, a silicone sealant is used for this, but it should be noted that it is not suitable for such purposes in the best way, since it is difficult to remove from the glass surface. You can make a frame from pine wood, or you can use white oak wood or other blanks. Before cutting the material for the window frame, you should carefully measure the perimeter of the window opening and increase the result by another 10%.

To assemble the binding shown here, you will need to cut the material at an angle. Joints consisting of grooves and tenons hold the structure stronger, but continuous grooves are better suited for the seal. To connect the frame parts to each other, it is best to use screws with a flat head and large threads. Screws with flat heads are best to be sunk into special holes.

Do-it-yourself window frame assembly

The glass cutting process is essentially not complicated, but it is important to take into account some of its nuances. First of all, you should take care of observing safety precautions: reliably protect your eyes and hands from possible surprises. Glass must be strong and completely intact. Before cutting, the glass is thoroughly cleaned and then lubricated with a small amount of grease.

Experienced craftsmen advise always cutting glass in one cut. When the glass is pressed, a sound is heard, after which the glass is shifted to the very edge of the working surface and pressed on. To make such a double-glazed window, as discussed here, it is necessary to make measurements with an accuracy of a millimeter.

The edges of the glass after cutting are processed for polishing with sandpaper.

First, the fitting glass is inserted into the frame, and then the sealant is removed and put in its place. The glass is put back into the frame and wooden glazing beads are installed for the windows, and then the window is painted and equipped with handles.

When attaching the glazing beads, the screws must be tightened slowly, starting from their middle. This is necessary so that too much pressure is not exerted on the fragile corners of the frame.

Based on the fact that the window should be easily repaired if necessary, the hats of the used screws should not be painted over, but many prefer that they not be visible. The ideal way to hide the screws has not yet been found, so everyone chooses what suits him best.

We install a window frame in a house from a bar

A dehumidifier must be placed between the panes. To do this, a hole is added at the top of the window sash, which is later caulked with a wooden pin. If you have a compressor on hand, you can fill the gap between the panes with dry air. The pins are painted with paint before installing the window and repeat this procedure after it.

The window referred to here does not fog up even after a year, and if the glass needs to be replaced, it will not cause too much difficulty. Such windows can be installed even in rooms with high humidity (that is, in the bathroom or in the kitchen).

The screw holes can be covered with decorative handles. When using standard screws, you can also scrape the paint out of their grooves.

For reliable sealing, experienced craftsmen insert glass, having previously applied a sealant to its joints with the structure. To make the window more resistant to weather conditions, after the sealant has dried, you can apply window putty on top of it. It is important to know that some modern putties can be difficult to remove from glass, so it is much easier to work with traditional window putties.

It is best to paint windows a few days after putty has been applied.

Wooden window options

For the manufacture of laminated window blocks, specialized technologies are used. A special film is applied to the plastic profile, which is attached to the surface with glue. The film consists of several layers with embossing on its surface, and in order to apply it to a plastic surface, it is necessary to use laminating equipment.

Lamination is necessary not only to make windows look more aesthetically pleasing: in this way they become more resistant to all kinds of atmospheric phenomena and are durable and remain extremely easy to clean. There is a film whose surface resembles natural wood. On such a decorative film, dust and dirt are practically invisible, therefore plastic windows, laminated under a tree, the photos of which can be seen below, are incredibly practical.

In addition, film-coated windows are resistant to temperature fluctuations and weather conditions. The structure covered with PVC film is not sensitive to precipitation, and the film itself retains its color even under prolonged exposure to sunlight.

Another indisputable advantage of PVC film lamination is its wide range of colors and textures, among which there is a suitable option for any occasion.

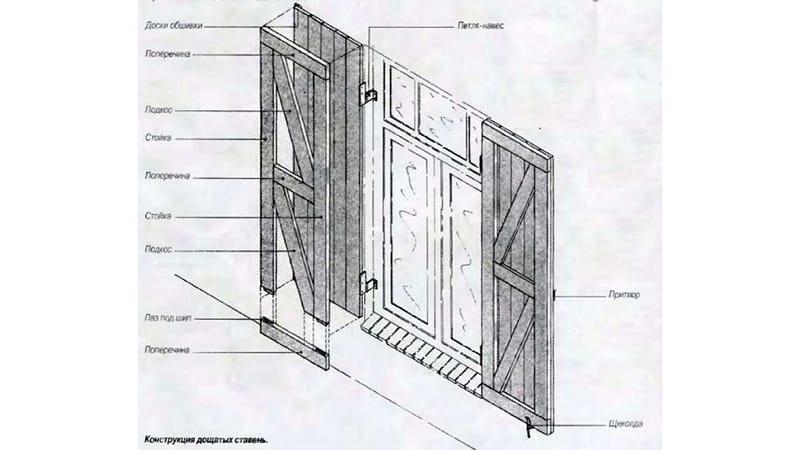

After installing the shutters, the room becomes additionally protected from the cold and atmospheric phenomena. Wooden shutters on windows, photos of which can be seen at the end of the page, are made external or internal, and in structure - one- or two-sided, panel or panel. Anyone can make such shutters on their own.

Window shutter designs

To make wooden window shutters, you will need boards 100-200 mm wide and more than 20 mm thick. Hardwood veneer boards are considered the most suitable, but a smooth fugue is also quite suitable.

In addition, you will need to take care of the availability of tools for woodworking: hacksaws, drills, screwdrivers, planers, chisels, etc. You will also need measuring tools: a level, a tape measure and a carpenter's corner. For the final stage of work, you need to purchase drying oil, brushes and paint, as well as an antiseptic.

Window shutter assembly

How to make ordinary shutters from boards