From internal pipelines, drains are transported by external ...

Among the considerable number of tools demanded in the everyday life of almost any homeowner, there is an inexpensive and uncomplicated tool - a gun for polyurethane foam.

Is it possible to do without it?

I guess, yes. The reader probably knows that there are cartridges with polyurethane foam for domestic use. In this case, the use of mounting foam is possible without the use of a mounting gun. But my personal experience working with such cylinders (mounting seam in the photo on the left), as well as the subsequent experience in working with the mounting gun (mounting seam in the photo on the right) brought me the following thoughts:

Given that the gun is usually accompanied by an instruction, the above information will be enough to read and understand the article.

The reader probably knows or has heard of the law of "the transition of quantity into quality." But, unfortunately, this law does not apply to those “mountains” of mounting pistols that are on our shelves. Even the purchase of a relatively expensive pistol cannot guarantee its quality and serviceability. Therefore, the only right decision is to check the performance of the mounting gun when purchasing it. It’s easy to check the gun when buying, the only thing we need for this is a foam cleaner. You need to either take it with you to the store, or buy it directly in the store, since it is still needed when performing work.

There are two possible scenarios.

We need to check the performance of the gun, as well as the quality of its assembly (the presence of leaks, passes), without spoiling its presentation. So, for example, if you immediately start to use polyurethane foam, and it turns out that the gun for polyurethane foam is defective, it will be much more difficult to prove the marriage (in reality it is practically impossible). That is why a foam cleaner is used for testing.

For high-quality performance of work using an assembly gun, the following materials and tools will be required, which are almost completely shown in the photo below:

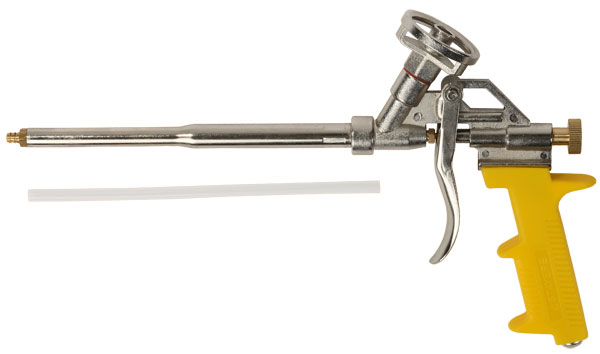

In addition, in the process of performing work, sometimes situations arise when it is difficult or impossible to perform foaming at the place of work (access to the place of foaming is limited, it is necessary to foam an extended internal cavity, etc.). In this case, it is convenient to use a flexible extension cord - a nozzle on the gun. It can either be included in the kit, or purchased separately or made independently. The photo below shows a gun with an extension - nozzle.

About the selection of polyurethane foam articles and debates on the net are enough. Based on practical considerations, when choosing a mounting foam (for beginners), I note the main thing:

For the mounting gun you need to buy the whole kit (bottle with mounting foam and bottle with foam cleaner). If, for example, you don’t buy a foam cleaner in advance, then it may happen that the gun turns out to be disposable and you have to throw it away after the first use. The main explanations and features of the cylinders are shown in the photo below.

When choosing a mounting foam, it is imperative to pay attention to the weight of the cylinder, which can significantly differ from a nearby cylinder of another manufacturer. You need to take those products that are more weight.

Important! Be sure to check the date of manufacture and the acceptable shelf life. I do not recommend buying stale products.

Polyurethane foams are summer and winter. Depending on the time of year and place of work, this also needs to be paid attention to.

In most cases, if we are not talking about specific requirements for the work performed, observing the above points when choosing supplies will allow you to buy a normal high-quality mounting foam suitable for work.

Since the instructions for the mounting gun for its use are attached, I will note only those moments when performing work that I personally adhere to.

Everything that is necessary for the performance of work should be prepared and be close to the place of work. It is also necessary to check and make sure that there is a sufficient supply of funds in the bottle for cleaning the foam, which will allow you to rinse the gun with high quality after performing work.

a) The flow (exit) of foam from the gun should be stable and constant (and small).

b) The movement of the gun along the seam should be uniform.

In words, this is easy to do, but in practice, only after gaining practical experience.

Note. All decelerations in the movement of the gun, and even more so stops for "supposedly more thorough foaming," actually worsen the quality of the assembly seam and work.

It is important to understand that after completing work, it is impossible to leave the assembly seam (foam) not weatherproof (moisture, ultraviolet) for a long time. Therefore, only after the implementation of protective measures, work can be considered completed. What to use as protection?

Depending on the characteristics of the work, this can be painting, plastering, the use of special tapes, etc. A little more about this, we will talk below.

Since the range of application of foam and a mounting gun is huge, starting with construction work and ending with design and even auto-tuning, we will consider the most typical (demanded) examples in relation to the needs of an ordinary homeowner.

The most typical and common use of a mounting gun and foam is the installation of window and door structures. The execution of work in this case is much similar, with the exception of some features, therefore, we will consider them in more detail separately.

Consider the example of mounting a plastic window, which was partially discussed in my previous article. In this case, we need a gun with mounting foam to perform three operations:

A brief description of these operations is shown in the photo below.

Some important points that you need to understand and consider before starting work on the installation of window structures:

Window openings in brick wall structurally, they can be different, for example, a window opening with a quarter (external or internal) or without a quarter.

Depending on this, there may be significant differences, both in installation and in the choice of materials used.

The photo below shows how the protection of the installation joint is implemented using the example of windows installed by me in a brick building. In the photo on the left - from the inside of the room, in the photo on the right - from the side of the street.

Explanation of the photo:

The protective tape inside the room during the work is also protected by plaster, as well as the surface of the window opening.

More details about the installation features plastic windows when doing work independently, an inquisitive reader can look in my previous

When installing plastic windows in wooden house, the interaction system of the window profile, window box and bearing wall very different from the previous version.

Two fundamental errors are possible here:

The photo shows some points regarding the installation of plastic windows in a wooden house.

In this case, a plastic window cannot be installed directly in the wall opening (as in a brick wall). And when installing (fixing) the window boxes themselves to the wall, it is also impossible to use mounting foam (nails or screws). The window unit in the wooden wall cannot be fixed rigidly and it must be movable in relation to the wall. But the installation of the plastic window itself in the window frame must be performed, as in a brick wall. That is, with the use of mechanical fastening and subsequent foaming with mounting foam. A fragment of the work is shown in the photo below.

More details about the features of installing plastic windows in a wooden house can be found in

The use of polyurethane foam when installing doors is now widespread because of the simplicity, convenience and significant time savings when performing work. Since the process of installing door structures is in many ways similar to the process of installing window structures, we will consider only certain points (features) when performing these works. The photo below shows fragments of door installation work at the very beginning of the work and at the final stage. It is important to note that the door (doorway) in the photo on the right is the interior door, and the other door is the front door.

The main differences front door (in addition to overall dimensions) are concluded in the conditions of its operation. That is, the front door, unlike interior doors, is subject to a significant temperature difference. Therefore, after foaming, the mounting seam for the front door must be protected, both from the inside and from the outside.

Before foaming, the mechanical fastening of the door block of the entrance door should be performed, more reliable and thorough than when installing interior doors. The photo below shows the corresponding fragment of the work before foaming. The dowel length is 180 mm, installed in an amount of 8 pcs. on the sides of the block.

For interior doors, operating conditions are much easier, therefore, there is no objective need to protect the assembly seam (foam). Another question is that, from the point of view of aesthetics, to close the seam (foam) is quite logical. The photo below shows a fragment of the installation work interior door inside the house.

When performing thermal insulation works using polystyrene foam insulation, the use of polyurethane foam minimizes heat loss (eliminate cold bridges) that may occur when it is not possible to precisely fit the joints of insulation sheets, at the joints of insulation sheets with building structures, etc. Some are shown below in the photo. moments of thermal insulation work. In most cases, modern heaters can be easily adjusted at the joints using a mounting knife. At the same time, for example, due to the incorrect geometry of the insulated room, inaccuracies in sheet fitting, especially in the corners, cold bridges may occur in the heat-insulating layer when mechanical fitting is not possible. In this case, the use of polyurethane foam allows you to easily and simply eliminate such shortcomings.

In some cases, without the use of a gun and mounting foam, the volume and complexity of thermal insulation work would increase markedly. The photo below shows an example of insulation of the lower building structures of a house.

Photo No. 1 shows the insulation of the site with polystyrene foam at the border of thermal insulation between the wall of the house (cotton wool) and the basement of the house (polystyrene foam). Without the use of foam, it would be impossible to fix the foam under the base drain without the formation of cold bridges.

Photo No. 2 shows the use of mounting foam for fixing thermal insulation under a galvanized drain (protective peak).

Photo No. 3 shows sheets of thermal insulation of the basement of the house, which are tightly (without the formation of a cold bridge) adjacent to the basement of the house, including the thermal insulation installed under the protective peak of the basement.

Photo No. 4 shows the installation of thermal insulation of the blind area of \u200b\u200bthe house, adjacent also close to the insulation of the basement of the house. As a result, we got a monolithic (in fact) heat-insulating pie in the lower part of the house, which protects the lower building structures of the house.

On the far approaches to the house, protection is provided by a warm blind area, the bottom of the house is protected by a warmed base, the wall of the house is protected by a cotton insulation, and the border between the cotton (house wall) and polystyrene foam (house base) is reliably protected using polystyrene and polyurethane foam.

Two important properties of polyurethane foam: the adhesive ability and the ability to expand during polymerization (solidification) allow the use of polyurethane foam as a universal building adhesive. In this case, the versatility also lies in the fact that the mounting foam allows you to connect completely different (in terms of their properties) materials.

The photo below shows fragments of the work when I used polyurethane foam in this quality. The photo on the left shows the arrangement of niches in a brick wall. Installation is carried out using a mounting foam. The photo on the right shows similar work done to install multimedia equipment in the room (projector and rear rear speakers of the speaker system).

The photo below shows a fragment of the work when the mounting foam was used to fix the colored window sill used in the decoration of the room for the spatial delimitation of the basement of the wall (dark stone) and the room wall (light stone).

The properties indicated above make it possible to effectively use polyurethane foam as a building sealant to fill voids in technological holes in the presence of cracks in the mating structure, etc. The photo below shows fragments of work using polyurethane foam in this quality. In the photo on the left, the gap between the brick structure and the wooden wall of the house is closed with a foam seam.

In the photo on the right, the through hole in the wall is also covered with foam.

To summarize:

The use of mounting foam (and mounting gun) allows you to easily and efficiently solve the most diverse problems that the homeowner has to face. And how not to make a mistake when choosing a gun, we now know.

By the way, when I somehow rejected the gun during the purchase, the sellers put it back in the general “pile”, which means that it will wait for its buyer. Good luck with business!

The simple truth is that without a professional tool not a single installation is made - it is not in dispute. Repair work involving mounting foam is inconceivable without the appropriate device - a gun. The device facilitates the application, saves building materials, makes the seams neat and accurate.

Presented in many models will make the novice master confused. What to rely on when choosing - find out now.

The mechanism is a complex structure, which in the process will have to be disassembled more than once for cleaning and tuning. In order not to break the fragile interior, you should know how the gun is designed so that subsequently there is a chance for repair or replacement of components - this is another article to save the family budget.

So, any model of installation tool consists of the following:

Internal arrangement: pressure spring, adjusting valve, futorka and a through opening for creation of discharge.

The work is as follows: the composition of the cylinder falls on a ball gear and seeps into the rod. The force of the pressure is created by the control valve that pushes the foam into the barrel. The trigger opens the foam outward.

Having learned the purpose of the tool and the principle of operation, you can go directly to the choice of model. Any option can be classified according to many criteria, facilitating the work of the master, prolonging the operation of the device, its payback. So, by what criteria make your own choice:

As a rule, guns are made of metal, plastic or Teflon. What are the differences, advantages and disadvantages? Consider:

There are models made of durable plastic. However, there is a great risk of acquiring a fake for a high price. Only a professional can detect flaws, and in order not to run into such a product, it is better to prefer a proven metal to it.

There are only two options - collapsible and non-collapsible model. Therefore, the choice is also easy - it is preferable to choose a non-disposable gun with a monolithic body. After work, it is simply thrown away and for new installation they get a new one. The collapsible option is easily cleaned of foam, the details change, which means that such a purchase is much more profitable - as you know, repairs cannot be completed, but can only be postponed.

Chinese production cannot be completely ignored - there are worthy specimens among them. Likewise, European production is not always preferable to Russian quality. The main condition for choosing is not to consider pistols of unknown companies. In order not to be mistaken, the following is a list of brands that have been tested for years.

So:

Thanks to a specific list, choosing your own tool will not be difficult. The buyer should inspect the device for integrity and check the mechanism - such a service is provided to the client in construction stores with a good reputation. How this happens is described below.

Naturally, only reusable models are tested - cheap plastic, even in case of serviceability it will be unsuitable for further use. As a composition, not a foam bottle is purchased, but a container with cleaning acetone or any other solvent, whose action is inert to the material of manufacture.

The procedure is divided into two stages:

It will be useful to recall that the purchase of a gun for polyurethane foam is accompanied by the preservation of the receipt and commodity packaging. In this case, there will be no delay in refunding or replacing the model.

This is not difficult. A proven and reliable gun is turned in such a way that the handle is at the top. The nozzle on the cylinder is screwed to the body, and a plastic or metal cap is preliminarily removed from the container. It is important to shake the assembled gun several times intensively to create pressure.

Further, the device is turned over and the control valve is opened for several turns - if more pressure is required, it is gradually brought to the desired one. The barrel with the nozzle is directed to a place to be sealed and the trigger is pulled. Work is carried out from the bottom up, filling the voids only by a third - the resulting foam will complement everything else. If the mounting composition is not enough, repeat the cycle.

The remaining foam, unfortunately, is not used again, so it is important to calculate the required amount in advance, in order to avoid unnecessary waste. They need to be released from the cylinder at the end of work, as the gun will need to be cleaned and stored until the next time. The installation of the next cylinder is possible only with a good release from the previous composition.

It can be done in two ways. If you use a gun, it is decided the next day, then proceed as follows:

Better cleaning, if the gun is left for storage and use from time to time, is as follows:

We summarize: the correct choice and use of the mounting gun is described in detail.

The recommendations are simple to implement, as well as the prevention of the purchased device. Self-repair with a quality tool will save most of the family budget, as opposed to having to spend money on professional services.

Where is it used? Perhaps it will be easier to say where she has not yet found application. Installation of windows, thermal insulation of rooms, elimination of cracks and gluing of various materials. Soundproofing steel and acrylic bathtubs and kitchen sinks. Garden sculptures and decor elements.

This is not a complete list of the possibilities of using polyurethane sealant, which we know as polyurethane foam.

Foam is sold in packaging in the form of cylinders.

Moreover, the latter are of two types:

This device will be discussed in this article. What is the design of the gun? What to be guided by when choosing it? How to use it? We will try to find the answer to these questions with you.

The principle of operation of the gun, designed to work with mounting foam, is based on the simplest mechanics.

It consists of the following nodes:

From the cylinder, foam is fed through a ball valve into the supply tube. By pulling the trigger, a double valve is opened, which is located in the tube. Due to this, the foam can go outside. At the other end of the tube is a mechanism that controls the amount of foam supplied. A special nut, unscrewing or twisting, increases or decreases the foam output.

Due to the fact that the principle of operation and arrangement of guns for polyurethane foam are almost the same for all manufacturers, the choice is greatly facilitated.

Choosing a gun, look at:

How to check if the gun holds pressure? At home, a can of acetone is installed in the gun, and the solvent is launched inside. Then the cylinder is removed, and the tool is left for a couple of days. After that, you can determine the quality of the device. To do this, just pull the trigger. If the acetone that remains in the gun comes out under pressure, as in a shot, then the purchased product is of good quality. If there is no cotton, you can return the gun to the store. It retains its presentation and without any problems can be exchanged for another model.

In fact, there are no secrets and nuances when working with a gun. Everything is extremely simple.

First of all, the tool needs to be charged. To do this, raise the balloon holding ring up the thread until it stops. After that we screw in a full cylinder. We return the ring to its original position. In this case, you can hear the hiss of the compressed gas coming out under pressure.

After that, you can get to work. It is enough to point the gun tube to the right place and pull the trigger.

Foam at first can go a thin stream. If there is a need to increase the duct, you need to unscrew the nut, which is located at the end of the instrument. Need to adjust smoothly. Experimentally, you can choose the consumption of material that is required.

With proper handling, this device can protect the foam inside from drying out. To do this, just leave the balloon on it. If the packaging with foam is removed, then inside the polyurethane foam will harden. And quite quickly. To avoid this trouble, you can either rinse the tool with solvent, or install a new foam bottle and activate it. And one moment. If you keep the gun with the cylinder down the tube, then at any time it will be in working condition. Foam will not freeze.

As for the prices for this instrument, they can cost $ 10 (and there are no guarantees that it will work out its own), and $ 20-50. In the latter case, you will purchase goods of professional quality. And of course, it is advisable to purchase it not in the market, but in specialized stores.

Among the manufacturers, one can mention “Bison” (Belarus) and “Workman” (Canada). They are followed by Stayer, Hilti and Kraftool. The last group of manufacturers produces quite good products. However, there are many fakes. Original models last a long time. And fakes are surrendered after the first use. Therefore, it is advisable to be alert and purchase guns in trusted stores.

We wish you success and pleasure in using a professional high-quality tool. May every day bring you satisfaction from work and joy from the results.

Even the most expensive professional tool can be disabled by inept application attempts. Well, in order to get significant savings and to achieve high-quality sealing of window or door blocks (and not only) during installation, you need to know about how to use a foam gunWithout such knowledge, there is a high probability of getting only a headache.

First of all it is necessary to remember safety measures during the work with polyurethane foam.

The fact that the gun must be kept upside down is known to many, this is the basic rule. In addition, you should know some other regulations.

If there was no such sound, this indicates a malfunction (sticking) of the inlet ball valve, in some cases this may indicate the expired shelf life of the foam itself. To fix this problem, you will have to disassemble the gun, and clean it of old dried foam, or replace the foam.

After all work is completed, you must perform the following steps:

In order to use a gun with a wound balloon after a break, especially not for a long time, no special efforts are required. Clean the nozzle from a layer of hardened foam, it is best to use a sharp knife for this, it will be more convenient and faster.

After this, shake the bottle, as in the initial application, and then you need to bleed stagnant foam. This usually takes 5-10 seconds, after which you can begin to perform work.

First of all, remember that the gun must be regularly flushed. If the tool is used regularly (professional installation of windows, doors), it is worth installing cleaning after applying 3-4 foam cylinders. In this case, it is first necessary to skip the flushing through the entire device of the gun (by pulling the trigger), after which the tool should be postponed for 1-2 hours so that acetone dissolves all the foam inside. Then press the trigger again and flush the tool for 5-10 seconds.

The main malfunctions of the gun for polyurethane foam:

To eliminate this, you will have to unscrew the cylinder adapter and release the ball of the valve, and it may be necessary to flush it with liquid (foam solvent). It must be poured over the valve and wait a few. When removing the ball, be careful not to damage its surface and not to lose the valve spring.

After cleaning the unit, the tool is usually restored.

To eliminate the malfunction, you will have to disassemble the gun almost completely. Unscrew the regulator, disconnect the gun barrel, unscrew the nozzle (in some non-separable models the operations may be different, but the meaning remains the same - disassemble the foam supply unit).

Particularly carefully handle the needle and the nozzle itself, any damage to these parts will entail the need to replace them. After it is necessary to process all the parts by washing, the barrel can even be soaked in it. At the end of processing, all parts should be wiped with a soft rag.

After assembling the gun, the spontaneous flow of foam usually stops. In another case, most likely, you will have to change the parts themselves or seals.

In order to prevent this situation, you should remove the remaining foam from the adapter when replacing the cylinder.

When operating a gun for polyurethane foam, the main thing to remember is that any tool likes a neat and careful attitude to itself, do not forget about it.

When performing work with the use of polyurethane foam requiring increased accuracy, fineness and accuracy, the gun will be an excellent assistant, with the help of which the material is used much more economically, and the accuracy of applying the foam is increased. One of the main rules of a gun for mounting foam is how to use it; you should protect your eyes and hands with safety glasses and gloves.

Shake the bottle vigorously at least 20 times immediately before installing the can. Remove the protective cap from the cylinder with mounting foam, screw the cylinder into the gun holder, holding the tool handle with one hand, and screwing the foam cylinder with the other.

When screwing in the cylinder is in an upright position, and the gun rotates with the handle down. Then it is necessary to unscrew the adjustment screw half a turn back, which will translate the cylinder with the gun into working condition. When you press the trigger, the tool barrel will fill with foam. For a better understanding of what is a gun for applying foam and how to work with this tool, we recommend that you look at the video instructions below.

The design of the tool is quite simple and they are all designed according to one principle:

Thanks to this simple design, tool charging is the simplest procedure and is done in minutes.

Despite the simple device and ease of use, this tool requires a careful attitude and care. Before using a foam gun, you need to know and comply with a number of requirements:

If you poorly cleaned the gun or forgot to do it after completing work, most likely it will stop working. The dried foam remaining in it is the main reason for the failure of the tool.

How to clean the gun from the dried mounting foam video

If the gun does not work or the foam has become poorly passed, it is necessary to inspect it and establish the cause of the malfunction (see video).

The trigger is easy to push, but no foam is fed. Check the foam bottle; there may be a problem with a poor-quality bottle.

How to use a foam gun. If the problem is with the tool, then remove the bottle, insert the cleaner and try again. In the absence of operability, the likely cause will be a wedge or contamination in the ball valve gearbox:

If this procedure does not return the gun working foam, then the foam has hardened inside, where you need to completely disassemble the tool for further cleaning. This will require keys, a foam cleaner, wooden sticks, a screwdriver, a soft rag:

Comparison of foam guns video

After removing all the dried foam, we assemble the tool in the reverse order.

When working with mounting guns, it must be prepared, after which, for proper use, follow simple instructions: (see video for details)

Rules for applying polyurethane foam video

The tool needs periodic cleaning not only after completion of work, but also in its process when replacing a used foam bottle with a new one. The cylinder is replaced, similarly to the installation of the first cylinder:

How to use a foam gun video

The cleaned tool is stored with a wound cleaner.