From internal pipelines, drains are transported by external ...

There are many ways to build houses - both high-rise and low-rise. But in modern suburban housing construction most common:

In terms of popularity, a brick bypasses a monolith great, and in this article we will analyze - is it deserved?

But before comparing these materials, one question needs to be clarified: it is impossible to build a low-rise house exclusively from monolith, and only from brick - it is undesirable.

In any building I will always be both monolithic and "structural", moving elements. Only their combination can provide both reliability and flexibility of your structure. And now for the case.

... should worry you only if you choose an apartment in a multi-storey building. In low-rise buildings, both because of the greater technical complexity of a monolithic building, and because of the need to mix types, the difference is not so great. The only area in which you will definitely feel the price difference is the quality of the materials.

But at this point, monolithic construction is ahead of the brick, and significantly. The secret is in the way of laying: if the brick requires thoughtful and concentrated laying in several layers, monolithic walls are simply poured into the "mold" of the formwork. Thus, in this "nomination" the monolith wins, but ...

You guessed that not everything is so simple? As soon as it comes not to standard, but to individual housing construction, standardized formwork becomes useless. For each interesting idea, for each unusual corner you will need your own “mold”.

Thermal insulation and wall thickness are an important factor. But here, a monolith is preferable. "Why?" - you ask? Its final heat-conducting properties are several times better than that of brick. This is largely facilitated not only by the use of cellular concrete and porous insulation, but also by the absence of seams.

This means, with the same thermal insulation, the wall thickness in the brick version of the house will be much larger. And who wants to give precious square meters?

A spoon of honey: The use of ceramic hollow bricks slightly reduces this gap in thermal insulation, but only slightly.

The weight of the house determines both the massiveness of the foundation and the overall complexity of the building. And again, due to the variety of light impurities, the monolith will be 15% -20% lighter than its brick "brother". What does this mean for you, as the future owner of the house? Save time and reliability - a monolithic house will be less affected by groundwater or excessive flooding.

And again, the monolith is in the forefront. Earthquakes in Russia are rare. But no one is safe from petty troubles, therefore, it is worth taking into account the ability of the house to resist the elements: both earthquakes and hurricanes. The monolith, having a more flexible structure, will bend and calm down, while the brick is more likely to crack.

But what if you have a crazy or insanely interesting plan and you want to "pack" your home in unimaginable forms?

Well, in this case, monolithic buildings - your choice. They easily "pour" into any formwork, although it is important not to overdo it: despite all the strength, each unevenness will reduce the stability of the structure. Brick, of course, is also capable of folding in completely futuristic forms, but it does so with great difficulty.

To represent this spatial functionality of a monolith and a brick, compare the curing rubber and the Lego constructor.

Do you want the same robe, but with mother-of-pearl buttons? Well, both brick and concrete give you complete freedom of action - you can make a facade to your taste and discretion. But in this category, a brick simultaneously wins and loses: in contrast to a concrete monoblock, a brick wall is itself a beautiful facade.

It also happens: the layout did not fit, the living room should be made bigger, and the annex should be integrated, but this wall needs to be ...

Infrequently owners monolithic houses they decide to make such major changes in their home - and it’s not so much the cost, but the time and troubles of this occupation. And sometimes in impossibility! After all, a brick is much more “mobile” than a monolith: it is easier to tear out and restore a single piece from it. Moreover, to make internal partitions of concrete monoblocks, the solution is truly ... strange. They constrain you like handcuffs.

In terms of engineering communications - electrical wiring, sewage, heating - brick, in view of its collapsible structure, furnishes two-piece monolithic walls. And although a concrete monoblock will not fall apart from the fact that you drill a couple of holes in it, you will have to abandon large-scale changes.

If we take the bare brick and the monolith, the first will leave the dull grayness of the monoblocks far behind. The only catch is that the monolithic houses are covered with a special finish, or even “wrapped” in their current competitor: brick. It only fits in one layer.

Of course, nothing bothers and brick walls to get some unusual decor, but admit - a brick is beautiful, presentable, comfortable. And usually I don’t want to cover it with something else.

However, in today's market, brick is preferred in. Causes?

No one conducted qualitative research, but we assume that the role is played by:

But in the end, the brick is a reliable, time-tested and beautiful material. And although its physical characteristics are inferior to a monoblock of concrete, the difference is not so significant, and the material itself is associated with comfort and warmth.

In fairness, it is also worth mentioning the shortcomings monolithic housing construction. Here is a pair of tar spoons:

In general, cast concrete during solidification is more susceptible to environmental influences than brick. Accordingly, it will be necessary to take into account heat and frost, and rain, which requires both good materials and professionalism from the construction company.

Of everything! External and bearing walls they will feel great if they are made of cast concrete: both the house will stand, and the heat will remain, and the sound insulation is excellent, and the facade can be decorated as you like.

However, the internal partitions will feel much better in a brick version, especially if you want to change something.

Sometimes it happens. However, the internal partitions do not bear as much weight as the external walls, which means you can use any material that is close to you: panels, wood, rubble stone. Even drywall! Although the latter, we would still not recommend using it actively.

And in order not to get into a mess and precisely calculate everything, while not studying sopromat - it is best to turn to. This eliminates complex calculations, guarantees reliability and helps to realize your wishes and ideas.

By the way, in our company TopDom there are excellent specialists.

Many people imagine a country house as brick or wooden. This creates a constant demand for such houses. But modern construction technologies are much more diverse. And there are significant advantages in the construction of other technologies. Monolithic construction technology more common for urban housing. But now more and more people want to build or purchase a country house from a monolith.

Monolithic construction Until the last 10 years, due to the lack of high-quality formwork and technological problems associated with hardening of concrete during cold weather, almost no development in the private sector. Today, there are many high-quality formwork (foreign and domestic) for construction, special additives accelerate the hardening of concrete.

Purely monolithic low-rise houses on the suburban real estate market are quite rare: buildings with no removable formwork make up no more than 5% in the market of low-rise buildings. The houses of combined technology (from a monolith, faced with bricks, blocks, tiles ...) are 60-70 percent on the market, and in the majority of houses or duplexes. In most cases, in suburban construction, a monolith is used for foundations or ceilings, sometimes developers use this technology for load-bearing walls. Such villages are considered to be built of monolith (brick or decorative tiles are used for their exterior decoration).

Technology of monolithic construction simple: the principle of creating a house frame is created similar to the gulf of its foundation. The construction of low-rise buildings using monolithic technology is carried out using the method of removable or fixed formwork. At removable formwork the iron frame is enclosed with formwork, concrete mortar is poured into the formed niches. When it hardens and dries out the formwork is removed, the resulting concrete walls are lined with brick or other materials.

Sometimes the formwork is not removed and it will remain part of the structure. These materials include expanded polystyrene, the use of which in the construction of a house in the form of fixed formwork significantly reduces the construction period and facilitates its construction, which reduces the cost of the foundation. After reinforcing the reinforcement of the space inside the formwork and supplying concrete to it, it is compacted with vibration tools and, if necessary, leveled. Concrete then gains strength, and the formwork is removed (if it is removable). If it is additionally necessary to mount the insulation, after dismantling the removable formwork, it is mounted on the walls. When using non-removable formwork, the insulation, as a rule, is the formwork itself. Then you can perform the cladding and other finishing work. This technology allows you to complete the construction with a minimum of losses for the adjacent landscape.

Monolith Advantage: short construction time; lack of restrictions in the configuration and use of architectural elements (bay windows, ledges, arches and special design ideas); higher seismic stability of the structure, monolithic ceiling and floor have good sound insulation and durability. The monolith in the first years settles entirely, without the appearance of cracks (like wooden and other houses). Disadvantages of monolithic construction technology: the dependence of the construction site on the weather and negative temperatures. Catch up build a monolithic house best for the summer season. After all, concrete hardens in the open air and is affected by precipitation and temperature fluctuations, which then affects the structural strength.

A beautiful, strong and durable monolith deserves to be used for the construction of cottages no less than wood or brick. Monolithic houses are the most promising and modern housing technology. Monolith in many respects is no worse than traditional materials. If the monolithic house is well built, it will last more than a hundred years. Its strength will increase over time. Quality finished houses depends on the observance of construction technology (quality of installation and formwork material, quality of concrete used, compliance with temperature and other conditions). However, it must be remembered that the quality of the building as a whole will depend not only on the type of building materials used, but also on geodetic control during construction work.

Monolithic cottages are usually lighter than brick cottages, and their walls and floors can be much thinner in design while maintaining the same characteristics as brick. Less materials for construction and costs. Monolith houses do not need a powerful foundation, which reduces the cost of their construction. Monolithic houses are being built very quickly, which significantly saves money. The cost of construction depends on the complexity of the project and the area of \u200b\u200bthe building, the number of window and doorways and many other factors. A large number of interior rooms will increase the cost of the house. At construction companies the cost of installing monolithic foundations up to about 13,000 rubles. per cubic meter of concrete. The construction of wall and floor structures will cost monolithic construction 15,000-22,000 rubles per 1 cubic meter of reinforced concrete. On average, a monolithic cottage with an area of \u200b\u200bup to 150 square meters. m. will cost about 3.5 million rubles., and a cottage with an area of \u200b\u200b300 square meters. m - up to 5.5 million rubles. Monolithic house under construction using fixed formwork area of \u200b\u200bup to 150 square meters. m. with a roof and windows can cost about 19,000 rubles. per sq. m. If they are built from a monolith with lining with other materials, the cost will increase to 24,000-30000 rubles. per sq. m

To begin, let's list the advantages of a monolithic building:

Now let's move on to the list of shortcomings:

Creating a project of the future monolithic structure and choosing between removable and fixed formwork is necessary based on many factors. These include your region of residence, the area on which the construction is supposed to be, as well as your other personal preferences.

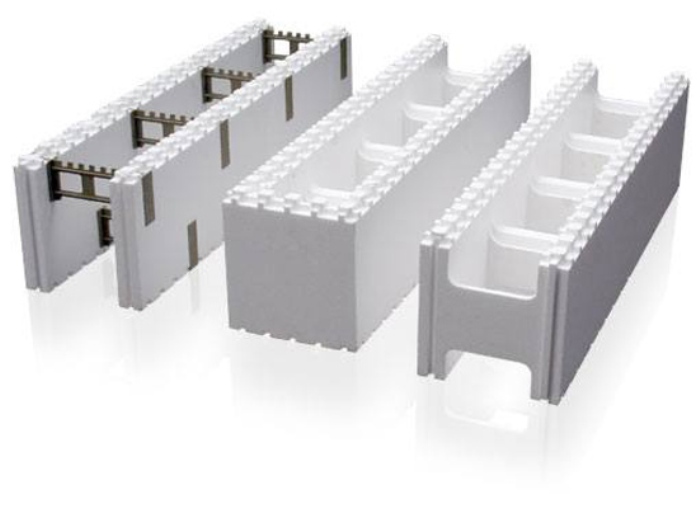

The most convenient is the option with fixed formwork, since a monolithic house in this case is built on the principle of "Lego". Most often, hollow polystyrene blocks are chosen as fixed formwork. The first row of blocks is laid on the foundation, reinforcement is laid in the voids for greater strength. Then the empty space is poured with concrete mixture. After the mixture dries, a second row of blocks is placed, which are also reinforced with reinforcement and poured with the mixture. This procedure is repeated until the desired wall height is erected.

As a concrete mixture, expanded clay concrete, aerated concrete, wood concrete, cinder concrete, perlite concrete can be used. By changing the type of concrete, it is possible to differentiate between different properties of the walls, such as vapor permeability, total weight, heat retention, etc.

Simplicity of construction in this way can be very alarming, but there are no "buts" here. By building walls with a fixed formwork, you save on additional wall insulation, create excellent sound insulation, and as a result get a solid monolithic structure.

With formwork, things are not much more complicated. First, a framework is created based on the prepared project. For formwork, which is attached to the frame, materials such as wood, iron, plastic and plywood are most often used. The distance between the walls of the formwork should be equal to the thickness of your future monolithic wall.

When the frame is evenly assembled and welded, and the formwork is firmly and tightly sewn to it, you can start pouring. Here, in one approach, it is necessary to fill in approximately 40 cm of concrete. And after each approach let it harden for about a day. Then we lift the formwork to the next level and fill it in the same way.

On a note. Particular attention should be paid to concrete compaction, this procedure is performed by a special construction vibrator. Most of all, concrete needs to be compacted at corners and bends in the structure in order to increase the strength of the structure.

After the walls are erected, you need to give them time to dry completely. This time is in the range of 4-5 weeks. Also, during this time the walls sit down a bit, and there is no way to rush to continue the construction. If you create an additional load, for example, by erecting a roof or just a frame for the roof, then the wall structure may give a crack or slightly slant.

On a note. In intense sun, moisten concrete walls with water. Otherwise, the concrete will quickly dry out and crack. It is best when the concrete dries slowly and gradually.

When building with fixed formwork, you may not pay much attention to this procedure. It is enough to plaster the walls, make them fireproof. But with removable formwork, you need to decide which method you better use. You can make simple warming with warm plaster or glass wool, but the most successful way is a well facade.

A well facade is understood as lining with a facade brick at a small distance from the monolithic wall, after which the remaining distance between the masonry and the monolith is filled with insulation. This method will be the most optimal, since the house acquires breathable qualities, that is, in the summer it will be resistant to heat, and in winter to freeze. This means that in winter the walls will keep warm, and in the summer keep a pleasant chill.

Having become acquainted with all of the above, the question arises, what materials will be needed during construction? And the best answer to this question will be a complete list of the necessary materials, which includes:

A relatively new low-rise construction technology for Russia involves the erection of load-bearing structures made of concrete monolith.

A common plus for all monolithic houses is the wide range of possibilities in choosing architectural solutions and exterior decoration: any complex shapes and a wide variety of facing materials are available.

Common cons

As for other features, this technology has become the subject of heated discussions about its real or imaginary cheapness, environmental friendliness and the “thermos effect”. Given the variety of materials and construction methods for monolithic houses, you should not "chop off your shoulder", hanging the label "harmful to health" or talking about "environmental friendliness". Each of the varieties of monolithic technologies has special properties, its pros and cons, which we now consider.

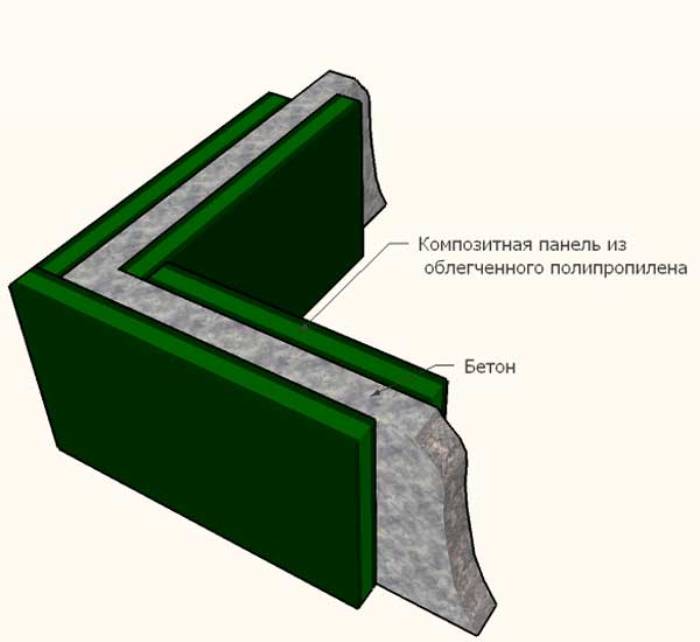

The supporting structures of such a building consist of

The construction period is longer than according to the method of fixed formwork: having laid about 50 cm of concrete in the formwork, it is rammed with a deep vibrator, waiting for solidification, the formwork is dismantled and it is collected one level higher.

Depending on the soil and foundation, it is necessary to choose the material of the walls. Concrete and reinforced concrete are strong, but also heavy, have high thermal conductivity. In addition, reinforced concrete products with reinforcement from 8 to 18 mm will create “cold bridges”. Such walls need good thermal insulation.

Arbolit, foam concrete, expanded clay concrete, etc. well save heat, lighter, but less durable than concrete. In order to avoid "cold bridges" for reinforcing, you can use plastic mesh

Houses with fixed formwork are being built using

Houses based on wood-concrete (arbolitnogo) or chip-cement slabs do not have the effect of "thermos", non-combustible and resistant to moisture. The arbolite frame is strong enough to fit wall cabinets. The house needs to be insulated with polystyrene foam, but only on the outside, which in the end does not reduce the vapor permeability. This is a relatively expensive construction method compared to other types of monolith with fixed formwork.

Non-removable facing panels as a frame consist of several layers: the base, insulation, fastenings of the facing, the facing plate itself. There are combined offers on the market combining removable and non-removable elements in which the base of the cladding is removed after the concrete has hardened, leaving the facing panel bolted to the wall. Such houses are characterized by vapor permeability, good thermal conductivity. The problem may be the choice of the project, because finishing plates have fixed sizes and it’s most likely that it will not work out on complex forms of the cottage.

The wall of reinforced panels (COTA) consists of expanded polystyrene with a spirit side reinforced with steel mesh. After installation, special concrete is applied from the plaster station on top of the finished panel (this is called the method of soft tankreking). Experts doubt the ability to build load-bearing walls in this way, because there is no monolithic thick layer of concrete in them - only thin on the surface. Expensive fittings and high grades of concrete for tanketting entail a high cost of structures. Among the advantages are high heat and sound insulation properties and speed of assembly.

This is without a doubt the cheapest and fastest way to build a monolithic country cottage. Expanded polystyrene blocks are mass produced, have standard sizes, are made including angular, assembled by means of spikes and grooves.

Great doubts arise about the safety of this material for health, because it will be located not only on the outside, but also on the inside of the wall of the building.

The cause of other problems of houses on polystyrene fixed formwork is a violation of construction technology. For example, ignoring corner blocks leads to the formation of cracks in the corners of the house. And these are, firstly, “bridges of cold”; secondly, the road for rodents and insects to soft, warm and comfortable polystyrene foam, where it is so convenient to make a nest.

The notorious “thermos effect”, for which such cottages are often scolded, arises if the project did not use supply and exhaust ventilation.

Prices of contractors for the construction of 1 square. m of a monolithic cottage in a fixed formwork vary as follows:

Houses with removable formwork are more expensive - from 14 thousand rubles. for a house made of concrete M 150 in a wooden formwork.

Thus, we must admit that fast-to-build, warm and inexpensive monolithic houses are a very attractive option for the construction of a suburban cottage. The most common and cheapest option, on a polystyrene frame, unfortunately, is not the best for health. However, many unpleasant features of this material can be avoided if the construction technology is strictly followed.