From internal pipelines, drains are transported by external ...

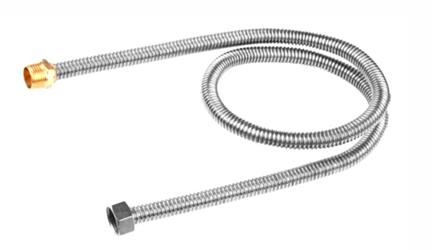

All plumbing equipment is connected to the water pipes with hoses of rigid or flexible eyeliner. Rigid hoses are less preferred because they require higher definition when selecting and do not allow the device to be moved in any direction. Connecting a flexible eyeliner to a mixer or other plumbing device can be done independently.

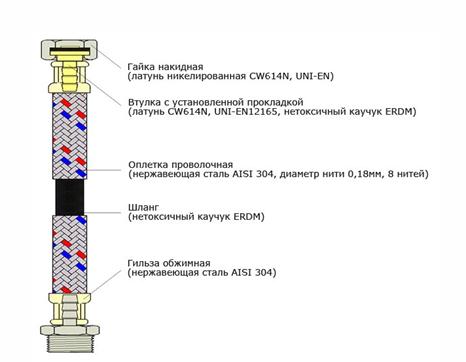

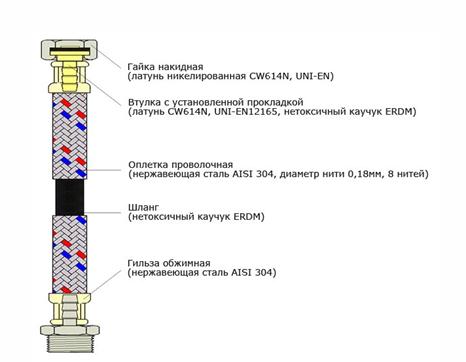

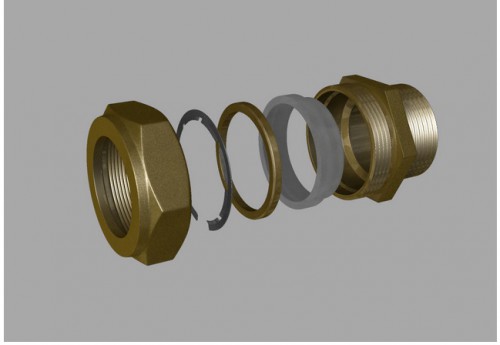

Flexible eyeliner is a hose protected by a special braid. On one side of the hose is a crimp sleeve designed to be connected to the mixer. On the other hand is a flare nut, supplemented with a rubber gasket. With the help of a nut, a connection is made between the liner and the branch.

Eyeliner hose can be made:

The rubber hose has an unpleasant odor and cannot be used to supply drinking water.

For braiding can be used:

The most common home applications are stainless steel braided hoses.

If replacement of a flexible eyeliner is required, then first of all it is necessary to choose the right hose for connecting the mixer. When choosing you need to rely on the following factors:

Based on the factors presented, each user can independently choose the most suitable and durable product.

Change the hose if:

To install a flexible water supply for connecting a mixer, you must:

To avoid flooding with the water remaining in the hose, it is recommended to substitute a container under the connection points of the wiring.

It is required to screw the hoses to the mixer and the branch without special effort, which can lead to the formation of a crack in the union nut or fitting. To seal the connection, you do not need to use additional tools, since the eyeliner already contains built-in gaskets.

The process of replacing the connecting hoses is presented in the video.

Replacing the flexible eyeliner yourself is not a problem. The main thing is to choose the right hose that matches all the parameters.

What plumbing fittings are used in our time? We will analyze the main types of pipes and methods for their connection.

Alas, in the framework of a small article it is impossible to pay attention to all the details of the device and the use of existing fittings, so our acquaintance with them will have a somewhat superficial character.

For the installation of plumbing, two fundamentally different pipe connections are used:

In this order, we will consider the relevant sectors of the modern market.

Please note: galvanizing is strongly recommended to be assembled on threads.

Welding breaks the protective zinc layer, making the seam vulnerable to corrosion.

Two types of fittings are used to connect them:

![]()

Their compounds are usually soldered with a gas torch using flux and solder. Fittings for copper are corners, crosses, tees and solder bends. Before joining by means of rolling, a sleeve is formed on one of the connected products, into which the edge of the other is inserted.

Between the two layers of plastic there is a stiffness and strength giving the structure an aluminum layer. Pipes are delivered in bays, which allows dispensing with short splices.

When a fork is formed or plumbing is connected to the water supply, one of two types of fittings is used:

![]()

Metal-plastic corner - thread with compression joint.

Curious: the author suspects that only fittings with rubber sealing rings displaced during assembly on the nozzle flow.

If this is the case, a more thorough calibration of the pipe and lubrication of the fitting with solid oil should help, which may well prevent the displacement and damage of the rubber rings.

Here, the assembly instruction is also not very complicated: the pipe outside and the fitting inside are fused with a low-temperature soldering iron with a nozzle of the corresponding diameter, after which their surfaces are combined. A few seconds - and we have in our hands a whole product.

Both pipes and elements for their connection are the cheapest. However, it is worthwhile to use them, in addition to cold water, in autonomous systems of hot water supply and heating: a combination of high temperature and a pressure jump during a water hammer can well lead to a break in the piping or riser.

In the photo - tees on a polypropylene water pipe.

Ordinary polyethylene is used exclusively for cold water.

Pipes are connected in several ways:

On hot water and heating, the so-called cross-linked polyethylene is used, which differs from the usual strength and heat resistance. During installation, the pipe is stretched by a special expander and put on the fitting, which, thanks to the effect of molecular memory, after a dozen or two seconds is very firmly crimped. An additional fixing of the connection is provided by a sleeve worn on the outside.

The device of its fitting almost exactly repeats the compression joint for a steel pipe. However, thanks to the corrugated surface, the connection is not only tight, but also extremely durable: it is almost impossible to tear out a section of the water supply.

Here docking methods are much less.

Traditionally, chasing is used for joining cast-iron sewers:

Accordingly, fittings are combinations of bends with the same diameter as pipes and sockets.

However, new pipes and pipes are increasingly supplied with rubber seals, ensuring tightness during ordinary docking.

And polyethylene, and much more common PVC pipes for sewage, and fittings for them are again equipped with rubber seals in the sockets.

Two details are connected with the docking:

Of course, we have provided only the most general information about the types of connections used in modern plumbing, heating and sewer systems. The video in this article will give you some additional information on this topic.

Good luck in the repair!

In addition to all of the above, it is worth noting the installation speed separately, since steel communications are installed much longer.

But the main difference is the internal section, which in PP products does not decrease with time, but in steel it is overgrown with serious calcareous deposits.

There is also no need to clean, paint and oil the communications, and water hammer in the system will not affect at all.

It is noteworthy that plastic pipes for hot water supply relate to a synthetic material, which has several qualities at the same time. Flexibility and hardness, with such hardness that counteracts the mechanical influence and flexibility that is inherent in all polymer derivatives. The extreme melting and softening temperature of the pipe is 150 °. And if heated to 180 °, then the polymer will flow and gradually turn into a viscous liquid.

![]() As most manufacturers indicate, PP products will withstand maximum temperature water at 95 °, so any temperature rise is only harmful, but since in all heating and water heating systems the temperature does not exceed 95 °, there is no need to wait for problems.

As most manufacturers indicate, PP products will withstand maximum temperature water at 95 °, so any temperature rise is only harmful, but since in all heating and water heating systems the temperature does not exceed 95 °, there is no need to wait for problems.

There are certain areas where systems can operate above 100 °, but more often they either use reinforced pipes or increase the pressure in the system.

Reinforced pipes always withstand thermal fluctuations upward. Composition: the same plastic pipes for hot water supply, but already with protection against bursting, represented by a layer of putty and aluminum foil.

What does the reinforcement look like?

What does the reinforcement look like?

The foil is not very successful in the sense that if contact with water occurs, there may be electrical activity that causes corrosion. Therefore, it is worth using fiberglass, in which there will be no electricity, and the service life is many times higher.

In a reinforced pipe, 2 layers of polypropylene are laid, between which there are fibers of fiber and fiberglass. Three layers are welded to each other, thereby providing extreme strength.

This strength becomes the key to safety in working with high water temperatures and the heavy weight of the entire structure. An unreinforced compound may swell and burst when heated.

Plastic pipes for hot water supply and heating have many common stereotypes about their unreliability. Stereotypes are completely untrue. Communications are reliable for domestic hot water and heating according to the above-mentioned qualities, in addition, they are much cheaper than steel communications, and are easy to install. For installation you need only one soldering iron for plastic.

Also, their small weight plays an important role, since the joints can be laid even on the roof of the building. Reliability is not inferior to metal.

In conclusion, it must be said that polypropylene pipes able to create communications with almost all types of materials, including steel. In addition, the scope is not limited to hot and cold water supply systems, and is also used to install sewers, irrigation systems of private areas at home, gardens and greenhouses. Due to their flexibility and low weight, their installation brings only pleasure, as it pleases that you can install absolutely any water supply scheme.

And as mentioned earlier, pp pipes are not subject to corrosion and deposits on the walls. And their care is so simple that it can be said that they are ideal for heating and domestic hot water systems.

And as mentioned earlier, pp pipes are not subject to corrosion and deposits on the walls. And their care is so simple that it can be said that they are ideal for heating and domestic hot water systems.