From internal pipelines, drains are transported by external ...

The place where the gas stove or other equipment is installed should be provided for by the design of the house and apartment. Otherwise, it is necessary to obtain permission from the state gas service.

It is better to entrust the connection of devices to specialists, but if you want to do it yourself, you should study the relevant rules. Remember that mistakes can lead to a gas leak, and also you automatically lose a number of advantages:

Modern gas stoves are sold with a complete set of devices necessary for connecting: fittings, adapters and hoses. For individual models can be from 2 to 4 nozzles of various types. Detailed and clear instructions explain the entire connection procedure quite clearly. So, after unpacking the stove and checking the availability of all parts, you should prepare the necessary tools:

To check the quality of the connection, you will need a soap product or shaving foam and a brush for applying.

The first thing to do is turn off the gas supply by shutting off the tap on vacation. Then check the supply shut-off by turning on the hotplate. Simultaneously with the change of plate, you can replace the floor crane.

How to check the reliability of the connection: apply soap or shaving foam to the joint. In the event of a leak, it will begin to bubble.

Now, in place of the old or in any other part of the kitchen, it is necessary to put a new stove, having maintained such a distance from the wall as specified in the installation instructions, usually from 6 mm. Align the plate horizontally with the adjusting legs and level, make sure it is stable.

It is assumed that there is already a flexible connection hose, and therefore the next step will be to connect it to the stove, and then to the gas riser. Wrap a sealant (thread or tape) on the hose fitting, and then screw it into the dispensing tap. Do the same with the second end, attaching it to the gas stove. Often new gaskets come with a metal mesh gasket to protect against contamination. It must be installed between the flexible hose and the entrances to the slab. For the most reliable fixation, the connection is tightened with two keys.

Note! The hose must be flexible and of such a length that no tension is created. After connecting, it should sag. A special, certified metal-braided hose with a yellow mark should be purchased. The inlet type is also noteworthy: for plates with a straight, a hose with an angled end is purchased and vice versa.

The final step in installing a gas stove is to check the quality of the connection. Use a soap preparation prepared in advance. The absence of bubbles suggests that you have handled the connection with the gas stove perfectly!

If the plate you purchased has an inlet of a smaller or larger diameter than the diameter of the dispensing valve and hose, you must purchase an adapter in a specialized store. When installing it, you should also use a sealant, and tighten with two ball wrenches. When checking the quality of the connection, be sure to check the joints of the plate, adapter and hose.

By the way. In industrial gas equipment, avk gas supply fittings are used.

Before installing a gas stove in the country house and in a private house using liquefied gas cylinders, make sure that your room meets all safety rules. Then, the nozzles in the burners should be changed to a smaller diameter, since the bottled gas has a high pressure.

The rest of the instructions for connecting and subsequent verification repeats all the steps of connecting a gas stove to a stationary gas source.

Proper connection of the gas stove ensures that there are no leaks, problems with the local gas service and positive emotions during cooking.

When connecting a gas stove, be sure to read the operating instructions for the stove. There probably is a point of safe connection of the plate with your own hands.

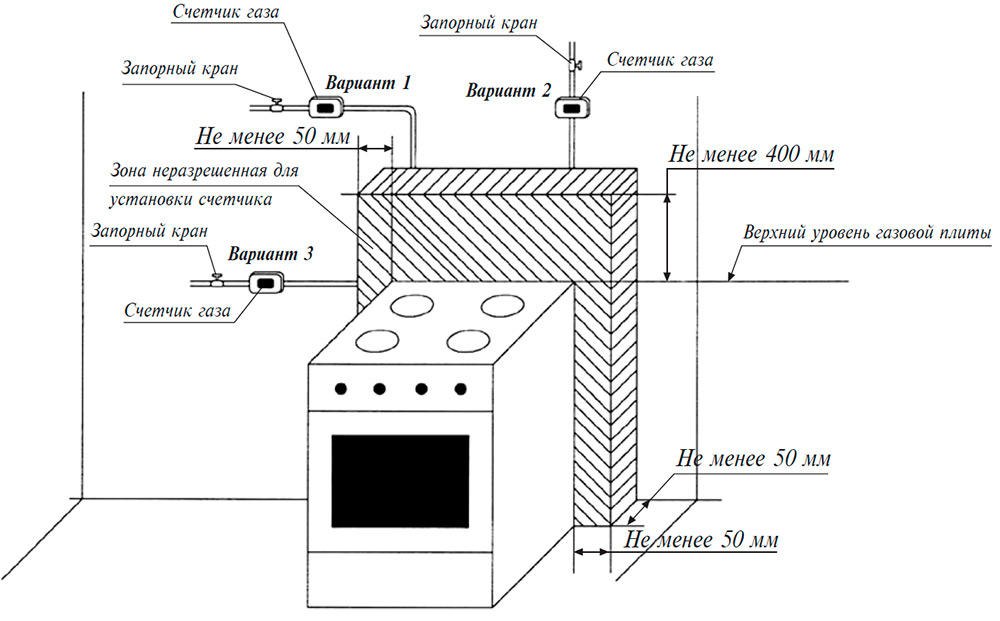

The photo shows how the devices important for the device are arranged. But in words it looks like this: from a pipe in the kitchen running from the ceiling in each apartment (called a “riser”) there is a branch called a “lowering”, which acts as the place where the stove is connected directly. At the end of the lowering is placed a crane from which a rubber-fabric hose is attached, or in other words, a gas path.

Rubber allows you to move the device in the direction you need. How the gas stove is connected behind the circuit, you now know, but it is worth learning some nuances of the connection.

It occurs due to the placement of a new valve on the lowering of the pipe, so that the gas cannot escape. Twisting takes place to the extent that the seal no longer allows the crane to spin. Sealing is provided by the elbow and the tape fum. In the case of gas leaks, the action is repeated again.

In order to connect the gas stove in the country, you should prepare a cylinder and a flexible hose. Also, the specificity of this installation is that it is necessary to replace some burners so that they do not smoke or stain dishes, and also check the operation of electric ignition, if any. For summer cottages, a stove is often selected for low gas, but it does not quite cope with the flame and goes out.

As for the rubber hoses for installation, first of all, it is necessary to check which outlet on the plate and the thread. For threading, an adapter is immediately selected, which can be included.

Important! Do not buy used hoses, because no one will give you quality guarantees for them, and your safety depends on them.

You are almost ready to install, but in the end, each installation should take into account the following parameters:

Theoretically, it is possible to carry out the gas stove connection on its own, but if the technical work is not your hobby, and there was no fungus before, perhaps you should contact the gas service masters. If, say, improperly assembled plumbing communications threaten a pipe breakthrough and financial waste, then gas is much more dangerous and you should not risk it.

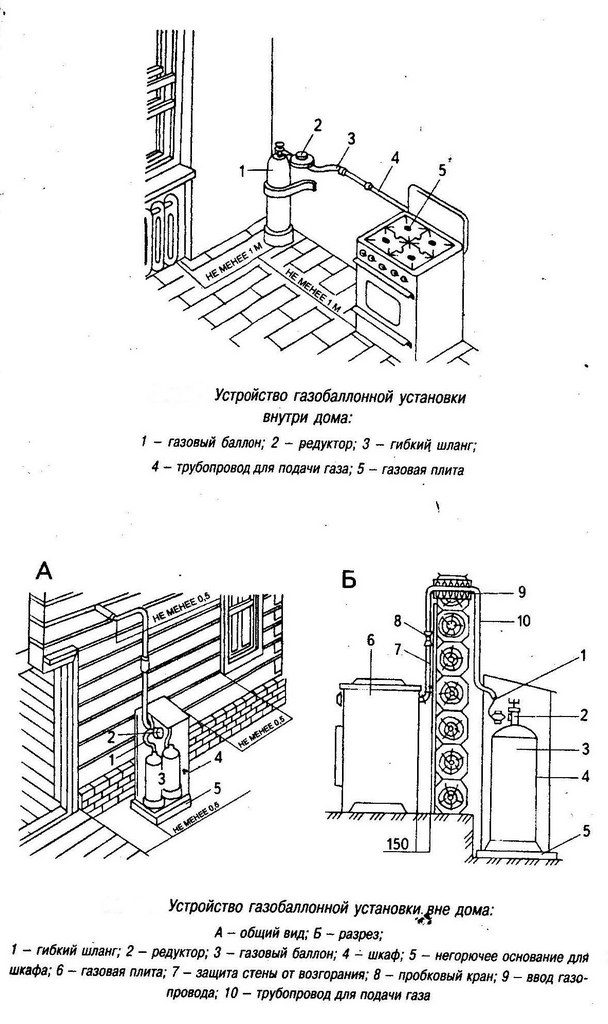

The use of bottled gas requires a thorough approach to ensuring safety and ease of use. We propose to consider the simplest example of connecting a propane cylinder to a gas stove: connection diagram, shut-off and control valves, organization of storage conditions.

The main generalized requirement for the use of gas cylinder equipment can be called ensuring the safety of people. For this reason, gas cylinders are not recommended to be installed in inhabited rooms and technical rooms connected with the residential building directly or through ventilation.

A distinctive feature of propane gas is its high density. Balloon gas is heavier than air and can accumulate in the lower floors of buildings. Therefore, to install cylinders in the underground or technical rooms below ground level is strictly not allowed. If in the usual case small leaks are not dangerous due to constant air exchange, then in the lowlands gas can accumulate for a long time to explosive concentrations. According to SNIP 42-01-2002, gas cylinders can only be installed inside buildings no higher than 2 floors, in an amount of not more than one, and at a distance of 0.5 m from gas stoves and 1 m from heating appliances.

To make the installation safer and to prevent access to gas equipment by unauthorized persons, the cylinders are placed either in a room with a separate entrance or in an outdoor metal cabinet. Especially important for outdoor installation temperature condition operation. Balloon gas consists of a mixture of propane and butane, each of which has a different boiling point. When the cylinder is cooled below 0 ° C, only propane will evaporate from the mixture, while the remaining butane in the cylinder cannot be used rationally. At lower temperatures it is possible to completely stop the flow of gas to the stove.

The main way to achieve normal operation at low temperatures is the use of so-called winter gas mixturescapable of evaporating at temperatures up to -40 ° C. However, the problem is that such gas may be in seasonal shortage, and the possibility of filling a mixture of mediocre quality cannot be ruled out. There are two ways to solve the warranty issue: either insulate the attached metal cabinet, counting on the penetration of heat from the building, or additionally heat the cylinders using a self-regulating cable.

The height of the cabinet must be at least 20-30 cm higher than the height of the cylinders so that they are not installed on the floor, but with a gap, for example, on two metal rails or a high pallet. In this case, the cabinet must be protected from the penetration of melt, rainwater and heat from sunlight above 40 ° C.

Gas stoves have built-in jets designed for constant gas pressure, while the pressure in the cylinder decreases as it flows. To normalize combustion, the cylinder is connected to the stove not directly, but through the gearbox. Reducers for liquefied domestic gas are called propane and, as a rule, have a red or metallic color of the case.

The main characteristics of the reducer - outlet pressure and throughput - must be selected for the parameters of a single plate. If it is not possible to establish the pressure rating value, it is necessary to purchase a reducer of an adjustable type and carry out its adjustment manually. Also, adjustable gearboxes are directly shown when using cylinders with a capacity of 20 liters or more, where the pressure drop is more pronounced.

For the use of propane for domestic purposes, reducers of the opposite principle of action are recommended. Due to the low pressure of the liquefied gas and the low difference at the inlet and outlet, the use of multi-stage gearboxes is economically unreasonable. The only requirement is to use reducers provided for by their technical standard together with composite cylinders.

A separate nuance in the choice of a reducer can be the temperature regime of cylinder operation. The fact is that during the evaporation of liquid gas, an intensive decrease in its temperature is observed. So, if initially the propane-butane mixture is at a temperature of -5 ...- 10 ° С, its temperature in the gearbox may drop to the condensation mark, due to which the gas becomes liquid again, and the gearbox stops working. One way out of this specific situation is to use gearboxes with an integrated heating system.

According to the rules for safe operation of gas equipment, it is not allowed to use oxygen and hydraulic hoses for laying gas pipelines. This is due to the high temperature difference between the transported gas and the external environment, which leads to accelerated degradation of the hose material and the appearance of microscopic leaks. With the properties of liquefied gas to accumulate in the premises, such phenomena pose an increased danger.

There are three options for connecting a gas bottle to a stove. The first is to use special flexible rubber hoses for combustible hydrocarbons. In this case, their connection to the gearbox is carried out through a standard fitting with reinforcement with a screw clamp. The same fitting is installed on the inlet pipe of the gas stove, the hose is also connected to it with a compression clamp. If it is necessary to connect two pieces of hose, the use of double-sided fittings is not allowed, threaded connectors with double crimping of the shank with clamps should be used instead. A distinctive feature of such connections for gas pipelines is a tapered thread and the absence of elastic seals.

The connection of the plate to the cylinder using flexible hoses has a number of limitations. The length of the hose should not exceed 150 cm, its gasket should remain visible for constant monitoring of the condition of the shell and the absence of damage. Some of the prohibitions can be partially circumvented using metal bellows hoses. They form a semi-rigid steel, which can have an almost unlimited length, while maintaining resistance to temperature influences and mechanical damage.

At the same time, safety rules prohibit the passage of flexible and semi-flexible channels through walls, where their condition cannot be visually assessed. If necessary, connect the stove with a cylinder mounted on the street, in the hole in the wall should be on cement mortar the case from a steel pipe is built in. Inside the case there is a steel tube of a smaller diameter with a thread at both ends, the space between the walls is filled with plastic sealant, for example, polyurethane foam or silicone. Bellows or flexible hoses should only be connected through threaded adapters of the appropriate type.

At the place where the gas pipeline is connected to the stove, a gas valve must be installed to block the gas supply in the event of a stove malfunction. It can be either a ball valve with a yellow flywheel or a cork gas valve. The disadvantage of the latter is the need for periodic maintenance.

Another useful addition to a gas pipeline can be a flow meter. Its inclusion in the transportation chain will help to respond in a timely manner to the exhaustion of the mixture in the cylinder and to carry out its replacement. The metering device should not have the outstanding accuracy necessary to control the gas flow in the trunk networks; a device costing up to 2 thousand rubles will suffice.

If several cylinders are connected at the same time, a connecting ramp can be used. Its installation helps to reduce the rate of gas evaporation from each cylinder and make the risk of freezing the mixture in the gearbox less likely. The installation of the ramp can be done independently with any material for the production of the gas pipeline.

Not every stove can initially work from liquefied gas. The main obstacle is a higher working pressure, due to which a lack of oxygen is observed in the burners, which is expressed in the yellow color of burning and the appearance of soot.

The situation can be corrected by replacing the jets for methane with nozzles for LPG. They have exactly the same form factor, but the diameter of the hole is slightly smaller. If you plan to connect a new stove, a set of nozzles for liquefied gas should most likely go with it. If there are no jets to replace, they can be purchased at a reasonable price.

The diameter of the holes in the nozzles for liquefied gas depends on the pressure in the outgoing chamber of the gearbox and the power of the burner. So, the diameters of 0.43-0.6 mm for a pressure of 50 mbar and 0.5-0.75 for a pressure of 30 mbar are considered standard values \u200b\u200bfor liquefied gas stoves. Some plate manufacturers can set their own diameter values, while using nozzles with different hole diameters may void the warranty.

![]()

Replacement of the nozzles can be performed in two ways, depending on the design of the plate. In the simplest version, it is enough to remove the burner body and look inside the landing sleeve. If the jet is visible at the bottom - a hexagonal head with a hole in the center - it is unscrewed with a socket wrench by 7 or 8 mm and the nozzle is screwed in for replacement. If a cone with a hole is visible inside, you will have to remove the top panel by unscrewing a few bolts on the sides from different sides. The jet itself in this design version is not twisted, it is pressed onto the stuffing box seals. It is necessary to unclench the mustache of the crimp sleeve, move the nozzle down together with the inlet pipe, and then pull out the nozzle from the seat fitting and install a new one.

The entire installation of the gas pipeline is carried out without connecting it to the cylinder. When the tubes or hoses are connected to the plate and interconnected, the gear nut is screwed and tightened onto the cylinder valve. Then, if a flexible hose is used, it is put on the fitting and crimped with a hose clamp. If bellows tubes are selected, the union must be unscrewed from the gearbox housing and screwed into it a threaded adapter of the appropriate size.

When the installation is assembled, you need to open the valve on the tank and, turning the regulator of the gearbox, set the required output pressure. When gas has entered the system of tubes and hoses, each connection is thickly coated with a foamy soap solution and checked for leaks. After the integrity of the gas pipeline is confirmed, you can open the stove tap and try to sequentially ignite the burners.

If each of them smokes or the flame burns with a color other than blue or greenish, it is necessary to reduce the pressure by the valve on the gearbox. If a malfunction is characteristic of only certain burners, it means that the nozzles for them were selected incorrectly. If the burner goes out in the low-fire position, adjust the low-flow screw on the stove tap or try to slightly increase the pressure with the gear screw.