From internal pipelines, drains are transported by external ...

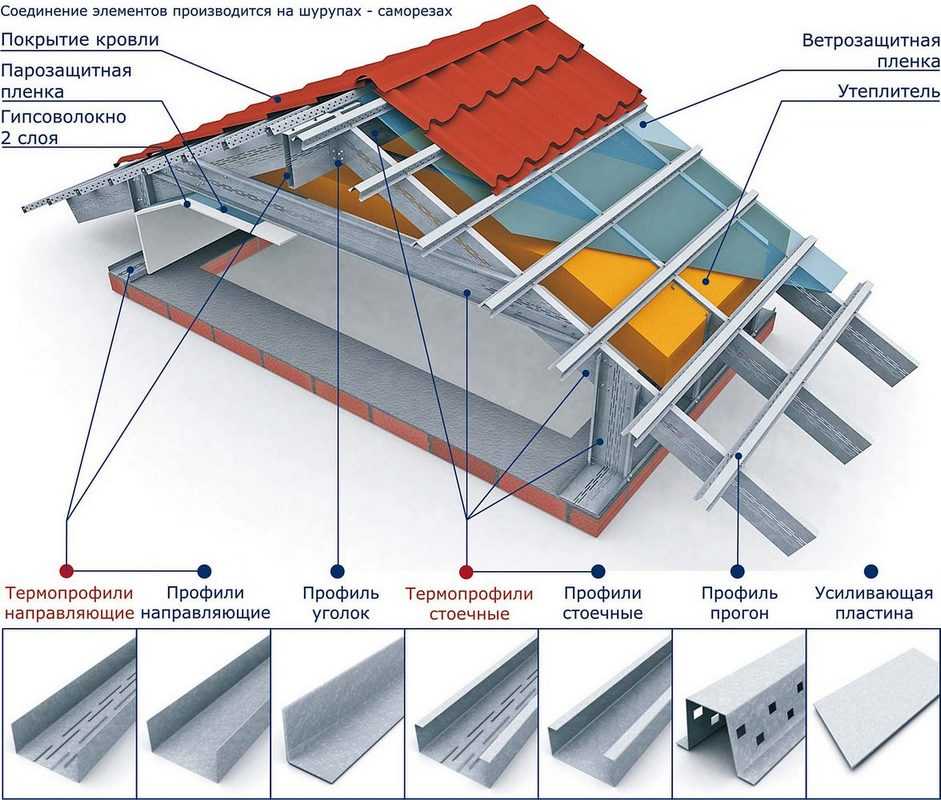

The construction of buildings on a metal frame has been practiced for a long time, but they mainly built industrial and technical premises, buildings of shopping centers, etc. The use in private housing construction was limited by the high thermal conductivity of the metal: heating bills would be unrealistic. Manufacturers solved the problem by making the so-called thermal profiles, which, combined with modern heaters, make it possible to get a warm house. If you need an inexpensive, reliable house that is being built in a short time, perhaps a metal frame house will suit you. It has a low cost - two times lower than brick, assembly takes place quickly, the service life of the factory frame is 70 years.

The technology is very flexible: you can adapt to any metal frame you like for a house. First, a frame plan is drawn up, the type of finishing materials is determined (only your wishes affect). Further, the developed project is processed by a special program that breaks everything down into components, issues a list of elements with all parameters. Profiles of the required size are made and labeled, bundled, packaged, delivered to the construction site. In short, this is the entire technical process - from project development to the start of assembly frame house from metal profiles.

This technology is becoming increasingly popular in European countries (including northern), in Canada and America. And all because steel does not decay, insects do not eat it. A metal frame structure weighs several times less than a wooden house (twice), and even more so, it is lighter than brick houses and other similar materials. The low weight of the building means lower costs for the foundation, since its parameters depend on the load, which further reduces the cost per square meter of development. Usually they put pile houses under such houses, or. On average, one square of the area costs 4-5 thousand rubles (excluding the cost of finishing materials).

The technology by which a metal frame house is built is called - light thin-walled steel structures, or LSTK for short. Lightweight does not mean fragile. Houses built using LSTK technology withstand earthquakes of nine points. But this applies to buildings no higher than 3 floors.

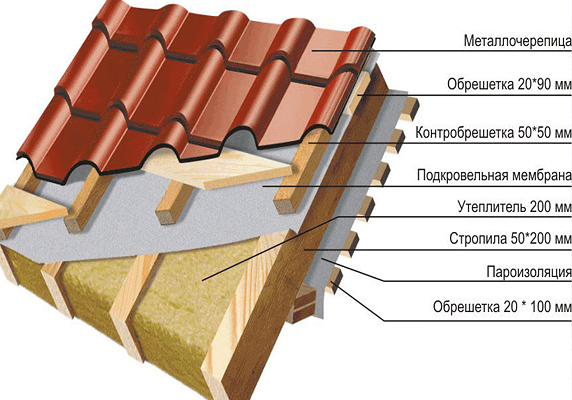

Another advantage of a steel frame over a wooden one is that its strength is sufficient to withstand heavy roofing materials. If you decide to use ceramic tiles - please. Only its weight must be laid when calculating the parameters of the foundation.

The very design of the pie wall is almost the same as that of. All the difference is in the material used for the frame and the assembly method.

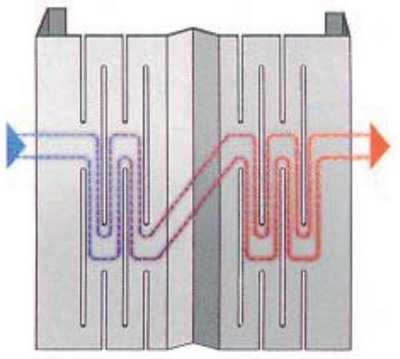

What about cold bridges? Manufacturers claim that the problem is resolved. Modern thermal profiles, from which private houses are built, have sections staggered. They prevent the through freezing of structural elements.

This is the picture of the “work” of the thermal profile

And although thermal profiles really work, still such a house is colder than. Nevertheless, the problem can be solved by making quality insulation. With the correct execution of the “pie” of insulation with all membranes (windproof, vapor permeable outside, vapor barrier inside), the metal-frame house will be warm and will go no more for heating than in the so-called “warm houses”.

For insulation, you can use any modern insulation - mineral wool, polystyrene foam, extruded polystyrene foam, foamed glass, ecowool. Foam glass has the best characteristics, slightly worse for extruded polystyrene foam. But they have a solid price, although the required thickness is several times less than mineral wool. As a result, the costs of insulation are comparable.

The best combination of qualities and prices for mineral wool. It is more convenient to work with basalt. She has good characteristics. Fiberglass performance is also good, but difficult to work with. Slag is the cheapest, but it is very afraid of getting wet, when using it, it is mandatory to install a ventilated facade.

For the above reasons, of the whole variety, I most often choose basalt cotton wool. It is well installed in the frame, has good thermal insulation properties, is relatively inexpensive, and is also a good soundproofing material, which is important for this technology.

LSTK elements are made of durable structural steel by cold stamping. The sheet has a protective zinc coating with a thickness of 18 to 40 microns. Some plants make structures of hot-dip galvanized sheets. Such elements are more expensive, but they are also more durable.

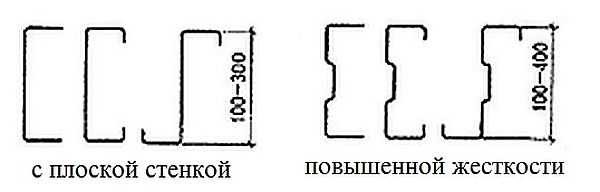

The thickness of the sheet from which they are molded from 0.7 mm to 2 mm. The choice depends on the necessary bearing capacity of one or another element. The following types of profiles.

Most often, the following types are used.

There are also special floor and ceiling beams. The rafter system of the house is made up of similar elements. The elements are connected to each other by bolts, screws, rivets, contact welding can be used.

Now about the quality of components from different companies. There are about a dozen factories in Russia. The quality is different for everyone. Therefore, carefully look at the quality of galvanizing, metal bending. There should not be anywhere, even the smallest, traces of rust. In general, even the best “our” profiles are significantly inferior to imported ones. It's a shame, but it is.

From the factory all the material comes packaged in packs. Each part has a marking, the same marking is present on the working drawings. The frame of the LSTK house is being assembled as a designer: everything is ready, even holes for hardware are stamped. Put the parts in place, align the grooves and install the hardware. A metal frame house is peeled off in exactly the same way as from wooden bars. In brief, the steps look like this:

Steel house frame is ready. Remaining insulation and finishing work. It is a remark: as much as one would not want to save, the crate should also be assembled from metal. The same expansion coefficients are exactly what contributes to the high strength of such structures. When connecting metal and wood, this cannot be achieved: the fasteners gradually weaken. This is especially critical in regions with increased seismic activity. But in calmer regions, there is little joy in rattling finishes.

If we are talking about assembling the parts that arrived from the factory in one design, then easily, but with assistants. All work consists in finding the desired part and installing it in the place indicated in the drawings. At first it’s difficult, then - get comfortable.

If “building a metal frame house with one's own hands” means welding it from a profile pipe, then this is an ambiguous business. If you are planning to build a small summer house, then there are no questions: the frame can be put on the same principle as a wooden one and for a one-story building, pipes 80 * 80 mm are enough for corner racks, and for intermediate ones you can take less. But the installation step is still dictated by the insulation: the distance in the lumen should be 58-59 cm (slightly less than the standard width of mineral wool).

The only thing to remember: when using a profile pipe, cold bridges will be required. Then the insulation itself will need to be done in several layers, blocking the heat leakage, which will solve the problem. One layer is traditionally placed in the strut between the racks. The cross section of the profile pipe is far from 200-250 mm, which are necessary for warming the house in the Moscow region (under mineral wool) Therefore, under the missing layers, a transverse crate is arranged (on one or two sides - decide for yourself). It turns out that between the racks the heater is laid vertically, and horizontally along the crate. Bridges of cold became much less.

From the side of the room, the insulation is closed by a vapor barrier membrane (it should not allow moisture to pass into the insulation). From the side of the street, a windproof vapor permeable membrane with waterproofing properties is fixed to it. It performs three functions at once:

Only with such a pie and the presence between the outer membrane and decoration materials ventazor can be sure that the insulation will not get wet. Only in order for the ventilation gap to work, ventilation holes at the bottom of the wall and an airtight outlet under the roof from above are needed: the air flow between the exterior of the metal frame house and the windproof membrane must pass without encountering obstacles.

For inspiration - a video on which the process of welding a country house from a profile metal pipe is shot. Those who know how to make a metal frame house with their own hands from a pipe will not be difficult.

Add to bookmarks

More recently, metal frame construction was used for the construction of industrial buildings: hangars, workshops, warehouses. Today, even in housing construction, you can meet the frame of the house from a profile pipe. Usually these are low-rise buildings (no more than 3 floors). Even more often you can find public, commercial buildings, the frame of which is made of a metal profile. Metal frame construction technologies are used in the construction of various kinds of add-ons, outbuildings, attic rooms.

A similar method of construction is most common in Japan, USA, Western Europe. The share of residential buildings erected there using similar technology is 45-70%.

For the construction of residential buildings, the metal profile began to be used after it had established itself in the best way in other sectors of construction. Rectangular and square pipes have long been successfully used for the construction of:

It has long been used for structures of various designs.

Profile pipes are made by the electric-welded method on welding mills. This ensures accurate product geometry. High quality is confirmed by non-destructive testing devices. The profile can be made of ferrous metal, galvanized or stainless steel. The latter option is the most expensive and is usually used as an addition (including decorative) to a frame made of cheaper material.

The construction of a metal frame house on labor costs is significantly inferior to buildings erected in the traditional way. In reality, all the main stages of the installation of a one-story country house can be completed in less than a month (not counting interior decoration) In addition, houses with a metal profile frame:

The serious advantages of buildings with a metal frame do not mean that there are no shortcomings. The main disadvantage is the complexity of the design, including load calculation. It is quite difficult to make such calculations on your own, so you have to turn to specialists. It is necessary to know exactly what mass can withstand 1 m of pipe. Another disadvantage is the high price of the metal profile. When buying material, you have to choose between financial costs (if you buy thinner pipes) and the ability to build a frame with a safety margin (if you purchase a thicker profile). And another problem that arises in the arrangement of houses with a metal frame is thermal insulation. Metal is a good "bridge of cold", so you should responsibly approach the process of insulation, i.e. make the right choice of insulation and spend money on quality material.

The foundation is constructed easier than for houses built by the traditional method. If the construction of a greenhouse, greenhouse or other structure intended for relocation is supposed, then the foundation is not needed.

The use of expanded polystyrene (it is better to purchase extruded PP) with a thickness of 80-100 mm gives good results. Sometimes mineral wool is also used. In the latter case, the installation of insulation should be carried out in the absence of rainfall on the street. Metal racks are thermally insulated using foam insulation strips.

Interior decoration is done by means of a grooved board (width 4-6 cm) from coniferous species. Lumber must be pre-treated with an antiseptic (from decay) and flame retardants (to reduce the combustibility of the tree).

Exterior finish is done through facade plastering, siding. You can use natural wood, but this option will cost more.

A roof from a profile pipe can be an element of the frame or be constructed as a separate structure. The calculation is made taking into account the angle of inclination, type roofing material. Also, specific climatic conditions are taken into account: the amount of snow falling, wind loads.

The foundation can be anything: tape based on reinforced concrete, screw, columnar. If the base is non-capital, then the structure can be transported. The frame is constructed from a profile pipe pre-treated with a primer. This operation will not be needed if a more expensive version of the profile pipes is used, with galvanization or stainless steel. You can connect pipes in one of two ways:

Installation should begin with the installation of vertical racks, which should have a larger cross-section than the horizontal profile. Additionally, the racks are best strengthened by braces. The roof is mounted last. The use of shaped pipes in housing construction will bring the proper effect only if correctly carried out calculations. And if you can mount the frame yourself, then the calculation of the size of the pipes, their number per unit area is best entrusted to a trained specialist.

Timber frame houses have been popular lately, and their materials are diverse.

The main criteria underlying the choice of building materials are sufficient strength, durability, safety for human life, water resistance, heat protection, and high resistance to fires.

The standard option is wireframes. wooden houses. About 85% of residents of European countries and the USA live in frame-type houses with metal profiles. In the regions of Russia, before, the steel frame was used in the construction of production facilities, warehouse hangars and workshops. Today it is most often used in the construction of residential buildings.

The basis of this type of house is completely made of metal. From it the frame of all floors, as well as, is made. The thickness of the profiles used, and their shape for each particular case, is different, because they experience various external loads.

These buildings have certain features:

When building a house on the basis of a steel frame, they are used, and their choice depends on climatic conditions. The metal will not need certain processing and coloring, it is not subject to shrinkage, does not burn and does not decay, and has an extended service life.

When building a house on the basis of a steel frame, they are used, and their choice depends on climatic conditions. The metal will not need certain processing and coloring, it is not subject to shrinkage, does not burn and does not decay, and has an extended service life.

It can be completely disposed of, at the same time, without polluting the environment and saving the forest from deforestation.

A frame house made of metal can be built at any time of the year and in various climatic regions.

Light steel frame technology involves the construction of small facilities. As a rule, frame houses are erected on one or two floors.

For production purposes, these facilities are built 6 meters high, and spans up to 12 meters. Truss trusses with a length of 24 meters will require the installation of special profiles.

Modern technologies are based on the use of lightweight steel structures made of sufficiently thin galvanized steel, which will not yield to the wooden structures of houses. The cross-section of metal profiles is made in the form of letters C, S and Z, and this ensures reliable rigidity of the frame.

Modern technologies are based on the use of lightweight steel structures made of sufficiently thin galvanized steel, which will not yield to the wooden structures of houses. The cross-section of metal profiles is made in the form of letters C, S and Z, and this ensures reliable rigidity of the frame.

By perforating profiles and creating certain air gaps, as well as using metals with different thermal conductivities, the main problem of increased thermal conductivity of the material, which affects the formation of cold bridges and the formation of a certain condensate, has been solved. This technology is called light steel construction. It provides the construction of high-quality houses and allows for the timing of its construction.

Currently, there is a certain bias towards this option of houses. It is believed that a residential frame house made of metal profiles is colder than houses made of wooden beams.

By creating modern technology, this myth is completely destroyed. The profile for the frame of the house is protected from heat transfer by certain heaters. And the space between all frame racks is filled with insulating materials, such as ecowool or. All this will maximize and qualitatively warm the house. It is generally accepted that the wooden base of the house is more environmentally friendly and more attractive than metal. But in fact, wood, having a natural origin, requires additional processing from decay and various insects by impregnation with the use of chemical components and various varnishes, paints and other means. They significantly degrade the ecological cleanliness of wood. And you will need to use this treatment regularly, and this will additionally require financial costs.

By creating modern technology, this myth is completely destroyed. The profile for the frame of the house is protected from heat transfer by certain heaters. And the space between all frame racks is filled with insulating materials, such as ecowool or. All this will maximize and qualitatively warm the house. It is generally accepted that the wooden base of the house is more environmentally friendly and more attractive than metal. But in fact, wood, having a natural origin, requires additional processing from decay and various insects by impregnation with the use of chemical components and various varnishes, paints and other means. They significantly degrade the ecological cleanliness of wood. And you will need to use this treatment regularly, and this will additionally require financial costs.

It is also believed that wooden houses are cheaper than houses built from metal profiles, since wood is less than metal at a cost. In the manufacture of the frame of the house from metal, a smaller amount of material is used than when choosing the basis of wood. The mass of the wooden object is much larger and should be of high quality and the most costly than a lightweight house with a metal skeleton.

Installation and installation of a house using the technology of metal structures is much simpler and much faster. Steel construction can be dangerous from the point of view and can attract lightning in a thunderstorm. But houses of this type are provided with the correct and high-quality grounding of all steel parts. In addition, there is a special, and outside certain dielectric materials, and this allows you to completely insulate the metal elements and parts.

The steel profiles used to create the structures of houses are very light, they provide a certain strength, allowing the use of housing for a long time.  Reliability of metal structures is ensured by special profiles equipped with stiffeners.

Reliability of metal structures is ensured by special profiles equipped with stiffeners.

At release, galvanized steel is used. Coating profiles with zinc protects them from external corrosion. The steel frame is very resistant to external mechanical influences: it does not shrink and crack over time, it is not afraid of any pests, and is fireproof.

In combination with heat-insulating layers of reliable materials, this frame house will allow you to live in it all year round.

The lightweight design of the metal frame and the low weight of the house itself allow you to create, which does not require increased indicators of strength.

The lightweight design of the metal frame and the low weight of the house itself allow you to create, which does not require increased indicators of strength.

For these houses, a shallow foundation is made. The production of the foundation, and the type of construction, for the most part, depends on the nature. Before starting laying the foundation, it is necessary to study all soil indicators at different times of the year.

As a rule, the space between all wall panels filled with foam concrete or aerated concrete. You can use thermal insulation with polyurethane foam. For this, a specific spraying method is used.

The space that we filled should form a special dense layer that holds heat reliably and efficiently. It is necessary to fill with foam all the cavities inside the metal profiles, and all the problem areas. The insulation material must be of high quality and, when solidified, form a dense coating.

The surface of the internal insulated walls must be covered with vapor barrier building material in the form of a film. From the outside of the house, the walls reliably protect from the wind. Recently, heat insulation blocks, including thermal insulation material, are increasingly used for insulation and decoration.

Stone finish

To decorate the frame walls of the house, all common finishing building materials are used.

For their decor, you can use only painting, as well as plaster. The original solution will be a natural stone finish.

Silicate or decorative bricks are also used,.

The cost of a house with a metal skeleton will consist of the cost of the following important indicators:

When buying a particular home assembly, the price will decrease due to the exclusion of an individual development plan. But a standard common project has a certain price. The cost of building materials and work does not exceed the price of houses made of wood.

For example, the cost of a two-story house 6x6 m of panels with rough finish will cost about 700 thousand rubles. If you choose the assembly yourself, you can significantly save.

The construction of frame houses is becoming more common. There are many materials for the manufacture of frames, and some of them allow you to do the construction of a frame house yourself.

So, for example, you can build a house frame from a profiled pipe with your own hands. This material is easy to process, pipes can be cut, bent, fastened together, the technology of these operations is not very complicated, so almost everyone who knows how to do something with their own hands is able to do it.

When building a house, it is necessary to present the final result, for which you need to perform at least a pencil sketch of the project of the future house. This project will help in calculating the required amount of materials that will be needed to erect the frame of the house. You can calculate the number of pipes, their length and cross-section using special calculators that are available on the Internet. At the design stage, it should be considered which of the parts of the future building will be made of pipes.

These elements can be:

Compared to concrete walls, walls on a metal frame has a significantly lower mass. This feature allows you to make a cheaper foundation under such a house, which can be welded from relatively small beams or made block. After the foundation is installed, you can proceed to the direct installation of the frame.

For the construction of a house, you can purchase a finished frame, the release of which is established by some enterprises. In such frames, the developers have provided a simple way to connect different elements of the frame to each other using bolts. But with self-made the frame, this connection method is not suitable, in this case you will have to use welding.

Welding of individual elements of the frame must be carried out carefully, otherwise the finished structure may not last long. You should also pay attention to the correct position of the elements to be welded: vertical racks should be strictly vertical, and horizontal racks strictly horizontal, their position in space should be checked by level.

Also, to exclude possible surprises, it is better to install the structure directly at the location of the future home.

Installation of a house frame from a profiled pipe can be divided into several stages:

Those parts of the frame that will bear the main load should be made of pipes of large cross section and with a large wall thickness. These elements include the lower harness and the uprights. As for the struts, the requirements for them are lower, so they can be made from pipes of a small cross section.

Logs designed for flooring and floors must not be mounted at a great distance from each other, maximum - 60 centimeters. If this distance is exceeded, the floor and floors will bend too much.

Installation of the frame of the house ends with the installation of rafters for the roof. Depending on what materials it is planned to cover the roof, the direct method of mounting the roof itself is chosen: separately or as a continuation of the house frame.

If the project provides for lightweight materials for roofing, then materials for rafters can be selected with a small section and thickness. In this case, all the rafters can be mounted separately, and then with the help of lifting equipment the resulting structure can be lifted and connected by welding to the main frame of the house.

In the event that it is planned to make roof ceilings from materials having a large mass, then the entire roof structure will turn out to be heavy and bulky, which means if it is welded separately, not every crane will be able to lift it up the top of the wall frame, so it is better to separate roof elements immediately mount on the frame of the house.

For the main elements of the roof - mauerlatto which the remaining elements of the roof structure will be attached - you should choose a powerful channel, all other structures, such as rafters and skate supports, can be made from a profiled pipe.

As you know, metal is a good conductor of heat. Therefore, in cold weather, it can remove heat from the inside of the house to the street if the insulation of the house was improperly done. Therefore, at the end of construction, the house must be carefully insulated, and for the insulation of racks, you can additionally use penoizol.

A metal frame frame house is a more reliable and durable construction. Such buildings will have a high level of sound and thermal insulation. It is worth noting that metal products replaced wood, which has a number of disadvantages, including exposure to atmospheric precipitation and decay processes. In our article, we will examine in more detail the features of a metal profile, and how to make it yourself.

If you use a metal profile of galvanized type, then due to its special design, you can increase the level of thermal and sound insulation of the frame. Plus, it should be noted such advantages:

The use of a metal profile will speed up the construction process, while reducing financial costs for work. This option is ideal for you if you are looking for a practical and economical material for the frame.

The main part of the metal frame can be considered a transverse frame formed by columns and trusses. These products are connected to the base of the building. The load volume is distributed to the fulcrum. The main amount of pressure falls precisely on the first element. The column is affected by the mass of all elements, the load from the wind and atmospheric precipitation.

Attention! The amount of load obtained from the coating and bonding between the columns is transported to the devices of the truss trusses having a lattice design.

Frame houses made of metal profile include the following elements:

Attention! You can create the spatial rigidity of the frame from a metal profile with your own hands by creating a system of frames, columns and trusses.

You can create a frame of a house from a profile pipe with your own hands in a frame and truss structure. The first type is characterized by the presence of I-beams made of steel, which bind at the corners, forming a frame. In such a system, the frame is installed from vertically placed support posts, and horizontally placed crossbars. Such a device takes the load from the ceiling of the building.

Frame house metal frame, which is made from truss beams, consists of steel rods forming a triangle shape. Such a system is formed using half-timbered panels or fields. Such fields form farms that serve as the roof of the base. They are attached to steel racks using a welding machine or bolts.

The disadvantage of a metal profile house is the need for additional thermal and steam insulation. In this case, insulation is necessary to do the insulation not only of the frame structure, but also the walls inside the building. This action will help block the bridges of cold.

At this stage, it is better to use modern materials, such as mineral wool or polystyrene. Such products can provide an optimum level of temperature to maintain indoor comfort.

When creating a house with a frame structure with your own hands, it is best to use a profile pipe. At first glance, installation work will seem easy, but such a design has a complex layout. The first thing to consider is the need for a foundation for the building.

Attention! A frame house can be built without a foundation, but this option is rational to use if in the future the building will be transported to another locality. Such buildings can be greenhouses or hotbeds.

Frame elements are created in this way:

To decorate the exterior, you can use siding or special plaster. If income allows you, the facade can be finished with natural types of wood. So, we examined the features of a frame house made of metal. This construction option has optimal strength and quality.