From internal pipelines, drains are transported by external ...

If you have come across this article, then such a problem as the soundproofing of an apartment has come up against you. There may be several reasons why you wanted to soundproof from the outside world: noisy neighbors (you got it), you yourself are noisy neighbors and don’t want to disturb others (less common option), street noise, etc.

In any case, the reason for your concern is the noise. How to get rid of it? Quite a difficult question. Sound insulation of an apartment should be undertaken only by carefully studying all stages of work and the necessary materials. There are nuances, and the main thing is not to miss them, in order to get the result of such an option in which neither you nor the neighbors jumped periodically with a cry: "Give rest !!!"

So, how to make noise insulation in the apartment with your own hands? Let's go in order ...

First, decide which room and what exactly are you going to isolate in it? If neighbors from below prevent you from living, for example, it will be natural to make the floor soundproofed. And if you are going to install a home theater in your living room and have fun in the evenings, watching football at full volume with your friends, then the floor is not enough: shock :. In our case, we will analyze the complete soundproofing of the apartment with our own hands ...

Let's start with the walls. First of all, you need to understand that any noise just does not penetrate your apartment and does not leave it. So you need to carefully check your walls for cracks, holes and other imperfections that contribute to the penetration of any sound.

For example, when I myself went to bed in the evening with my beloved wife, I periodically had to listen to how the neighbors were engaged in the performance of marital duty. This continued until a flash of inspiration from above prompted me to look at the condition of the outlet, which is located just above the head of the bed. Having put the socket in a new box and on the gang, I got rid of the noise from the neighbors and from the fear that they, in turn, could "enjoy" the sounds of love from our bedroom

So, carefully close up all the cracks, joints between the ceiling plates, walls, and the floor with a rotband. If you want, you can. The process is time consuming, but the result is worth it.

In today's market, there are many offers of soundproofing walls. For starters, the budget option ... I already wrote about that,. The technology is the same, only there are a couple of nuances that you can’t do without if you want everything to be cheeks;), that is, wisely.

To begin with, the frame for drywall should in no case be attached to the wall, due to which there is noise. That is, the use of special suspensions is unacceptable. Why? The fact is that structural noise (if it comes from behind the wall) will be transmitted through these mounts.

How and why to fix the frame? It is a reasonable question. We attach the profile for drywall to the ceiling and to the floor. Necessarily through rubber gaskets, which again prevent the spread of structural noise. Gaskets can be made by yourself, or, for example, purchase VIBROSTEK-M - special soundproof gaskets. Between the profiles and the side walls it is necessary to leave a small gap of 4-5 mm, which is then filled with silicone sealant. It all looks approximately like in the photo below.

Further, one more nuance ... Naturally, for sound insulation it is necessary to fill the frame of profiles with mineral wool (ROCKWOOL, ISOVER). To prevent the drum effect, use cotton to the maximum. Clog all cracks so that there are no voids left.

You can also fill out a profile before starting work polyurethane foam, which will increase their strength and reduce sonority. Then it remains to sew up our frame with drywall. It is possible in two layers with the displacement of each layer relative to each other. You can use a layer of KGL and GVL (improves sound insulation due to different density of materials).

You can find recommendations and prices for materials and installation on the official website of the ACOUSTIC GROUP company. By the way, the option is not cheap. The price for 1 square meter is approximately 1200 wooden. Many positive reviews about this soundproofing system ...

Another option for soundproofing walls is the use of ecowool (cellulose insulation). By and large, I can’t say anything concrete about this technology. Let's just say this: it’s rather an insulation of the apartment, but also how sound insulation is quite suitable. At least that's what manufacturers say. Prices are not cheap either: 1300-1700 rubles per cubic meter.

Let's move on to the ceiling. The article “How to do it yourself” gathered a lot of comments and reviews. On its basis, we make soundproofing of the ceiling. Only again, categorically, the use of suspensions for mounting rails is not recommended. What to do in this case?

There are two options: either use special anti-vibration ceiling suspensions, again from the “ACOUSTIC GROUP” or “Vibrofix“.

So, let's go ... The idea is that the frame consists of load-bearing wooden beams, to which the profiles are attached with a certain step. And then a layer of drywall sheets. That is, there is simply no hard mount to the ceiling.

Let's go in order. To begin with, it is necessary on both sides of the room to tightly attach corners with shelves of 75-100 mm to the walls at a distance of about 110 mm from the ceiling. Next, we take wooden bars 100x100 mm and with a step of 1.20 m we put them on the corners, after laying rubber anti-vibration pads (for example, a medical tourniquet in several layers). This is the foundation of our framework.

Then, 60x27 mm ceiling profiles are attached perpendicularly to these beams with a pitch of 40 cm. The fastening should not be rigid, since with moisture fluctuations the wood changes its dimensions and there is a risk of deformation of the GKL ceiling itself. How to make a non-rigid mount? We take two adjustable ceiling suspensions, we fasten them on both sides of the beam ...

Next, the profile is attached with a string from the same suspension, which bends around the beam with the letter P and is inserted at both ends into two suspensions located on the sides of the beam. What the gimbal itself looks like in the photo on the left. Voila .. it turns out not a rigid and adjustable mount.

Now all that remains is to fill up all the cavities inside the structure with mineral wool to the maximum and fix the GCR sheets (it is possible in 2 layers for greater sound insulation).

Such a design will eat 20 centimeters from the ceiling.

In pursuit .. If there is any doubt about calculating the distance between the bars and their thickness (I do not want the ceiling to sag over time), then you can use the Romanov calculator to calculate wooden beams.

First of all, I note that for soundproofing the floor, soundproofing of the walls and ceiling is also necessary. Otherwise, you will not completely get rid of the noise.

So, for soundproofing the floor, we need the so-called "floating" screed. It is called floating because it kind of floats on a layer, which is just a soundproof layer.

As such a layer, dense materials are used such as mineral basalt wool intended for floors (for example, Rockwool FLOR BATTS, Schumanet-100Super, etc.).

Technology in a nutshell ... We clean our floor, close the deep pits with a mixture. At the edges of the wall, it is necessary to lay (glue with liquid nails) vibration-insulating gaskets a little more than the height of the screed (then the excess can be cut off).

Next, you need to set up beacons. We take the laser level and take measurements. Lighthouses can be made from simple wood screws. We screw them into the floor and set them on the level. We put the noise insulation material tightly to each other (piercing through the beacons through).

In our case, we make a dry cement-sand screed. Proportions 1: 3. The solution should NOT be wet, i.e. when squeezing by hand, water should not be released from it. We fill the base by about 2 cm, put a reinforcing mesh and another 2 cm of solution evenly on top. It remains only with the help of a rule and a level to align our mixture with lighthouses. At the end, remove the beacons and overwrite the surface with a grater. All!

The technology is described briefly ... There will be a separate article about the coupler soon.

Summing up, we can say that there are many myths and rumors about sound insulation in the apartment, sometimes not supported by either practical or theoretical experience. To properly make the apartment soundproofed with your own hands, you need to carefully study the issue, consult with specialists, and, after praying, proceed.

When you start repairing your apartment, you naturally think about how everything will look in the end and you don’t care about anything else. Eyes burn, smoke comes out of the nostrils: hurry to start. At this stage, it is often forgotten that the quality of the repair of your apartment depends on observing many subtleties that the eye just doesn’t [...]

At the beginning of the repair of their apartment, many are faced with a completely understandable problem. Throwing begins: what to do, what to grab and what sequence of actions is needed when repairing an apartment? I hasten to reassure you: all these issues were resolved long before you. Let's try to consider all the successive stages of apartment renovation, the use of which saves a significant amount of time and effort. Before [...]

Not sure where to start apartment renovation? In this matter, it is first necessary to turn to the opinion of repair professionals. Where to start, where to start ???)) That's a big problem. Well, for someone this is really a problem. We will proceed from the fact that you are not going to hire newcomers and repair specialists in this matter, but want [...]

Was this article helpful to you? Subscribe to site updates to receive the latest articles on repair and interior design before anyone else!

Sound insulation problems are more perplexing for residents of apartment buildings. Some of the neighbors are playing a musical instrument, someone is in the midst of repairs, the clatter of small legs is heard from the ceiling - “and such rubbish - all day”, and sometimes you really want to relax in complete silence. And it happens, and vice versa, you want a noisy party, but there is no desire to spoil relations with neighbors.

As a rule, new houses do not differ in good sound insulation: voids in the walls, openings of sockets and switches, heating inputs and water pipes, as well as the structural elements themselves perfectly convey any sounds. Therefore, sound insulation in an apartment is the work of the residents themselves.

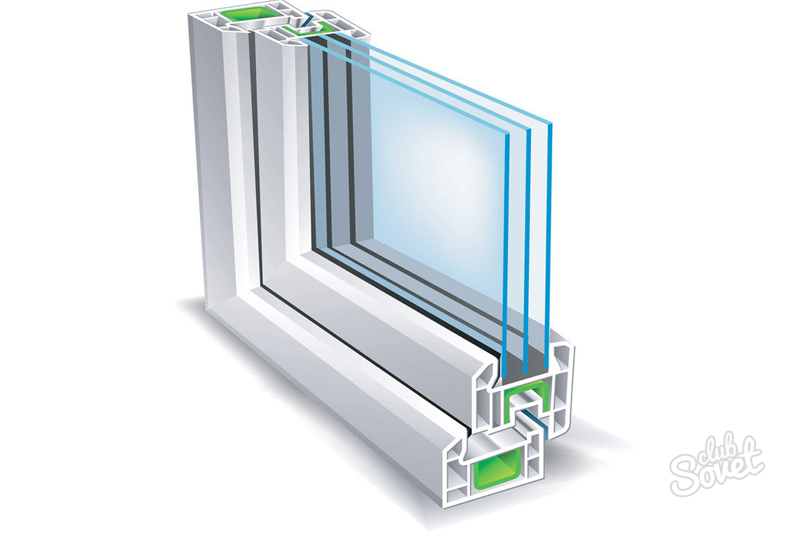

The main conductor of extraneous noise in any room is the walls and partitions. Walls bordering the street do not need to be further insulated. From the noise penetrating from the outside, you can get rid of just by installing double-glazed windows on the windows. If this is not possible, then you can replace the glass with thicker ones or provide a more tight connection with the frame. To do this, it is enough to walk around the glass perimeter with silicone sealant.

But the internal walls and partitions do not differ in particular thickness and perfectly transmit sound vibrations of any frequency from the next room. The easiest way to reduce the penetration of noise into the room through the walls is the sound insulation of sockets, installation boxes and joints, which we will talk about below.

For sound insulation of very thin walls and partitions, it is better to use a multilayer structure, characterized by the alternation of layers of different densities. This method has a high cost and gives a good result only when using high-quality materials. The most effective for this purpose are fiberglass, basalt, spatula or silica fiber, as well as ready-made sandwich panels. Soft layers are lined with drywall panels.

Having decided on a multilayer soundproofing, keep in mind that the area of \u200b\u200bthe room will be significantly reduced. Each lined wall reduces the linear dimensions of the room by more than 15 cm.

Technology of multilayer sound insulation of walls:

For example, we present to your attention a video that demonstrates the process of soundproofing a room using ISOVER material.

During construction, through sockets are arranged for outlets and mounting boxes, allowing you to simultaneously install electrical equipment and accessories in two rooms at once. Therefore, they serve as excellent conductors of noise from a neighboring room.

Before proceeding to isolation, it is necessary to de-energize them. After that, we completely remove all the electrics from the hole, and inside we put the cork cut out of any sound-absorbing material, such as basalt fiber, and carefully cement it.

Mounting boxes are insulated in exactly the same way, only they differ in the presence of a plastic plug, which must be removed. By the way, if you do not know, you can find the location of these boxes by tapping on the wall.

If the house is a panel, then as a result of the natural settlement of the building, deformations of structural elements and poor-quality work of builders, cracks are formed at the joints of adjacent walls, as well as walls and the ceiling or floor, which also transmit sound very well. Getting rid of them is easy. It is necessary to expand all the cracks with a screwdriver or any other sharp tool up to 30-40 mm, thoroughly clean their cavity, completely prime it and cover it with a layer of putty. After complete drying, the joints should be covered with sealant, preferably acrylic.

If the floor is already lying flooring, then you can not disassemble it. For good insulation, it is enough to fill the gap between the wall and the floor with silicone and cover it with the baseboard. As a rule, this helps to significantly reduce the level of vibrations transmitted through the floor.

A large number of sounds penetrate the apartment due to the front door. Conversations of neighbors, slamming doors, sounds of the elevator, steps on the stairs - you can also get rid of them. The main requirement for front doorproviding a high level of soundproofness is the absence of gaps. Therefore, it is enough to attach rubber seals at the places of contact of the door leaf with the jamb and equip the door frame with at least a small threshold. If there are gaps between the box and the doorway, they must be filled cement mortar.

The use of two doors gives a good soundproofing effect, and the second can be a thin decorative partition. The main thing here is the resulting small vestibule, damping vibrations.

Sound insulation of the floor must be taken care of before laying the flooring. Otherwise, it will need to be disassembled. To isolate the floor from the penetration of extraneous noise and to protect the neighbors living below, from the sounds penetrating from your apartment, you need to place special insulation material under the floor covering or, even better, under the screed. Such materials for sound insulation are a thin layer of fiberglass, polymer or other substance with high ductility and elasticity. It is necessary to lay such insulation so that its edges go onto the walls, in this case sound vibrations will not propagate further than the floor surface.

The best way to isolate the room from the penetration of extraneous noise from the ceiling is the installation of suspended or suspended ceilings. It is better to entrust such work to true professionals. It is almost impossible to stretch the fabric yourself without wrinkles and distortions. Especially if you have never done this work before.

If the funds do not allow you to invite specialists, then you can try to isolate the ceiling using a multilayer structure. The technology of this work is not very complicated and accessible even to a novice repairman:

When deciding to isolate the apartment yourself from noise penetration, keep in mind that for a good result it is important to use high-quality materials with high soundproofing properties. All expenses for them are quickly compensated by the calmness of your family and good relationships with neighbors.

If you are tired of being aware of all the events taking place at the neighbors, it's time to think about the sound insulation of the walls of your apartment. This is a very time-consuming process, but if desired, all work can be done on their own.

The first step is to look for various cracks and holes in the walls. Found holes must be carefully coated with putty.

The final preparatory stage is the sound insulation and sealing of the heating risers in the places of their connection with the walls. This procedure should not be neglected, since it is all the actions in the aggregate that will allow you to achieve the desired effect. There are special elastic sealants that are resistant to temperature extremes, with which you can effortlessly seal all the joints between the pipes and the wall.

These are the main preparatory steps that you should definitely carry out if you plan to carry out soundproofing of the walls with your own hands.

Arriving home after a hard day, we want to relax, do what we love. But then the neighbors start arguing about something outside the wall, the elevator rattles, and cars rush through the window with noise. Carrying out noise insulation work with their own hands, apartment owners often make various mistakes.

Of course, there are many more errors, but the ones listed above are the most typical. In order not to alter the noise insulation of the apartment, the best option would be to turn to the services of an acoustic engineer, who will make recommendations and schemes of technical structures and insulation units.

Perhaps the most common material used for soundproofing is drywall. The drywall profile is quite thin, so it can be used even with a small area of \u200b\u200bthe room. Usually it is mounted on a wooden crate, and fiberglass or foam is placed in the resulting space. This design absorbs sounds well. However, its disadvantages include the fact that if installed incorrectly, the opposite effect is possible, and there will be even more noise in the room.

They are becoming increasingly popular. soundproof panels. In the modern market, they are offered by various manufacturers and differ not only in characteristics, but also in cost. So, the average cost per square meter of the panel varies between 500-700 rubles.

Mineral slabs based on basalt “Shumanet” are easy to install and are one of the best materials used for sound insulation. They are based on environmentally friendly raw materials. Plates have a low cost, which is why most consumers prefer them. Among the disadvantages of the material, it should be noted that the installation of this design is not suitable for rooms with a small area, as it can visually reduce the space.

For soundproofing walls, ceilings and floors, Texaund is excellent, thin membranes based on a special mineral, aragonite. This is a new and quite effective material for noise insulation, which quite effectively copes with the noise problem. But its cost is quite high, which is not acceptable for all apartment owners.

For soundproofing the floor, it is convenient to use a specialmembrane. Its thickness is from 5 mm. It is laid directly on the concrete screed. Moreover, there are various types of material, depending on what surface it is intended for and what will be on top, the construction of underfloor heating, wooden flooring, parquet, etc.

By the way, the problem of sound insulation in an apartment can be solved comprehensively, that is, using various materials for walls, ceilings and floors. In some cases, this helps to achieve a better effect.

Electrical outlets in apartments (primarily in new buildings) are located strictly according to the project. And this means that, to save time and money, they are installed in one hole in the wall from different sides. And since the electrical outlets do not have soundproofing functions, the noise from one room penetrates into another without hindrance. This is not difficult to verify by putting your ear to the outlet (of course, without touching live parts). If you want to achieve full soundproofing room or apartments, you will need to block the noise and this loophole.

This work is not complicated, it does not require special skills. The only problem will be the presence of electric current at the outlet. If rooms in one room are sealed, then this problem is solved by turning off the power supply in the entire apartment. Worse when it comes to the wall between the apartments. You can turn off the power of your outlet, but the neighbor ... it’s better, of course, to agree with the neighbors and also turn off the electricity.

After disconnecting, you need to dismantle the socket, then the mounting box. Ideally, the bottom of the mounting box of the outlet installed by the neighbors should appear. Then the soundproofing layer is laid. It can be basalt cardboard, asbestos fabric, dense mineral wool, you need to cut a cork from these materials, as shown on the dagger. It should be ensured that the layer is not very thick. It must be borne in mind that in place of the hole should be enough to install the outlet back. Then the noise reduction layer is sealed with gypsum putty or cement mortar. At the last stage, it remains to mount the electrical outlet, in reverse dismantling, sequence. If the described process raises doubts or there is no certainty that it will be possible to cope with it yourself, it is better to turn to a professional electrician for this.

Do not use mounting foam for sealing - it does not have soundproofing properties. Moreover, the mounting foam burns well, and the electrical wires become very hot in case of poor contact.

Sound insulation is best done at the repair stage so as not to redo expensive repairs later. The big disadvantage of this layer is that along the entire wall it will be removed approximately 8 centimeters. If the apartment is large, then this is not very noticeable, but if it is small, then it’s a shame to lose almost a whole square meter of living space. Here you have to decide what is more important for you.

To carry out the work you will need: profile, drywall, sound absorbing material, hardware and screws.

First, you need to calculate the size of the walls through which sound insulation will be laid in order to buy the right amount of all materials. They are not too expensive, but if you miscalculate, you will have to either throw them away, and this is also time and effort, or buy them. And on a regular passenger car, even one sheet of drywall is problematic and you have to order a truck.

If the wall is solid (brick, blocks) then the profile can be attached directly to it. If she "walks", then vibration-isolating material between the wall and the profiles should be used. Especially if there is a highway or railway near the apartment.

We build a strong metal construction (you can use wooden profiles). It is necessary to attach the entire profile well so that drywall can be tightly screwed to it. We insert soundproofing material into this design. What kind of sound insulation you get, you decide. It all depends on how much loud noise needs to be removed. Typically, sales consultants in construction stores very competently give advice on the choice of material. Most commonly used mineral wool. Due to its softness, it absorbs sound more. Yes, and insert it into the frame is not difficult.

Most importantly bought the material is inserted very tightly into the metal frame . If there are gaps, then all the work will be done in vain. After that, we sew the entire structure with drywall and putty the seams for finishing work.

The whole process of soundproofing walls is not complicated and does not require large material investments. Cope with this work, if desired, can any man alone. And the price per square meter of the finished layer of sound insulation is about 300-500 rubles. Compared to many repairs, it’s quite inexpensive.

For many people whose windows open onto busy highways, noise from passing vehicles is a serious problem. To correct the situation, you need to change the windows in the respective rooms.

When ordering new frames, you can choose wood or metal plastic as the material of manufacture. Pine or oak constructions made in compliance with processing technology look very attractive and last long enough. However, in recent years, windows made of metal-plastic have been in high demand. It is easy to care for, aesthetic, and resistant to environmental influences.

For sound insulation, glass quality and thickness are of great importance. The last indicator should be different for the internal and external parts of the glass, then the reflection of noise will be more complete. The best option would be to use triplex or glass 6 mm thick as external protection. They absorb most of the sounds from the street. The internal components of the chamber can be represented by 4 mm or energy-saving glasses.

To protect the apartment from noise, the owners need to carefully consider the process of installing new windows. Any defect in the seams will cause a decrease in the effectiveness of the measures taken. A ventilation valve should also be used in the window construction. It will provide an influx of fresh air without raising the noise level.

Noise isolation of the garage is necessary if the garage is built-in. To prevent the noise of a running engine from being heard in the house, first of all, carefully close all the cracks around windows and doors. If the walls are constructed of porous material, they must be plastered. Naturally, it is necessary to leave ventilation openings in the walls of the garage and install special noise-absorbing fans in them. Such fans can reduce the noise level to 25 dB.

For better sound insulation, wall thickness must be increased by lining them with sound-absorbing material. Of course, the volume of usable area will be reduced, but it's worth it.

Make an insulating layer as follows.

Cotton wool, 50 mm thick, which serves as a good sound insulator, is mounted close to the wall with mushroom-shaped dowels. A thin (10-14 mm) layer of sound-absorbing material is attached to the cotton. Sheets of material are overlapped (15 mm) and securely secured with adhesive tape at the joints. A metal profile is attached over this structure, and drywall is laid on it in a double layer. The profile is fastened in such a way that there is an air gap of 20 mm between the noise insulator and drywall. This will create an extra air gap. The profile must be elastic. This multilayer insulation absorbs sound and dampens vibrations.

In the same way, soundproofing is mounted on the ceiling.

With such sound insulation, the noise level outside the garage is reduced to 60-80 dB.

If the walls of the garage are made of drywall, then such insulation can also be built by placing the described structure inside the wall.

You need to start with the fact that you should disconnect the wiring. After that, you should disassemble and pull out all the sockets. The holes where the sockets were installed are filled with noise-insulating, non-combustible material and covered with a solution of gypsum. Those places in which pipes exit the walls are also coated with mortar so that there are no cracks. After the completion of all noise isolation works, external sockets are mounted.

In the walls of the house, also, all existing cracks and crevices are carefully putty. If the gaps are large, they can first be filled with cork or mineral wool.

The next stage is the direct installation of sound insulation.

First decide on the choice of material. This can be mineral wool, sandwich panels, chipboards, or some other suitable material.

When performing sound insulation with mineral wool, it is laid between the wall and drywall, mounted on the wall using a profile. Or, first, mineral wool is fixed, then the profile is mounted, and drywall is already attached to it. Drywall serves as the front surface of the wall and, of course, other material can be used instead.

More recently, the issue of sound insulation was not considered especially during construction. You don’t have to go far for an example: most of the high-rise buildings, not only new, but also Soviet-built, let you hear perfectly what is happening both with immediate neighbors and on neighboring floors. Modern construction technologies using lightweight materials need even better sound insulation.

Today, the mounting of soundproofing plates on a metal profile frame fixed to the walls is widely used. It is not difficult to establish high-quality sound insulation, but knowledge of several nuances discussed below is required.

At first, the frame cannot be mounted directly to the wall. Between the wall and the metal profile, a special sealing tape should be located. Experts advise laying it even in 2 layers.

Secondly, in attempts to save money or speed up work, mineral wool or polystyrene are used as a noise insulator. Both that, and another - heat, but not sound absorbers, therefore their indicators in this area are several times lower than that of special materials. In addition, both materials are not environmentally friendly enough, and the foam is also combustible, therefore, it is recommended only for external insulation. For internal noise insulation, it is necessary to use acoustic plates, for example, ECO plates "MAXFORT" or Schumanet-ECO from AMiT. Drywall in wooden house. How to decorate the house ... Drywall for decoration wooden house apply quite actively. With its help, walls and ceilings are aligned, podiums and niches are created. ...

Residents of apartment buildings most often suffer from poor sound insulation. prefabricated houses. The high noise level in the apartment is ensured by poor joining of the panels, the small thickness of the ceilings between floors. Repair, noisy festivities, loud sound of the TV or music ... All extraneous sounds can be left outside the door, if you make good sound insulation in the apartment.

Soundproofing in a living room depends on what type of noise you want to eliminate. All noises are divided into two categories: vibrational (those that arise under the influence of shocks and propagate exclusively in a solid medium) and acoustic (which are transmitted in the form of vibrations by air). Impact noise can be well “felt” on oneself during repairs by neighbors. Acoustic noise is what you hear during a noisy party with neighbors, music, laughter, loud conversations. Sound insulation of the apartment should be comprehensive. That is, walls, floor and ceiling are subject to special decoration. In addition, doors and windows should protect your home from extraneous noise as much as possible. It is best to take care of the soundproofing of the dwelling even at the stage of its construction, however, since this option is not suitable for an apartment, you can ensure silence in the room using special sound-absorbing materials.

Remember that the best effect is achieved only with an integrated approach to solving the problem of excess noise in the apartment. Use only high-quality materials, and if necessary - seek the help of specialists.

If in the house thin walls, between neighbors often there are conflicts over noise. The reason may be loud music, children's crying, neighbor's dog barking, etc. This problem is especially relevant for panel high-rise buildings. An excellent way out of the situation is soundproofing the walls in the apartment with your own hands.

There are two main areas of sound insulation:

High-quality sound-absorbing walls are an obstacle to any sounds, and serve as a guarantee of calm nerves.

Before you make soundproofing of the walls, you need to determine the causes and sources of noise. He can get into the apartment:

If sounds enter the room through a power outlet, you need it, and foam the hole with a special mounting foam. Sometimes it’s enough for silence to return to the apartment. If this does not help, you should pick up good material and proceed with sound insulation.

Walls can be insulated in many ways. The main thing is to choose the right option that is optimal in price and quality. The most popular are the following materials.

The range of noise insulation materials is quite wide, but there are manufacturers offering quality products with the necessary technical parameters at an affordable price:

The most popular and cheapest is Sound Protection from ISOVER, its price depending on the thickness of the material is 100-200 rubles / m 2. Rockwool Acoustic Butts, costing 110 rubles / m 2 is also in demand.

More often than others in the process of soundproofing use. For their construction you will need:

Interior soundproofing always begins with the preparation of the walls: searching and and cracks in the walls, etc. After this, the frame for drywall is installed at a distance of 2 cm from the wall. When installing it, it is recommended to use an anti-vibration rubber gasket.

Sound-absorbing material is laid under the constructed frame (the softer it is, the more effective the result). Then, drywall plates are attached to the profile. The final step is the sizing between the sheets.

The wall thickness with such sound insulation increases by about 8 cm. If this option is not suitable, roll materials can be used. They are sold and glued to the walls with special glue. But there is a significant drawback in this method - it reduces the noise level by only 40-50%.

As sound insulation can be used and. They are interconnected by the thorn-groove method, and are attached to the wall by means of liquid nails. The range of such material is quite wide, you can choose the finish for every taste.

How much does soundproofing walls cost? The main costs when using drywall panels:

The cost of self-tapping screws, profile and glue is added to them.

Sound insulation of the walls in the apartment from neighbors, for example by Polif, will cost 1310 rubles per roll, which is enough to cover 7 m2 of the wall.

The average cost of decorative panels is 750 rubles / m 2.

Everyone chooses the best method for themselves based on the calculation of strength, personal preferences and financial capabilities.