From internal pipelines, drains are transported by external ...

There is hardly even one person left in our country who does not know that plastic pipes are not only cheap, but also very convenient and safe. Now pipes from polyethylene, polyvinyl chloride, polypropylene and other synthetic materials are used everywhere for a variety of purposes: they are used both in production and in the creation of plumbing, gas, fuel, sewer and other life support systems in residential buildings. In the construction market today you can find plastic pipes of various sizes and types. An unenlightened person, looking at such a variety, can simply be confused. Here, for example, HDPE pipes - what is it and what advantages do they have? Let's try to figure this out.

First you need to understand what HDPE pipes are. The abbreviation with which they are designated is deciphered as follows: pipes made of low-pressure polyethylene. Of course, for an ordinary person, this is unlikely to clarify something, because few people know how low-pressure polyethylene differs from any other. Nothing complicated here, in fact, there is. As the name implies, low-pressure polyethylene is produced by polymerizing ethylene under low pressure. Such polyethylene has a number of advantages over polyethylene produced under higher pressure. The main one is that low-pressure polyethylene begins to melt at a temperature twenty degrees higher than its "rival". This property significantly expands the scope of application of pipes made of this material.

So where exactly are these pipes used? There are many areas of their application, but the main of them are two: plumbing and sewer systems. Moreover, both cold and hot water supply systems are mounted from polyethylene pipes, because they function perfectly at almost any temperature. For the same reason, such pipes are very often used in the northern regions of the country: unlike other plastic pipes, they can be mounted outdoors, even when the temperature outside the window has dropped much lower than zero. At the same time, HDPE pipes are also very elastic, easily bend and stretch without the threat of deformation, which allows you to create designs of almost any complexity with their help.

One of the undoubted advantages is their resistance to chemicals. The walls of the pipes do not react with the substances passing through them, and therefore such pipes serve without fail for many years and do not lose their properties over time.

The durability of HDPE pipes is also due to their special strength. It is no coincidence that such pipes are often called so - pipes of increased strength. Thanks to this, the systems are most resistant to mechanical stress.

Well, and, of course, many people are attracted to HDPE pipes by their relatively low price. If you compare it with the price of copper or steel pipes, the difference is very, very eloquent.

The production of HDPE pipes and their sale is gaining momentum every year. Is this fact surprising? Hardly. The advantages possessed by pipes made of low-pressure polyethylene fully explain their high demand. And it is worth thinking that in the future the trend of increasing the share of HDPE pipes in the Russian construction market will continue. After all, as you know, they quickly get used to the good, and there is a lot of good in HDPE pipes. After all, these are the real pipes of the future, which can greatly facilitate a person’s life!

Over the past few years, materials made of low-pressure polyethylene have become particularly popular in the arrangement of various gas. Manufacturers engaged in the production of this kind of product put on them certain indicators that help consumers understand what the product is intended for, as well as what its technical characteristics are.

Polyethylene products have a very wide range of applications - from communication systems, to water supply, gas pipelines and. It has established itself as the most practical and durable, allowing you to equip networks for various purposes. Therefore, the range of products from polyethylene is very large.

Among all this diversity, it is possible to choose the right product if you know in advance what labeling of HDPE pipes means. The decoding of these symbols makes it possible to understand whether this form is suitable for specific conditions.

Specifications are indicated as a combination of characters on the surface (numbers, letters, words). In this case, the word "" is not applied.

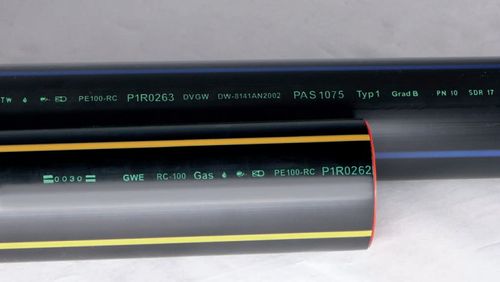

Example of marking.

The marking on the pipe includes several indicators. Basic and obligatory are:

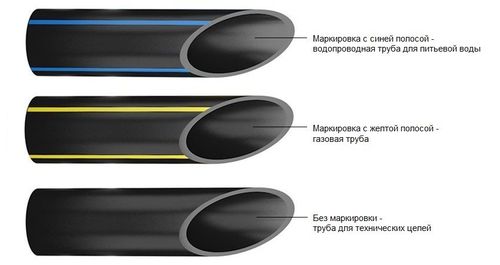

Each HDPE pipe, the marking and characteristics of which are applied by stamping or by printing on a special device, is equipped with strips of different colors for simplified determination of its scope.

For instance:

All collectors are manufactured in accordance with standard sizes according to GOST 18599-2001. Depending on the size, the readings of the working pressure of the products (between 5 and 16 MPa) may vary. The diameters of their holes are also different. This indicator is indicated on the outer wall along with other values \u200b\u200bin the form of a Ø symbol. It can vary between 16-200 mm with a shell thickness of 1.5-14.6 mm.

Such materials are sold in bays (usually 100, 200 m), but can be sold in separate segments (from 6/12 m). The total footage of the bay depends on the diameter

Marking HDPE pipes according to SRD means a series of products with certain strength parameters. SRD (Standard Dimension Ratio) is determined by the ratio of the outer diameter of the collector to the thickness of its walls. It allows you to understand what the maximum pressure inside the system can be, so that its shell can withstand it.

A high numerical value of SDR means that the collector can be used with low wall pressure. Conversely, the lower the indicator, the greater the pressure can be.

A high numerical value of SDR means that the collector can be used with low wall pressure. Conversely, the lower the indicator, the greater the pressure can be.

All of them are operated at a certain temperature, since there is a specific maximum temperatureat which the material loses its strength or begins to melt (+ 60⁰ - + 80⁰). And, if served cold water If PE 100 (or at least PE 80) can be used, then products with special technical parameters, which are defined by the letters PE-RT, should be used.

The market for polyethylene products is represented by a wide variety of products that differ technical characteristics. The idea of \u200b\u200bwhat kind of collector it is, and also where it can be used, helps to make up exactly the decoding of the characters on its shell. Knowledge of these indicators will help to obtain the most effective solutions for the arrangement of water supply systems, gas pipelines, supply / transportation of other materials.

The video shows marking PE pipes:

Recently, plastic pipes have been actively displacing competitors from other materials from the fields of water and gas supply, drainage. One of the most popular examples of this class, especially for external and trunk networks, is the pressure pipe HDPE.

About what operational qualities are inherent in this material, about its advantages, disadvantages and technological features of laying and use - further in the article.

Polyethylene is one of the first polymers used to make pipes. There are two types of it that have different production technologies - high-pressure polyethylene (LDPE, obtained in the 30s of the 20th century), and low pressure (HDPE, synthesized in the 50s).

Both materials are used for the production of pipes for various purposes, the specific use of one or another type depends on the purpose and operating conditions.

Product requirements, depending on whether HDPE HDPE pipes are used for cable, pressure or pressureless pipelines, due to a wide range of use, are regulated by a sufficiently large number of GOSTs that determine various regulatory requirements.

The main ones are SDR (the ratio of wall thickness to pipe diameter), long-term (based on a life expectancy of 50 years) strength, as well as ring stiffness and the maximum allowable internal pressure (for pressure pipes).

The PND pipe itself carries the data on these parameters - their interpretation is regulated by the international standard ISO / TC SC4 No. 651.

By purpose, polyethylene pipes are divided into:

At the same time, the design of the walls may be different. So, for example, pipes for HDPE cable can have one layer and smooth inner walls, which allows laying communications in relatively simple conditions. For complex soils, at intersections of overpasses and other areas with increased load, a double-walled HDPE pipe is used to better protect the contents (cable).

Here, the internal smooth-walled pipeline is designed specifically to accommodate the line, and the outer shell is corrugated, has increased rigidity and is subject to external pressure.

However, for the same reasons, two layers can have and. Also, a smooth HDPE pipe for internal water supply can be made of cross-linked low-pressure polyethylene according to one of three technologies.

Depending on the method used, the result is modifications that are classified according to the European standard as RE-Xa, RE-Xb and PEX-s. Each of them has its own set of specific properties, but common are increased strength, heat resistance and low fluidity at high temperature.

In this case, modifications b and c, due to the peculiarities of the technology, have limitations in diameter: b - up to 63 mm, c - up to 32 mm.

For the construction of internal water and heat supply networks, it is better when a smooth HDPE pipe made of cross-linked polyethylene is used.

It has a lower ability to gas diffusion, so air does not pass through its walls.

Saturation of water with air leads to vibration and noise in the system, and in the case of using ordinary polyethylene pipes requires the installation of air baffles and other trapping devices.

Low fluidity allows the use of pipes with a diameter of 25 and 40 mm for the installation of risers, including - and under hot water.

There are two forms of production of HDPE and LDPE pipes: in the form of segments of 6-12 m and bays. As a rule, HDPE pipes of 110 mm and smaller diameters are supplied in coils, while the length of the coils is usually 100 and 200 m, but some manufacturers “reel” up to 500 m.

Sometimes pipes with a diameter of up to 160, and even 315 mm, are “packed” in the same way, but, of course, their length will be less. Such impressive segments are convenient when using the PND pipe for cable, and for trunk pipelines.

They reduce the number of joints, and this reduces the amount of welding and increases the reliability of the finished object.

Important information!

If it is supposed to lay a pipeline having open sections, black PE pipes should be selected.

Pure polyethylene breaks up under the influence of ultraviolet radiation, soot is added to the raw material to avoid this, which gives the material a characteristic color.

When using HDPE pipes for the cable, as a rule, no lateral branches are assumed, therefore the simplest connections are used here. In plumbing and sewer systems, schemes are more complex - and for them there are own solutions.

In general, there are the following methods for connecting polyethylene pipes:

In addition to low weight and long life, the polyethylene pipeline has the following features:

Knowing what HDPE pipes are and what their operational characteristics are, it is easy to choose the right brand for the needs of any pipeline - both domestic and industrial. At the same time, the costs of its organization will be 5-10 times lower than when using classic metal, and the service life is 2-3 times longer.

When installing a plumbing system in a private house or apartment, various pipes can be used. More recently, only steel products were used for these purposes. But recently they have been replaced by plastic pipes.

So, quite often products from HDPE are used. But this material is used not only for the production of pipes, it is widely used for the manufacture of a wide variety of products, from household items to accessories to equipment. And what is it? What features does this material have? This will be discussed in the article.

IPA is the abbreviation of a product such as low-pressure polyethylene. In its production using three different technologies. Namely:

Depending on the method of preparation, it may have some differences in its composition and structure. Thus, the suspension material contains various chemical stabilizers. And the material produced by the gas-phase method incorporates the remains of gases and oils.

As a result of such processing of primary raw materials, high-density material is obtained. This indicator for PND exceeds the value of 0.941 g per cubic centimeter. As a result, the strength of the products increases, but its transparency decreases.

PND received such properties because of its molecular structure. Its structure is dominated by a low degree of branching of molecules. From this it follows that PND has large intermolecular forces. That's why he has great tensile strength.

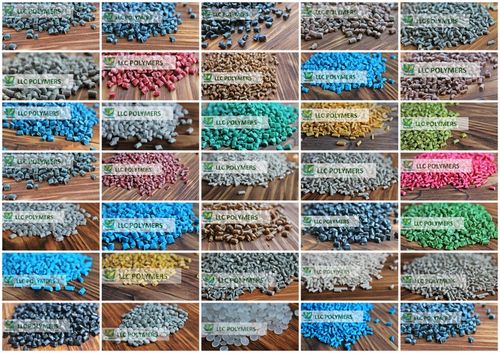

The material is available in the form of granules, with fractions of 2-5 mm. It is from them that a wide range of products is produced. The material itself has the following characteristics:

Low-pressure polyethylene is a highly demanded material in modern industry, construction and other industries. Products from it possess not only high strength indicators, but also low cost. It was the latter fact that made PND popular.

This material is used in the manufacture of:

All these products are manufactured. extrusion method. But with PND, you can use other technologies. For example, under pressure, you can pour various household items (toys, dishes, containers, etc.), accessories (for the clothing and furniture industries), components and parts for various equipment (household appliances, cars). If the rotor method is used, then it is possible to produce tanks, pillars, volumetric structures (for example, for children's playgrounds).

Very often, when carrying out a water supply system, pipes of low pressure polyethylene are used. And what is the reason for such popularity of this material? What improved characteristics do HDPE pipes have?

Very often, when carrying out a water supply system, pipes of low pressure polyethylene are used. And what is the reason for such popularity of this material? What improved characteristics do HDPE pipes have?

Firstly, such products not afraid of exposure to aggressive environments. Chemicals, corrosion, moisture - all this is not a problem for HDPE pipes. This means that the products have a long service life. Most manufacturers indicate that their pipes will last 50 years or more.

Secondly, HDPE pipes are lightweight. This greatly facilitates installation work. There are many fittings for connecting pipes from HDPE. At the same time, highly qualified specialists for installation work are not required. And the delivery to the installation site itself will not cause problems. Pipes are produced in bays, which are very easy to transport from place to place.

The operation of pipelines from HDPE is also facilitated. The inner surface of the pipes is absolutely smooth, which prevents clogging. Products are not afraid of frost. Even if water freezes inside the pipes, this will not harm them. HDPE is very elastic. The formed ice cork will simply increase the diameter of the pipes, but will not break them.

If a breakthrough occurs, the repair will not take much time. Inserting a new piece of pipe using existing fittings is not a big deal. In addition, pipelines from HDPE do not require special care.

HDPE or low-pressure polyethylene - modern and practical material. It is widely used in many industries. Various household items, toys, components and many other products are made of this convenient material. HDPE is also used for production water pipes. Pipelines made from such products meet all sanitary standards and serve more than half a century.

Pipe products made of low-pressure polyethylene are mainly used for the installation of cold water supply, gas networks and sewers, but their scope is much wider. When using such products throughout the pipeline, water will reach your tap in a perfectly clean condition. They are ideal for indoor and storm sewers.

The key difference between HDPE pipes is environmental friendliness, biological neutrality, resistance to deposits on the walls and most chemicals, including acids and alkalis. Features of production (as in other types of pipe products) are reflected in the labeling code, the decoding of which will help in choosing the right type from the presented assortment.

Polyethylene tubular products can be made from different materials that affect their performance, in addition, they are divided into pressure and pressureless. Non-pressurized have less strength and are used in gravity systems, as well as in apartment or house water supply.

On sale you can find products from the following types of PE (see photo):

For example, marking HDPE pipes for cold water supply will begin with PE63 or PE80, contain a marking of drinking water and a diameter of 32 mm.

Marked with a colored line - indicates the scope and averaged characteristics:

Other values \u200b\u200bare allowed.

An approximate marking of the PND pipe for the water supply is shown in the photo. It clearly shows what information is applied to the tubular product. The labeling procedure for this type of product is governed by GOST. The cipher usually contains characteristics for which technical or drinking water this product is intended. Also pay attention to the diameter, for loops with a low pressure they usually take 32 mm.

Marking and characteristics of the HDPE pipe contains the following data sequence (see photo):

SDR stands for Standard Dimension Ratio. It refers to the pressure that is exerted on the walls. This parameter is not calculated, but is typical. The value is taken from the state standard, in accordance with which the pipe products are manufactured.

The lower this indicator, the more pressure the product is designed for. The wall thickness can not be measured, but calculated by pushing, for example, from a typical diameter of 32 mm.

HDPE pipes are widely used for laying engineering networks in connection with a long service life. The warranty period is 50 years, in this case it indicates the minimum possible time of use. On average, such pipelines can be operated for 300 years.

This type of pipe products can be used in hot and cold water supply systems, as well as high-temperature heating due to the ability to expand thermally. The service life and resistance to aggressive environments, including non-freezing coolant, in many cases determine the final choice of consumers.