From internal pipelines, drains are transported by external ...

In modern construction, various types of roofing materials are used, which provide reliable protection of the roof from rainwater.

But the review of roofing materials will be incomplete, if not to mention the roofing galvanized iron, widely used in individual suburban construction.

The galvanized roof looks neat and is able to reliably protect the building from atmospheric moisture for many years. Snow on the pitched roof of galvanized steel is practically not delayed, which allows to reduce the cross-section of the elements of the rafter system and save on the purchase of materials for construction.

Galvanized iron produced by industry must comply with GOST 14918-80.

Galvanized sheet steel according to its purpose is divided into groups:

For cold stamping - ХШ;

For cold profiling - HP;

For coloring - PC;

General purpose - OH.

By the uniformity of the thickness of the zinc coating, galvanizing happens:

With normal thickness variation - HP;

With reduced thickness variation - UR.

The thickness of the sheet may be from 0.5 mm to 2.5 mm. The thickness of the zinc coating of grade Ts0 and Ts1, depending on the class, can be:

For galvanized steel of groups ХШ, ХП and ОН insignificant flows, grains of zinc crystals, local roughness and light or dull spots are allowed. Violation of the integrity of the zinc coating is unacceptable, as this will lead to corrosion and destruction of steel.

Galvanized iron has high strength, able to withstand significant snow and wind loads without destruction. It resists solar radiation and precipitation.

Galvanized steel is used to stamp such popular building materials as metal tile and corrugated board.

In accordance with GOST 14918-80, galvanized iron is available in widths from 750 mm to 1800 mm.

In accordance with GOST 19904-90, cold-rolled sheet metal for subsequent zinc coating can have the following dimensions:

As you can see, the assortment of galvanized iron sheets is very diverse, so you should choose based on the size of the roof covered by galvanization, the possibility of delivery, unloading and installation.

Most often, in individual construction, sheets of galvanized iron with dimensions of 1000 mm by 2000 mm, thickness 0.55 mm and 1250 mm by 2500 mm are used.

The guest does not regulate the weight of each individual sheet of galvanized steel. But, if you need to calculate the weight of the roof or the weight of the sheets for choosing a vehicle for their transportation, then based on the specific gravity of steel 7.8 g / cm3, you can tentatively use the following table:

|

Sheet size mm |

Sheet thickness mm |

|||||||||||||||

The price of galvanizing varies depending on the thickness of the sheet, the thickness of the zinc coating and the number of sheets of galvanized iron purchased. In order to cover a bathhouse or a cottage, you are unlikely to need a wholesale lot for which you can get a discount. Therefore, you should focus on retail prices offered by sellers today.

In your region, prices may vary slightly, but on average, for example, you can use the galvanizing price table below:

|

Sheet thickness mm |

Sheet width mm |

Sheet length mm |

Sheet price, rub. |

Despite the wide selection of roofing materials on the modern market, today galvanized sheet is increasingly being used, the sizes and shapes of which allow decorating the roof or facade of any structure. Due to its high performance, corrugated sheets occupy a leading position among the materials for roofing and cladding of buildings.

The profile galvanized sheet, the dimensions and thickness of which depend on the application, is a rolled metal with a corrosion-resistant coating. Steel billets are cold rolled on special machines that form the so-called corrugations. They have the shape of a trapezoid and act as stiffeners. Thanks to them, steel profile sheets have an increased level of strength.

Profile shape and rib height affect strength steel sheet. This kind of corrugated board is used for different purposes - from the installation of gates, fences and ending with the roof.

The main advantages of profile sheets are ease of installation and maintenance, durability, versatility and low cost compared to peers. In addition, the professional sheet has a small specific gravity: depending on the thickness of the metal and the presence of the polymer coating, a square meter of this material weighs from 5 to 10 kg. The most durable metal profile copes well even with supporting functions.

Of the disadvantages, it is worth noting the high noise level during physical impact on steel sheets. For example, during rain, the corrugated sheet enhances the sound of drops falling on it. Another drawback is the unattractive appearance, but this opinion is not shared by all. It has the color of steel of a slightly yellowish hue and, due to the lack of paintwork, is more affordable.

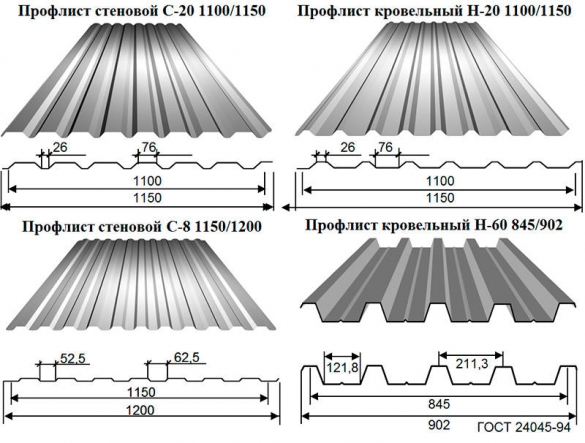

Profile hire is classified by purpose and is divided into 3 types:

Corrugated galvanized sheets, like all metal, have their own standard sizes, which are regulated by GOST 14918 and are indicated by the symbol “O”. There are also rolled products with an electrolytic zinc coating according to TU 14-1-4695-89 (denoted by EOCP). In addition, products are classified by the presence of a protective polymer coating.

The standard sizes of galvanized iron sheet are in the range from 2.4 to 12 meters (NS). Depending on the application, the size has different multiplicity. So, for example, roofing sheets (H) have a length of 3 to 12 meters and a multiplicity of 25 cm, and rolled products for wall fencing (C) - from 2.4 to 13 m with a multiplicity of 30 cm. However, on an individual order, manufacturers produce sheets of any sizes.

Roofing profiled sheets (marking “N” - bearing) are also used for the construction of bearing and supporting structures. Due to the high profile, large thickness of the metal and the wide step of the wave, these sheets can withstand heavy loads. For example, with a certain laying, H75 grade flooring with a sheet thickness of only 0.9 mm can withstand a load of up to 720 kg / m2.

During the manufacturing process, marking is applied to finished shaped sheets, which indicates its main characteristics. This procedure is mandatory and all manufacturers of metal products label their products. Labeling of different companies may vary, but usually it contains all the information necessary for specialists.

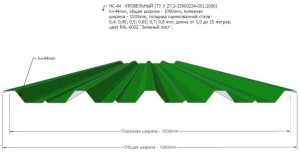

We will understand the sizes of galvanized and corrugated sheets on the example of one of the most popular brands. An example of a complete marking of profile steel is C21-0.45-750-11000, where:

In most cases, for the installation of walls, fences and gates, the following brands of sheet profile are used: C8, C10, C18, C21, C44.

Profiled sheet C8 has a useful length of 1 to 11.5 m and is often used for the installation of facade and wall coatings, as well as ceilings. The corrugation height is 8 mm, and the sheet thickness is from 0.4 to 0.7 mm, making this brand one of the most affordable. Another advantage of this type of profiled sheet is its low weight, which greatly facilitates installation, transportation and increases the economic benefit as a whole.

Galvanized profiled sheet of the C18 brand, despite its belonging to the category, is often used for roof installation. As you know, one of the drawbacks of the seam roof is noise with strong gusts of wind. The design of the C18 brand with small stiffeners and wide shelves almost completely solves this problem.

C21 corrugated galvanized sheet has a high level of stiffness, despite the low profile height. Waveforms provide a reliable connection, and their frequency and symmetry increases the stability of the sheet. Profiled sheet C21 is used for the installation of fences and walls, as well as for the roof of residential buildings.

The most popular brands of galvanized sheet roofing are H60 and H75.

The H60 brand is distinguished by high operational characteristics, versatility and a relatively low price. It is often used as an independent roof profile and for the installation of formwork. The useful width of the profiled sheet is 8.45 meters.

It is believed that H75 brand decking is the most popular roofing metal. It is used in many areas of modern construction for the installation of membrane-type roofs, seam roofs and fixed formwork. This brand is made of the highest quality steel and is the leader among production volumes roofing sheeting. High rigid ribs and a thick sheet of galvanized steel can withstand enormous loads.

The most popular universal brands of professional sheet are HC44 and HC57.

HC44 is a typical representative of the class of universal corrugated board. It is equally suitable for both roofing and wall coverings. The increased strength of this brand allows you to mount the rental in increments of 2.5 meters.

HC57 differs from the previous one in higher resistance to mechanical loads. The maximum thickness of the steel sheet is 1 mm and the wave height is 60 mm.

Of course, these are far from all sizes of profile galvanized sheets. Their range is much wider, and it is unlikely that it will be possible to list all the features of each brand within one article. However, this information is quite enough for selection or at home.

Rolled color is a matter of taste. But one thing is for sure - it is better to choose a professional flooring with a protective paintwork. It is slightly more expensive than a simple galvanized profile, but has a longer service life and a more aesthetic appearance.

In private construction, the device of fences and roofs from profiled sheet metal is actively practiced. Consider the characteristics of galvanized corrugated board, as one of the varieties of this material.

Despite the emergence and widespread use of painted corrugated board, galvanized has not lost its popularity. This is due to the fact that at low cost the scope of its application is not limited, and, in practice, much wider than that of the painted analogue.

The use of a galvanized profiled sheet is advisable in cases where it is necessary:

Tip. Galvanized corrugated board can not be painted with ordinary paints. This should be taken into account when planning to build a capital long-term construction.

For sheathing (decoration) of vertical surfaces, a sheet with a wave height of 8 to 21 mm is used. This size is due to the fact that with a low profiling wave, more than the useful area of \u200b\u200bthe sheet is preserved, and the stiffness during vertical installation on the frame is not a determining parameter.

Note. Installation of corrugated board on vertical surfaces can be performed both vertically (stiffening ribs of the sheet are perpendicular to the line of the base of the building) and horizontally (lines parallel to the foundation).

It is used for use on horizontal and inclined surfaces. A sheet with a wave height of 20 mm is suitable for the roof. In practice, the larger the roof pitch, the lower the wave height may be applicable. And vice versa, corrugated board with a wave height of 45 mm is installed on a flat roof, and taking into account the amount of precipitation in the region, the thickness of the snow cover, the roof configuration - with a wave height of 75 mm.

Tip. Installation of corrugated board on the roof is carried out only in accordance with the direction of runoff of water.

For the formation of ceilings, it is reasonable to use only zinc-coated profiled sheets, as here the determining parameter is the stiffness and load-bearing capacity of the sheet, and not its aesthetic properties or corrosion resistance. For these purposes, it is preferable to use a corrugated sheet with a wave height of 75 mm.

Regardless of the purpose, a profiled sheet is manufactured in accordance with the standards contained in GOST 24045-94 “Galvanized professional flooring” on special equipment. As a result of the passage of the galvanized sheet through the shafts, waves are formed - profiles (stiffeners), which inform the finished corrugated board of its properties.

Galvanized corrugated board has two determining parameters:

On the market there is a professional sheet with a thickness of 0.3 to 1.7 mm. The most popular is considered to be the thickness of corrugated board 0.45-0.7 mm.

This indicator directly affects the anticorrosive properties of the material. GOST regulates that the thickness of the galvanized coating should be 275 g / m2. The estimated service life of such a profiled sheet is 15-20 years. Reducing the thickness of the coating entails a reduction in price, but also a decrease in the life of the product.

We also note that zinc is a volatile material and eventually erodes from a steel base. In addition, violation of the integrity of the layer (mechanical damage) also contribute to the rapid development of corrosion.

Tip. For temporary fencing, in order to save money, it is reasonable to use corrugated board with zinc coating of 100 g / m2. The estimated service life is 5-7 years.

Galvanization of sheet steel not only determines the life of the profiled sheet, but also its appearance.

Three types of galvanized surface are distinguished, depending on the crystallization pattern:

With a normal crystallization pattern, the appearance of the sheet will be covered with “stars”, “snowflakes”, etc. The choice of “picture” depends on the preferences of the buyer.

Note. Uneven crystallization indicates violations in the technology of applying the zinc layer.

Due to the fact that the sheet is profiled from a roll blank, the width of the corrugated board is determined by the wave height - the higher the wave, the narrower the sheet. This property must be taken into account when calculating corrugated board. In addition, it should be borne in mind that different manufacturers have installed different roll forming equipment. Those. wave configuration (the angle of its inclination relative to the plane of the sheet), and hence the working width of the sheet will differ. So, at the same wave height, the width can vary by 5-15 mm.

The length can be any and is determined by the needs of the customer. In terms of ease of transportation and installation, the maximum length of a sheet of galvanized corrugated board for most manufacturers is 12,000 mm. The minimum length of corrugated board is 200 mm. At the same time, the dimensions of the profiled sheet are discrete 50 mm. Those. equipment allows you to cut a sheet into a multiple of 50 mm.

When installing corrugated board without a polymer coating (decorative finishing layer), you should be prepared that the appearance of the lined surface will change over time. Due to the volatility of zinc, the surface of the sheet will lose its luster and acquire a dirty gray tint. In places where the zinc layer is slightly thinner or there is mechanical damage - rust will appear on the sheet.

The thickness of the zinc layer only affects the rate of change, but is not able to prevent them.

The price depends on such parameters as sheet thickness, zinc layer thickness, wave height (working width) and differs depending on the manufacturer.

For comparison, the price of galvanized corrugated board of several manufacturers is shown in the table.

| Type of corrugated board | Sheet thickness | Cost, rub.m. | ||

|---|---|---|---|---|

| LLC Profmetall | Krona LLC | LLC "Yugmontazh" | ||

| PS-8 | 0,35 | 167 | 143 | 159,01 |

| 0,40 | 175 | 154 | ||

| 0,45 | 196 | 176 | 201,97 | |

| 0,50 | 208 | 191 | 220,16 | |

| 0,55 | 225 | 218 | 243,19 | |

| 0,60 | 246 | 237 | ||

| 0,65 | 264 | 253 | 283,17 | |

| 0,70 | 279 | 269 | 301,70 | |

| PS-20 / PK-20 | 0,35 | 126 | 149 | - |

| 0,40 | 183 | 160 | 181,55 | |

| 0,45 | 204 | 183 | 230,61 | |

| 0,50 | 217 | 199 | 251,37 | |

| 0,55 | 235 | 228 | 277,67 | |

| 0,60 | 257 | 246 | - | |

| 0,65 | 276 | 265 | 323,32 | |

| 0,70 | 291 | 273 | 344,48 | |

| PK-44 | 0,40 | 236 | - | - |

| 0,45 | 263 | 208 | - | |

| 0,50 | 287 | 208 | 249,24 | |

| 0,55 | 306 | 226 | 275,31 | |

| 0,60 | 325 | 249 | 300,20 | |

| 0,65 | 344 | 288 | 320,57 | |

| 0,70 | 358 | 306 | 341,55 | |

| PN-75 | 0,70 | - | 385 | 482,39 |

| 0,80 | 619 | 437 | 541,94 | |

| 0,90 | 681 | 490 | 606,25 | |

| 1,00 | 735 | 550 | 671,44 | |

| 1,10 | 789 | - | - | |

| 1,20 | 859 | - | - | |

The table shows that manufacturers have significant fluctuations in the cost of the material.

It is not surprising that galvanized corrugated board is firmly held among the most popular materials for construction and decoration. So, if you need to purchase reliable and inexpensive material for a wide variety of needs, you should take a closer look at the profiled sheet with a galvanized surface.

Not a single type of industry can do without any metal products — one of them, galvanized steel sheet.

Galvanized sheet is a flat thin metal product, coated with a protective layer of zinc, which protects the substrate from corrosion. As a base, various alloys of iron are used, - steel of various grades.

For the production of galvanized products, cold-rolled steel is used, which is passed through industrial equipment in order to obtain the desired shape.

A protective coating is obtained:

Galvanized products can be compared with a composite material with electrochemical cathodic protection in a pair of "iron - zinc". A light metal, acting as an anode, takes on oxidative reactions, gradually collapses, thereby protecting the base metal. In addition, zinc itself has a high chemical resistance to weathering, so its service life is quite long.

Galvanized products are in steady demand in many industries:

The advantages of galvanized steel:

Disadvantages:

Galvanized products are available in two types:

It is a rolled steel several tens of meters long wound into a roll. The average width is 1250 mm. The thickness of the metal is in the range of 0.2 ... 4 mm. Roll winding is convenient for use in automated processes for the production of similar products.

Available in a width of 1 ... 2.5 meters. The thickness is 0.35 ... 3 mm. The length is 1 ... 6 meters. The size is selected for a certain type of production of any industrial product in order to reduce the amount of waste.

Hire is carried out in accordance with GOST 14918-80 from carbon cold-rolled steel.

Appointment:

Extractability:

The uniformity of the thickness of the zinc coating:

Rental accuracy:

In appearance:

Coating thickness:

Flatness:

One of the most popular applications for galvanized sheet is the production of corrugated products.

Corrugated sheet (corrugated sheet), corrugated sheet - a type of industrial product, which is a wave-like profile. In appearance, it very much resembles the well-known asbestos-cement roofing slate.

The corrugation is a continuous sinusoid - due to this form, there are no points of mechanical stress in the places of bending, in which the process of structural destruction is most likely. At the same time, this shape of the sheet profile significantly increases rigidity, especially in the transverse sinusoid direction.

This type of product has found wide application:

A corrugated sheet has a number of certain advantages:

In addition to the protective galvanized coating, the product is covered with decorative polymer or paint coatings, this contributes to the additional protection of the entire corrugated sheet and increases the aesthetic perception of the whole structure as a whole.

The sizes of the corrugated board are in the range:

When installing corrugated products as a fence (fence) or roofing material No special knowledge or skills are required. It is enough to own a hammer, screwdriver and other common construction tools. Installation of a corrugated sheet is very similar to working with conventional asbestos-cement slate.

The cost of the final product is affected by:

A very important point is the quality of products, which entirely depends on the manufacturer and the production culture, for example, smooth galvanized sheet with a width of 1250 mm costs:

High-quality galvanized product must be produced in accordance with the requirements of technical documentation, in particular, according to GOST 14918-80, in compliance with the entire technological chain.