From internal pipelines, drains are transported by external ...

Use natural stone for decorating, few people can afford. Needless to say, pleasure is not cheap. In addition, to select for personal needs a sufficient amount of material of one tone is also extremely difficult.

Recently, the topic is manufacturing.

With a serious approach to business, you can start the production of artificial marble yourself.

Most often, artificial marble is produced in three main types:

- based on concrete;

- based on polyester resins;

- based on gypsum.

For a decorative effect, artificial marble is coated with gelcoat, while the filler consists of mineral chips, resins and pigments and hardeners. The appearance of cast marble as a whole will depend on the color of the gelcoat. When using a transparent gelcoat, the color will be determined by the pigment or filler added to the polyester resin.

It is the polyester resin that is the binder for the casting type of marble, to which filler in the form of mineral chips is added. The size of the fractions and the amount of mineral filler depends on the desired end result.

Thanks to a certain technique in the production process, when mixing the components, spots and stains similar to natural marble are obtained.

The resulting building material is not combustible; interferes with the conductivity of electric current. The homogeneity of the structure of the material, resistance to corrosion and alkaline environments.

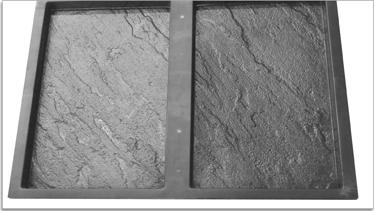

How to make artificial marble based on concrete? Everything is simple. Use a building mixture of crushed stone, river sand or pebbles. Additionally, you need to prepare construction equipment: matrix or polyurethane form; mixer; gelcoat, brush.

The technology based on concrete involves the preparation of the working composition, strictly following the proportions of cement, sand and filler. Plasticizer, dyes and 80% liquid are added to the main materials. Using a mixer, get a plastic mass. Then add the remaining 20% \u200b\u200bwater, mix again and distribute in polyurethane forms.

Forms must be clean, dry, pre-treated with gelcoat. After uniform distribution of the mixture in the matrix, removal of excess solution, cover the mold with a specially designed film. After 10-hour exposure of the working mixture, the finished monolith of artificial marble is removed from the mold.

Forms must be clean, dry, pre-treated with gelcoat. After uniform distribution of the mixture in the matrix, removal of excess solution, cover the mold with a specially designed film. After 10-hour exposure of the working mixture, the finished monolith of artificial marble is removed from the mold.

From all the above, it follows that it is not so difficult to make artificial marble with your own hands.

The process of preparing artificial gypsum marble is as follows: gypsum powder, carpentry glue is added to the specified amount of water; as well as resin previously melted in hot turpentine. After thoroughly mixing these components, pigment or acrylic dyes are added to the mixture. With their help, the desired patterns from stains are obtained.

It is known that using various coloring pigments it is possible to obtain the desired shade of artificial gypsum marble. So, to get the milky tone of marble, you need 1000 grams of technical alcohol, add 200 grams of white humilax and 50 grams of gypsum powder. If it is necessary to obtain brown tones of artificial marble, orange gumilax must be used, and accordingly, aniline paint is used for black or dark gray varnish.

The liquid substance of the mixture is poured into a special form of polyurethane, sprinkled with gypsum powder on top, and left to solidify for 10 hours. After the indicated time, the artificial gypsum marble is carefully removed from the mold. In order for the surface to be waterproof and more practical, it should be treated with potassium silicate on the front side.

If necessary, the semi-finished product is immersed in the bath and processed on both sides. After the surface finally dries, it should be treated with a soft felt material or a special abrasive material with colored polish. With this treatment, they tend to a perfectly smooth surface.

Based on the review, it can be concluded that the use of artificial marble is currently cost-effective.

Such material can withstand significant loads. It has low thermal conductivity. If mechanical damage to the product made of artificial marble occurs, restoration to its former shape is possible. In everyday life, artificial marble surfaces are quickly cleaned of lipstick, tea, coffee, red wine, tomato juice, etc. The main care for the artificial marble work surface is to polish it with a special paste using a felt nozzle on a drill.

Faux marble It has the hardness inherent in natural stone, is easy to process, which allows you to give the product the desired shape. Artificial marble is warm, pleasant to the touch, has a high resistance to wear. The main advantage is that its production can be carried out at home, it is enough to carefully study the manufacturing technology of an excellent substitute for natural marble from concrete.

It happens natural and unnatural. Artificial is a material obtained from concrete. It differs little from natural stone. Production technology is different. Depending on this, the following types of artificial stone are distinguished:

This article discusses the latter form.

This material is most often used for exterior cladding of buildings. It is used as an alternative. ceramic tiles for bathrooms, flooring, the manufacture of countertops for kitchen tables, sinks and sinks, steps, and sculptures, bank, office and bar counters, fireplaces and many other items. Fireplaces serving as a center of comfort in the house are decorated with such material, and recently - a sign of prosperity and luxury. Artificial concrete marble, wherever it is applied, is a sign of exquisite taste.

Decorative concrete, artificial marble, colored concrete, artificial stone, decorative marble call the same material, the basis of production of which is a cement-sand mixture, which is characterized by high qualities. Products from it have a highly artistic appearance.

Thus, marble made of concrete has found the widest application in the construction and facing works.

Marble is a special natural material that gives grandeur and beauty to any building. Recently, it is often used in the interior of a house. But natural stone is expensive, not everyone has the opportunity to purchase it. Therefore, experts have developed a technology for the production of artificial marble from concrete, the appearance and quality of which are identical to natural stone, which has the following advantages:

To make marble out of concrete with your own hands at home, you need to stock up on:

After preparing all the necessary materials, you can safely get to work. The production of marble from concrete begins with the preparation of the mortar. It should be kneaded in a ratio of 1: 3. The best filler is fine pebbles. Although you can use other additives: expanded clay, ceramic chips, pumice.

Technology marble concrete provides the following steps:

Recently, the use of stone as a finishing material has gained wide popularity. But construction materials, such as marble or natural granite, are not always affordable for us (prices bite). But why pay more, and besides, spend your nerves and time when choosing when there is an option to create artificial marble with your own hands at home?

Artificial marble has long been used for the manufacture of products such as sinks, window sills, lady's racks, countertops and much more. A huge plus of this material is that it is very easy to work with, which explains such widespread use in marble decoration. All we need before making artificial marble with our own hands is to prepare a mold for casting the part.

Artificial marble is a simple combination of acrylic resin with a mineral filler. This hardness material is easily comparable to natural stone, and it is very easy to process, it can take absolutely any shape. Also, a rather big plus of artificial stone from natural is warmth, it is warm and pleasant to the touch. By the way, in terms of resistance to wear, artificial material is in no way inferior to natural.

The basis of artificial marble laid polyester resins. They are the main element of the strength of this unique material. The composition also includes fillers and color pigments (dyes). With proper mixing of dyes, we get on the material the so-called marble effect (simulated streaks, stains, stains). Also, during the production of artificial marble, you can achieve any color of the material.

The uniqueness of artificial marble:

All these uniqueness provide this product with a wide range of applications in any field of activity.

First of all, for the manufacture of artificial marble with your own hands, select a separate room, since the manufacturing method involves working with chemicals. Choose a place where there is more space to place forms, so as not to feel cornered, but feel free.

1.

Before proceeding directly to the manufacturing technology of the product, check the list of all the components for the manufacture of marble: a matrix of polyurethane for the finished product, two parts of sand (river). One part of cement, water 0.2 parts, dye (with the calculation of about one percent of the part of cement), pebbles for filling, plasticizer (calculated, like dye, one percent of the weight of cement), mixer and film (cellophane).

1.

Before proceeding directly to the manufacturing technology of the product, check the list of all the components for the manufacture of marble: a matrix of polyurethane for the finished product, two parts of sand (river). One part of cement, water 0.2 parts, dye (with the calculation of about one percent of the part of cement), pebbles for filling, plasticizer (calculated, like dye, one percent of the weight of cement), mixer and film (cellophane).

2. First, molds are made for the future product. They should not be contaminated or wet. Also, in advance it will be necessary to prepare the mixture for manufacture, for this we take and mix cement, sand and pebbles. We mix until all this dry mass is homogeneous, until everything turns one color, after thorough mixing we add dyes, due to which artificial marble becomes like natural marble stone, streaks, stains and stains appear.

In this case, it makes sense to quote: “the worse, the better”, the naturalness of artificial marble and higher similarity with natural depends on the uneven distribution of the dye in the mass.

3. There comes a time to add water to this bulk mass, add about 0.8% plus a plasticizer and mix thoroughly. After some time of mixing, the mixture acquires plasticity, then it is necessary to pour out the rest of the water prepared for the manufacture of the product. Now we take the mixer and mix it all thoroughly, it is to this moment that special attention needs to be paid, since it is from the uniformity of this mass that the quality of marble depends.

4. We place the prepared mixture at home in the pre-cooked form of the part; when placing the mixture, try to shove as much elastic mass as possible into the mold, expelling air from there. In order for the porosity of the product to be as low as possible and no sinks to appear after extraction from the molds directly on the surface of the product, special vibratory platforms are used for this in a large industry.

They put a mold with a mixture on the platform, and with the help of vibration the mixture is rammed, giving the product high strength and a long service life. In home production, too, when filling the form with a mixture with your own hands, you need to give it vibration, only then the product will gain high quality and the desired appearance.

They put a mold with a mixture on the platform, and with the help of vibration the mixture is rammed, giving the product high strength and a long service life. In home production, too, when filling the form with a mixture with your own hands, you need to give it vibration, only then the product will gain high quality and the desired appearance.

5. After proper filling, remove all excess from the edges of the form with a spatula and cover it with a thick cellophane film. The prepared product is given time for complete hardening, this occurs within ten to twelve hours. After hardening, the film is carefully removed from the product and removed from the mold.

6. Cooked marble using this technology, the slabs can be used for a variety of room decoration, you can also try a little and modify the product, giving it the desired shape. Midday material has low porosity, so it is resistant to various kinds of processing and external influences.

Modern analogues of traditional natural materials have received the widest distribution today. The advantages of using artificial stone in the interior design are innumerable, just mention the exceptional strength of the material and the relatively low cost.

The possibility of self-manufacturing, ease of installation and processing of the finished product, as well as the use of innovative technologies in the manufacture - all these aspects are described in detail in the information in this article.

The use of natural stone in the design of residential and public buildings has more than one hundred years of positive use. Such cladding has always been the prerogative of the upper strata of society, but with the advent of artificial analogues, such luxury has become more affordable.

You can find out how it looks from this article.

This significantly expands the scope of use and contributes to the popularization of products made of artificial marble.

Advantages of using artificial stone in the interior:

You can find out what it is from this article.

On the video - artificial marble manufacturing technology:

At the same time, one should not forget about some of the features of this material: the finished product must be properly certified, and with independent production it will be useful to study the production technology in advance, stock up with all the necessary materials and tools. The manufacture of artificial marble requires compliance with safety rules, since during work there is contact with chemicals.

Here everything is limited only by your imagination! Artificial marble is widely used as a facing material, both indoors and outdoors. Facades made of artificial marble are characterized by absolute resistance to atmospheric phenomena, ultraviolet radiation and mechanical damage. The scope of this material is very wide, good strength and harmlessness to others will allow the material to perform the most diverse tasks.

On the video - the use of artificial marble:

A few examples of the use of artificial stone:

In principle, artificial stone in general and marble in particular can be used to decorate any interior detail. Depending on the type of molding sand, marble can form a rather thin layer, which is successfully used for internal wall covering instead of traditional wallpaper.

In order to better understand the possibility and technology of self-production of artificial marble, it is necessary to study in more detail the qualitative composition of the molding mixture and the types of this material. A brief overview and a master class on making marble with your own hands - further in our article.

The following types of artificial marble are distinguished:

You should familiarize yourself with the undisputed leader of this list - cast artificial marble, which is most in demand in terms of performance and ease of manufacture.

Casting marble contains polyester resins, mineral fillers, water and special pigments. Thanks to its natural components, marble is obtained as natural as possible and has excellent characteristics. Thanks to dyes, you can recreate the structure of almost any natural stone, but imitation of marble has gained the most popularity.

The algorithm for creating cast marble products:

The resulting part is then subjected to grinding for the final removal of burrs and impregnations of the mixture. Also, the surface is polished with a special brush to give smoothness and visual appeal to the product.

The process of making artificial marble with our own hands is not much different from the industrial method. The tool can be used the same, only expensive forms to create a single product will be impractical to buy. That is why there are many ways to make matrices yourself.

Typically, plastic containers of suitable size and configuration are used for this. For the manufacture of a conventional plate, a wooden pallet with reclining sides will be enough. Dimensional accuracy will not be so important, because the finished product can be cut to the required values.

The presence of a vibrating table will greatly facilitate the task and make the structure of the artificial stone more durable and uniform, but for lack of a better one can use the manual method of mixing. The gelcoat layer can also be applied with a hand gun or a regular paint brush. In general, any home master can independently choose what to replace industrial equipment with. Special mixing containers can be successfully replaced with a “mixer” nozzle for an electric drill. The top layer of the home-made form is insulated with a plastic film for successful removal from the hardened mass.

Artificial marble is an excellent finishing material, which has found the widest distribution in everyday use. It is used for aesthetically attractive and durable cladding of internal walls and external facades of buildings.

In the video -

Floor tiles made of this material are extremely resistant to abrasion and mechanical damage, and kitchen countertops and an apron very successfully resist aggressive effects temperature condition and chemicals.

Sinks made of artificial marble are distinguished by their superior design and trouble-free operation. Do it yourself artificial marble will significantly reduce the cost and will allow you to get original configurations and colors of finished products.

Comments:

Everyone who has taken at least a minimal part in construction works is well aware that concrete is an important building material. Concrete products are used to build the foundations of buildings, floors between floors, serve as the basis for the installation of stairs. However, many do not even suggest that you can make marble from concrete with your own hands. This work is simple, not requiring special professional skills.

Marble concrete withstands temperature extremes and retains its strength.

Marble made of concrete is an ideal facing material in its properties.Products made of artificial marble are excellent for exterior decoration of buildings, as they withstand temperature extremes without losing their original strength.

Before making marble from concrete, you should carefully study the technology of its production, and then purchase the components necessary for the manufacture.

Regardless of the number of manufactured marble products for work, it is necessary to prepare a place protected from atmospheric precipitation. To mix the mortar, it is better to use a construction mixer, but if the house has a powerful hammer drill, then usually there is a special nozzle in the kit, with which it is easy to prepare a high-quality concrete mortar.

If artificial marble will be produced in solid quantities, you will have to purchase or rent a vibration table designed to seal the finished solution and remove air from it. Thus, the perfect fit of the solution to the surface of the polyurethane form is achieved. This procedure makes it possible to obtain a finished product with a glossy surface that does not require further processing. In the manufacture of small marble products, you can do without a vibration table, replacing its work with vigorous shaking of a mold filled with a solution.

For the manufacture of artificial marble from concrete, the following materials will be required:

Vibrating tables come in horizontal and vertical vibration.

Of the tools necessary to create marble from concrete, it should be noted:

For this purpose, the prepared wire is simply recessed in the solution until it is completely frozen. Then the concrete with which the molds are filled is closed with a polyethylene film. The availability of artificial marble is at least 24 hours. During this time, the mass of concrete should completely harden. It must be borne in mind that the surface of the mold must be absolutely smooth, and before pouring concrete into it, it is installed strictly horizontally. For the finished product to be easily removed from the mold, it must be detachable.

The connecting elements of the tiles to each other are practically invisible.

The main advantage of marble, for the production of which concrete is used, is the absence of the need for additional processing. Products are immediately made of the required shape and size, with a smooth surface, the pattern of which completely imitates polished natural stone. In the manufacture of tiles used both for walls, steps, and for use in the form of pavement coverings, it is possible to give them such a shape that they will be connected to each other, creating a perfectly smooth surface. The joints of such tiles will be almost invisible. The affordable cost of this remarkable finishing material to the mass consumer is also a very important reason for the high demand for products from it. Few consumers can afford to finish the house with natural marble. It is especially difficult to choose the right shade of finish, as some colors of marble can be mined far from the construction site.

For this reason, its price becomes inaccessible to consumers with average incomes. Artificial marble gets its color with the help of pigments added to concrete, so getting the right shade of the product is not difficult.

The product, made of artificial marble, has a strength higher than natural stone, there is no waste during its creation. All components used in its production are environmentally friendly; when heated, harmful impurities are not released from them.

Those consumers who are distrustful of marble made of concrete should be reminded that the most affordable of natural materials - granite - has increased levels of radioactivity.