From internal pipelines, drains are transported by external ...

There are many types of welding. The division is based on a method for producing a high-temperature weld pool (type of energy). For example, electric arc welding, ultrasound, gas flame and others. Such a torch can cut and weld any metals. The edges of the metal parts to be welded literally melt and, joining together, make up a new single structure in place of the alloy, called the weld.

Welding gases include, first of all, acetylene for welding, released as a result of reaction with calcium carbide with water. Mixing with oxygen, it allows you to get a flame temperature in excess of three thousand degrees.

Also considered to be welding are propanes, butanes, liquefied MAFs (new gases that replaced acetylene), benzenes, kerosene and others. An important feature of the use of welding gases will be the mandatory presence of oxygen as a combustion catalyst. Moreover, the developed temperature also depends on the quality (purity) of the oxygen supplied to the burner.

Gas mixture for welding using technically pure oxygen gives a very intense and complete combustion of the mixture itself or the evaporation of combustible substances, since it provides very high combustion temperatures. The amount of oxygen in the flame will determine its oxidizing or reducing properties.

On the other hand, the use of technical (pure) oxygen requires special cylinders for its storage and supply. When mixed with such oxygen, some gases or compositions may be explosive (due to the extremely high rate of combustion in such a catalyst).

Often they can themselves be dangerous due to their toxicity. For example, acetylenes, dicyans, etc.

The use of oxygen contained in atmospheric air makes welding gas mixtures less effective. Their combustion slows down, which dramatically reduces the temperature of the flame. The reason is that in the air oxygen is not more than a fifth of it, other gases are present to a greater extent, the same nitrogen, for example.

In addition, welding under conditions of atmospheric oxygen often does not provide the required geometry of the joint, changes the properties of the metal in this zone, which ultimately affects the quality of the connection.

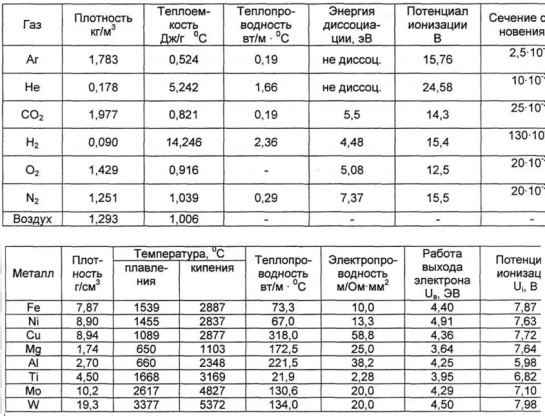

Technical gases are used not only in welding. Shielding gases are also widely used for electric arc welding, etc. The use of various inert (helium, argon) or active (nitrogen, CO2, hydrogen, oxygen) gases as a protective medium for a bath of a welding melt significantly improves the quality of the result, increases the speed of work, allows you to get the desired seam parameters, etc.

The principle of welding in the medium protective gases is simple. The desired composition is fed into the arc zone through the nozzle of a special burner under pressure, creating this very protective environment. Popular welding semiautomatic weldings are built on this principle.

Such welding is available not only in the factory, it is widely used in workshops and even in private garages. Most often, gas for welding by a semiautomatic device is a mixture of inert and carbon dioxide (in various proportions). Of the inert, helium and argon are more applicable. In practice, the use of argon is accepted, therefore, CO2 and argon are present in the composition.

In general, inert gas for welding is needed as a protection of the bath melt from external exposure to air, as well as, if necessary, high-quality welding work on stainless steels, titanium and its alloys, non-ferrous metals (nickel, copper, aluminum and alloys), etc. this electrode can be anything: a classic melting, not changing its shape and structure (used to create an arc), etc.

The choice of gas necessary for welding is influenced by which metal is used in the work. The same mixture of CO2 and argon during welding of steel elements contains more carbon dioxide component (about 18%). And when welding stainless steels, argon prevails (98%), CO2 is only two percent.

Thus, which gas is used for welding is determined by the metal, its brand, the necessary properties of the weld, types of welding equipment, the requirements for the chemical composition and even the shape of the welds, the conditions for the work, etc.

There are several types of welding that differ from each other by the method of producing a high-temperature weld pool designed for cutting or joining various metals and alloys: electric arc, ultrasound, gas flame. The principle of operation is that the edges of the structures to be reunited melt, and a completely new structural unit is formed at the junction of them — the weld.

The temperature indicator depends primarily on what gas is used in welding. For example, as a result of the reaction of water with calcium carbide, acetylene is released, which, interacting with oxygen, makes it possible to obtain a flame temperature of more than 3000 degrees. Welding gases include all types of propanes, butanes, MAF (an alternative to acetylene), benzene, kerosene and others.

The presence of oxygen, which is a combustion catalyst, is mandatory in the process of using any welding gases. The oxygen supplied to the burner must be of high quality and purity. Depends on these indicators maximum temperatureobtained during operation.

Regardless of which gas is used in welding, it is important to remember that it is possible to obtain a high combustion temperature and certain flame properties only when technically pure oxygen is used in the mixture. The completeness of combustion or evaporation of combustible elements depends on the quality of the component, and the properties obtained by the flame: reducing or oxidizing, depend on the quantity.

Special requirements apply to storage and supply conditions. The use of special individual cylinders is necessary in this case:

If atmospheric oxygen is used, it is unlikely to be able to get perfectly even seams. At the same time, the metal properties acquired during the process of melting and joining will change, which will significantly reduce the quality of the weld made.

It is considered not effective use in welding gas mixture ordinary oxygen in the atmosphere. The presence of impurities existing in the air significantly reduces the rate of combustion of elements, which affects the temperature of the flame.

Regardless of which gas is used in welding, inert or carbon dioxide, one should keep in mind the proportions in the mixture. The exact choice depends on the metal. For example, carbon steel predominates in welding steel structures (about 18%), and argon (almost 98%) when working with stainless steel.

In welding, inert and active gases are used. Inert elements, as a rule, are not toxic, do not interact with metal and do not dissolve in them.

Active gases protect the welding zone from air, enter into chemical interaction with metals and dissolve in them.

Improve the process and quality of the seam using welding mixtures. The most popular mixtures are:

When choosing which gas is suitable for welding in a particular case, several factors must be taken into account: the characteristics of the metal being joined, the type of equipment, the desired shape of the weld, the conditions for performing work, and the properties of the chemical composition.

Gas welding It costs more than electric, because the price of acetylene and oxygen is much higher than the cost of electric energy required for resistance or arc welding.

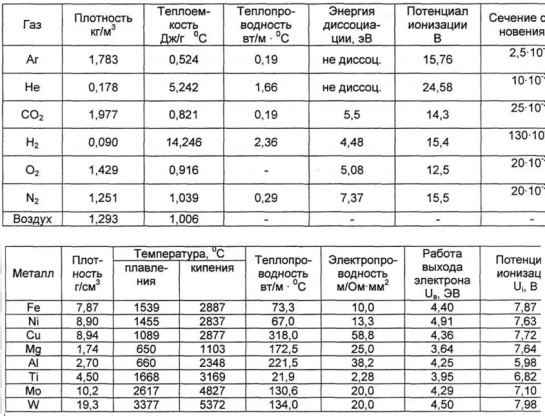

Gas welding is a type of welding work when parts need to be heated to a molten state by means of a high-temperature flame. This method is widely used in the creation of structures based on thin carbon steel, in the repair of cast iron products, and also when it is necessary to weld defects in different products obtained by casting from non-ferrous or ferrous metals.

When welding gas, combustible gases are used - natural, acetylene, gasoline vapors, hydrogen. These gases are distinguished by good combustion in air, without developing a high temperature, and an oxygen stream is sufficient for burning. Gas welding is most often based on acetylene, which is created on the basis of water and calcium carbide. It burns at a temperature of 3200-3400 degrees.

The advantages of gas welding include the following:

On the other hand, this process is not characterized by high productivity. Welding is carried out only by hand, and the mechanical and operational properties of the finished products are not always of high quality.

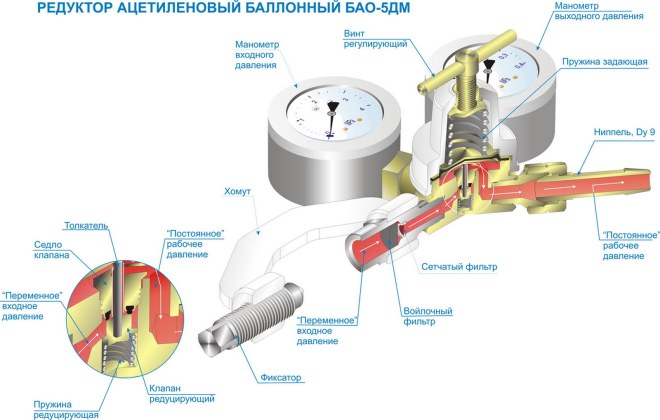

When welding, oxygen comes from a special cylinder - it is painted in blue or blue. In order to ensure normal operation, oxygen must enter the burner evenly and at low pressure. For these purposes, there is a reducer on the cylinders - it regulates the gas supply. In this case, hoses for gas welding - acetylene and oxygen - are brought to the torch. Oxygen is fed into the central channel, where the jet is discharged more, it sucks in acetylene, which enters the burner under slight pressure. The gases are mixed in the chamber, and then go out of the tip.

When performing gas welding, it is important to obtain a high-quality connection, therefore, great attention is paid to the careful preparation of the edges to be welded, the choice of the method of joining the metal, the installation of the burner in the desired position and the determination of the necessary parameters of the power of the burner. Gas welding technology suggests that the edges must be thoroughly cleaned of various contaminants. Beveling is carried out using a manual or pneumatic chisel, and sometimes special machines are involved. Dross and slag can be removed with a wire brush. The grasping of the edges allows you to prevent a change in their position during welding.

Gas welding can be done in several ways. The first is left-hand welding, which is the most common. It is used when working with thin and fusible metals. The torch moves from right to left, and filler wire is led in front of the flame directed to the un-welded section of the seam. In right-hand welding, the torch is driven from left to right, and the filler wire moves behind the torch. With this method, the heat of the flame is scattered to a lesser extent, therefore, the opening angle of the seam is not 90 degrees, but less - 60-70.

It is advisable to use right-handed welding to connect a metal whose thickness is from 3 mm and above, as well as metals with a high level of thermal conductivity. It is recommended to use filler wire with a diameter equal to half the thickness of the metal being welded.

The technology of gas welding involves a process that is conducted through a roller. In this case, the sheets are installed vertically to the gap - it is equal in size to half the thickness of the sheet. Using a torch, the edges are melted to form a round hole. Then it is melted from all sides until the seam is welded. This method is good in that the welded sheets have a tight seam without pores and slag inclusions.

Welding with trays is good for welding joints and joining angles of metals that have a maximum thickness of 3 mm. As soon as a bath is formed on the seam, the end of the filler wire is introduced into it, which melts slightly, then the end of the wire moves to another section of the seam. The peculiarity of this approach is in a weld of excellent quality, especially if thin sheets and pipes of steel (low-carbon and low-alloy) were welded.

Gas welding and cutting can be carried out on the basis of multilayer welding. This method has several features:

This affects the improvement of the quality of the seam. On the other hand, this method is characterized by low productivity, requires a high gas consumption in comparison with single-layer welding, therefore it is used if necessary to create responsible and high-quality products.

To work with horizontal seams, the right method is used, which makes it possible to easily form a seam, and the metal of the bath itself does not drain. Welding of vertical and inclined seams is carried out in the left way, and if the thickness of the metal is higher than 5 mm, a double roller is used. Welding of ceiling joints involves heating the edges until they melt, then a filler wire is introduced into the bath - its end is quickly melted. The process itself is conducted in the right way.

Gas welding equipment for gas welding is a wide selection of devices that allow you to carry out a number of works. This type of welding is considered simple, and the equipment itself is quite concise and easy to operate. Depending on the type of fuel, gas welding devices are propane-oxygen or acetylene-oxygen, gasoline or kerosene-oxygen. Most often, welding is based on propane-oxygen and acetylene-oxygen welding, since the flame of these gases has the highest temperature.

Gas welding equipment for gas welding is also a generator, which is supplemented by different types of gas. Also, during operation, an oxygen cylinder and gearboxes are required. The most common are acetylene generators for gas welding, which allow you to directly obtain acetylene by mixing calcium carbide and water. This type of generator is presented in five types, which allows you to choose the best option for a particular material.

Safety shutters play an important role when working with welding; their task is to ensure safety during welding. With their help, the passage of the reverse blow of the flame that occurs during welding is prevented. In addition, thanks to the check valves, the gas backflow into the rubber hoses is prevented during the flame treatment of metals and work with compressed gases.

Equipment for gas welding includes cylinders and valves for them. A cylinder is a cylindrical vessel that has a threaded hole in the neck where a shut-off valve is screwed. It is created from alloyed or carbon steel, and each such product has its own color depending on the gas contained in it. Cylinder valves are made of brass because steel is not resistant to corrosion.

A gas reducer is a device that constantly lowers or keeps a certain level of gas pressure. Gas welding and metal cutting are carried out on the basis of different types of gearboxes:

In argon-arc welding, argon reducers are widely used, which can work with non-combustible gases.

Gas welding of steels is a process that requires the use of a variety of devices. Gas burners are an integral part of equipment used in various industries. By design, the products are approximately the same: each burner consists of a housing. Several elements are attached to it at once: a tip, a valve that regulates the fuel supply, and a lever that regulates the height of the flame. The connection to the cylinder is carried out by a reducer, while the burner itself can often be supplemented by piezo ignition, wind flame protection and other components.

A gas torch for propane-based welding is safe to operate, providing a high flame temperature: it is enough to perform a number of works. Many types of welding are based on acetylene torches, which operate on a mixture of acetylene and oxygen.

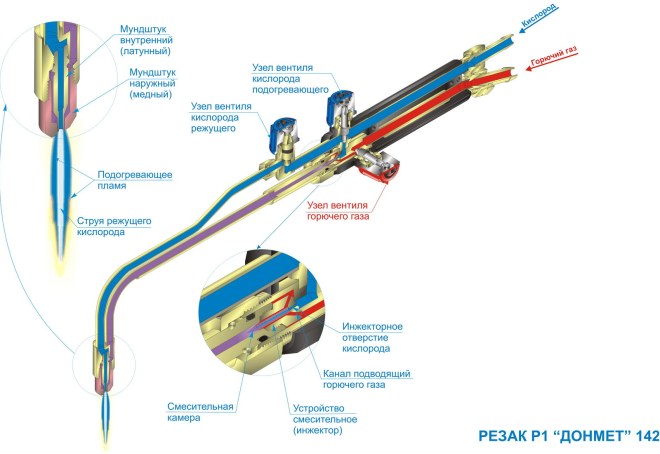

There are gas cutters different types: acetylene, propane and gas-fueled or liquid fuels. The design of the products includes a handle, nipples to which gas hoses are attached, a housing, an injector, a mixing chamber, a tube, a torch head and a tube with a valve. Gas welding of metals and its quality depend on how well the cutter is selected.

The essence of his work is as follows: from a cylinder, oxygen enters the gearbox, sleeve, and then enters the housing - here the cutter branches into two channels. Part of the oxygen passes through the valve and is sent to the injector. Gas comes out from here at a high speed, and during this process, combustible gas is sucked in. When combined with oxygen, it forms a combustible mixture, which is sent into the space between the mouthpieces and burns. As a result, a heating flame appears. Oxygen, which was directed along the second channel, goes into the tube, due to which a cutting stream is formed. It is he who processes the site of metal.

Welding of gas pipes is carried out in several stages. First, metal is prepared, that is, marking is carried out, pipes are cut and assembled. Due to the circular cross-section of the pipes, the cutting is carried out by a thermal cutter. Most of the welding work is the assembly of parts for it, when you need to take into account many parts - from a series of products to their diameter and other factors. The assembly is carried out by welding tacks, which prevent possible displacement of pipe sections, affecting the appearance of cracks during cooling.

The arc lights up. This is done in many ways. Then begins the melting of metals - the main and electrode. For a high-quality seam, it is important to pay attention to the angle of the electrode.

Oxy-fuel cutting is carried out using metals and their alloys, which burn in a stream of technically pure oxygen. This type of cutting is performed in two ways - dividing or superficially. The first method allows you to cut workpieces, cut metal, cut the edges of the weld seam. With the help of surface cutting, surface metal is removed, grooves are cut, surface defects are removed. This procedure is performed on the basis of special cutters.

Gas welding is a process that requires careful attention. Dangerous situations can occur in several cases:

Welding work should be carried out with the maximum observance of safety rules and using only high-quality equipment. This will make the process safe, and the connection of metals - reliable.

This method of joining metal parts, such as gas welding, has been around for more than a hundred years. During this time, this technology continues to improve successfully, although other welding methods that use an electric arc develop more actively and displace welding in which a gas torch is used.

This method of joining metals, such as gas welding, involves the melting of the materials to be joined, as a result of which a homogeneous structure is formed. Gas combustion, due to which heating and molten metal is carried out, is ensured by introducing pure oxygen into the gas mixture. This method of joining metals has a number of advantages.

This method also has disadvantages.

Gas welding technology involves the use of various types of gases, the choice of which depends on a number of factors.

One of the gases used for welding is oxygen. This gas is characterized by the absence of color and odor; it acts as a catalyst, activating the melting processes of the material being joined or cut.

In order to store and transport oxygen, special cylinders are used in which it is kept under constant pressure. Upon contact with technical oil, oxygen can ignite, so the very possibility of such contact should be excluded. Cylinders containing oxygen must be stored in rooms protected from heat and sunlight.

Welding oxygen is obtained by isolating it from ordinary air, for which purpose special devices are used. Depending on the degree of its purity, oxygen is of three types: the highest (99.5%), the first (99.2%) and the second (98.5%) grade.

For various manipulations with metals (welding and cutting), the colorless acetylene gas C2H2 is also used. Under certain conditions (pressures in excess of 1.5 kg / cm2 and temperatures above 400 degrees), this gas can explode spontaneously. Acetylene is obtained by the interaction of calcium carbide and water.

The advantage of using acetylene in metal welding is that its combustion temperature allows this process to be carried out without problems. Meanwhile, the use of cheaper gases (hydrogen, methane, propane, kerosene vapors) does not make it possible to obtain such a high combustion temperature.

To carry out welding of metals, in addition to gas, are also necessary. It is due to these materials that a weld is created, all its characteristics are formed. The wire used for welding must be clean, without signs of corrosion and paint on its surface. In some cases, a strip of the same metal that is being welded can be used as such a wire. In order to protect the weld pool from external factors, it is necessary to use a special flux. Boric acid and borax are often used as such a flux, which are applied directly to the surface of the metal being welded or to the wire used for welding. Without flux, gas can be performed, and when connecting parts from aluminum, copper, magnesium and their alloys, such protection is necessary.

Gas welding technology involves the use of certain equipment.

Water shutter

A water shutter is necessary to ensure the protection of all equipment elements (acetylene generator, pipes) from the reverse draft of the fire from the burner. Such a shutter, in which water should be at a certain level, is placed between the gas burner and the acetylene generator.

Gas cylinderSuch cylinders are painted with different colors, depending on what gas they plan to store. Meanwhile, the upper part of the container is not painted to prevent gas from contacting the components of the paint. It should also be borne in mind that valves made of copper cannot be installed on cylinders that store acetylene, as this can lead to a gas explosion.

GearboxIt is used to reduce the pressure of the gas leaving the cylinder. Reducers can be direct or reverse action, and for liquefied gas models with fins are used, which exclude its freezing when leaving.

Special hosesGas welding cannot be performed without the use of special hoses, through which both gas and flammable liquids can be supplied. Such hoses are divided into three categories, marked by 1) a red strip (operating at a pressure of up to 6 atmospheres), 2) a yellow strip (for supplying flammable liquids), 3) a blue strip (operating at a pressure of up to 20 atm).

The mixing of gases and their combustion is ensured by the use of a burner, which can be of the injection and non-injector types. Burners are classified by their power, which characterizes the amount of gas passed per unit time. So, there are burners of large, medium, small and small power.

Special tableGas welding is carried out in a specially equipped place called a post. In fact, such a place is a table, which can be with a rotary or fixed tabletop. This table, equipped with exhaust ventilation and everything necessary for storing auxiliary tools, greatly facilitates the work of the welder.

Adjustment of the flame parameters is carried out using a gearbox, which allows you to change the composition of the gas mixture. Using a gearbox, you can get a flame of three main types: reducing (used for welding almost all metals), oxidizing and with an increased amount of combustible gas. When welding metals in a molten bath, two processes occur simultaneously - oxidation and reduction. At the same time, when welding aluminum and magnesium, oxidative processes proceed more actively.

The weld itself and the area adjacent to it are characterized by different parameters. So, the metal section adjacent to the seam is characterized by minimal strength, it is he who is most prone to destruction. The metal adjacent to this zone has a structure with large grains.

To improve the quality of the seam and the area adjacent to it, perform additional heating or the so-called thermal forging of the metal.

Welding technologies for various metals have their own nuances.

Inert gases, active gases, and mixtures thereof are used as shielding gases in fusion welding.

Inert gases. Inert gases are gases that are not capable of chemical reactions and practically insoluble in metals. These are monatomic gases, the atoms of which have outer electron shells filled with electrons, which is the reason for their chemical inertness. Of inert gases, argon, helium, and mixtures thereof are used for welding.

Argon - non-combustible and non-explosive gas. It does not form explosive mixtures with air. Being heavier than air, argon provides good gas protection for the weld pool. Pure argon gas is supplied in accordance with GOST 10157-62 of three grades: A, B and C (Table 7-40). The moisture content for gaseous argon of all three grades should not exceed 0.03 g / m 3.

Argon grade A is recommended for welding and smelting of active and rare metals (titanium, zirconium and niobium) and alloys based on them, as well as for welding critical products from other materials at the final stages of manufacture. Argon grade B is intended for welding and melting with a consumable and non-consumable tungsten electrode of alloys based on aluminum and magnesium, as well as other alloys that are sensitive to impurities of metal-soluble gases. Argon grade B is recommended for welding and smelting chromium-nickel corrosion-resistant and heat-resistant alloys, alloy steels of various grades and pure aluminum.

Argon should be stored and transported in steel seamless cylinders that meet the requirements of GOST 949-57. A cylinder at a pressure of 150 atm contains about 6 m 3 of gaseous argon. The cylinder for storing pure argon is painted black at the bottom and white at the top. The inscription “Argon clean” is printed in black letters on the upper part of the cylinder. Argon is mainly obtained from air in which it is contained in a relatively small amount (1.28% by weight). Argon production is carried out on oxygen plants with argon prefixes. In these consoles, raw argon is purified to the required degree of purity from nitrogen and oxygen. Helium, like argon, is chemically inert, but unlike it, it is much lighter. Helium is lighter than air, which complicates the protection of the weld pool and requires a greater consumption of protective gas. In comparison with argon, helium provides a more intense heating of the welding zone, which is due to the large gradient of the voltage drop in the arc.

Heliumdeliver according to MRTU 51-77-66 two grades - helium of high purity and technical helium. Helium is stored and transported in seamless steel cylinders at pressures up to 150 atm. Helium cylinders are painted brown with the inscription in white letters "Helium". Cylinders must meet the requirements of GOST. Helium is extracted from natural hydrocarbon gases by cooling them in special plants. In this case, gaseous methane, ethane and other hydrocarbons are liquefied, and helium remains in a gaseous state, since it has a very low liquefaction temperature (-269 ° C).

Natural gases in the USA are especially rich in helium, which determines the widespread use of helium for welding in this country. A small amount of helium is contained in the air, and it is obtained, like argon, as a by-product in oxygen plants.

Inert gas mixtures usually consist of argon and helium. Having a higher density than helium, such mixtures better protect the weld pool metal from air. An inert gas mixture consisting of 70 vol.% Argon and 30 vol.% Helium has especially good protective properties. The density of such a mixture is close to the density of air. For welding chemically active metals, an inert mixture containing 60-65 vol. % helium, and the rest is argon. Inert gas mixtures, although noticeably more expensive than argon, but surpass it in the intensity of heat generation from the electric arc in the welding zone. This is significant when welding metals with high thermal conductivity.

Inert gas mixtures of the required composition are usually obtained by mixing gases from two separate cylinders using special mixers. Some foreign companies supply ready-made argon-helium mixture in cylinders of the required composition.

Mixtures of inert and active gases find wider application in the welding of various classes of steels with a consumable electrode due to their technological advantages: lower intensity of the chemical effect on the weld pool metal compared to active gases, high stability of the arc process, favorable transfer of electrode metal through the arc. Compared to pure argon, mixtures of inert and active gases have advantages in welding structural steels. It is known that with a melting electrode, the best characteristics of the welding process are usually achieved with direct current of reverse polarity. However, when welding steel, the use of pure argon as a protective gas is accompanied by instability of the position of the cathode spot on the surface of the product. The result is poorly formed welds.

The addition of a small amount of oxygen or other oxidizing gas to argon significantly increases the stability of arc burning and improves the quality of weld formation. The presence of oxygen in the arc atmosphere contributes to a more droplet transfer of electrode metal. This is due to the surface-active action of oxygen on iron and its alloys. Dissolving in liquid metal and accumulating mainly on the surface, oxygen significantly reduces its surface tension. As a result, the formation of individual metal droplets is facilitated, and their size is reduced. Therefore, for welding steel, not pure argon is used, but mixtures with oxygen and carbon dioxide Ar-O 2, Ar-CO 2, Ar-CO 2 -O 2.

Fig. 7-37. Form of penetration during welding in shielding gases:

a - in argon;

b - in carbon dioxide

For welding austenitic steels with a consumable electrode, it is recommended to use argon with an addition of 1 vol. % oxygen. Such a gas mixture provides a stable welding process and at the same time weakly oxidizes the weld pool metal. It is advisable to use a mixture of argon with 2 or 5 vol.% Oxygen when welding ferritic steels when jet transfer of electrode metal is required. When welding in such gas mixtures, the quality of the formation of welds is high; spatter of the electrode metal is very small. The disadvantages of the mentioned mixtures of argon with oxygen are the intense radiation of the arc and the finger-like penetration of the base metal characteristic of argon.

In this regard, mixtures containing carbon dioxide are significantly better. When welding in mixtures of Ar + 20% CO 2 and Ar + (15 - \u003d - 30%) CO 2 + 5% O 2, the radiation intensity of the arc column is relatively small, and the form of penetration of the base metal is the same as that of carbon dioxide (Fig. . 7-37). At the same time, these mixtures approach the carbon dioxide in chemical effects on the weld pool metal.

Adverse changes in the chemical composition of the weld pool metal occur when protected by carbon dioxide. The metal is carbonized, and the content of manganese, niobium and silicon is markedly reduced. As a result, the corrosion resistance of the weld metal is reduced, characterized by the ratio of the concentrations of niobium and carbon. The weld metal, welded in a mixture of Ar + 1% O 2, is least different in chemical composition from the original welding wire. Seams welded in gas mixtures containing carbon dioxide occupy an intermediate position in this regard. At the same time, the oxidation of the weld pool metal by the active gases included in the gas mixtures is also of positive importance.

An argon-hydrogen mixture (up to 20 vol.% H 2) is used in microplasma welding. The presence of hydrogen in the mixture provides compression of the plasma column, making it sharper, concentrated. In addition, hydrogen creates in the welding zone the necessary reducing atmosphere in some cases.

When transporting and working with gas cylinders, the rules for handling high pressure cylinders must be observed. Due to the high internal pressure, the walls of the cylinders are in a stressed state and any local increase in stresses can cause the destruction of an insufficiently high-quality cylinder. Therefore, compressed gas cylinders must not be thrown and subjected to shock and heat. Particular care should be taken in winter. At the workplace, the cylinder should be placed vertically and must be fixed.

Active gases. Active shielding gases are gases that can protect the weld zone from air access and, at the same time, chemically react with the metal being welded or physically dissolve in it. In arc welding of steel, carbon dioxide is used as a protective medium. Due to its chemical activity with respect to tungsten, welding in this gas is carried out only by a consumable electrode. The use of carbon dioxide provides reliable protection of the weld zone from contact with air and prevents nitriding of the weld metal. Carbon dioxide has an oxidizing and carbonizing effect on the weld pool metal. Of the alloying elements of the bath, aluminum, titanium, and zirconium are most strongly oxidized; silicon, manganese, chromium, vanadium, etc. are less intensely oxidized.

An obstacle to the use of carbon dioxide as a protective medium was previously the pores in the joints. The pores were caused by boiling of the hardening metal of the weld pool from the release of CO due to its insufficient deoxidation. The use of welding wires with a high silicon content eliminated this drawback, which made it possible to widely use carbon dioxide in the welding industry.

Carbon dioxide (carbon dioxide) is colorless, non-toxic, heavier than air. At a pressure of 760 mm RT. Art. and at a temperature of 0 ° C, the density of carbon dioxide is 1.97686 g / l, which is 1.5 times higher than the density of air. Carbon dioxide is highly soluble in water. Liquid carbon dioxide is a colorless liquid whose density varies greatly with temperature. As a result, it is supplied by mass rather than volume. When 1 kg of liquid carbon dioxide is evaporated under normal conditions (760 mmHg, 0 ° C), 509 liters of carbon dioxide are formed. On an industrial scale, carbon dioxide is obtained in special installations by extracting it from flue gases generated during fuel combustion, from fermentation gases in the alcohol industry and gases resulting from calcining limestone. Carbon dioxide is transported in a liquid state in steel cylinders or isothermal tanks. In steel cylinders, carbon dioxide is at a pressure of up to 50 bar, from where it is sampled in a gaseous state. Cylinders must meet the requirements of GOST 949-57, be painted black with the inscription "СО 2 welding", applied with yellow oil paint. 25 kg of carbon dioxide are poured into an ordinary standard cylinder with a capacity of 40 l, during the evaporation of which 12 600 l of gas is formed.

Carbon dioxide should not contain mineral oils, glycerin, hydrogen sulfide, hydrochloric, sulfuric and nitric acids, alcohols, ethers, organic acids and ammonia. In cylinders with welding carbon dioxide, in addition, there should be no water. Due to the scarcity of welding carbon dioxide of the first grade for welding, welding carbon dioxide of the second grade and food are used. The high content of water vapor in such carbon dioxide during welding can lead to the formation of pores in the joints and reduce the plastic properties of the welded joint.

The humidity of the gas rises at the beginning and end of the gas extraction from the cylinder, therefore in these cases defects most often appear in the joints. To reduce the moisture content in the carbon dioxide supplied to the welding to a safe level, a desiccant is installed in its path. To capture moisture, the desiccant is filled with calcium chloride, silica gel or other moisture absorbers. When the gas is released from the cylinder due to the effect of throttling and heat absorption during the evaporation of liquid carbon dioxide, the gas is significantly cooled. With intensive gas extraction, the reducer may become clogged with frozen moisture contained in carbon dioxide, as well as with dry ice. To avoid this, it is recommended to heat the carbon dioxide escaping from the cylinder.

Hard can be used for welding. carbon dioxide (dry ice), supplied in accordance with GOST 12162-66 of two grades - food and technical. By the content of impurities, edible carbon dioxide meets the requirements for welding liquid carbon dioxide, while technical carbon dioxide is contaminated with mineral oils. Dry ice is produced in the form of cylindrical or rectangular blocks.

It finds industrial application in welding low-carbon and low-alloy structural steels a gas mixture of carbon dioxide with oxygen (CO 2 + + O 2). A mixture containing 30 vol. % of oxygen, in Japan - a mixture with less oxygen (not more than 20 vol.%). A mixture of CO 2 + O 2 has a more intense oxidizing effect on the Liquid metal than pure carbon dioxide. Due to this, the fluidity of the metal increases, which improves the formation of the seam and reduces the weldability of metal droplets to the surface of the product. In addition, oxygen is cheaper than carbon dioxide, which makes the mixture economically viable. A mixture of CO 2 + 30% Oa is made from pure carbon dioxide and oxygen using special mixers.

Oxygen included in gas mixtures of CO 2 + O 2 and Ar + O 2. It is a colorless, odorless gas that supports combustion. Gaseous oxygen is obtained from atmospheric air by deep cooling or by electrolysis of water. Technical and medical gaseous oxygen is supplied in accordance with GOST 5583-68. Depending on the content of oxygen and impurities, technical gaseous oxygen is produced in three grades. The oxygen content in the first grade should be at least 99.7 vol. %, in the second - not less than 99.5 vol. % and in the third - not less than 99.2 vol.%. The water vapor content in technical oxygen of all three grades should not exceed 0.005 g / m 3, which corresponds to a dew point of 63 o C. Technical gaseous oxygen obtained by electrolysis of water should not contain more than 0.7 vol. % hydrogen. Oxygen gas is supplied in steel cylinders at a pressure of 150 or 200 kgf / cm 2. Cylinders must meet the requirements of GOST 949-57, be painted blue with the inscription "Oxygen", applied in black paint. On cylinders with oxygen obtained by electrolysis of water, the inscription “Oxygen is electrolysis” should be displayed.

Hydrogen used in atomic hydrogen welding. Hydrogen has no color, odor and is a combustible gas. Due to the fact that mixtures of hydrogen with air or oxygen are explosive, it is necessary to observe fire safety rules and special safety rules when working with it. Depending on the production method, technical hydrogen is produced in four grades: A, B, C and D. The purest is the technical hydrogen of grade A obtained by electrolysis of water. The hydrogen content in it must be at least 99%, the rest is mainly oxygen. Technical hydrogen is supplied in steel cylinders at pressures up to 150 bar, rubber-fabric gas holders and pipelines. Hydrogen cylinders are dark green with three red stripes around.

Nitrogen - colorless gas, odorless, does not burn and does not support combustion. Nitrogen does not dissolve in molten copper and does not interact with it, and therefore can be used in the welding of copper as a protective gas. According to GOST 9293-59, four grades of nitrogen are supplied: gaseous electrovacuum, gaseous 1st grade, gaseous 2nd grade and liquid. The nitrogen content in these varieties should be respectively not less than vol.%: 99.9; 99.5; 99 and 96. The main impurity is oxygen.

Nitrogen is obtained from atmospheric air by liquefying and rectifying it. Gaseous nitrogen is transported in steel cylinders under pressure up to 150 at. The cylinders are painted gray with a brown stripe and the inscription in yellow letters "Nitrogen" on the upper cylindrical part. Liquid nitrogen is transported in metal Dewar vessels and in transport containers. Under normal conditions (pressure 760 mm Hg and a temperature of 20 ° C) 1 kg of liquid nitrogen corresponds to 0.86 m 3 of gaseous nitrogen.