Job interviews are not easy. If you want to apply for...

Today humanity cannot imagine existence without electricity. An uninterrupted supply of electricity to each room depends on the competent laying of networks from directly to each consumer. This goal led specialists to the invention of reinforced concrete electric poles. The devices do their job very well. Before starting work, you should calculate how much the materials cost and how long the installation will take.

Before making an electric pole, it is necessary to take into account the advantages of such supports. The advantages include durability. Reinforced concrete electric poles can serve consumers for many years. It is important to take into account that high-quality building materials should be used in the construction of supports. They are more expensive, but their use guarantees durability to each concrete pillar.

Another plus is the choice of design. With the help of additional building materials (panels and other means), you can arrange. In addition, during installation work, specialists will not need expensive special equipment. This allows you to do the installation yourself and not turn to professionals.

How many disadvantages do such supports have? A concrete pole for electricity has only one drawback. It's about about laying the foundation, which is necessary in order to securely install a reinforced concrete electric pole. Otherwise, the structure may fall.

When installing an electric concrete pole, it is important to observe a number of conditions. First of all, builders must take into account the landscape, the strength of the wind gusts in the region, the traffic density of cars. Also, specialists should measure the distance between reinforced concrete supports. It is necessary to determine how many meters there are between each pillar. During installation work, a thorough check on the strength of the supports is carried out.

When installing an electric concrete pole, it is important to observe a number of conditions. First of all, builders must take into account the landscape, the strength of the wind gusts in the region, the traffic density of cars. Also, specialists should measure the distance between reinforced concrete supports. It is necessary to determine how many meters there are between each pillar. During installation work, a thorough check on the strength of the supports is carried out.

For uninterrupted transmission of electricity, it is necessary to install a structure in accordance with safety regulations. For the correct construction of supports, builders should adhere to the following rules:

Each reinforced concrete support is installed in stages:

For proper installation of concrete structures, it is necessary to adhere to safety rules. In particular, the marking of the selected territory involves choosing the place for erecting supports and determining the distance directly between the pillars.

The calculations should take into account the expected loads, as well as the characteristics of a particular area and soil. The markup should be done in such a way that as a result, uniform illumination of the areas by each pillar is achieved. Specialists carry out installation according to the technology of installation work. When marking, the number of concrete pillars and their location are determined.

After marking is completed, specialists begin drilling, following the marked parameters and taking into account the characteristics of the soil at the installation site. At this stage of work, a technique is used, which is a drill placed on a special platform.

Before starting work, it is necessary to recheck the supporting structures for possible cracks. Their vertical alignment is carried out using special levels and other means. A manipulator is used to erect concrete pillars. A thick cement mortar is poured into each pit where the supporting structures were installed. To give structures additional stability, specialists install props made of reinforced concrete or metal.

When installing and assembling support structures, you must carefully monitor the strict observance of the parameters:

The final stage is the laying of electrical wires.

The final stage is the laying of electrical wires. After the installation is completed, the installation of metal structures for attaching insulators begins. For this, clamps are used. There are also traverses that are not intended to transmit current. They are only needed to secure the electrical wires. Their dimensions will depend on the number of electrical wires that they have to hold.

To prevent possible corrosion of the traverses, it is necessary to cover them with a special agent that will ensure their protection. In addition, experts fix a cover that will protect them from harmful effects. environment. The laying is completed with the installation of electrical wires. At the same time, workers should take into account that the above actions must be carried out by representatives of an organization that has the appropriate permission.

Work on the installation of reinforced concrete structures for power lines is a responsible and complex process that involves the use of special equipment. If workers take into account the prescribed rules and safety precautions, they will be able to build a reliable and durable structure. Such a support will transmit electricity uninterruptedly for many years.

It is also important to remember that installation work should be carried out by employees of organizations with the appropriate permit.

Where can I install a pole for electricity in the country? What distances from surrounding objects should be kept? What should be the wires and insulators?

How much will it cost to connect the cottage to the electricity supply? Let's try to find the answers.

Our task is to find out how difficult it is to electrify a country house

Let's start with regulatory requirements. They are spelled out in the PUE - the rules for the installation of electrical installations. We have to study the latest this moment, the seventh edition of the document, adopted by the Ministry of Energy of the Russian Federation in 2003.

Please note: the adopted document canceled the effect of older PUEs. The changes affect, among other things, the chapter “Sewerage of electricity”, which is relevant to us.

Let's pay attention to the most important points of the document in our case.

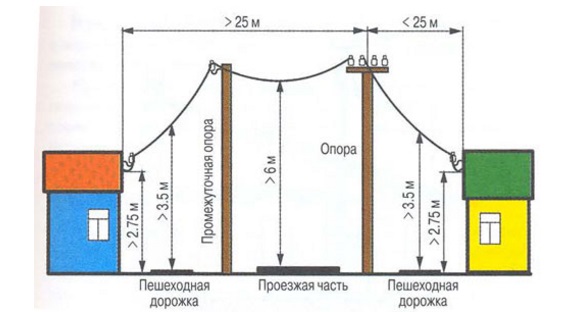

The height of the wires above the carriageway and footpaths

The height of the wires above the carriageway and footpaths Commentary: it would seem that this item puts an end to wooden poles. But ... no, a loophole remains: wood impregnated with a protective compound does not support combustion.

In the photo - porcelain insulators

In the photo - porcelain insulators The supports should not impede the passage and passage, block the entrances to the yards.

Where there is a possibility of a collision with a car, the support is protected from collision with it by a bumper bollard or in any other way.

The post must be marked at a height of 2.5 - 3 meters. It indicates the serial number of the support, the width of the security zone and the telephone number of the owner of the line.

All metal structures are protected from corrosion. The method of protecting the PUE is not specified; Traditionally, painting is used for this.

The minimum wire cross section for an overhead line is limited by its mechanical strength and is determined by the material.

It is curious: for a steel single-wire wire, not the cross-sectional area is limited, but the diameter. It should not be less than 4 mm.

Branching from the nearest support is carried out only and exclusively with insulated wire. The maximum branch length is 25 meters.

To connect the wires, connecting clamps or welding are used. Single-wire wires can be connected by twisting followed by soldering; but you can't butt weld them. In this case, a wire that differs in the material or cross section of the current-carrying core is connected only by clamps.

The minimum section for entering the house is also limited by the document; and in this case the cross section is determined by the type of wire:

For low-voltage lines, reinforced concrete, metal, solid wood and wooden poles with a concrete base can be used. All types of wood, except for larch, must be impregnated with an antiseptic; larch wood itself is exceptionally resistant to decay.

Wood is the most affordable material for a pole.

Wood is the most affordable material for a pole. When using a wooden support, its minimum diameter (at the upper end) should be:

Regarding the deepening of the supports, the document speaks somewhat vaguely - "depending on local conditions."

What should be minimum distance from the pole to the surrounding objects and communications?

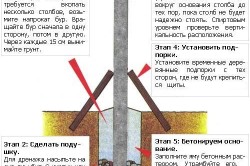

Is it difficult to put an electricity pole on the site with your own hands?

Here the simplest instruction for its manufacture from a bar with a section of 150 mm.

Comments:

Concrete electric poles are an integral part of the life of a modern civilized society.

It is impossible to imagine the modern life of people in large industrial centers, in megacities and in the most “seedy” village without concrete electric poles. Mankind has not yet come up with another way to supply electricity from transformer substations to those areas where people live, as soon as through wooden or concrete poles.

Electric poles for supplying energy from transformers to consumers are made of two types: wooden and reinforced concrete. In the Soviet Union, during electrification, wooden poles were installed for electricity, because reinforced concrete had not yet been invented. In our time, there is a widespread replacement of outdated wooden poles for electricity with reinforced concrete products, even in those places where there are no problems with the forest.

Wooden poles for electricity are used in places where it is very expensive to deliver reinforced concrete or there is no possibility: taiga, regions of the Far North, etc.

Back to index

Poles for electricity, having a concrete base, have a number of advantages:

The manufacturing technology of reinforced concrete pillars is simple and does not require qualified personnel and high-precision modern equipment.

From iron fittings of a certain diameter, a frame mesh is welded according to TU or GOST. This iron frame “frame” is placed in a mold and poured with a concrete solution of a certain consistency (cement / sand / water / any additives). The concrete hardens and after a while the form is disassembled, and the finished product "in the air" finally acquires its performance characteristics: strength, resistance to various aggressive environments, ignoring corrosion processes.

Back to index

No installation organizations and individuals do not have the right to install on adjacent to their land plots territory reinforced concrete electric poles, as and where they want. At first glance, it is easy and simple to install a reinforced concrete electric pole, but only an amateur can have such an opinion, because the production of such work requires professional knowledge.

You need to know how deep the product should be mounted, how many meters should be to the nearest pole from which the wires will stretch.

The installation of electricity poles requires approval from state specialized organizations. To begin with, it is necessary to draw up design estimates for the production of this type of work and coordinate it with state regulatory authorities. And only after obtaining permission to carry out specific work, you can begin to install reinforced concrete electric poles.

If you have money - the best option will turn to a law firm that, for a certain amount, will eliminate the need to fight Russian bureaucrats. If you think that you will not pay for what they are already obliged to do, be patient and calm.

Information for those who decide to independently install a reinforced concrete electric pole for their own needs.

Basic knowledge that 100% must be observed when installing reinforced concrete poles for electricity:

Pits for lighting poles are made with a special earthen drill.

When performing installation work, it is necessary to take into account the local "wind rose".

It doesn't seem to be very complicated rules, which everyone must comply with in order to install concrete pillars. But just think about the fact that you need to dig a hole 2.2 m deep, even in soft ground!

Therefore there are more fast way install a reinforced concrete pole for electricity - hire a specialized organization.

Of course, now it is impossible to take and simply entrust such a responsible matter as the installation of an electric reinforced concrete pole, even to a specialized organization. The customer or his authorized representative will be forced to be present during the production of all work - from earthwork and concrete, to the installation of wires.

Otherwise, the customer runs the risk of seeing, after a while, a small "Leaning Tower of Pisa" under his window. Such a “spectacle” is not only and not so much aesthetically pleasing, but also threatens with power outages in the house.

Back to index

In production necessary work it is necessary to control the following parameters:

Subject to these mandatory actions, the customer can be sure that the reinforced concrete electric pole will serve him for the prescribed period.

Installation of additional electric poles may be needed in the private sector, especially if the wooden poles have become unusable. You probably noticed rotting and rickety wood poles from which power lines run? Previously, only these were mounted, but after the expiration of the service life, old samples should be replaced with new ones.

Today, factories produce reinforced concrete and metal structures, and all because they are stronger, more stable and reliable, they are not afraid of temperature changes, insects and precipitation. Unfortunately, products for electricity are not cheap, so the installation of metal or reinforced concrete poles is affordable only for organizations funded by the state.

You can put wooden poles with your own hands; in villages and villages, just such poles for electricity are still used.

Before starting the installation process, it is necessary to study the features of the area, which can significantly affect the quality and duration of the use of electricity poles. So, pay attention to the factors:

The installation guide for electricity poles is as follows:

It may seem to the layman that the post holes have the same depth, but this is not so, because each recess depends on the following factors:

The depth of the pit is laid taking into account the turning of the poles for electricity - the overturning of the supports should not occur even in a natural disaster. There are also intermediate and main pillars - holes for the first ones are dug by self-propelled drilling equipment, where there is a crane for fixing the pillars in the soil.

Where the track is characterized by poor passability, the pit is reached by manual digging. At the same time, it is important to observe the period between fixing the pit and installing the support - no more than 1 day.

As for equipment, the following equipment cannot be dispensed with during installation:

If the pit has a cylindrical shape, the diameter of the rack becomes the reference point - the first indicator cannot exceed the second by more than 25%. If the difference increases, then the upper crossbar is installed. Crossbars on intermediate pillars are placed along the axis of the overhead line.

It is impossible to lift and immediately fix the free-standing poles with a crane, so that the supports do not fall, the workers securely fix the base with temporary braces, after which they place the upper and lower crossbars. The final fastening is carried out using the method of backfilling with soil, when alignment has already been made by backfilling into the sinuses of the earth with layer-by-layer tamping.

Whether the verticality of the poles for electricity, the voltage on which is 10 kV, is taken into account, is checked with a plumb line. If the voltage is increased to 35 kV, a theodolite is used. So that the traverses do not rust over time, it is advisable to walk over the material with a bituminous varnish composition.

The installation of insulation is carried out with polyethylene caps, in fact, the procedure looks like this:

You already understood that installing poles for electricity with your own hands is problematic - this requires equipment and special knowledge. Therefore, if there is a need to equip poles, you can leave a request at the nearest RES department. Privately, certain firms also perform such work, only this requires obtaining permission.

Before using the help of employees of a private company, read reviews on the Internet, find out how many objects the company has already equipped. If everything is in order, it is desirable to conclude an agreement on the provision of services and responsibilities of each party to the contract.

The technological procedure for the installation of a power line (power line) is carried out by the same company that you hired. It consists of several stages:

Many are interested in how much the purchase of supports will cost. Prices vary within different limits and depend on the size of the pillars, the material used and its quality:

In any case, no matter how reliable the supports are, it is important to fix them not only in the reinforced concrete foundation, but also in the soil - this is the correct installation, which will extend the service life to the maximum possible.