Temple in honor of Hieromartyr Hermogenes, Patriarch of Moscow and All Russia in...

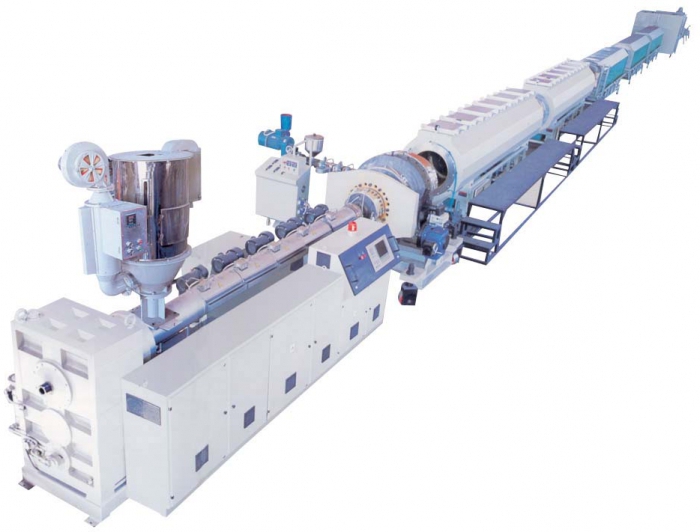

From the technological side, the production process is quite simple, with minimal energy consumption, labor-intensive and environmentally friendly. The production line is a continuous, technologically complete cycle.

This line consists of:

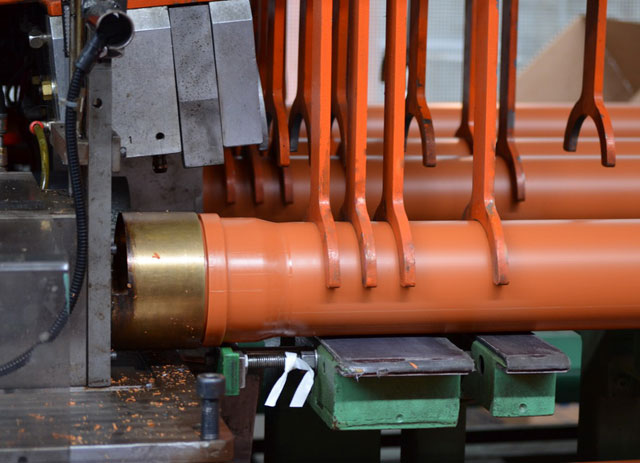

The line is equipped with a circular saw (or planetary saw) and has high productivity and excellent reliability. The planetary saw has automatic digital control: it is simple and reliable. Equipment for the production of polypropylene pipes complies with international quality standards.

Pipe lines are completed with special devices in accordance with the parameters of the manufactured products. Depending on the productivity and purpose, the lines can be equipped with loaders, dryers, various sets of tools (corresponds to a certain standard size). Depending on the additional conditions, additional accessories are required accordingly. For example, if you want to produce products with a color stripe, then you need a co-extruder. If marking is required, then a marker is used, etc.

Materials for the manufacture of polypropylene pipes are: polypropylene random copolymer, polypropylene homopolymer, polyethylene, polyvinyl chloride. These materials must be considered when choosing: for indoor or outdoor use. For example, polypropylene homopolymer becomes brittle at temperatures below zero degrees. Therefore, they must be used for internal pipelines. But polyvinyl chloride is suitable for outdoor sewerage, as it has high performance at low temperatures.

The following steps are included in the production:

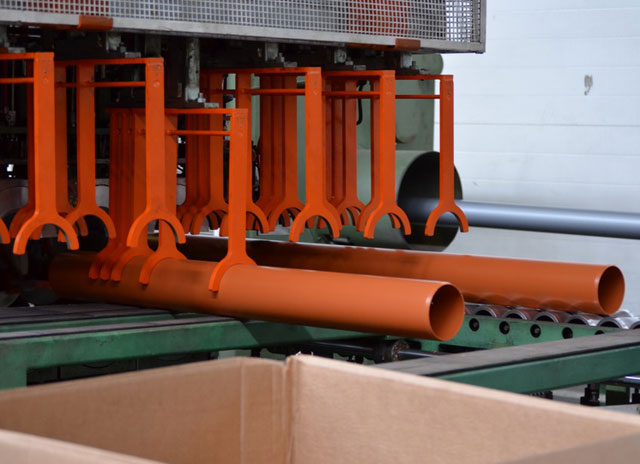

After the production process, finished products are packed and stacked for further sale.

The scope of polypropylene pipes is very wide. This is the construction and repair of pipelines transporting liquid and gaseous substances. Polypropylene pipes are used for transportation of gases in heating systems, in sewerage networks, in sewerage systems. Polypropylene is chemically resistant to all substances.

Today, the demand for polypropylene pipes is very high and exceeds all produced volumes. Therefore, equipment for the production of polypropylene pipes will always be in demand.

The use of polymeric materials for the manufacture of pipes greatly simplified the process of their installation, reducing the cost of the entire event.

Copolymer products have gained particular popularity. Special equipment for the production of polypropylene pipes will provide an opportunity to ensure a stable profit, but only if technological standards and proper selection of line components.

To organize any production process, at the first stage it is necessary to draw up a business plan. It includes a number of important factors: a list of equipment, the cost of renting (purchasing) premises. Obligatory costs are also taken into account - the purchase of raw materials. The latter indicator is important when choosing the types of finished product. Depending on the material of manufacture, the finished product may have different operational properties.

Regardless of which line for the production of polypropylene pipes is installed, it allows you to manufacture products from the following types of material:

Having chosen a certain brand of source material, you can begin to analyze the methods for the production of PP pipes.

To begin with, it is necessary to describe in detail the methodology for obtaining high-quality pipelines. Often, polypropylene copolymer is used for production.

Manufacturing technology is based on the properties of polymers under the influence of temperature to go into a plastic state. To preserve the molecular bonds of substances, special chemical reagents are added - catalysts. Subsequently, the heated mass acquires the required shape due to extrusion. These processes take place on the same technological line, and practically without human intervention. Modern equipment for the production of polypropylene pipes needs minimum quantity service personnel.

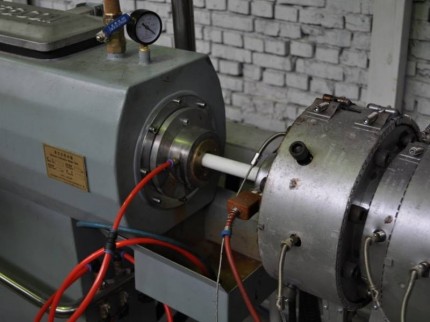

The extruder is a technological complex in which raw materials go through several stages of processing:

Let's consider each of the stages in more detail.

Through the loading chamber, the feedstock (granules) enters the machine for the production of polypropylene pipes. At this stage, they must undergo heat treatment to form a plastic mass of the desired consistency.

After being loaded into the bunker, the granules are subjected to primary treatment with a low temperature. Heating is carried out by means of electrical elements protected by an aluminum case. The screw device moves the plastic mass from one chamber to another. The temperature gradually increases, and the material becomes more and more plastic. The level of heating directly depends on the requirements for pipes.

After passing through the last chamber, the material moves to the product forming device. It is best to analyze the processes taking place at this stage on the example of the SJ 65 33 line. The extruder separates part of the volume of the mass and automatically places it in the high pressure area. With the help of hydraulic mechanisms, the material passes through a special molding insert - a die.

It is made of a durable material that does not change its geometric dimensions under the influence of high temperatures or aggressive environments. The shape of the holes on its surface coincides with the dimensions of future pipes. But since the temperature of the plastic is still high, there is a danger of changing the geometry. To prevent this, the equipment for the production of polypropylene pipes is equipped with a water cooling system.

Moving along the rollers of the transport belt, the still hot product is cooled by water flows. However, this does not guarantee perfect compliance with the desired dimensions. Having passed the entire stage of water cooling, the workpiece enters the final stage of manufacturing - calibration.

A special control and measuring device compares the current dimensions of the product with the normative ones. Then the workpiece passes through a vacuum calibrator, where it acquires desired shape and diameter. The next step is cutting the product to the desired size.

Professional equipment for the production of polypropylene pipes is the main factor in the profitability of the future enterprise. If you approach this issue in a balanced way, then in the end the excellent quality of products will become the starting point for successful business development.

The process of production of polypropylene occurs automatically from the operation of filling the granules into the bunker, to the exit finished products. All extrusion line equipment is controlled from one command unit. You just need to download the program for heating the material, transferring it from one mechanism to another, and all other operations will take place automatically. The accuracy of the specified dimensions of the pipe diameter occurs in a vacuum calibrator. The principle of setting the accuracy of geometric dimensions is as follows: the pipe enters the device. It is fixed along the outer diameter and locked on both sides in the vacuum calibrator. Since the two covers of the device are connected using rubber gaskets, the coolant cannot leak out. After that, cold water is supplied from the nozzles under pressure to the device, the material is finally cooled and hardened.

In the field of market relations, the main principle of which is based on a competitive price / quality ratio, the release of products, which, in comparison with analogues, is a unique offer for the consumer, naturally leads to high and stable profits. The production of polypropylene pipes is one of the most profitable areas for investment today. This statement is correct based on two factors. The presence of a growing demand for tubular products and high quality polypropylene pipes at a relatively low cost.

The high demand for pipes is determined by the construction of new facilities, both residential and industrial sectors, and the need, which is becoming acute in the next decade, to replace old metal pipe systems with new ones. The fact is that most of the water and sewer systems of the countries of the former Soviet Union, due to corrosive wear, need to be replaced for a long time. Polypropylene pipes are not only a more cost-effective alternative to metal pipes, but in many respects they win in quality, because due to their flexibility they can withstand significant overloads associated with the most extreme temperature regime and plus everything - more convenient for installation.

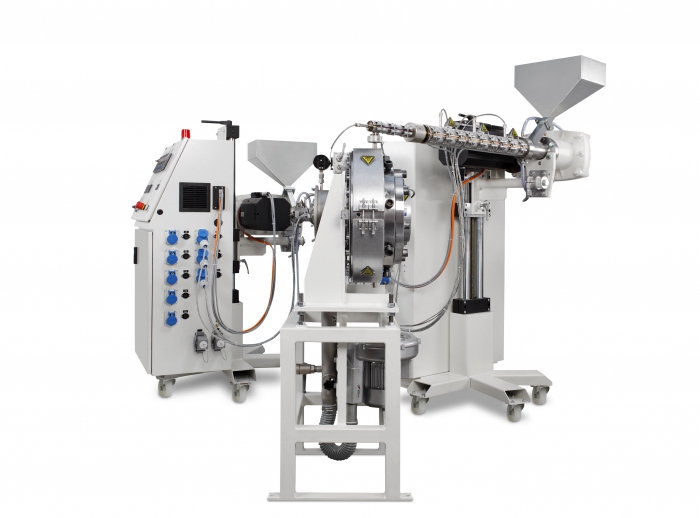

Pipe production line

Main Devices:

SJ-65/30 extruder - 2 pcs

SJ-50/30 extruder - 1 pc

SJ-25/25 extruder - 1 piece

Set of extrusion heads and calibrators.

Vacuum calibration chamber.

Cooling chamber

Pulling device.

Cutting device.

Stacker

The main advantages of PP pipes reinforced with fiberglass compared to standard PP pipes:

the coefficient of linear expansion is 75% less (compared to conventional polypropylene pipes);

no mandatory stripping is required (for pipes reinforced with aluminum foil);

due to the small linear expansion, the distance between the fasteners increases, which reduces the total number of supports and reduces the cost of installation;

fiberglass layer provides pipe strength with a smaller wall thickness;

conditional passage increased by 18%;

simple and quick installation of the pipe.

The rapid development of the plastic pipe market is due to moral and wear and tear iron and steel pipes. Polymer pipes are the optimal replacement for most metal pipeline networks. Polypropylene pipes are used in heating and water supply systems. For the production of pipes, high-quality heat-resistant polypropylene is used. It is polypropylene that is the most competitive material compared to copper, steel, etc.

Polypropylene pipes:

wear-resistant

resistant to aggressive environments,

environmentally friendly,

not subject to corrosion

do not overgrow with carbonate and other deposits.

The service life of PP-R pipes is up to 50 years in cold water supply systems and up to 25 years in hot water supply systems. In addition, the ease, simplicity and reliability of installation allow several times to reduce labor costs compared to the installation of metal pipes.

The lines are equipped with:

Single screw extruder

High Speed Tubing Heads

Vacuum calibrator

Water cooling section

pulling device

Cutting device

Markirator

Storage device

Polymer pipes are widely used in various fields. They are used in the transportation of drinking water, technical liquids (solutions of acids, alkalis, salts, mineral fertilizers); gas transportation and gas mixtures; when laying various types sewers; in the protection of power cables; in heating and reclamation systems; as waterproofing shells for heating mains; and also as shaping in monolithic housing construction.

A wide range of applications of polymer pipes is explained by durability, corrosion resistance, low thermal conductivity, environmental friendliness, and new laying possibilities.

Polymer pipes are made from HDPE, LDPE, cross-linked polyethylene, polypropylene and copolymers of propylene, polybutene, PVC.

Pipes made of polymeric materials are mainly produced by continuous extrusion. The main element of the pipe line is a screw extruder (single screw for HDPE, LDPE and PPS, twin screw for PVC). In the production of polyethylene and polypropylene pipes, granular polymer compositions are used.

Today, all over the world, especially in developed countries, polymer pipes occupy a leading position in the construction of water supply, sewerage and heating systems.

The main consumers of polymer pipes are construction and installation organizations, housing and communal services, as well as private developers and construction teams.

Based on world experience, we can conclude that in the near future the growth rate of consumption of polymer pipes will not be lower than in recent years, and the trend of replacing metal pipes with non-metallic ones will continue.

Implementation of the project is possible at JSC "Maloritskaya rayagropromtechnika" (Brest region, Malorita).

The reliability and durability of pipeline systems directly depend on the quality and properties of the source material and, of course, on the machine itself on which the tube was produced. The company "Global Group" is engaged in the supply of equipment for the production of polypropylene pipes (PPR). The machines of our company will help to significantly increase the efficiency of manufacturing due to high productivity and cost-effectiveness. We offer reliable extrusion lines made of quality materials, which, if used correctly, will last for a long time.

The emergence in the last decade of new polymeric materials has led to revolutionary changes in industrial and residential construction, in the installation and maintenance of utility systems. Polypropylene is a colorless thermoplastic polymer material. Along with many other products made from this material, pipes and fittings (connecting part) made of polypropylene (PPR) are widely used, which have a number of advantages, which makes them ideal for creating pressurized water supply and heating systems.

Benefits of products produced by the machine for the production of PPR pipes and fittings

Compared to metal products, PPR tubes have a number of advantages that have led to such a high demand for them in recent years:

Easily transported, transported, which reduces the cost of their loading and unloading;

Easy to install;

Safe for health;

Low installation cost due to the high weldability of propylene;

The service life is 3-4 times higher than the same characteristic of metal analogues;

Unlike steel, plastic is a material that is resistant to corrosion (does not rust or deform);

Easily withstand sharp temperature fluctuations, they are reliable in winter and never break;

Excellent permeability and resistance to various chemical environments;

Polypropylene pipes for heating and other communication plastic systems have excellent sound insulation.

Short description:

The process of production of polypropylene occurs automatically from the operation of filling the granules into the bunker, to the output of the finished product. All extrusion line equipment is controlled from one command unit. You just need to download the program for heating the material, transferring it from one mechanism to another, and all other operations will take place automatically.

Production of material for polypropylene pipes. Any production of polypropylene pipes begins with filling granulated polypropylene into a special bunker. Here the material is melted, the entire cylindrical device is divided into sectors, in each of these departments a certain, strictly controlled temperature is set. Since the screw of the device is constantly rotating, the granules of the substance are mixed and melted. At the exit of the device through special forms under high pressure a polypropylene pipe is formed.

The shaping of the product takes place in the extrusion head. It is here that the molds are installed to limit the inner and outer diameter of the product. The head itself is attached to the hopper cylinder with a flange.

The process of production of polypropylene occurs automatically from the operation of filling the granules into the bunker, to the output of the finished product. All extrusion line equipment is controlled from one command unit. You just need to download the program for heating the material, transferring it from one mechanism to another, and all other operations will take place automatically.

The accuracy of the specified dimensions of the pipe diameter occurs in a vacuum calibrator. The principle of setting the accuracy of geometric dimensions is as follows: the pipe enters the device. It is fixed along the outer diameter and locked on both sides in the vacuum calibrator. Since the two covers of the device are connected using rubber gaskets, the coolant cannot leak out. After that, cold water is supplied from the nozzles under pressure to the device, the material is finally cooled and hardened.

In addition to the cooling bath, pipe calibration is carried out by means of a pulling device. In addition to the accuracy of the outer diameter, polypropylene pipes have accurate dimensions of the wall thickness, therefore, by pulling the part, the guarantee of its inner diameter is also controlled.

The final stage of production of PP pipes. The complete production of polypropylene pipes implies the receipt of a marketable product, that is, the required technical indicators and geometric dimensions.

After specifying the exact dimensions of the pipe diameters, the process of cutting them into measured lengths begins. This operation takes place using either guillotine shears (product diameter up to 50 mm), or using circular saws.

The advantage of the second cutting method is the high quality of the pipe end obtained in the process of cutting. When using the same guillotine, the end of the PP product becomes substandard (slightly flattened).

For the manufacture of plastic pipes, various raw materials are used: high and low pressure polymers, polypropylene, polybutene, polyvinyl chloride, etc. Their production is environmentally friendly and uncomplicated, it is based on extrusion. Extrusion is the extrusion of pipes from molten plastic using a special machine (extruder). There are several types of extruders: screw, screwless and combined. The principle of operation of a screw extruder resembles a meat grinder, or a juicer. For screwless, the main working part is the disk; they are used, if necessary, for the production of pipes from mixed materials. The combined extruder combines both the screw part and the disc. The most commonly used screw extruders. They are single- and double-stage, specialized and universal, single- and twin-screw, equipped with a degassing chamber and without it, with screws rotating in one or in opposite directions, etc.

The production of plastic pipes is as follows. Raw materials in granules are filled up in the hopper-receiver of the extruder, where under high temperature it melts. Next, the mass is squeezed out through the forming head of the extruder, which determines the parameters of the future pipe. After the initial molding, the pulling machine pulls the billet into the primary cooling bath, where it is finally shaped under pressure by means of a sizing mold. Next, the pipe is cut and either stacked (large-diameter pipes) or coiled (small-diameter pipes).

Equipment and raw materials

The full-cycle plastic pipe production line, in addition to the extruder, includes a pipe cutting machine, a raw material supply system, calibrating and cooling baths, a mixer, a pulling device, a conveyor belt, a vacuum former and a pipe stacker.

Productivity depends on the size of the pipe: pipe diameter - 20.25, - 80 kg / h, pipe diameter - 32.40.50 - 100 kg / h, pipe diameter - 63.75,90,110 - 130 kg / h. The line can produce about 1000 meters of pipes per day, depending on the diameter. The lines have different parameters, so you can order machines for your business, or you can save money and buy used equipment. The lowest cost of such a set is about 400 thousand rubles.

Granular polymers are purchased for raw materials. It is important to be demanding on its quality and shelf life. Polyethylene and polypropylene are very advantageous materials due to their almost unlimited shelf life. Polypropylene copolymer is one of the the best materials for the manufacture of pipes. Its cost is about 50-70 rubles per kg. Low-pressure polyethylene (HDPE) is also often used for production, its cost is lower - about 32 rubles per kg and more. The best option will arrange the supply from one plant, because the change of raw materials will require a change in the characteristics of the equipment.

Premises and staff

For the production of plastic pipes, any room outside the city is suitable, which has a convenient entrance, in which you can locate a workshop, a large warehouse, a bathroom, and premises for staff. All equipment can be located in the workshop area from 40 sq.m to 200 sq.m. For its maintenance, you will need from 3 people per shift. It is necessary to hire technologists, machine operators, auxiliary workers. The average salary of a technologist is about 50 thousand rubles, workers - about 25-30 thousand rubles.

Requirements

To open production, you will need to obtain permits from the gas service, the fire inspectorate, the sanitary and epidemiological station, the local division of Gosnadzorohrantrud, local executive authorities, etc.

According to GOST 18599-2001, the conditions for transportation and storage of plastic pipes are as follows.

It is allowed to transport pipes by any means of transport in covered bodies (wagons). To protect the pipes from dust and external influences, they must be closed with plugs and placed in a package. The mass of spools of pipes together with packaging should not exceed 1.25 tons, the length of pipes - no more than 5.5 m.

Store pipes in warehouses in a horizontal position away from sun rays and heating appliances. The height of the stack when storing pipes for more than 2 months should not exceed 2m. When stored for up to 2 months, the height of the stack should be no more than 3m. Storage of pipes is possible no more than 12 months. Shelf life - 2 years from the date of manufacture.

Durability of operation

The service life of the pipeline is 25-50 years, depending on the temperature and pressure during operation. Polypropylene pipelines meet the functional requirements of SNiPs and can be used for transportation cold water under pressure up to 2.0 MPa (20 atm), while ensuring the pipeline service life of at least 50 years.

When transporting hot water under pressure up to 0.6 MPa (6 atm) and constant exposure to a temperature of 60°C, the durability of the pipeline is also 50 years, and with an increase in the operating constant temperature to 75°C - 25-30 years. You can read more about service life here.

Constant pressure Pipes made of polypropylene do not overgrow throughout the entire service life. This is achieved due to the high purity of the inner surface of the pipes (0.003-0.005 mm), as well as the chemical inertness of the material.

Highest Reliability

Polypropylene pipes "TransFormer" are absolutely homogeneous and with temperature changes the entire pipe array behaves in the same way, which ensures the absence of internal stresses during operation. The connection of polypropylene pipes with fittings is carried out by polydiffusion thermal welding at a temperature of 260°C without the use of flame. You can read more about the welding process here. Thanks to this method, a connection is formed that does not differ at all from the array of the pipe itself.

Thus, the uniformity of both the pipe itself and the connections of polypropylene pipes with fittings ensures the highest reliability of the entire system, which, of course, is one of the main advantages of using polypropylene pipelines. It is thanks to the highest reliability that polypropylene pipes have become so widespread throughout the world.

Also, polypropylene pipes are distinguished by: low weight (4-7 times lighter than metal pipes), high culture, manufacturability and installation speed (it takes only about 12 seconds for one connection with a diameter of 20 mm), the absence of the “defrosting” effect when the system freezes, high noise and vibration absorbing ability.

Pipes "Transformer" do not conduct current, are white and do not require painting after installation. The smooth outer surface of pipelines makes it possible to remove from them dust and dirt that enters during installation and operation. If necessary, the pipes can be hidden in the walls.

The cost of a system of polypropylene pipes "TranFormer" is significantly lower than the price of pipeline systems made of metal and metal-plastic, with higher performance. You can see a comparison of the cost of pipes here.

In recent years, the number of manufacturers supplying polypropylene pipes to the Russian market has grown significantly.

This is due to several factors, but only two are of particular importance:

Many modern Russian entrepreneurs strive to become producers of polypropylene pipes. However, at many enterprises these tubular products are produced in parallel with other products.

Production of PP pipes on site Russian Federation carried out by hundreds of enterprises. However, only a few are popular.

The list of the main enterprises for the manufacture of polypropylene tubular products and related parts does not end there. In Russia, a huge number of companies working in this area.

The popularity of such products is due to many reasons, among which the most important are positive characteristics polypropylene:

The main work on the production of polypropylene products is carried out on a special machine for the production of polypropylene pipes, which is called an extruder. Such equipment performs multi-stage processing of the material, which subsequently becomes a pipe.

The technology for the production of polypropylene pipes involves the following stages of work:

Equipment for the production of pipes from polypropylene works offline, and the whole process takes place within a short period of time. The operator monitors the operation of the machine. He also sets the necessary parameters and troubleshoots the problems that have arisen. The average productivity of the best Russian machines is about 200 kg per hour. A typical plant producing plastic products in Russia can produce more than 1,000 meters of pipe.

The manufacture of each type of pipe is carried out on its own production line. Each line consists of special units.

Russian enterprises for the production of polypropylene pipes use the following machines and devices:

The main types of raw materials used in Russia are: