Tsar Fedor ascended the throne in full accordance with the tradition of succession to the throne and ...

The durability and appearance of a metal tile roof depends primarily on what kind of coating it is covered with. Types of metal tile coatings are different, and they differ not only in strength and service life, but also in color fastness.

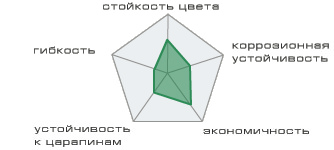

The basis of this coating is polyester. The material has long been used in the production of metal tiles, has a glossy appearance and is characterized by plasticity and high color stability.

Metal roofing polyester shiny, smooth, relatively inexpensive. It is highly resistant to corrosion and UV rays, that is, it will not fade for a long time under the sun. However, in thin layers (up to 30 microns), it is damaged by light mechanical stress, for example, when snow layers leave the roof. Do not use polyester where weather conditions are unfavorable.

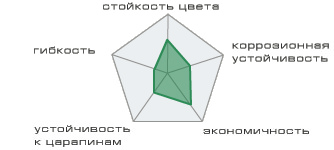

Among types of metal roofing matte polyester looks the most attractive. It is a polyester with Teflon added to give it a matte finish. In addition to resistance to UV rays, it also has increased resistance to mechanical damage due to the increased coating thickness (35 microns). Even in difficult weather conditions, it will last a long time.

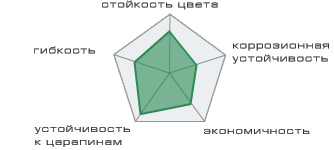

Pural coated metal tile It is based on polyurethane, the molecules of which are modified with polyamide. The thickness of the coating is 50 microns, which gives it additional mechanical stability. Ultraviolet light and even chemically aggressive substances, such as acids that precipitate in areas with polluted air, do not change the properties pural coated metal tiles. She serves long time without color change and mechanical resistance in all conditions.

The surface of such a metal tile is silky to the touch and matte in appearance. Due to the properties of the pural, the roof with such a coating is easy to handle and install. Temperatures at which it retains its properties - from minus 150 to plus 1200 degrees Celsius.

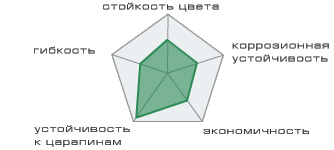

Plastisol 200 - metal roofing from polymer 200 microns thick. Differs in volumetric embossing, imitating leather or tree bark. It was developed specifically for difficult climatic conditions, including industrial areas with a high level of environmental pollution.

Plastisol 100 has half the thickness and is used mainly indoors. It is also produced with a coating on both sides and is used for the manufacture of weirs.

Of all kinds metal roofing this is the most suitable for the design of facades. It consists of a mixture of polyvinyl fluoride and acrylic in a ratio of 4:1. Contains high quality pigments for high gloss and long lasting UV resistant color.

The polymer is quite hard, has hydrophobic properties, which allows it to “repel” dirt, while being quite plastic. It can be either matte or glossy. Metal roofing can be shiny like metal. To do this, it is varnished on top with the addition of a special dye. Resistant to weathering and corrosion.

Coated metal tiles - pural, polyester, plastisol, etc. Characteristics and manufacturers, current prices for polymer coatings of metal tiles.

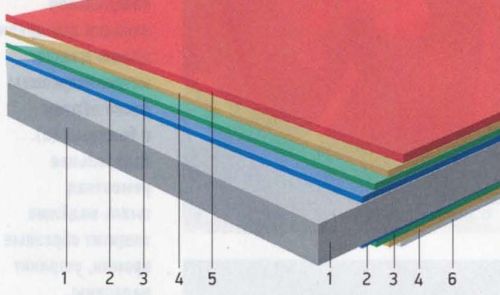

In the production of corrugated board and metal tiles, steel sheet with a protective polymer coating. Coatings vary in thickness and characteristics and significantly affect the price of the finished material.

Sheet structure:

A properly applied coating will protect a sheet of metal from rust for decades. At the same time, the bright color of the roof will be preserved.

Polyester is the most inexpensive option for polymer-coated metal tiles. This protective coating is made on the basis of polyester.

The main advantage of polyester metal tile is that it perfectly withstands adverse climatic influences - temperature extremes, rains, hail, heating up to +90 and frosts down to -60 ° C. Suitable for all climate zones. Color fastness is good.

The thickness of the polyester layer is 25 - 27 microns. Therefore, it is not as resistant to mechanical damage as plastisol. It requires careful handling during installation and delivery. Coated with polyester, both Finnish metal tiles, and Swedish, and Russian ones are produced.

Matte polyester

Matte polyester - a coating based on polyester enamel with the addition of metal particles. Thickness of a layer of opaque polyester on a metal tile - 35 microns. This coating has all the advantages of ordinary polyester, but the matte metal tile looks nobler on the roof and does not shine in the sun.

In addition, the resistance to mechanical damage of matte polyester is slightly higher than that of ordinary polyester due to its greater thickness (35 microns instead of 25-27 microns) and a more durable surface layer.

With a matte polyester coating, we offer metal tiles from Sweden Mera System.

Prelaq Nova is a modern protective coating. Produced by a large Swedish concern SSAB. Thickness 50 microns.

The properties are similar to polyurethane-coated metal tiles - it also tolerates climate influences and not very careful handling during installation. But the Nova coating does not contain polyurethane.

Top Coat 50, P50 and HBP (High Build Poliester) are the old names for Prelaq Nova metal roofing.

Metal tile Prisma (Prism)

The protective and decorative coating Colorcoat Prizma ® was created by the Anglo-Dutch metallurgical concern Corus. Coating thickness 50 µm. Corrosion resistance is 2 times higher than that of polyester.

Prism metal tile is one of the most interesting roofing options. Several original colors with a metallic effect make it unique.

Pural (Pural™)

Pural ®* is a polymer coating based on polyamide-modified polyurethane. The coating is designed and manufactured by Rautaruukki.

Metal tile Pural (Pural ®) has a silky-matte surface with a slight sheen.

Its resistance to “weather impacts” is better than that of polyester metal tiles. The coating withstands heating up to +100°C and cooling down to -60°C. Resistance to mechanical damage is higher due to the greater thickness compared to polyester - 50 microns.

Matte Pural (Pural Matt ™)

It is also a product of the Rautaruukki concern. The main characteristics are similar to Pural ® metal tiles.

Only the appearance differs - such a roof does not shine at all in the sun. Outwardly, its surface is similar to ceramic tiles, and to the touch it resembles Teflon.

Plastisol

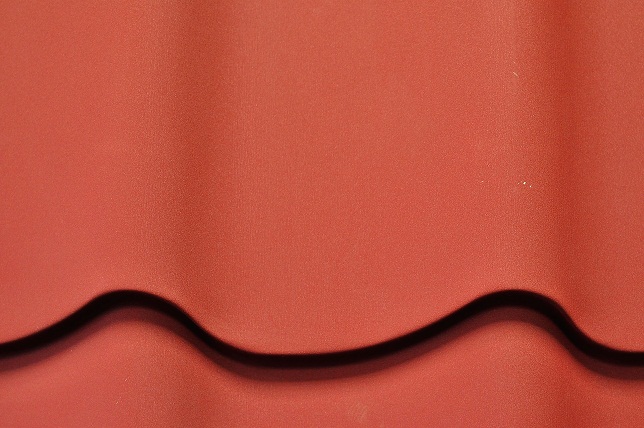

Plastisol is the thickest coating with a thickness of 200 microns. It resists scratches better than any other. It consists of polyvinyl chloride (base) and plasticizers. Outwardly, it is distinguished by a pattern on the surface - strokes, dotted recesses, "shagreen leather".

Resistance of a metal tile plastisol to corrosion high. In the conditions of a modern city with its polluted aggressive atmosphere - a very valuable quality.

But in terms of resistance to ultraviolet radiation and elevated temperature plastisol is inferior to other coatings. Heating above 60 ° C is undesirable for him. Such a roof cannot be installed in the southern regions. Plastisol metal tile, price:

HPS 200 is a coating similar to plastisol metal tiles. Produced by the Anglo-Dutch metallurgical concern Corus. The resistance of HPS 200 to corrosion is higher due to the presence of zinc alloy (95%) and aluminum (5%) on the surface of the steel.

This is a new development of the Arcelor Mittal concern. Thanks to a special technology, Cloudy metal tiles have a matte smoky surface - as if it were natural fired clay tiles.

Any other coating is one-color. Moreover, the appearance of the Cloudy metal tile coating is such that from a distance of about 2 meters it is difficult to distinguish it from natural clay! By the way, translated from English Cloudy means "cloudy".

The thickness of such a cloud cover is 35 microns. According to the characteristics, it approximately corresponds to the purala.

Metal tile Printech

Printech Terracotta Burn metal tiles are produced from DONGBU STEEL metal, a South Korean steel manufacturer, one of the largest in the world.

When choosing metal tiles you are faced with a large variety of it, so the logical question is what to choose. This text is dedicated various types polymer coatings and manufacturers of metal tiles.

Today, the most popular in Moscow and the region are polymer coatings such as: Pural, Armarcor, Granite, Prism(based on polyurethane PU). You can also find the PUR coating of the Swedish concern SSAB. However, its comparison with these species is not very correct, because. PUR is a two-layer polyester with a minimum installation temperature of -10° C versus -15° C for polyurethane coatings. The latter are more UV resistant. The stable thickness for PU is 50 µm, for PUR it is from 42 to 48 µm.

First on our list, we will consider Pural. This polyurethane coating is optimal for different types roofing materials. Pural is well processed and mounted from profiled sheets. This material has a slightly structured surface with high resistance to the mechanical effects of snow and ice, as well as to ultraviolet sunlight. It is also easy to paint in repairs and is resistant to chemicals.

Pural was developed by the Finnish concern Rautaruukki in 1999, and in Russia the first metal tile with pural was presented by Rannila. This tile has received great popularity from private developers in the construction of cottages. This is easily explained by its quality and durability. In this case, the price plays a role in the second place.

Rannila STEEL OY (Rannila) is part of the Ruukki metallurgical concern (until 2004 - Rautaruukki) and has been called by the same name since 2005. Today, the products of Corus (England) and Arcelor (Germany, Belgium, Great Britain) are gaining more and more popularity. Polyurethane-coated metal tiles from Corus are called Prism and Armarcor, and from Arcelor - Granite. The characteristics of these coatings are completely similar to the properties of the Finnish pural. All these types of coatings are guaranteed for 15 years.

Now let's turn our attention to plastisol- polymer coating based on PVC(PVC plastisols). Typically, such materials are in the form of a liquid or pasty mass and are stable. But if it is heated, then plastisol quickly turns into a monolithic plastic compound, as they say, “gelatinizes”. This coating has excellent physical and mechanical properties, high electrical resistance and chemical resistance.

Metal for metal tiles is produced by different manufacturers. For example, Corus has dot-embossed plastisol, it is marked as HPS200 (RAL color). Finnish Ruukki plastisol is embossed with strokes, marked as PVC200 (color according to RR standard). The German company EKO Stahl has released a leather embossed plastisol, marked as PVC200 (color standard P).

The main advantage of plastisol is its thickness (200 microns). This is a serious protection against mechanical influences. For this reason, plastisol is popular with builders - the risk of scratching or damaging this coating during installation is minimal compared to other metal tiles. For at least 5 years, a roof with such a coating will not bother the developer. This is important, given that most construction organizations give a guarantee of 2-3 years, after which their responsibility both formally and actually ends.

Surely you have seen how asphalt or black rubber heats up in the summer in the sun. The metal tile, and, accordingly, the coating itself can also heat up on hot days, the temperature sometimes reaches + 100 ° C. This is especially true for dark-colored tiles. The average operating temperature of plastisol is +60-80° C. Already at this temperature, the coating begins to soften. As a result, the strength of the connection with the metal is lost, which can lead to moisture getting under the coating, as a result of which a water bubble forms under the film. The consequences of this are the irreversible delamination of PVC from the metal. It is important to keep in mind that metal tiles with such a coating are processed at +10 ° C. Also, this type of coating is not sufficiently resistant to ultraviolet rays, which may cause uneven burnout of the roof. In terms of cost, plastisol is in the same price segment as the coatings mentioned above. Not all manufacturers provide a guarantee for plastisol, for example, the Ruukki concern does not give it at all.

The next material is matte polyester– polyester coating 35 microns thick. This is a type of regular polyester that has been modified with Teflon. The main advantage of a metal tile with this coating is its matte surface. It is known that manufacturers of artificial roofing strive to imitate natural ceramic tiles as accurately as possible. It is a metal tile with matte polyester that is best suited for this purpose. This coating has a thickness of 35 microns, which is enough for resistance to weak mechanical stress. In addition, matte polyester can be produced in the unique CLOUDY color (manufactured by the ArcelorMittal concern). In the city of Lobnya there is a plant where metal tiles are produced from this metal. The matte surface of the metal tile does not glare and looks like an aged natural tile. This type of roofing is very popular among our customers today.

Lastly, we will consider the coverage polyester- a high-molecular compound, which is obtained as a result of the interaction of polybasic acids or their aldehydes with polyhydric alcohols.

Today, polyester-coated metal tiles are one of the best-selling roofing materials. This is easily explained by its lowest price - only 220 rubles/m. That is why it is so common in budget development - in office buildings, cottages, small country houses. The polyester coating is only 25 microns thick. This does not provide sufficient resistance to mechanical stress, but with a limited budget, this is not the most significant factor. The main thing is that there is a roof.

Polyester-coated metal tiles are made both abroad and in Russia. The main among domestic metal suppliers is Novolipetsk Iron and Steel Works. In addition, metal is imported into our country from Europe and Asia. If the metal tile was made of imported metal, it is guaranteed for 10 years. Russian-made metal tiles do not have such a guarantee.

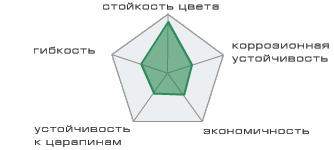

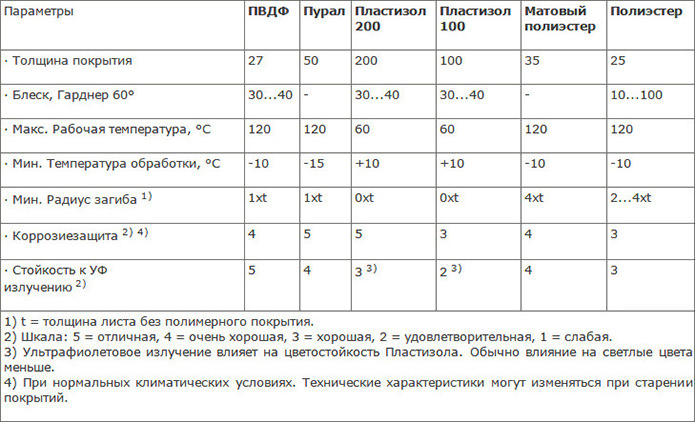

The table shows all the data on the main coatings that will be used in Russia.

Comparative characteristics of coatings

Technical

|

Polyester |

Matte

|

Plastisol |

Pural |

|

Surface |

embossing |

|||

|

Coating thickness, µm |

||||

|

Primer layer thickness, µm |

||||

|

Protective varnish thickness |

||||

|

Maximum temperature |

||||

|

Minimum temperature |

||||

|

Minimum bend radius |

||||

|

Color fastness |

||||

|

resistance to mechanical |

||||

|

Corrosion resistance |

||||

|

weather resistance |

I am sure that the information in this article will help you choose the right roofing. Our specialists will be happy to answer any of your questions.

|

Technical |

Polyester |

Matte |

Plastisol |

Pural |

|

Surface |

smooth |

matte |

embossing |

smooth |

|

Coating thickness, µm |

||||

|

Primer layer thickness, µm |

||||

|

Protective varnish thickness |

12-15 |

12-15 |

12-15 |

12-15 |

|

Maximum temperature |

60-80 |

|||

|

Minimum temperature |

||||

|

Minimum bend radius |

||||

|

Color fastness |

* * * * |

* * * |

* * * |

* * * * |

|

resistance to mechanical |

* * * |

* * * |

* * * * * |

* * * * |

|

Corrosion resistance |

* * * |

* * * * |

* * * * * |

* * * * * |

|

weather resistance |

* * * |

* * * * |

* * * * |

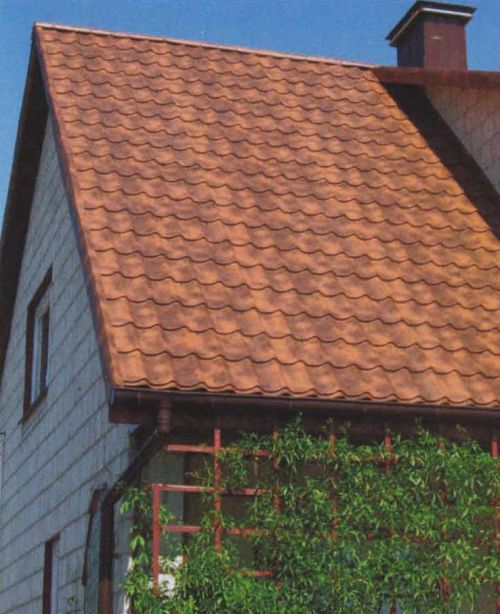

A metal tile is a very reasonable choice for the roof of a country dwelling. It is lightweight, strong and durable material. It is easy to install, has a reasonable price. Thanks to a wide color palette and a large assortment of patterns, metal tiles become a real decoration of the house. Metal roofing is one of the most popular roofing materials today. Since its appearance on the domestic market, its sales have been steadily increasing. Even the recent crisis has only moderated this growth somewhat.

Metal tiles are used on pitched roofs of private and public buildings with a slope of at least 11-12°. But in order for such a roof to reliably protect your house from cold and bad weather for a long time, it is important to choose the right material, invite skilled installers, and then correctly operate the “fifth facade”.

Sheets of metal tiles are made from rolled steel with a thickness of 0.40 - 0.55 mm. During the production process, it is coated with zinc or a zinc-aluminum alloy, passivated, a layer of primer is applied, then a polymer coating is applied to the front side, and a protective varnish is applied to the back. (The quality of the material must comply with GOST R 521 46-2003 "Thin-sheet cold-rolled and cold-rolled hot-dip galvanized steel with a polymer coating from continuous lines.") ) is obtained by stamping. As a result, the surface of the polymer-coated metal really becomes similar to the relief of a clay tile roof.

Now let's talk about what you should pay attention to when choosing a metal tile. One of the most important parameters is the thickness of the steel sheet. It is responsible for the load-bearing characteristics of the roofing: strength, rigidity, and, consequently, the ability to retain shape. The thinnest (0.4 mm) profiled sheet outwardly looks the same as its thicker "brothers", but in places of bending the thickness of the steel may be less than the original due to deformation, which will definitely manifest itself during the installation and maintenance of the roof. The probability of deformation or damage to metal tiles made of thin steel when moving along it is much higher than sheets with a thicker base, besides, the latter will last longer. However, the price at high rates will also not be low.

Experts believe that the optimal thickness of the steel base is 0.5 mm. To ensure the desired strength, it must be the same over the entire area of \u200b\u200bthe sheet. However, rolled steel is produced by different companies in various countries, and it differs markedly in quality - for example, galvanization. The more zinc per 1 m² contains a protective layer of steel sheet, the more resistant it is to corrosion. According to European standards, there are four classes of galvanizing.

The first includes rolled steel, which contains 275 g / m² of zinc on each side, the second - 200 g / m², the third - 140 g / m², the fourth - 100 g / m². In Europe, where the climate is milder than in Russia, materials with a galvanizing class below the first are not used for residential buildings. After all, zinc performs the function of cathodic protection: gradually collapsing under the influence of moisture, it saves the steel base.

It is quite difficult for an ordinary buyer to determine the quality of galvanized steel. Sometimes this circumstance is used by unscrupulous construction teams, using low-quality, but cheap products and hoping that in a few years after the completion of construction, there will simply be no one to file a claim with.

Quality assurance roofing material the well-known name of the manufacturer and the long experience of its work in the roofing market can serve. Such products, as a rule, are more expensive, but it is unprofitable for serious companies to produce low-quality products. They are focused on long-term work and development, so they value their reputation.

Specialist comment:

Due to the natural process of expansion and contraction of the metal, with temperature changes, the fasteners of the metal tile loosen. With a sheet length of less than 4 m, the coefficient of linear expansion can be neglected, but if it is more than 4 m, this loosening will be more noticeable, especially on the extreme self-tapping screws. Therefore, we do not recommend using custom-made metal tiles longer than 4 m. If the length of the roof slope is 6 or 8 m, it is better to cover it with not one, but several sheets.

The edge sheet is mounted so that it protrudes 40 mm from the cornice, and space is left on the ridge for ventilation. Managers of sales offices will calculate the amount of material, select the optimal length of sheets and offer a scheme for their laying. Of course, the reliability of fastening the roof depends on many factors: the quality of the screws, the correct adjustment of the torque of the screwdriver, the quality of the lathing (the tree must be dry, without signs of decay). But whatever the length of the sheets of metal tiles, a year after installation, we advise you to check the self-tapping screws and, if necessary, tighten them.

In this section, we will turn your attention to the polymer coating of metal tiles. The idea of applying them to galvanized steel sheets was not born by chance. They perform not only a decorative, but also a protective function. The fact is that polymers are resistant to ultraviolet radiation and mechanical damage, and also have good corrosion resistance. All these properties will help to resist climatic and mechanical influences on the roof. On our market, you can find metal tiles coated with ordinary and modernized polyester, polyurethane, polyvinyl chloride (plastisol).

Polyester- the most common and most budgetary of them. It has good resistance to corrosion and UV rays, is ductile, but has an average resistance to mechanical damage. The layer thickness is usually 25 - 30 microns. The surface of the sheet looks even and even slightly glossy. Some time ago, opponents of "gloss" could opt for matte polyester with a slightly rough and more durable outer layer than regular polyester. But today it is practically not used. It was replaced by a modernized polyester (35 microns), which has the best characteristics in this group. Its pronounced matte texture looks very attractive.

Polyurethane coating has a thickness of 50 microns, has the most attractive characteristics for consumers. It is created from polyurethane modified with polyamide and acrylic, resulting in a silky-matte surface. Polyamide granules give the coating texture, and acrylic provides high strength. The coating easily tolerates weather disasters, it is indifferent to sudden changes in humidity and temperature, is not afraid of ultraviolet and chemical aggression, scratches. Sheets with polyurethane coating are easy to process, cut and do not give microcracks on the bends when low temperatures. At the same time, they absolutely do not lose their external characteristics - the brightness of the color or the integrity of the coating. The polyurethane coating easily tolerates exposure to ultraviolet radiation, significant daily temperature fluctuations, as well as staying in the aggressive environment of coastal areas with a high salt content in the air. A metal tile with a polyurethane coating has the longest warranty period (15 years) and a service life (40-50 years), but therefore it costs 20-50% more.

Prism, Colorcoat Prisma– thick-layer material (layer thickness of about 50 microns) using polyurethane, an excellent combination of modern design and reliability. The optimally selected composition of the Galvalloy layer (95% zinc and 5% aluminium) in combination with a highly effective polymer coating provides reliable anticorrosion protection of steel.

Polyvinyl chloride (PVC) cover- it is also called plastisol - it is applied in a thicker layer (100 - 200 microns). It reliably protects the steel base from scratches and other mechanical influences, even with unskilled installation. At the same time, it is less resistant to sunlight, under which it heats up, becomes soft and deforms. Some manufacturers use modified plastisol, the properties of which are significantly improved with the help of various stabilizing additives. But if in the middle lane a metal tile covered with polyvinyl chloride will serve faithfully, then for areas with high solar activity this is not the best the best choice. Other manufacturers use PVC coating only in the manufacture of finishing elements and gutter systems, where protection against mechanical damage is most relevant, and the effect of the sun is not as strong as on the roof plane. After all, drainage systems are often located in the shadow of the facade of the building, and the area that Sun rays, is small.

Polyvinyl fluoride (PVDF)- coating 27 microns thick, consisting of polyvinyl fluoride and acrylic. Has a glossy surface, can be metallic colors. PVDF is self-washing, but does not have high resistance to mechanical damage. This material is particularly resistant to ultraviolet radiation, it practically does not fade.

Decorative polymer coating (DPP) of metal- these are coatings with all kinds of patterns: subwood, brick, natural stone, natural materials, tiles and many others, which allows you to give finished products a unique appearance. The pattern is applied to a galvanized/aluminum-galvanized steel sheet using an offset method. It has excellent wear resistance, longer preservation of color and gloss of the coating, increased resistance to weather conditions and mechanical damage (scratches).

Plastisol has a thickness of 200 microns. This coating is based on modified polyvinyl chloride, which has an attractive appearance and provides reliable and durable protection of the roofing in all weather conditions. It is more resistant to mechanical damage, to the "aggression" of nature, but is destroyed under the influence of high temperature.

In the assortment of large manufacturers of metal tiles there are materials with different polymer coatings. However, be careful: unscrupulous companies can resort to various tricks to reduce the cost of the final product. For example, manufacturers reduce the amount of zinc in the protective coating or reduce the thickness of the polymer layer, which naturally leads to poor quality. Unfortunately, the buyer is not able to detect this.

Often sellers give out one coating for another or exaggerate the thickness of the layer. The "indicator" is the warranty on the polymer coating or on the material given by the manufacturer, not the seller. Moreover, the guarantee should not be oral, but written - in the form of a special coupon, which lists all the defects to which it applies, its conditions, as well as the rules for transportation, unloading, storage and installation that are not subject to violation.

Note that a written guarantee is not widespread everywhere - it is given only by large manufacturers of metal tiles. The leading positions in the Russian market are occupied by metal tiles from the companies Interprofil, Metal Profile, Odintsovo Lightweight Construction Plant, Unikma, Grand Line (all - Russia), Pelti Ja Rauta, Poimukate, Ruukki, Weckman (all - Finland) , Mera System (Sweden).

Specialist comment:

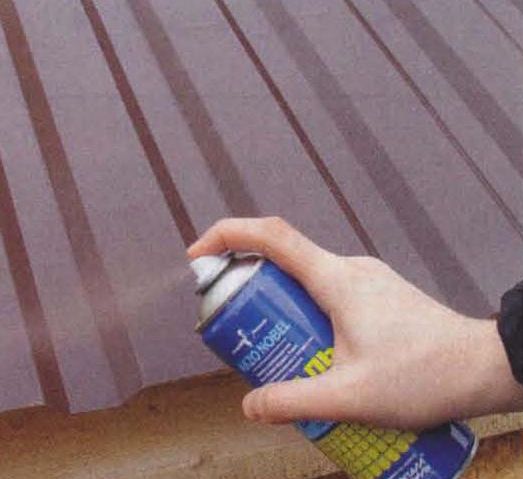

Metal tiles and elements (transactions should never be cut with an angle grinder (grinder) with abrasive discs. At the cutting point, the disc and metal heat up, which leads to the burning of zinc and the polymer coating. In addition, sparks fly, which, falling on the protective layer of the polymer All these places will soon become centers of corrosion formation.A professional installation team should have a special tool: non-abrasive saws, electric cutting shears or ordinary metal cutting shears, etc. Places of cuts, chips and damage to the protective layer must be treated with a special repair enamel for polymers.

Sheets of metal tiles in one or more sizes (the most common - 2200 x 1180 mm) and colors offer many construction markets and shops. These are the so-called stock lists. The same sales organizations and numerous specialized companies provide such a service as custom-made material (sheet sizes will be calculated for a specific roof project). In this case, their length can be any in the range from 400 to 8000 mm, and the width, as a rule, is 1180 mm (working width - 1100 mm). The waiting period is about 3 days, although at the height of the construction season, when enterprises operate at their capacity, this period increases.

Which do you prefer: stock sheets or custom-made? It depends on many circumstances. For example, on roofs of complex configurations, full of breaks and protrusions, there will be a lot of waste when working with warehouse sheets, and custom execution will minimize their amount. If you are running out of time, you should use the warehouse program, since the production of custom-made sheets will take some time. Small gable roofs are easier to cover with whole sheets, the length of which corresponds to the length of the slope. If this parameter is more than 6 m, it may be difficult to transport and install the material, for example, climbing to the roof. In a word, in each specific situation, you will have to look for a middle ground.

Ideally, professional roofers with experience in working with metal tiles should help with the choice. A prerequisite for the provision of guarantees by the manufacturer is compliance with the rules of transportation, storage, loading and installation. In production, finished sheets are packaged before transportation in accordance with the standards. They are stacked one on top of the other, using a special lubricant so that they do not stick together, rub or scratch each other. Then they are placed in a special pallet made of wooden beams, covered with the same one on top, tightened with straps and transported. Packaging with metal tiles must be attached to the body. It often happens that the car moves off the hill and loose cargo falls out of its body.

It is useful to control the process of manual unloading at the facility. The fact is that metal sheets should be carried only in an upright position. If you hold a sheet 6 m long by two edges, like a blanket, it will bend and deform. At the facility, packs with metal tiles are laid out of the blue on the beams. If it is expected that they will be stored for more than 1 month, the sheets are unpacked and stacked on top of each other, always laying with the same wooden slats to ensure ventilation.

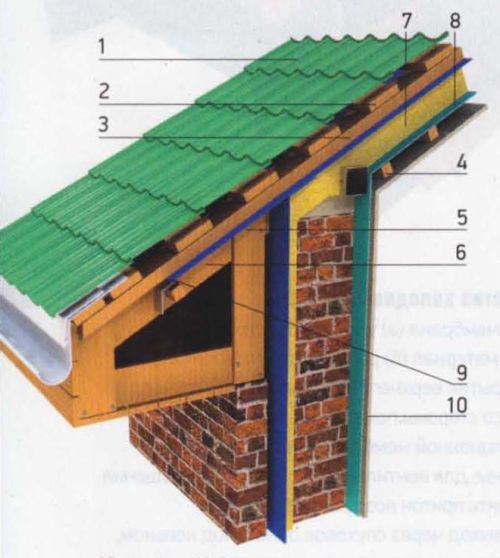

The metal tile is only part of the roofing system, which should keep the heat in the rooms in the winter, and in the summer to prevent the heat from the hot roof from entering the house. This kind of "pie" Protects the insulating material from the penetration of vapors generated during human life, and also passes those that have already leaked into it through the thickness of the insulation and, importantly, takes it out into the street.

At the same time, the daily temperature difference even in summer leads to the formation of condensate on the inner surface of the sheets. Moisture or water drops can cause timber roof structures to rot, and dampened thermal insulation materials are known to lose their properties.

Therefore, it is not so important which room is under the roof - residential or cold attic; in any case, during its installation, special attention should be paid to the under-roof ventilation and waterproofing. Waterproofing membranes laid under the metal tile (under the crate) will not allow moisture to penetrate further into the under-roof space. And vapor barriers, laid under a layer of thermal insulation, will protect it and the roof from fumes coming from residential premises. The Russian market offers many different manufacturers, including Jutafol (Juta, Czech Republic), Eurotop (international concern Fakro), etc.

![]()

This is a complex structure, consisting of a large number of layers. Each of them performs a specific function. But only in aggregate, and also with right choice materials, calculation and installation, they will work reliably and for a long time. Therefore, when installing a roof, it is extremely important to strictly follow the instructions of the manufacturers.