Of the many questions and topics that are asked to tarot cards, not a small one ...

Company "Reinforced Concrete Slabs" produces prefabricated reinforced concrete floor slabs at competitive prices in Moscow, according to established standards and to order. They come in a certain type and size, so when creating a plan for any concrete structure where precast floor slabs are used, their type and standard dimensions must be taken into account. Prefabricated floors have great advantages than monolithic ones:

Quick installation;

. possibility of installation under any weather conditions;

. lower cost (by 10-15%).

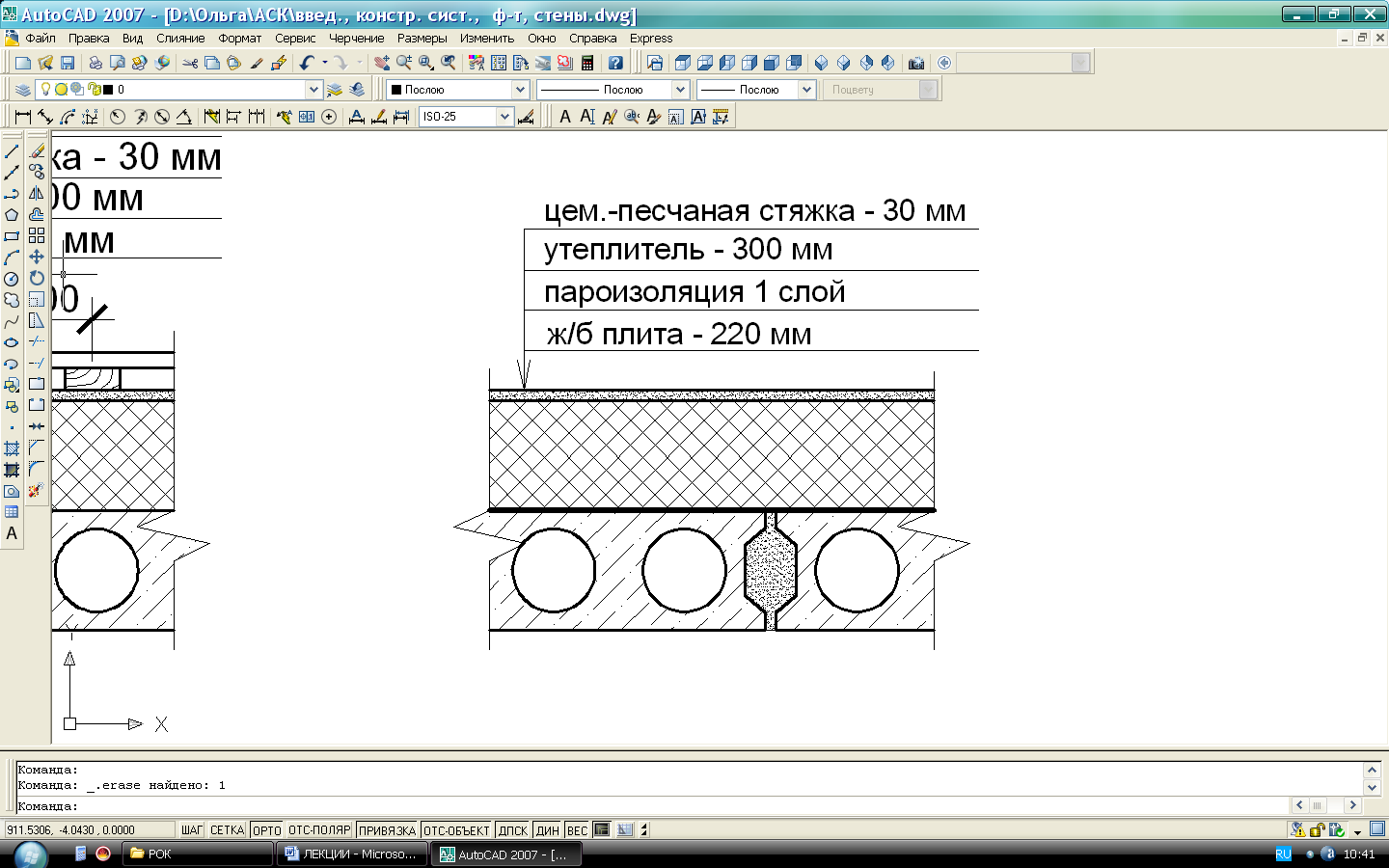

The disadvantage of prefabricated reinforced concrete slabs (as well as other precast concrete) is a rather high weight, which significantly limits their scope in construction. The thickness of reinforced concrete slabs used to cover the floors varies from 140 to 220 mm, and the length depends on the length of the span (up to 9 m). Prefabricated concrete floors are divided into 3 types:

. solid (inside without voids);

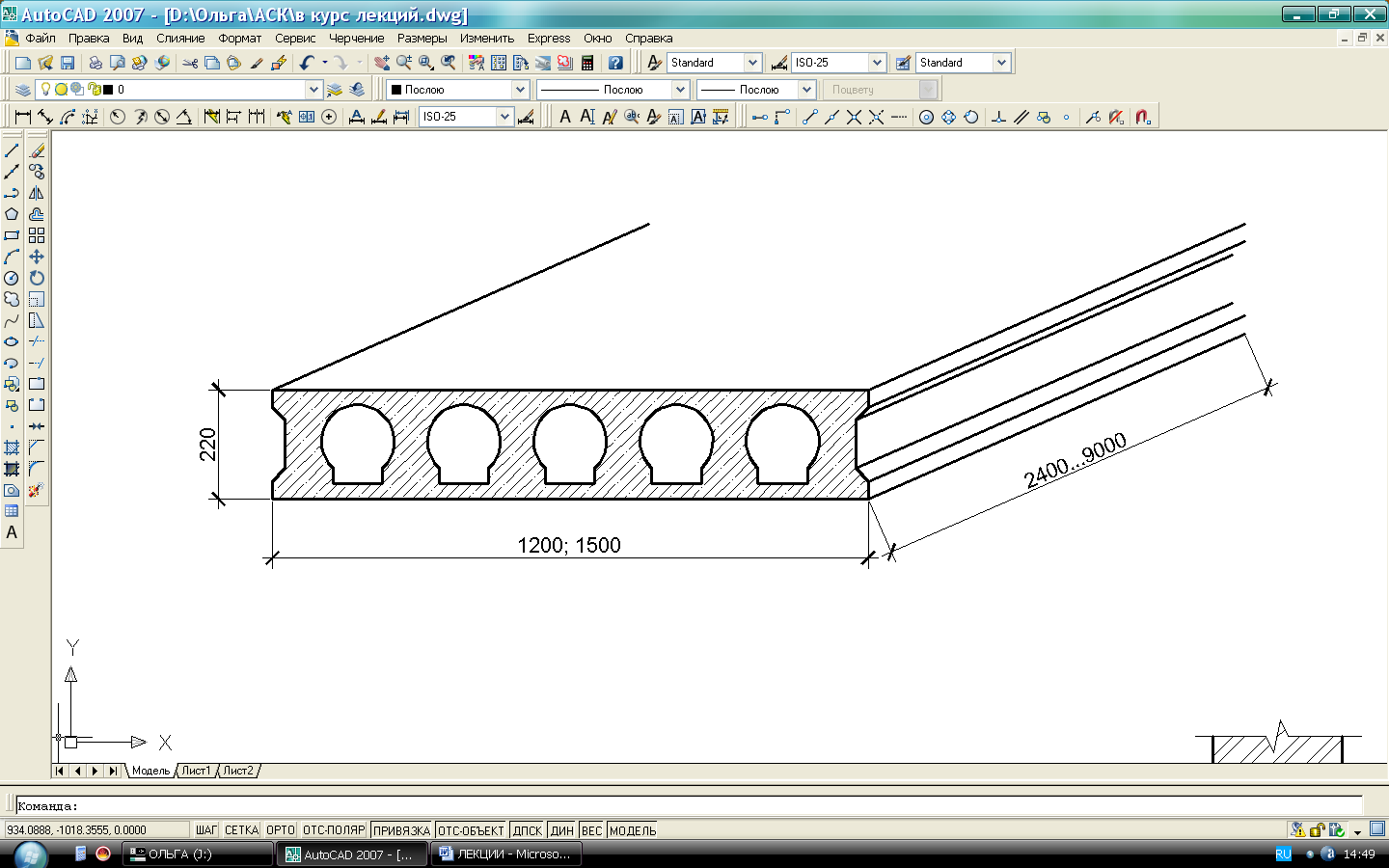

. hollow (they have longitudinal parallel voids inside, most often round, less often of a different shape, thickness - 220 mm);

. tented (they look like a tray with ribs up or down, thickness - 140-160 mm).

Solid (solid) reinforced concrete prefabricated slabs are characterized by high strength. They are added to the construction plan of a high-rise building in order to create floors between floors. Their disadvantage is that they are smaller than hollow slabs sound and heat insulation. Another distinguishing feature is their very large weight.

Hollow core slabs are the most common precast slabs in construction. They have very good insulating properties. Due to the peculiarities of their design, such slabs greatly facilitate the pressure on the foundation and load-bearing walls of the building.

Production is carried out in accordance with all the criteria and standards of GOST.

- 100% quality assurance of products, which is confirmed by all the necessary certificates.

- We cooperate taking into account the individual characteristics of each customer.

- Affordable prices, thanks to our own production.

- Prompt and careful delivery of our products throughout Russia.

Reinforced concrete floors are the most reliable and durable, therefore they are widely used in civil engineering.

Currently, the following types of reinforced concrete slabs are produced:

1.Overlappings with round voids

2. Ceilings with vertical voids

3.Overlappings with oval voids (economical, but time-consuming)

4. Tent

5. Ribbed cover

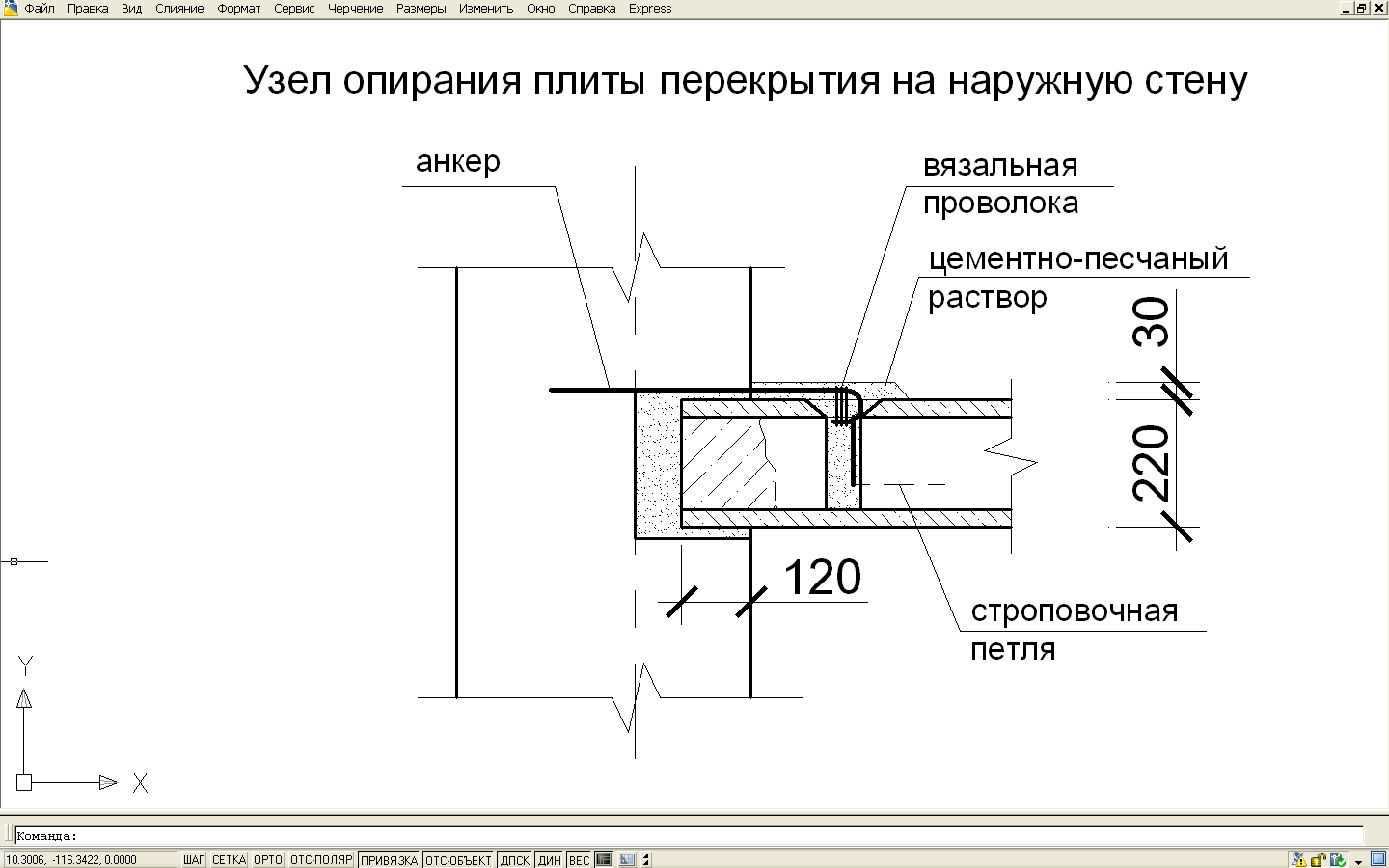

Multi-hollow reinforced concrete slabs are laid on load-bearing walls along a layer of mortar. The seams between the floor slabs are covered with M100 cement mortar or heavy concrete, thus forming a rigid monolithic floor disk.

To ensure spatial rigidity, the slabs are anchored to the outer walls and to each other.

Floor slabs rest on a brick wall by 100…200 mm. On a wall built from blocks, floor slabs are supported by 120 mm.

Features of design solutions

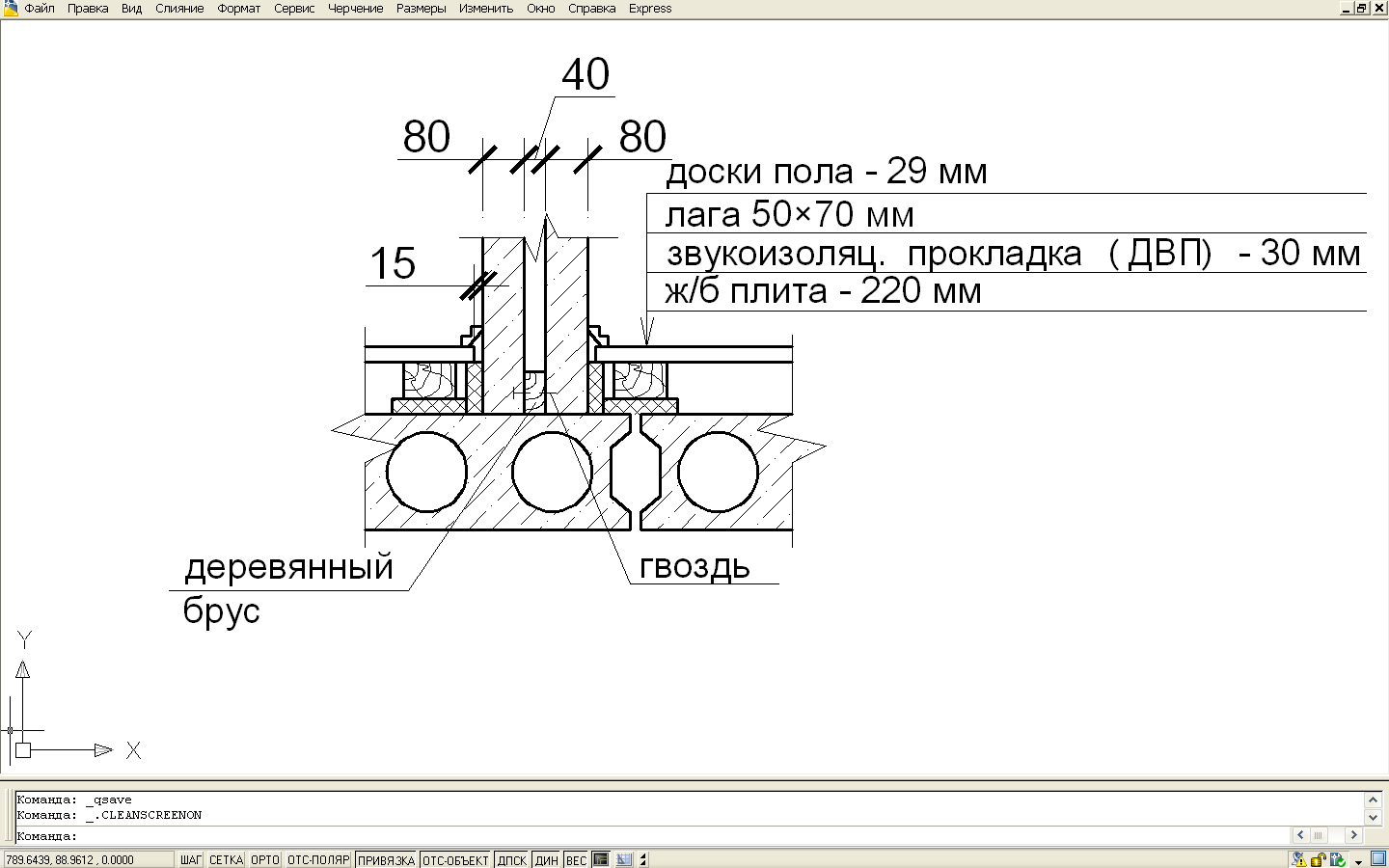

Interfloor floors with plank flooring

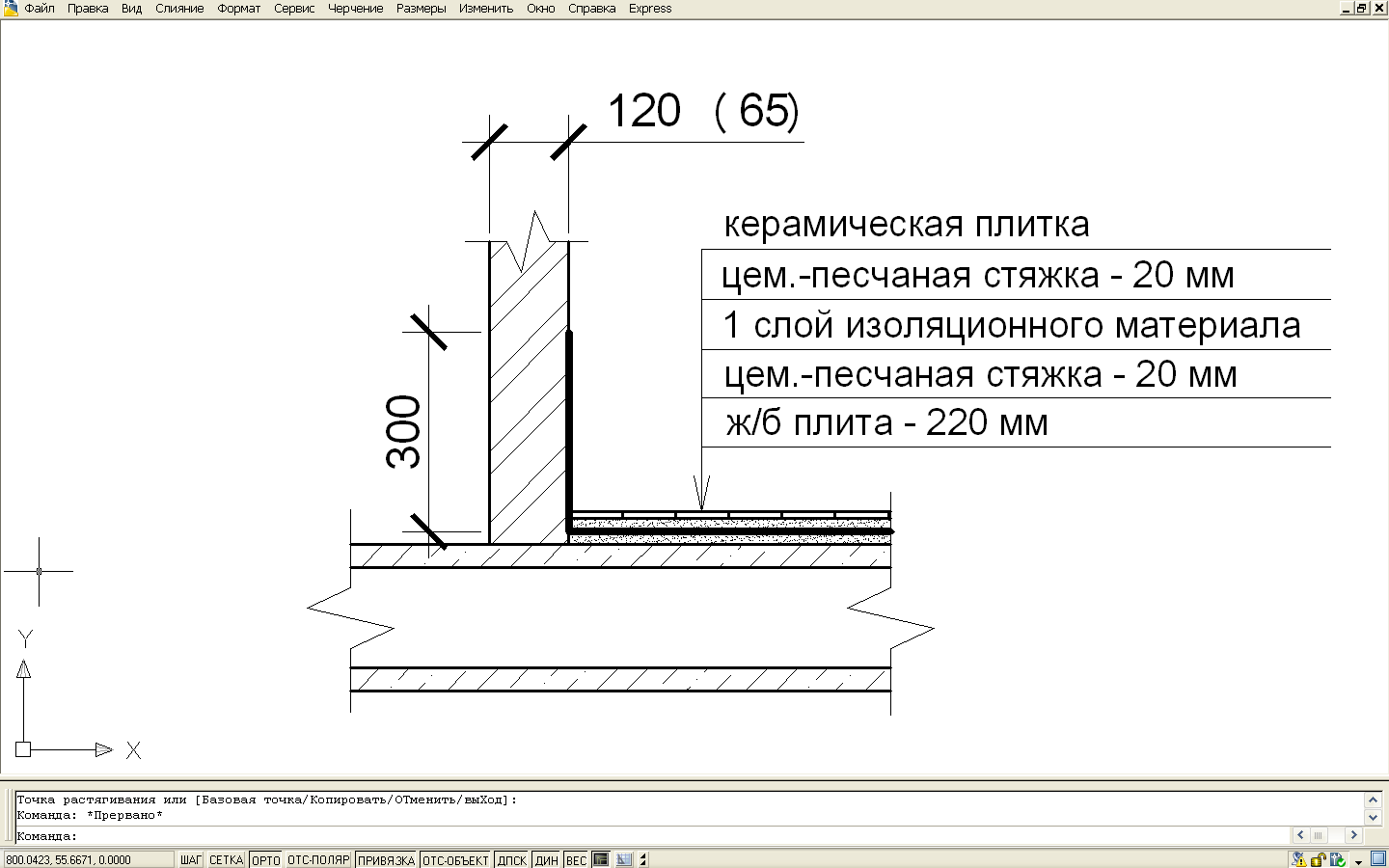

Covers in bathrooms

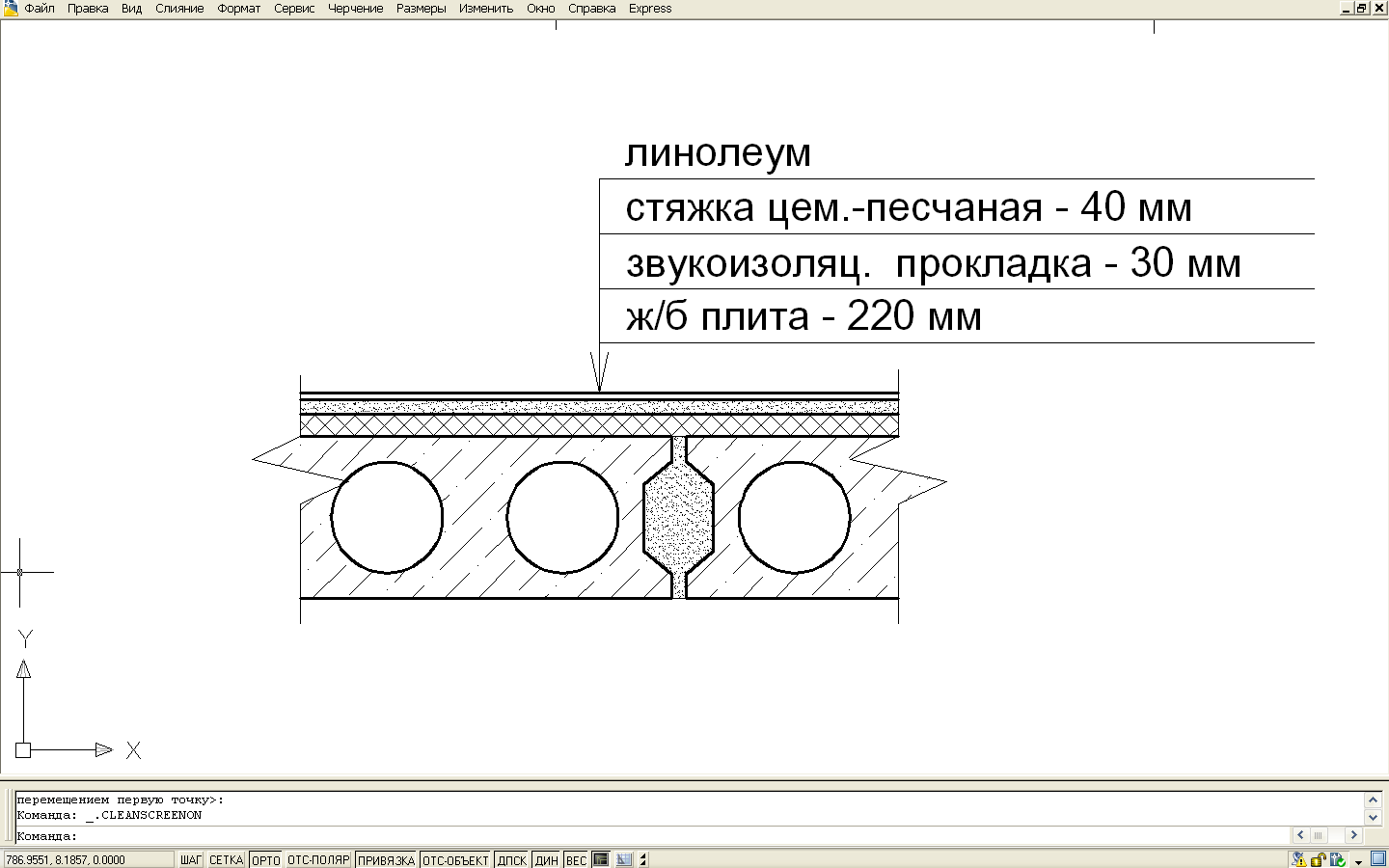

Linoleum flooring device

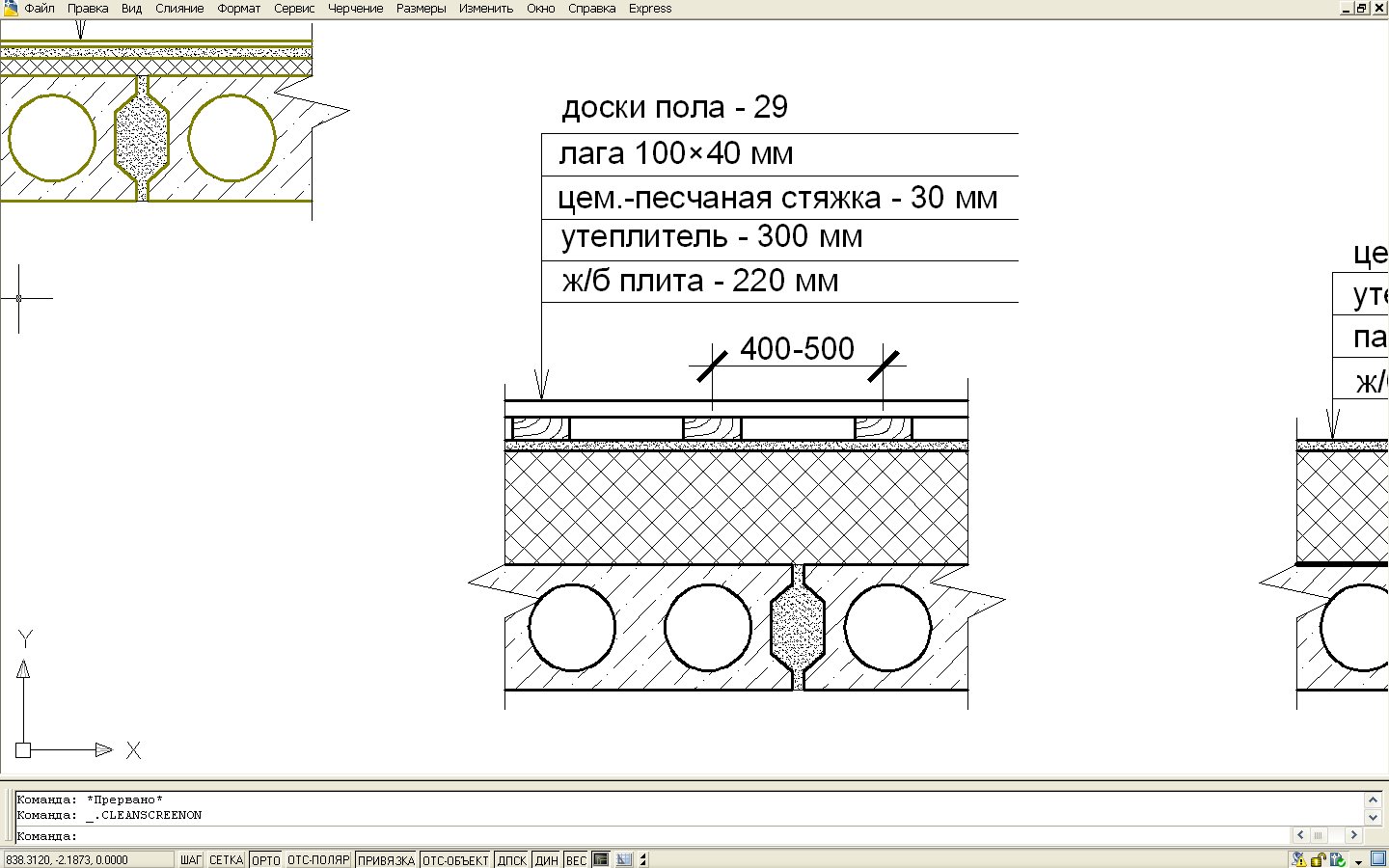

Ceiling over basement

Attic floor

Screed- a layer that serves to level the surface of the underlying layer or to create the desired slope. Material: cement-sand mortar, asphalt, gypsum concrete, fine-grained concrete, expanded clay, self-leveling screed, polylix mortar, ceresit c#72 (with rigid insulation) thickness 110 mm.

insulation(thickness is taken from the heat engineering calculation):

bulk material (expanded clay, slag)

slab (gas silicate, mineral wool plates "Izover", "Parok", fiberglass URSA, expanded polystyrene)

vapor barrier- under a layer of insulation serves to protect it from vapors and condensate (“polymix GS” 2-3 layers, mastic “Autocrin”, glassine P-300, P-350, roofing material RKP-350, roofing elast G-PKh_BE_PP / PP-3, 0, bikrost ST-200). Fitted from the side of a warm room.

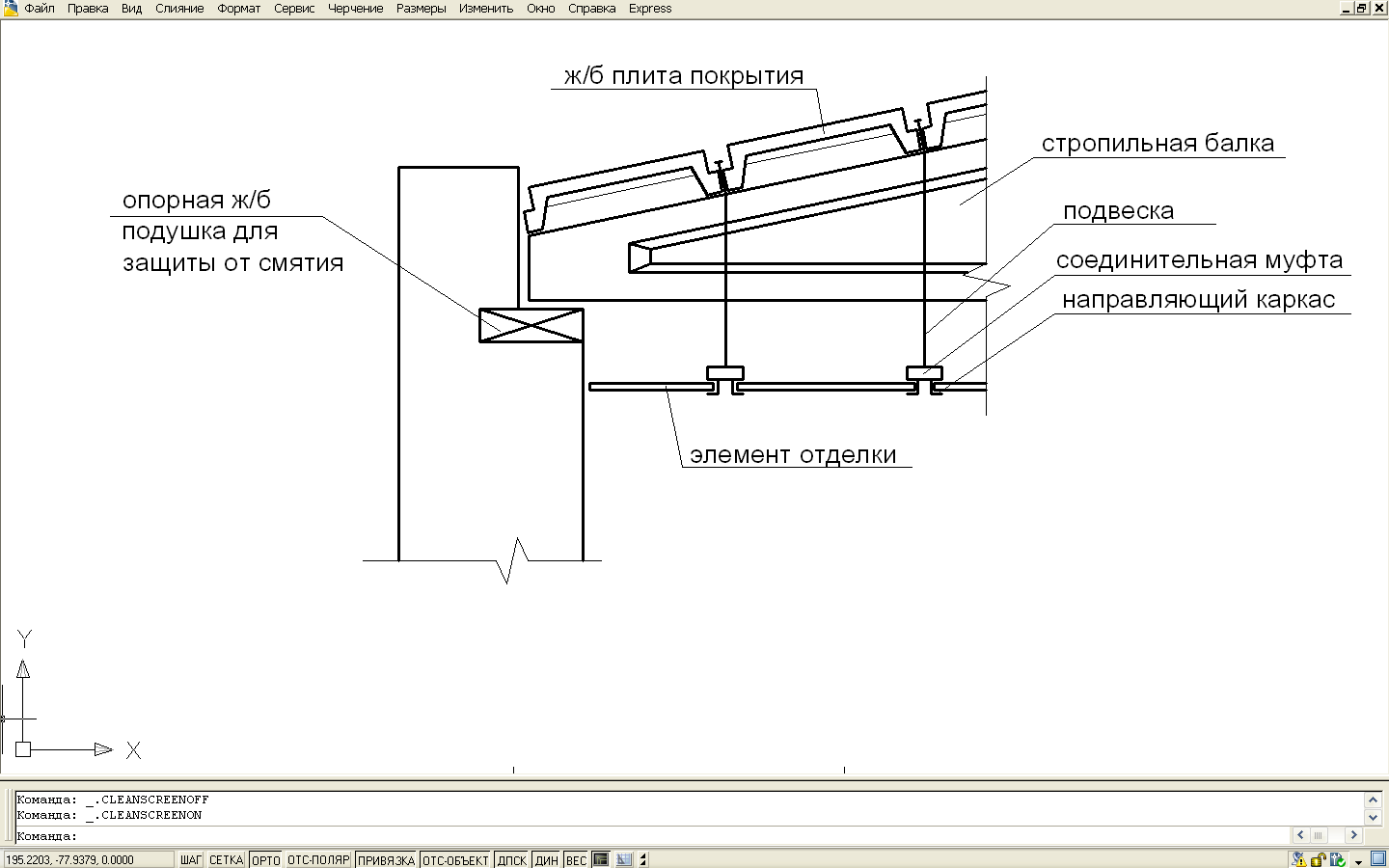

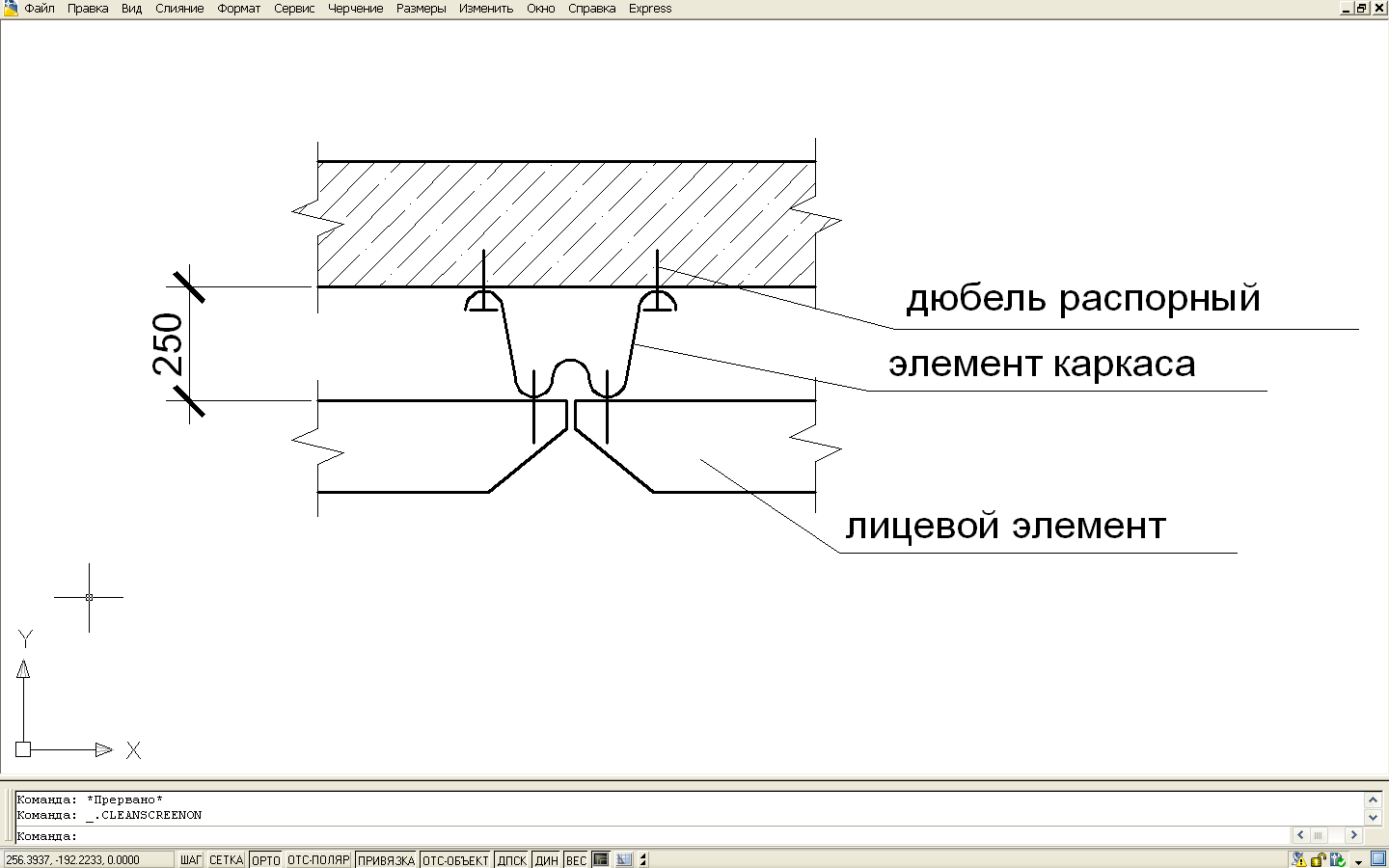

Suspended ceiling- element interior decoration public and residential buildings.

The use of suspended ceilings is necessary to hide engineering networks and equipment located under the ceiling, to improve the acoustic qualities of the room, the decorative properties of the room, etc.

The main elements of suspended ceilings:

bearing part;

front element.

The bearing part consists of a frame, hangers, fastening and regulation parts.

Depending on the purpose of the premises, suspended ceilings are designed in 2 types: through passage impassable.

Walk-through suspended ceilings are accepted in buildings with large spans covered by trusses with an accessible height of the inter-truss space for passage.

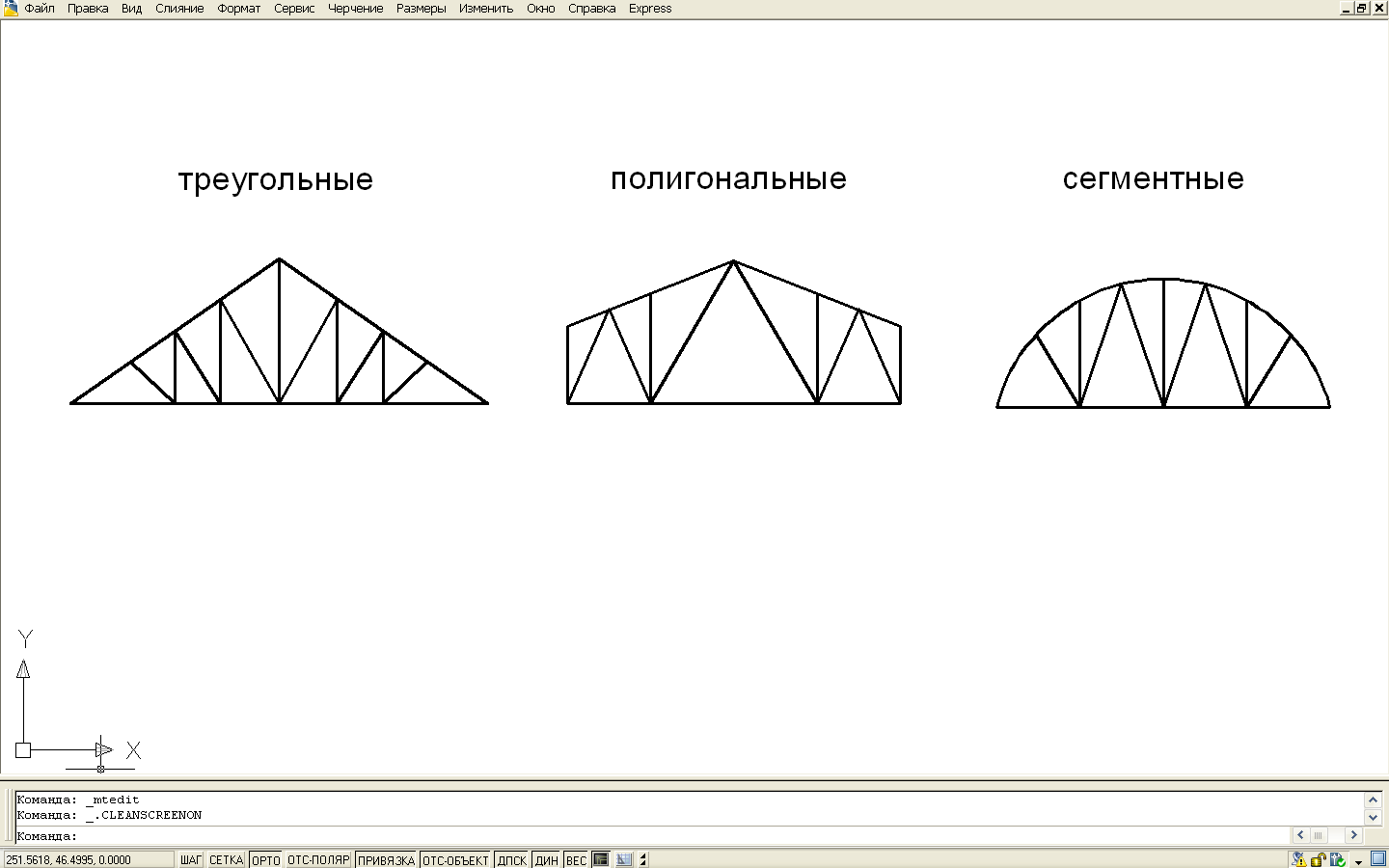

According to the geometric scheme of the farm, there are:

Ribbed slabs are laid along the trusses.

The design of the suspended ceiling

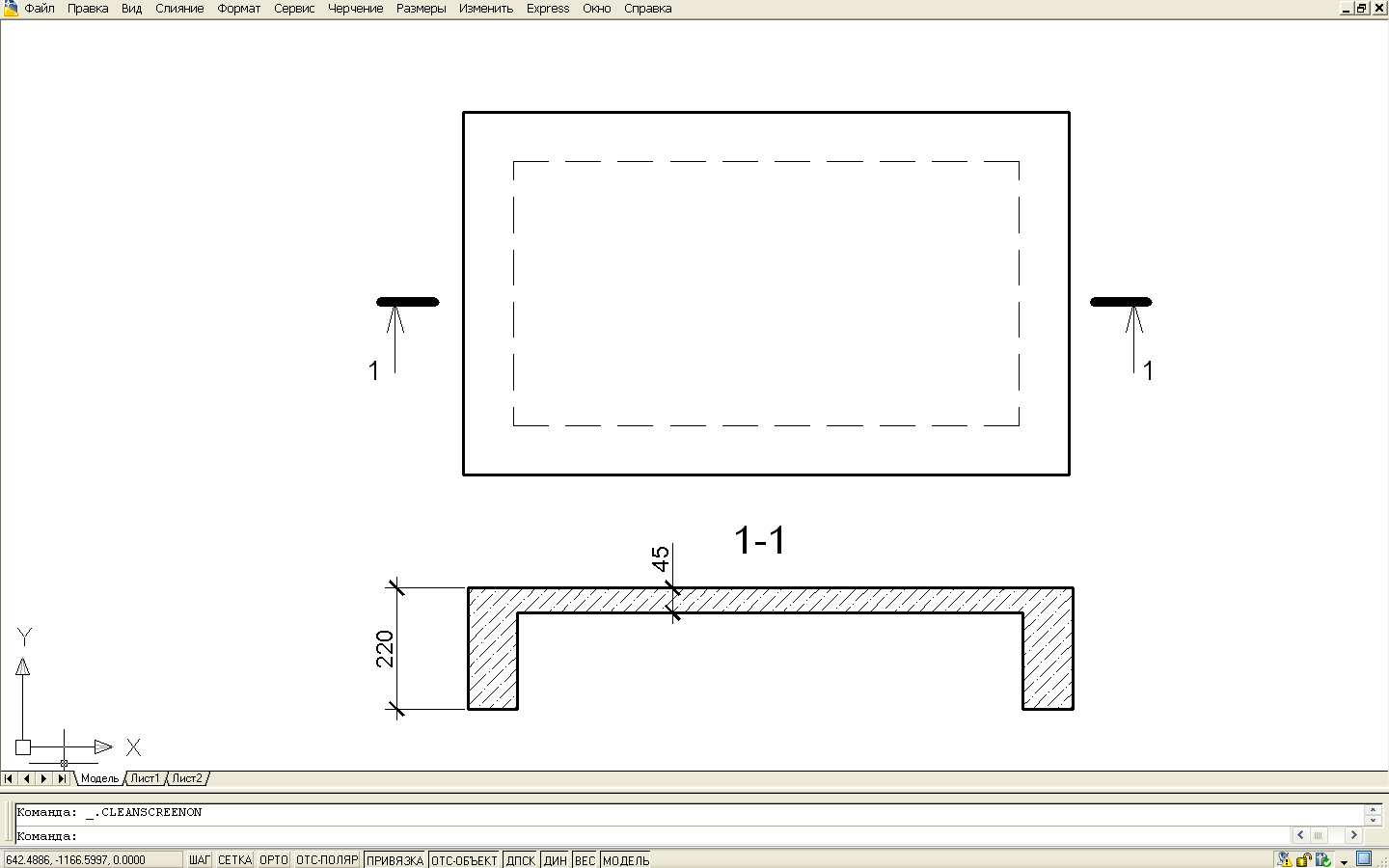

Impassable suspended ceilings are used in residential and public buildings with a low height of the premises. Ceilings are suspended below the ceiling 250-450mm, suspension pitch 1200-1500mm. For lighter pitch 2000-2200 mm. Hangers are made of galvanized steel and can be flexible and rigid.

Suspended ceilings are also used, in which there are no suspensions and the front element is located 250 mm from the covering panel.

Stretch ceiling They are a thin film or fabric stretched over a special frame called a "baguette", which is fixed either on the base ceiling or along the perimeter of the walls under the ceiling. The ceiling surface is perfectly flat and looks like a solid ceiling.

Advantages of a stretch ceiling:

Hiding the irregularities of the base ceiling;

Hiding in the interceiling space of insulating or acoustic materials;

Moisture resistance, chemical resistance;

Ease of dismantling;

Device in premises of any configuration, at any slope (creation of arches, tents, etc.)

The distance from the base ceiling is arbitrary, allows you to install built-in lights; minimum distance 25…30 mm. The thickness of the PVC film is 0.15…0.35 mm, the width is 1.3…2.2 m. The seams are joined by welding.

Stretch ceilings are attached along the perimeter to the walls, and sometimes to the main ceiling, at a selected height, using a fixing and suspension device specially designed for this purpose and equipped with a control interlock.

The main element of the stretch ceiling is baguette- fixing profile. The main function of the baguette is to ensure the fastening of the stretch ceiling while maintaining its tension. The baguette for fixing along the perimeter consists of a PVC profile or an aluminum profile.

The baguette is equipped with a pressure compensation system, which ensures good ventilation of the space between the ceilings (with the exception of aluminum profiles). Air regulators allow you to maintain a good microclimate under the ceiling.

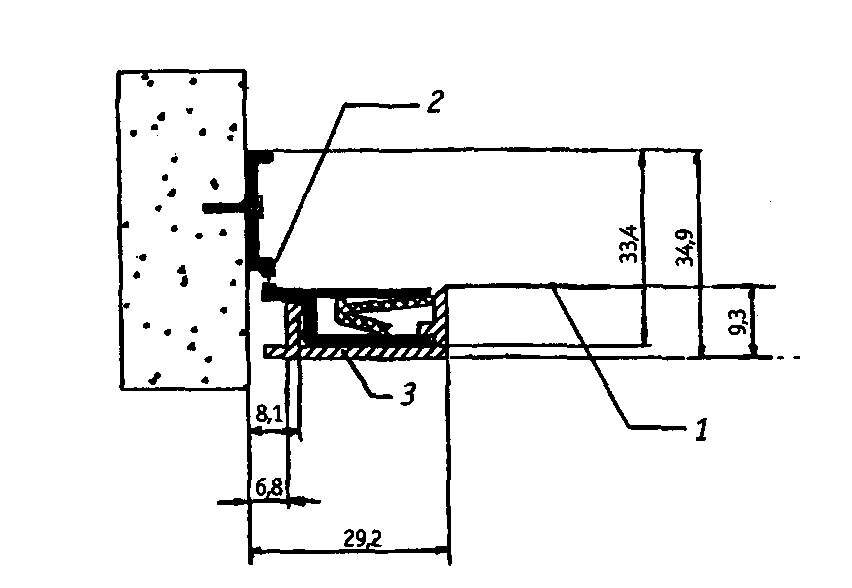

Plastic wall molding with lining Ceiling molding with lining

1 - stretch ceiling; 1 - stretch ceiling;

2 - ventilation holes; 2 - harpoon;

3 - overlay 3 - overlay

For fastening the stretch ceiling canvas to the baguette is used harpoon- This is a semi-rigid profile that is welded around the perimeter of the ceiling.

Stretch ceilings are easily dismantled using a special mounting spatula.

The presented structures are assembled from reinforced concrete slabs, which are manufactured at specialized factories. They are one of the types of floors that do not contain beams. Plates or panels in this case are stacked tightly to each other, and the gaps between them are then sealed.

In this form, they bear the entire burden placed on them. At the same time, during laying, it is necessary to strictly observe the level of the plates. The plates can be connected to each other using steel anchors. They are fixed in special metal loops.

Since they are manufactured in the factory, and only then brought to construction site and they are mounted there, this greatly facilitates the work of builders who do not have to pour such plates directly at the construction site. Moreover, they often have a higher quality than those prepared directly at the construction site.

Precast concrete floor slabs are usually made with cylindrical voids inside, and can be presented in the form of solid panels. The first type of slab is poured from a mixture of lightweight concrete, and the second is a block with a large number of round holes that make the slabs lighter.

They are made taking into account the bearing capacity of the floor, as well as depending on the desired span. It is best to use these types of structures in brick houses in private construction. And speaking more concretely, such slabs cover the basement or basement floor.

Such types of structures have an undoubted advantage: they are not afraid of moisture and dampness, therefore they do not rot and do not corrode. Moreover, after laying the floor, it is very easy to finish it. However, installation requires minimal amount time, and there is no need to wait for the shrinkage of the plates, so finishing work can be done immediately.

It is also necessary to pay attention to the relatively cheap cost of reinforced concrete slabs, because expensive materials are not needed for their manufacture. In addition, concrete is not subject to combustion and deformation. Another advantage is the qualitative variety of construction in terms of thickness, shape and size.

However, these reinforced concrete structures also have their drawbacks - for example, the need for special lifting equipment for installation, since the slabs are quite heavy. Naturally, in this case, additional funds for transportation are required. Still have to calculate the possibilities bearing walls to prevent their destruction under the weight of the overlap.

As for the variety of structures, reinforced concrete prefabricated slabs can be welded or knitted. The fact is that to enhance the strength of the plate, metal reinforcement is used, which is fastened together in several ways.

Welded are usually made by welding a frame of reinforcing bars. For this, point or arc technology is used. The best option is still contact-spot, which uses a semi-automatic welding method, and the quality of the process is constantly monitored. Moreover, both horizontal and vertical reinforcement bars are used.

Knitted frame is a more complex option. For its assembly, already bent rods are used, which are interconnected with a soft but strong wire.

Reinforced concrete floors usually have a thickness of 6 to 10 cm, and the dimensions of their area may be different, depending on the span. All these parameters should be determined at the design stage, correctly calculating the load on the foundation and supporting structures.

The use of scientific and technical innovations is especially noticeable in construction - structures appear in different regions of the planet, the construction of which would have been unthinkable some time ago.

New materials, new machines and tools make it possible to build faster, higher and more reliably. But there are elements in construction technology that do not lose their relevance very much. for a long time. Such is the reinforced concrete slab - the principle was invented a century and a half ago, but the most futuristic projects cannot do without it.

Many people know the story of the French gardener Joseph Monnier, who reinforced a thin-walled concrete barrel he made with a frame of metal rods and covered it with a layer of cement mortar. The resulting monolithic product had properties unattainable for other materials. Monnier patented in different countries methods for the production of various structures from reinforced concrete, including a reinforced concrete slab for walls and partitions.

Professional builders made their own amendments to the inventor's developments: he placed the reinforcement exactly in the middle of the concrete layer, and the calculations showed that the location of the reinforcement cage should be chosen based on the specific situation, taking into account the loads acting on this structural unit. So, it is more logical to reinforce horizontal reinforced concrete slabs by placing the rods closer to the lower plane of the slab, where the greatest tensile forces are.

Today, reinforced concrete is given the properties necessary for the most exclusive situations. Strength elements - reinforcing cages - can be spatial and flat; prestressed (string, beam) reinforced concrete with improved structural qualities has appeared. Various additives in concrete slow down or accelerate setting and gaining strength. Reinforced concrete is widely used in the construction of both unique, single objects, and mass, economical buildings.

Manufacturability, strength, durability, moisture, bio- and fire resistance, economy - these advantages will determine the use of reinforced concrete in the future. Monolithic reinforced concrete slabs or those made for prefabricated housing construction will be in demand for a very long time, because, among other things, consisting of natural components, these structures are environmentally friendly and easily recyclable and reusable.

According to the place of application, foundation, road and floor slabs are distinguished. Such a product can be manufactured in the factory, then delivered to the construction site and mounted. Most often, a reinforced concrete slab, like other prefabricated housing construction products, is fixed by welding using embedded metal parts.

The plate can be made on site. A monolithic slab, both for the foundation and for the installation of intermediate floors and roof coverings, is especially often used in objects of non-standard architecture or where it is difficult to use cranes necessary for the installation of precast concrete products. The market offers a sufficient number of devices (including formwork) that make this process accessible for self-construction.

This construction of the base under the building is not the cheapest option, but often the most logical. A monolithic reinforced concrete slab, repeating in terms of the outline of all the outer walls of the first floor, is often called a floating foundation. This means that the load from individual parts of the building is transferred to the ground base evenly, the slab works as a single element, it is not subject to deformation due to heaving soil, large freezing depths or high groundwater. Of course, this is all valid for a foundation slab made with proper quality.

An important and rather costly stage in the construction of such a foundation from all points of view is the preparation of a sandy base, on which the slab will be cast. It is necessary to perform a certain amount of excavation work, to fill up and compact the sand - spilling water or tamping.

The bottom layer is usually rolled geotextile, which prevents the solution from seeping into the ground. Then concrete leveling preparation for waterproofing is done. After hardening of this layer, roll waterproofing is rolled out with overlap and gluing.

Reinforcement is a device of two interconnected mesh layers. The reinforcing bars of the lower layer are installed in special clamps so that it is deepened into the concrete layer. It is convenient to carry out concreting directly from the automixer along the tray, concrete pump, etc. After the prescribed period of curing, the reinforced concrete foundation slab is ready for the construction of the house.

AT low-rise construction such a floor slab, cast in the formwork in place, is used very often. There are specific prerequisites for this. Except common for reinforced concrete positive qualities- strength, fire resistance, uniform distribution of perceived loads - there are specific advantages when choosing this technology. The main ones are the absence of the need for heavy construction equipment and the possibility of arranging a ceiling of any shape in plan.

It is better to entrust the calculation of the required thickness of the slab and the scheme of its reinforcement to specialists. Otherwise, you need to know the following. The slab is made no thinner than 150 mm, while the thickness of the floor slab is determined based on the length of the opening to be covered, in the ratio range of 1:30 - 1:35. When reinforcing, it is necessary to remember about strengthening the edge of the slab with U-shaped and L-shaped brackets.

There are many options for reusable formwork for monolithic slabs on the market. But buying it for an amateur builder is too expensive. Although there are opportunities to rent such professional equipment, and this would be the best option- a guarantee of speed and quality of the overlap device. In any case, it is much more convenient to use it as a support than boards or bars, because it is very important to set the formwork along the level.

Concreting must be carried out in one step, with compaction and vibration of the mixture. The concrete should be moistened by spraying for the first three days to avoid cracking from uneven drying.

The construction of buildings from reinforced concrete products made on special factory lines is considered the most suitable for mass multi-storey housing construction. But even for small-sized cottages, prefabricated floor slabs are quite a suitable option. Reinforced concrete prefabricated slabs are a cheaper option for flooring, they can be mounted in any weather, and the installation speed is much higher.

The use of a prefabricated floor is hindered by the large weight that reinforced concrete slabs have. Their dimensions are standard - this should be taken into account at the design stage. Another problem is the need to use a crane even for a small floor area.

Solid, full-bodied slabs are used for special structures and assemblies: as additional elements or for arranging channels for laying communications. They are distinguished by high strength and high weight.

Slabs with round or arcuate longitudinal voids are lighter and have better sound and heat insulating characteristics. Reinforced concrete multi-hollow slabs are the most used type of products for prefabricated ceilings. They are used for buildings with a power reinforced concrete frame, panel housing construction, brick walls etc. Voids can be used for laying cables for various purposes - electrical, low-current.

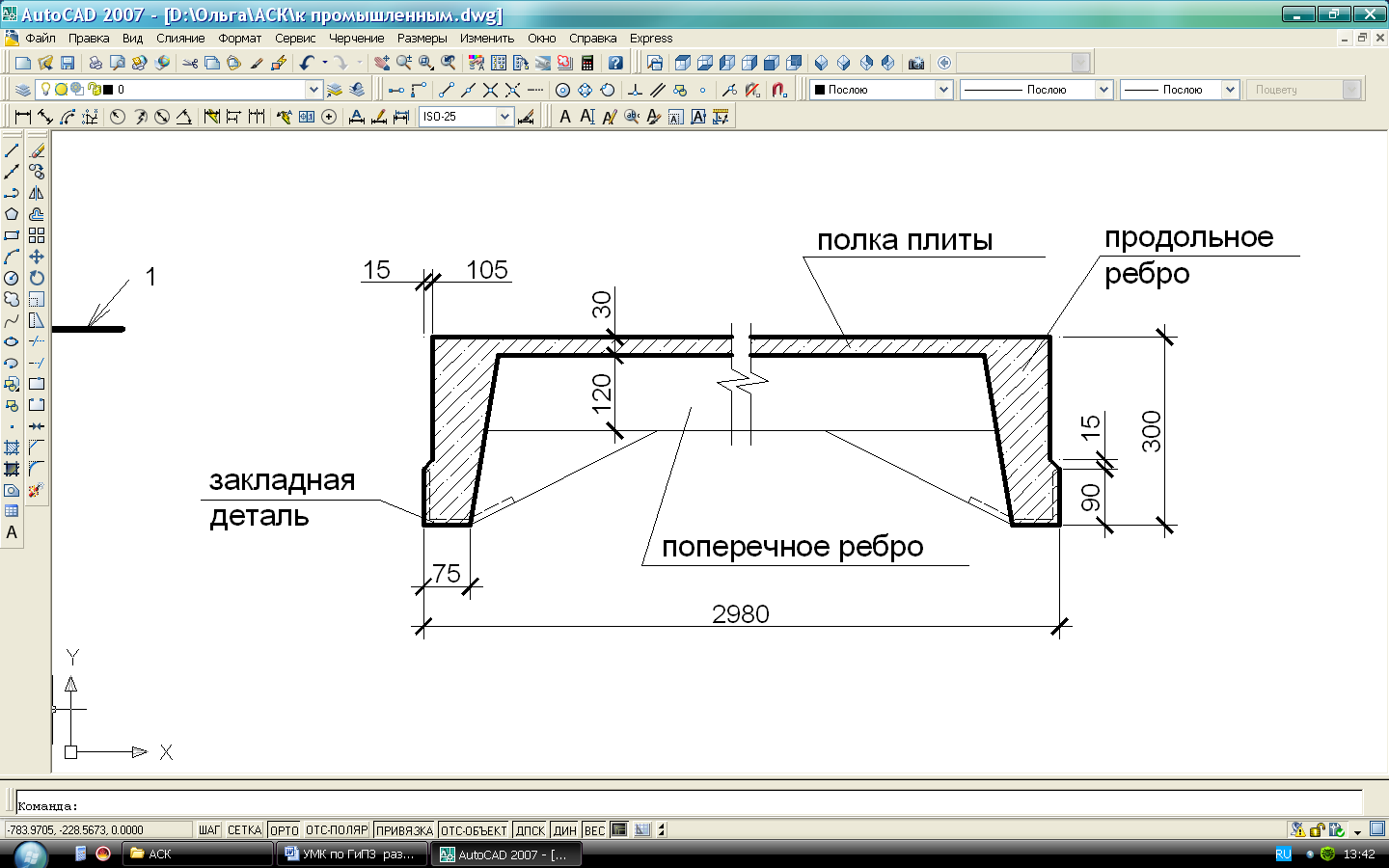

The third type is ribbed or tented, more often used in industrial construction to cover large spans. The thickness of the floor slab without taking into account the power ribs is 140-160 mm.

For the production of floor slabs, prestressed reinforcement is used, which makes their strength indicators similar to those of monolithic reinforced concrete floors.

The use of prefabricated hollow flooring should be envisaged at the design stage of the future house. The standard dimensions of the slabs can be a determining factor in the development of the layout of the future home. A floor that requires slabs of non-standard shapes or sizes can be too expensive.

Therefore, the design should provide for the use of standard formats: the thickness of the slab is 220 mm, the width is 1, 1.2 and 1.5 m, and the length is from 2.4 to 9 m, a multiple of 100 mm.

Two main methods are used in the production of hollow core slabs. One is more traditional, using reusable formwork molds to produce slabs of a fixed, standardized size. After installing the reinforcement and elements that form voids, the mold is filled with a concrete mixture and heated in order to accelerate the process of concrete hardening and gaining strength. The reinforced concrete slabs obtained in this way, GOST 9561-91 prescribes to be marked with the letters PK.

With another - more progressive - the plate is stretched on stands, on a heated track in the form of a continuous tape 100-200 m long using a special molding machine. Prestressed reinforcement has the form of stretched required section. When the mixture reaches a certain degree of strength, the tape is cut with a diamond tool into sections of the desired length and even at the required angle. Reinforced concrete slabs are obtained, the price of which is 20% lower than that of products of the usual - cassette - production method. Such plates are marked with PB symbols.

Hollow core slab designations have several alphanumeric character groups. They mean the type, length and width in decimeters, design load (in kPa), type and class of reinforcement. Example: PK 63-12-8-ATV - a plate with round voids 63 dm long, 12 dm wide, allowable load - 800 kg per m 2, AtV - type of prestressing reinforcement.

The quality of a prefabricated floor made of hollow-core slabs directly depends on the correct preparation for installation, on the careful and accurate installation of the slabs with constant monitoring of the process using a measuring tool.

It is possible to ensure the reliability of the structure only if the unit for supporting the slab on walls or columns is correctly performed. The optimal depth of such support is selected based on the design of the wall, the material from which the supporting structures are made. For example, 70 mm of slab support is sufficient for metal beams, 75 mm for reinforced concrete crossbars, and 90 mm for a brick wall.

For walls where elements with a low bearing capacity are used as a material - lightweight concrete blocks, gas silicate or polymer concrete panels, most often professionals recommend creating a reinforcement in the form of reinforced concrete armored belts on top, on which the floor slabs will rest.

The professionalism of the builders is clearly expressed during the installation of prefabricated ceilings. If the fastening of floor slabs by welding embedded parts to each other occurs using not unitary parts, but random waste of reinforcement, you should be wary, the risk of destruction of the entire building structure is too high.

A product called a plate is a parallelepiped with overall dimensions, in which the thickness is much less than the length or width. This fully applies to road slabs. They are applied to the device of a firm covering of roads or airfield runways. Such a coating can be permanent or temporary, i.e. these slabs can be used several times, and this is one of the advantages of the technology. The calculation of a reinforced concrete slab is carried out based on the area of application, the planned load on the coating and the service life.

When laying road slabs, it is very important to perform the necessary preparation of the base with high quality - usually these are layers of crushed stone and gravel, as well as a sand cushion of the required thickness and density.

There are road and airfield slabs, for permanent and temporary coverage. They differ in the thickness of the product and the type of reinforcement used in its manufacture. All these data are reflected in the marking applied to the plates.

Example: 1P30.18-30AV - reinforced concrete slabs, dimensions - 3000x1750 mm, for permanent coverage (2P - for temporary), designed for a car weighing 30 tons, class AB reinforcing steel was used.

A well-designed design stage will help you choose the right option for the design of the foundation, walls, ceilings or pavement of roads and runways. Modern precast concrete plants offer a wide range of prefabricated parts for the most specific tasks in the construction process.

It is quite real to buy reinforced concrete slabs, the price of which will be quite reasonable, and the quality will meet the norms and standards.