It must be said that the problem of how to manually compact gravel is quite relevant in private construction. No, of course, we are not talking about global projects, such as, for example, ramming rubble pillows under the foundation of a house with an area of \u200b\u200bover 100 square meters. m. here, you certainly will need special tools in the form of an asphalt compactor or a construction vibrating plate, since the volume of work is too large, and this will resemble the “sunset by hand”. Let's talk about small forms: a parking lot in the country, a path in the garden or the like. When you can really cope - and this is real and tested on the experience of many - on their own, without resorting to the help of expensive teams!

How to tamp gravel by hand? The problem is not easy: in the sense, physically. But its technical resolution has several options invented by our powerful inventions and savvy people. We will talk about them in our article today, but first, about some general principles of ramming.

Why do you need to ram gravel?

Frankly, the problem is quite interesting and some are not entirely clear. And among beginners in the construction business, this is the most common question. It would seem that he covered the surface with this strong and strong material, leveled it all - you can cover it with a final coating, what can happen, because a stone is a stone?

But not so simple. As you know, crushed stone is not a simple stone, natural (like gravel), but crushed in an artificial way. It is durable, but has sharp corners due to the technology of its production. Thus, additional tampering of the material creates a denser fit of individual fractional fragments to each other, and excessive voids between them disappear or are reduced in volume. This creates an additional margin of safety for laying.

We listen to the opinions of professionals. They confirm that the compaction of crushed stone during construction is necessary without fail.

The exceptions may be such options when the natural soil on which work is being carried out is rocky. Then it will be sufficient to thoroughly level the gravel before the subsequent laying of concrete, tile or asphalt on it. In all other cases, the idea is this: crushed stone as a base should not just lie in the ground, but form together with it such a compacted mixture by ramming with a dense filling of cracks between fractional fragments with soil. The thickness can vary for different purposes from 50 to 250 mm or more (this depends on what kind of load the final coating will experience in the future). Now that with the theory - why tamping is necessary - everything is more or less clear, we are moving, so to speak, to practical exercises.

Manual tamper

When there is no vibrating plate and roller at hand, ramming tools can be made with your own hands. But we repeat, these mechanisms, driven by the muscular strength of man, invented by craftsmen, are relevant only for tamping not too large fragments of surfaces, or those that subsequently will not experience too powerful loads on themselves.

There are many options for how to make a device for manual tamping. The simplest one is as follows. We take a wooden beam with a cross-section of at least 100X100 mm, and better - 150x150, then we get a wider grip of the rammed surface. The height of the beam should be convenient for work (usually about the chest performing tamper).

From timber rounded 50x50 mm, we make handles that we nail to the base with nails and fastenings made of iron or galvanized sheet. The bottom of the device is also sheathed with galvanized sheet to increase strength. In principle, the simplest device, known, probably, even at the time of the pharaohs, is ready for use. Of course, he did not get too much surface capture area for tamping, but if there is free time and desire, they can tamp even a crushed stone pillow under the foundation, for example, a small outbuilding.

True, it will take more time and energy to do this than when using a gasoline vibrating plate, but as an option, it is actually quite widely used. Using such a manual mechanism is quite simple, however, it requires some physical preparation, because you really get tired. We lift the device by the handles and lower it with force, for example, onto a garden path covered with gravel. Repeatedly repeat the movement, moving in a given direction. Thus, you need to go all the way several times.

One note: There are many options for such a device. There are more durable ones made of a metal pipe of about the same diameter with a metal “leg” welded to the base. True, this design creates too much vibration when applied (which, for example, dampens a wooden device), and then work should be done with special gloves.

DIY skating rink

The same applies to the manual asphalt compactor, which is also used with might and main for compacting small fractions of crushed stone (especially for various track options). To make it, in the presence of a grinder and a welding machine, as well as certain materials, is not difficult. Cut a metal pipe with a diameter of at least 30 cm to a length of one meter. On the one hand, we weld with a metal sheet and cut it in a circle with a grinder. Precisely in the middle of the sheet there should be a hole for fixing subsequently the handle.

Turn the pipe open end up and fill in the sand. The other end is also welded with a sheet and cut around the circumference. We put on the device for manual tamping a handle from a bent pipe. It turned out a universal device that, due to its weight, can be used for tamping small gravel, and for laying asphalt in the yard, and for sand and soil to make them denser. Using it is quite easy, but it will also require some skill and good physical development from you.

More options

If, for example, you need to tamp a small parking lot for your car in the country, then you can use the following method, invented by the people and successfully used, since there is nothing particularly complicated in technology. So, we sprinkle crushed stone over the territory measured in advance and marked with pegs (be sure to leave a certain amount of it on bedding).

We level it with a shovel so that the layer everywhere is the same thickness. Then we get behind the wheel of a car and methodically begin to park in the future parking lot in various places - either in the center, then on the left, then on the right, then sideways - trying to maximally cover the space covered with rubble. We do the procedure many times (20, 30, 50), until we are convinced that the rubble is tamped over the entire plane by the weight of the car. Shallow ruts may appear in some places. Pour the prepared crushed stone into them and continue. Here is such a simple but effective way, however, it is not entirely obtained manually, but using the weight of your car.

A well-prepared base is the result of the durability of the industrial floor and the building as a whole. Soil compaction methods are different, one thing remains the same - the use of special compaction equipment. The soil is compacted to increase its ability to withstand heavy loads. The principle of operation is based on air displacement. At maximum compaction, its content is not more than 3-5%.

When installing a concrete floor slab on a soil foundation, it is necessary to carry out work on planning the existing soil foundation. Peat, plant soil, construction debris must be removed. Clay soils also need to be removed to a depth of about 0.5 m. This is necessary to create a “trough”, which is subsequently filled with sand and gravel to create the bearing capacity of the base. Sandy soil removal is not required. Sandy soils consist of small particles of 0.1-2 mm in size. Dense sand is an excellent basis for the construction of structures, because it has a small compression ratio.

Depending on the loads acting on the soil base, a calculation is made. Depending on the loads, the thickness of the sandy, gravel, and sand gravel are determined. The fraction and material of crushed stone, soil compaction coefficient, etc. are also determined.

Compaction Methods.

To select a compaction method, you need to know several parameters - humidity, degree of uniformity, the desired density of sand or gravel, season, and so on. Compaction is carried out only with a certain percentage of sand moisture, so if necessary, moisten the soil with watering hoses. Compaction of frozen soils cannot be made. Before the start of the sealing phase, a test seal is carried out. Usually the test section is not larger than 3dx3d, where d is the diameter of the rammer.

Basic soil compaction methods:

- rolling - using rollers

- tamper

- vibratory ramming

Very often, several methods are combined.

When rolling, static pressure is transferred from the roller to the ground. It is carried out by self-propelled and trailed skating rinks. The thickness of the sealing layer is 35-50 cm. Several passes are required in the same place.

Conventional ramming is based on the transfer of impact force from a discarded seal (large mass slab) to the ground. This method has a large load, which provides compaction of crushed stone and sand to a depth of 2 m. It is carried out using ramming plates weighing 1-2 tons, which are dumped from a height of 1-2 m. For small volumes of work, manual ramming is performed - it is used for compaction sand in small volumes.

The most common soil compaction method is vibration ramming. This method is based on the transmission of mechanical vibrations. Vibration compaction is carried out by vibratory rollers, self-propelled vibratory rammers and vibrating plates. The thickness of the compacted sand or gravel is 30-50 cm.

Sand preparation works are carried out in layers, with compulsory compaction by vibratory rollers, and in places near walls and columns by vibrating plates and rammers. The sand compaction factor should be at least 0.95. The upper preparation layer is usually made from crushed stone of a fraction of 40-60 mm, followed by a rasklantovanie crushed stone of a fraction of 5-20.

In the case of shallow groundwater, the crushed stone base must be separated from the floor plate (to exclude the rise of water vapor) using a plastic film (two layers of 200 μm) or a waterproofing membrane.

All materials for the preparation of the base must comply with GOST. The resulting base should not have differences of more than 20 mm over the entire area. The compaction of crushed stone and sand increases the strength of the soil, reduces compressibility. The process is mandatory to ensure the strength of the base and foundation.

The average cost of preparing a soil base.

| №

|

Name of works |

Cost |

| 1

|

Sampling of the earth trough with the subsequent removal and planning of the territory under the mark |

450 rub / m 3 |

| 2

|

Sand base with 50 mm thick seal

|

90 rub / m 2 |

| 3

|

The device of crushed stone base with a seal thickness of 50 mm from limestone crushed stone |

180 rub / m 2 |

| 4

|

Sand base with 100 mm thick seal |

140 rub / m 2 |

| 5

|

The device of crushed stone base with a seal 100 mm thick of limestone crushed stone |

280 rub / m 2 |

MINISTRY OF TRANSPORT CONSTRUCTION

STATE ALL-ROAD ROAD SCIENTIFIC RESEARCH INSTITUTE

Approved by the Director of the Union State, Candidate of Technical Sciences E.M. Good

Approved by Glavdorstroi

(Letter No. 5603/501 of 08/01/83)

Moscow 1985

The design of crushed stone foundations treated with a sand-cement mixture, developed by the Union, Hyprodornia and State Dorodnia, provides a method for determining the calculated modulus of elasticity of a layer; requirements for a sand-cement mixture and crushed stone treated with a sand-cement mixture. Recommendations are given on the selection of mixtures that provide the required strength and frost resistance of the base layer; according to the technology of building a crushed stone base, treated in the upper part with a sand-cement mixture using two methods: mixing using a profiler and pressing using a vibratory roller, cam roller and pneumatic tire roller. The need for quality control of construction is indicated. 2, tab. 8.

Foreword

The pace of pavement construction is constantly growing. The relevance of the task is increasing - to develop the construction of the foundation using local materials and to propose appropriate technology that would improve the quality and efficiency, as well as accelerate the construction of foundations with increased load-bearing capacity. "Guidelines for the construction of crushed stone substrates treated with sand-cement mixture" were developed based on the results scientific research and experimental work of the Union, Hyprodornia, State Doroga and the construction of pilot plots by the Magistraldorstroy trust of Glavdorstroi and other organizations. These Guidelines describe the design and construction technology of a crushed stone base treated in the upper part with a sand-cement mixture or other inorganic binders. The proposed base design and technology of its device allow: to increase the bearing capacity compared to widespread crushed stone and gravel substrates and reduce material consumption by 10 - 20%. reduce cement consumption by 10 - 20% due to edema of coarse-grained materials in comparison with fine-grained materials with a smaller amount of binder; to ensure that construction vehicles can pass on the base without destroying it due to the manifestation of load-bearing capacity at an early age due to the skeleton of the material compared to sand and soil cement; to lengthen the construction season due to the removal of crushed stone in winter and the final construction of the base in the summer, which reduces the need for vehicles in the summer; use mixing plants with a small capacity and for high-speed construction of foundations due to the smaller volume of mixed material; reduce fuel consumption by 10 - 20%, reducing the volume of road transport compared to transportation in the construction of traditional crushed stone or gravel substrates; reduce labor and energy costs for mixing the mixture due to less work on the mixing plant. The total economic effect of reducing material consumption, reducing the consumption of binder and fuel and energy resources during the construction of 1 km the estimated cost is approximately 1 - 6 thousand rubles. The novelty of the work is protected by copyright certificates: No. 903446, No. 960348, No. 483477, No. 924211. “Methodical recommendations” were made by candidates of technical sciences V.S. Isaev, V.M. Yumashev, A.O. Sall, I.Z. Dukhovny, O.N. Rudaya, engineers N. A. Yorkina, M.F. Fomina, V.M. Beskrovny, V.M. Belousov, E.V. Volkov.

1. General Provisions

1.1. These Guidelines are developed in the development of SNiP II-D.5-72 and SNiP III-40-78 and are intended for use in the construction of crushed stone substrates treated in the upper part with a sand-cement mixture or inorganic binders based on production waste (metallurgical slag, whitewash sludge, active fly ash, etc.). 1.2. The crushed stone layer should be treated with a sand-cement mixture by the mixing method and the impregnation-indentation method. When using the mixing method, the necessary processing depth is provided by adjusting the working bodies of the DS-108 type profiler, which distributes a layer of crushed stone and sand cement using a screw-cutter and then mixes them. When using the impregnation method - indentation, the working depth depends on the voidness of the crushed stone layer and the machines used - cam roller, vibratory roller, pneumatic tire roller. 1.3. The basis of the developed design must be arranged on an approved subgrade or underlying layer. 1.4. The length of the interchangeable gripper should be assigned based on the planned pace of construction and the availability of machines and mechanisms. 1.5. Crushed stone bases treated with a sand-cement mixture or other binders should be arranged in dry weather at an average daily air temperature of at least 5 ° C. Crushed stone is allowed to be transported in winter to intermediate warehouses to the place of future construction. 1.6. Works on the installation of foundations must be carried out in accordance with the "Safety Rules for the Construction, Repair and Maintenance of Roads" (M .: Transport, 1978) and SNiP III-A.11-70 "Safety in Construction" (M .: Stroyizdat , 1972).

2. Pavement foundation structures

2.1. The average modulus of elasticity of the base structure with a modulus of elasticity variable with respect to the depth of the layer can be determined by conditionally dividing the base into two parts: the upper, treated with a sand-cement mixture, and the lower, untreated, with the corresponding calculated parameters shown in Fig. 1 and tab. 1.

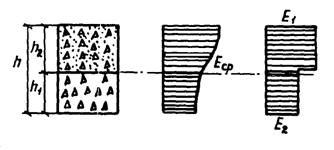

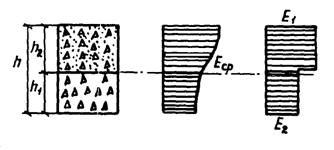

Fig. 1. Diagram of the modules for the construction of crushed stone base, treated in the upper part with inorganic binders: h - total thickness of the base, cm: h 1, h 2 - thickness of the upper processed and lower untreated parts of the base layer, cm; E 1 E 2 - moduli of elasticity of the processed and untreated parts of the base layer, MPa; E cf - the average modulus of elasticity of the base layer, MPa

When designing, it must be borne in mind that the bearing capacity of the design of the crushed stone base treated in the upper part with a sand-cement mixture, characterized by the average modulus of elasticity of the layer E cf, depends on the values \u200b\u200bof the elastic modulus of the processed E 1and untreated E 2 parts and their thicknesses h 1 and h 2(see Fig. 1) with a total layer thickness h.

Table 1

|

The ratio of the heights of the layers

h 1

/

h

|

The elastic modulus of the untreated part of E 2, MPa

|

The value of the average modulus of elasticity of the base E cp, MPa, equal to E 1, MPA, equal

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The value of the average modulus of elasticity of the base layer E cf when calculated according to the "Instructions for the design of pavements of non-rigid type" BCN 46-83 (M .. Transport, 1983) for the most common values \u200b\u200bof the modulus of elasticity of processed and untreated binders depending on the depth of impregnation according to the table 1.2.2. The calculated modulus of elasticity of the lower, untreated part of the base, depending on the properties of the materials used, must be taken according to the "Instruction" BCH 46-83 with the additions given in table. 2 of these "Guidelines." 2.3. The calculated modulus of elasticity of the upper, treated part of the base, depending on the grade according to the strength of the used sand cement and its amount in the crushed stone layer, providing various grades for the strength of the processed material that meets the requirements of GOST 23558-79, should be taken according to Table. 3.

table 2

|

Brand on the strength of crushed rock

|

The calculated modulus of elasticity of the untreated part, MPa, with crushed stone size, mm

|

carbonate

|

igneous

|

sandstone

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 3

|

Resistance of sand cement to compression, MPa, with the ratio Щ: ПЦ,% (K sec)

|

The properties of the processed material

|

|

|

|

Modulus of elasticity, MPa

|

|

Bending tensile strength, MPa

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.4. The minimum total thickness of the base layer should be at least 10 cm, the maximum not more than 25 cm. The maximum grain size of crushed stone should not exceed 2/3 of the thickness of the base. The maximum depth of processing of crushed stone with sand cement when setting the base by the mixing method using a profiler and the impregnation method using the cam roller should be no more than 15 cm, and using rollers on pneumatic tires and vibration - no more than 7 cm. The surface layer of sand cement in the design of the crushed stone base, processed th peskotsementnoy mixture should not exceed 1 - 2 cm.

3. Requirements for the materials used

3.1. The stone materials used for the device of the proposed design should have requirements for strength, frost resistance and grain composition. For a mixture of sand with cement or other inorganic binders, requirements for composition, strength and frost resistance should be made, 3.2. The strength of crushed stone from natural rocks must meet the requirements of GOST 8267-82, the strength of slag crushed stone - GOST 3344-73.3.3. Frost resistance of crushed stone should meet the requirements given in table. 4 of these "Guidelines".

TABLE 4

|

|

Climatic conditions

|

Mark of crushed stone by frost resistance, not less, for

|

grounds

|

coverings

|

|

Harsh |

|

Do not use

|

Moderate |

|

Soft |

|

|

Harsh |

|

|

Moderate |

|

|

Soft |

|

|

3.4. When arranging the base using the mixing method, it is advisable to use crushed stone of a fraction of 5 - 40 (70) mm, by impregnation-indentation using rollers on pneumatic tires - crushed stone of a fraction of 40 - 70 or 70 - 120 mm. When using cam and vibration rollers, it is also advisable to use crushed stone of a fraction of 20 - 40 mm. 3.5. The content of weak and weathered rocks in gravel should not exceed 15%, lamellar (flaky) and needle-shaped grains in gravel should not be limited, dust and clay particles should be no more than 4%, including lumps of clay particles larger than 5 mm - 2% .3.6. Losses in mass when testing slag crushed stone for structural stability should not exceed 7%. 3.7. For processing crushed stone, you can use sand cement, sand and slag (based on crushed slag of ferrous metallurgy and activator cement) and sand-ash mixture (based on ash and slag of thermal power plants), as well as non-crushed granulated blast furnace slag and whitewash sludge. 3.8. The mixtures listed in clause 3.7 must meet the requirements of GOST 23558-79. Resistance to compression of sand cement at the age of 28 days, and slag and sludge at the age of 90 days. must be at least 3 MPa. In each case, the brand of samples from the mixture should be assigned so as to obtain the required strength (calculated elastic modulus) of the treated part of the layer and the entire structure of the base as a whole according to Table. 3. The composition of the sand-cement mixture is determined in each case by laboratory selection. Frost resistance of sand cement, determined according to GOST 23558-79, must meet the requirements given in table. 5.3.10. Cement for sand-cement mixture must meet the requirements of GOST 10178-76. The beginning of cement setting is not earlier than 2 hours after mixing. It is recommended to use Portland cement and slag Portland cement of grades 300 and 400.

Table 5

|

|

Climatic conditions

|

Sand cement grade for frost resistance, not less than, for

|

base layer

|

top layer of the base

|

coverings

|

|

Harsh |

|

|

Do not use

|

Moderate |

|

|

Soft |

|

|

|

Harsh |

|

|

Moderate |

|

|

Soft |

|

|

|

Harsh |

|

|

|

Moderate |

|

|

|

Soft |

|

|

|

3.11. Granulated blast furnace slags or slag fines with activity in accordance with GOST 3344-73 more than 5 MPa and a maximum particle size of 5 mm can be used as jamming and cementing materials in the proposed design. Instead of a sand-cement mixture, alumina production wastes can be used for crushed stone - belitic (nepheline or bauxite) sludge with the following characteristics: Maximum grain size, mm, not more than 5 Coarseness module according to GOST 8736-77 1 - 2.5 Content of β-two-calcium silicate,% 40 - 85 Bulk density, kg / m 3 900 - 1200 Natural humidity,% 15 - 30 Optimum humidity,% 20 - 25 Strength at compression of sludge at the age of 90 days, MPa, no less than 33.13. Sand should meet the requirements of GOST 8736-77 with the following additions. The content of dusty clay and silty particles, determined by elutriation, should not exceed 8% in natural sands, 10% - crushed from screenings, including the clay content in lumps should be no more 2%. The content of particles less than 0.14 mm in natural sands should not exceed 30%, in crushed from screenings of carbonate rocks - 40%. The number of plasticity of sand fractions smaller than 0.63 mm should not exceed 2.3.14. When processing crushed stone of a fraction of 70 - 120 mm, it is allowed to use a sand-gravel mixture and screenings of crushing with a maximum fineness of 20 mm. When processing crushed stone of a fraction of 40 - 70 mm in the sand there should not be grains larger than 10 mm, while processing crushed stone of fractions of 20 - 40 mm - larger than 3 (5) mm. 3.15. For the preparation of mixtures and pouring gravel, it is recommended to use water suitable for drinking. To reduce cement consumption by 10 - 15% and improve the technological properties of sand cement (increase mobility), it is necessary to introduce SDB in the mixing water in an amount of 0.5 - 1% of the mass of cement. The flow rate of SDB is specified during laboratory selection of the composition of sand cement mixture from specific materials.

4. Technical and economic choice of the foundation of pavement

4.1. Depending on the depth of impregnation, as well as the required average modulus of elasticity of the base layer, the base designs shown in Fig. 2.4.2. The base design must be selected on the basis of a technical and economic comparison of the options taking into account the cost of materials and the composition of the mixture. The cost of a unit of the base construction area C npc is the sum of the cost of crushed stone C n a cement-concrete mixture C nc spent on the construction of this structure: where is the cost of 1 m 3 of crushed stone , rub.; l, in - the length and width of the plot, respectively, m; h 2 is the thickness of the lower, untreated part of the layer, K pr is the crushing compaction coefficient; K p is the loss coefficient, K p \u003d 1.03; h 1 - the thickness of the upper processed part of the layer. m;

ρ shpts - the average density of the mixture of crushed stone with sand cement, t / m 3; - the content of crushed stone in the upper, processed part of the layer, a fraction of a unit;

ρ nsch - bulk density of crushed stone, t / m 3. The cost of a sand-cement mixture is determined by the formula:

where, - the cost of 1 m 3 sand and 1 ton of cement, respectively, rubles .; - the content of sand cement in the mixture, with crushed stone, fractions of a unit;

ρ pc - the average density of sand cement, t / m 3;

ρ np - bulk density of sand, t / m 3; - cement content in sand cement, fractions of a unit; - sand content in sand cement, fractions of a unit. 4.3. Since the cost of crushed stone most often is 3 - 8 rubles, and sand - 2 - 5 rubles. per 1 m 3, the best design option from those shown in Fig. 2, it is advisable to take into account the following: while maintaining a constant total thickness of the structure, the average elastic modulus and the ratio of the thicknesses of the upper and lower parts of the layer, it is economically more profitable to use a material with a high modulus of elasticity in the lower layer and low-quality processed materials in the upper layer; while maintaining a constant average the modulus of elasticity and the total thickness of the base layer with an increase in the modulus of elasticity of the upper treated part of the layer and a decrease in the depth of impregnation, the cost of the structure decreases; If the depth of impregnation is constant with an increase in the average elastic modulus (with a decrease in the thickness of the base), the cost of the structure decreases; arranging a base of crushed stone treated in the upper part with a sand-cement mixture is more economical than an equal-strength base completely made of these materials (with equal costs). Sand cement base is cheaper than crushed stone base with sand cement at the cost of crushed stone more than 4 - 5 rubles. for 1 m 3.

5. Ground design

5.1. For the design of the bases, it is necessary: \u200b\u200bthe required modulus of elasticity of the base structure; the required frost resistance of crushed stone and sand cement; the thickness of the base; characteristics of crushed stone (grain composition, strength, frost resistance, initial rock); sand characteristic (particle size, type of sand by origin); cement grade; mechanisms for impregnation and the depth of impregnation of crushed stone with sand cement adopted in accordance with this; 5.2. When designing the bases, it is necessary: \u200b\u200bto determine the required modulus of elasticity of the upper, machined and lower, not processed according to the "Instruction" BCH 46-83 parts of the layer for a given general modulus of elasticity of the structure and depth of impregnation, as well as for known characteristics of crushed stone; determine (based on the elastic modulus ) the required strength of the upper, treated part of the layer; determine the necessary strength of the sand cement that provides the required strength of the processed part of the layer; check whether the frost resistance of the sand cement corresponds to the specified t fucking; determine the amount of binder in the sand-cement mixture of the required strength; determine the required amount of water in the sand-cement mixture per unit area of \u200b\u200bthe structure; determine the amount of water required to irrigate a unit area of \u200b\u200bthe crushed stone layer; set the amount of sand-cement mixture required for impregnating the crushed stone of a given grain composition to an accepted depth per unit area of \u200b\u200bthe structure; determine the consumption of crushed stone, sand and cement for a unit area of \u200b\u200bthe designed base structure. 5.3. The required modulus of elasticity of the upper, treated part of the layer can be determined by the formulas: where E cf is the design average modulus of elasticity of the structure, MPa; E 1 is the required modulus of elasticity of the upper, treated part of the layer, MPa; E 2 is the specified modulus of elasticity of the crushed stone layer, permeable by tab. 2 of these "Guidelines" depending on the strength, grain composition and breed of gravel intended for use, MPa;

h 1 - the thickness of the upper processed part of the layer, m; taken on assignment, taking into account the requirements of these "Methodological Recommendations", depending on the intended construction technology; h 2 - thickness of the lower crushed stone part of the layer, m; is taken on the basis of the total required thickness of the base. The value of the elastic modulus of the upper, treated part of the layer for the most common values \u200b\u200bof the average modulus of elasticity of the layer and the elastic modulus of crushed stone layers can be found in table. 1 of these "Guidelines" .5.4. The required strength of the upper, treated part, layer can be calculated by the correlation between the strength R cr (MPa) and the elastic modulus E 1 (MPa) of this material: The strength grade of the processed materials in accordance with GOST 23558-79 for different elastic moduli should be taken according to tab. 3 of these "Guidelines" .5.5. The required strength of pescement or other binder, providing the necessary strength of the treated part of the layer R shpts should be calculated according to the dependencies:

|

2.08 R sppc + 0.3 at W: PC \u003d 80:20,

1.1 R sppc + 0.8 for SC: PC \u003d 65:35,

1.2 + 1 at Щ: ПЦ \u003d 50:50.

|

|

To establish the brand of sand cement for strength (compression resistance), required to provide the necessary brand for strength of the treated part of the layer at different ratios of crushed stone and sand cement, you can according to table. 3 of these "Guidelines" .5.6. Peskocement with the characteristics calculated in accordance with the requirements specified in paragraphs. 5.8 - 5.5, should be checked for frost resistance. The requirements for frost resistance of sand cement for specific climatic conditions of construction, category of road and pavement layer are given in table. 5 of these "Guidelines". Roughly frost resistance of sand cement depending on its brand in strength can be calculated from the following correlation dependencies:

Finally, the frost resistance of sand cement is determined in the laboratory experimentally in accordance with GOST 23558-79. In the event that sand cement with the required grade does not meet the frost resistance requirements given in Table. 5 of these "Guidelines", then experimentally select sand cement with the necessary strength, which also meets the specified requirements for frost resistance. After that, if necessary, recount the design with a new brand of sand cement. 5.7. Consumption of cement grade 400pc (%) to obtain sand cement of the required grade for strength at the age of 28 days R pc, (MPa) can be estimated using the following correlation dependencies: When using sands of different grain composition and nature, the estimated consumption of cement grade 400 can be taken according to table . 6 of these "Guidelines" and clarify during laboratory selection of specific materials in accordance with the requirements of GOST 23558-79. In this case, three series of samples with different amounts of cement should be prepared.

Table 6

|

The amount of cement,% required for processing

|

Resistance to compression of sand cement, MPa

|

screenings crushing carbonate rocks

|

coarse and medium grained sands

|

fine sand

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

When using cement grades 300 and 500 specified in the table. 8, the quantity should be changed, using coefficients of 1.2 and 0.9, respectively. When using slag and ash binders according to GOST 23558-79 grades for strength 50, 100, 150, their number must be increased by 3; 2; 1.5 times compared with the data in table. 6. Slags, ashes and sludges with an activity of at least 5 MPa at the age of 90 days. can be used as an independent binder. To increase the strength of the treated part of the layer by 10 - 30% or reduce cement consumption by 10 - 20%, it is advisable to introduce SDB in the amount of 0.5 - 1% of the cement mass. 5.8. The sand cement of the greatest strength at a given cement content can be obtained with the optimum amount of water in the mixture (approximately 7 - 10% of the dry mix weight), established experimentally when selecting the composition of the mixture. The amount of water (t) for the preparation of sand cement with the base using the mixing method or pressing with a cam roller should be calculated by the formulas: where l, in - the length and width of the plot, respectively, m;

h 1 - the thickness of the upper processed part of the layer, m; - the content of sand cement or other binder in the treated part of the layer, a fraction of a unit;

ρ pc - the density of the sand-cement mixture, t / m 3; - the optimal water content in the sand-cement mixture, a fraction of a unit; Q PC is the amount of sand-cement mixture, i.e., when the base is equipped with vibratory rollers or rollers on pneumatic tires, the amount of water in the sand-cement mixture for its good penetration into crushed stone should be 3 - 5% less or more than the optimum calculated by formulas (9) .5.9. To obtain the maximum strength of the layer from crushed stone treated with sand cement, the crushed stone should be moistened before sand distribution to create a mixture of optimal moisture content (approximately 7 - 9% of the mixture weight). Approximate amount of water for watering the crushed stone (t) when installing the base by mixing and pressing with cam rollers should calculated according to the formula: 5.10. The amount of sand-cement mixture Q pts or other binders introduced into the crushed stone can be determined by the voidness of the crushed stone and the specified processing depth (thickness of the treated base layer), approximately according to the formulas:

,

,

|

Q pc \u003d lv h 1 ρ pc V psc K r K p,

|

|

or

Q pc \u003d lv h 1 ρ pc K p,

where ρ 1 is the density (bulk density) of grains of crushed stone, t / m 3; ρ 2 is the bulk density (bulk density) of crushed stone in a compacted state, t / m 3; To r - the coefficient of expansion of grains of crushed stone, K p \u003d 1 ÷ 1,15; V n u- void gravel, fraction of a unit; K p - loss coefficient, K p \u003d 1,03. The value of ρ 2 can be determined by compaction of 10 kg of crushed stone in a steel cylinder with a diameter and height of 234 mm with a load of 10 kg on a vibrating table with a vibration frequency of 3000 rpm min, amplitude 0.4 mm for 30 s. 5.11. When arranging the base using the impregnation-indentation method, taking into account the processing depth, fractionated gravel should be treated with 35 - 40% of the sand-cement mixture, which corresponds to the voidness of the material to be laid. 5-40 mm fraction gravel should be treated when mixing the foundation with the mixing method, taking into account the processing depth, it is advisable to process the sand-cement mixture in an amount of 20 %, which also corresponds to the voidness of the mixture. It is allowed to process crushed stone of 35 - 40 and 50% of sand-cement mixture during a feasibility study. Before starting work, to determine the consumption of sand-cement mixture, determine the voidness of the materials used and use formulas (12). The approximate consumption of sand-cement mixture for a device of 100 m 2 of a base at different depths of processing crushed stone, taking into account the surface layer of sand-cement 1.5 cm thick, is given in table. 7 of these "Guidelines".

Table 7

5.12. After the laboratory composition of sand cement has been established, the need for materials per unit area of \u200b\u200bthe base should be calculated. The required amount of crushed stone (m 3) can be determined by the formulas: where K cr - crushed stone compaction coefficient. The amount of sand (m 3) for the preparation of a sand-cement mixture should be determined by the formulas: where is the sand content in the sand-cement mixture, fractions of a unit; ρ np is the bulk density of sand, t / m 3 .5.14. The amount of cement Q c (t) for the preparation of sand cement can be determined by the formulas: where is the cement content in the sand cement mixture, fractions of a unit. 5.15. During work, amendments should be made to the calculated composition of materials, taking into account the actual moisture content of the materials. According to the formulas:

|

|

|

where W p W W - the moisture content of sand and gravel, respectively, fractions of a unit; - the amount of water required to prepare the sand cement mixture in wet sand, t; - optimal water content in the sand-cement mixture, t; - the amount of water needed to prepare the mixture on wet crushed stone, t.

6. The technology of construction of foundations by mixing

6.1. During the construction of foundations by mixing, crushed stone is taken out onto the prepared underlying layer, the amount of which should be determined taking into account the design thickness of the base and compaction coefficient. In winter, crushed stone can be transported to intermediate road storage depots in the area of \u200b\u200bthe planned construction. 6.2. Pre-distribute the crushed stone with a bulldozer or grader, and finally at the design thickness of the base, taking into account the compaction coefficient, with a DS-108 type profiler or other distributors in one pass. When distributing the crushed stone with the profiler, the cutter and the cutter blade are lifted. The auger blade is installed at the design level with a margin of seal. The auger is raised 2 - 2.5 cm above the cutting edge of the blade. 6.3. After distribution, if necessary, crushed stone should be moistened before processing with sand cement to obtain subsequently a mixture of crushed stone with sand cement of optimal moisture content (estimated water consumption - up to 10 l per 1 m 2) and rolled for passage of construction vehicles (two or three passes of the ice rink along one track). 6.4. The sand-cement mixture intended for processing the upper part of the crushed stone layer must be prepared in mixing plants of the SB-78 or DS-50A type. To ensure the quality of the mixture, the accuracy of the supply of sand is not less than ± .5%, cement and water ± 2% of the mass of the supplied material. The mixture should be transported by dump trucks or other vehicles and with the appropriate feasibility study.6.6. The sand-cement mixture must be pre-distributed with a grader, and finally laid on the surface of the distributed gravel by a profiler or other distributors. The consumption of sand cement is determined taking into account the specified depth of processing of the crushed stone layer and the ratio between crushed stone and sand cement in the treated part of the layer. The sand cement mixture is planned by the profiler in one pass at a working speed of 10 - 15 m / min. When planning, the auger and blade are raised to the thickness of the layer of the mixture to be distributed, and the milling cutter and blade of the milling machine are transported. 6.7. At the end of the distribution, the sand-cement mixture must be mixed with the crushed stone laid to the calculated (required) depth. The maximum mixing depth for the profiler should not exceed 15 cm. Mixing is performed at an operating speed of 5 m / min. milling cutter at maximum speed and auger; while the dumps are raised to the transport position, and the cutter and auger are set to the depth mark. If necessary, the resulting mixture is humidified so that the mixture has optimal humidity and is mixed again with one or two passes of the profiler. At the end of mixing, the base is planned in one pass of the profiler. The working bodies are installed in the same way as when planning the gravel. Working speed 7 - 8 m / min. 6.8. The base immediately after mixing should be compacted in 12 - 16 passes of the roller on pneumatic tires in one trace. In this case, the compaction coefficient at a depth of 5 - 20 cm should be at least 0.98. Compaction starts from the edges of the base to the middle. 6.9. Compaction should be completed within 3 hours from the preparation of the sand-cement mixture, including the time for transportation of the finished sand-cement mixture to the road section under construction, its distribution and compaction. The technological gap between the preparation and compaction of sand-slag mixture based on crushed slag or crushed slag with the addition of an activator - cement should not exceed 4 - 5 hours. When processing crushed stone with uncrushed granular blast furnace slag without activator cement or bauxite and nepheline sludge of technol cal gap may be increased to 6 - 8 hours 6.10.. At the end of compaction, the base should be finished with a profiler and finally the surface layer should be densified with a heavy smooth-roller compactor in one or two passes along one track. In the final layout, the milling cutter and blade are raised; auger blade set at the design level; the screw is raised 1 - 2 cm above the cutting edge of the blade. 6.11. At the end of the final layout, it is necessary to care for the foundation with one of the generally accepted methods used in the care of cement concrete, in accordance with SNiP III-40-78. It is allowed to lay the coating on the day of the foundation device; in this case, the care of the base is excluded. 6.12. It is necessary to open the movement of transport on a foundation constructed using cement after gaining 70% of the design strength of the foundation, but not earlier than 7 days later. after finishing work.

7. Construction technology of the bases by impregnation-indentation method

7.1. The essence of processing a crushed stone layer with a sand-cement mixture is to fill a mixture of voids of the crushed stone layer under its own weight and indentation during rolling (mechanical impact), in several ways; vibration using vibrating plates of laying machines; vibration and pressure using vibration rollers; depth pressure using cam rollers; surface pressure - rollers on pneumatic tires. 7.2. Before crushing with sand cement, it should be carefully planned with a grader and poured with water in an amount of 3-10 l per 1 m 2. If necessary, to ensure the passage of construction vehicles, crushed stone is rolled with a light roller in two or four passes along one track according to SNiP III-40-78.7.3. The sand-cement mixture prepared in the installation must be distributed on the surface of the crushed stone layer by a profiler or grader. The consumption of sand-cement is determined depending on the voidness of the crushed stone and the depth of processing of the layer. The time of the technological gap between the preparation of the mixture and the end of the seal is recommended to be taken in accordance with paragraph 6.9 of these "Methodological recommendations". 7.4. For processing crushed stone by vibration, it is recommended to distribute the sand-cement mixture with stackers of the DS-97, DS-108, D-345 type, equipped with vibration sealing bodies. In this case, at the same time, in one pass of the stacker, the sand-cement mixture is distributed and penetrated into the gravel layer. 7.5. To treat the crushed stone layer with vibration and pressure, a DU-54 type roller should be used, the vibration roller of which contributes to the penetration of the distributed sand-cement mixture into the voids of the crushed stone layer in three to four passes along one trace. To process the crushed stone layer by the deep pressure method, it is advisable to use a cam roller, which during operation increases the gaps between the individual crushed stone, providing an increase in the depth of penetration of the sand-cement mixture into the crushed stone layer. It is recommended to use cam rollers of the type DU-28, DU-3A or DU-32A at a speed traffic 4 - 8 km / h.7.7. Depending on the required thickness of the treated monolithic base layer, indentation can be carried out in two ways. With the required thickness of the monolithic layer of not more than 13 cm, it is recommended to press the sand-cement mixture or other cementitious binder into the crushed stone by successive passes of the cam roller, and with a thickness of more than 13 cm - alternating passages of the cam and pneumatic or smooth rollers through each passage. The approximate number of passes of the cam roller can be assigned in accordance with table. 8 of these "Guidelines" and clarified by the results of the test indentation at the beginning of work.

Table 8

Injection into the crushed stone layer of a sand-cement mixture or belite sludge by a cam roller starts from the curbs with the subsequent passages moving to the longitudinal axis of the road and overlapping the track of each previous pass by at least 20 cm.7.8. To process the crushed stone layer by the surface pressure method, rollers on pneumatic tires should be used, pressing sand cement with two or three passes of the roller along one track. Finally, the layer should be compacted after processing crushed stone using one of the previously mentioned methods follows by rollers on pneumatic tires of the type DU-29, DU-16V, DU-31 for 12 to 16 passes along one track and in accordance with paragraphs. 5.42 - 5.46 of the "Technical Instructions" BCH 184-75. When using the method of pressing by alternating passages of the cam and pneumatic or smooth rollers, the number of passes of the pneumatic roller can be reduced to five to eight due to the fact that partial compression of the base occurs simultaneously with the indentation. passages of the smooth-roller rink. 7.10. At the end of the compaction of the base, it is necessary to take care of it (see paragraph 6.11 of these "Guidelines"). 7.11. The movement of construction vehicles on the base can be opened after they gain 70% of the design strength when processing crushed stone with a sand-cement mixture or slag binders with activator cement. On the base of crushed stone treated with white clay slurry, the movement of vehicles can be opened immediately after the device. If the next day after the installation of such a base it is not intended to lay the overlying layer, then the base should be maintained by watering it daily (in dry weather) with water in an amount of 1.5 - 2 liters per 1 m 2 throughout the entire warm period before laying the overlying layer of pavement.

8. Construction quality control

8.1. All materials for the foundation device should be checked for compliance with the requirements of the standards for these materials. 8.2. The composition of the sand-cement or sand-slag mixture and its amount per 1 m 2 of the base, ensuring the design strength of the mixture of crushed stone with sand cement, the laboratory must determine before construction by selecting materials. 8.3. The design composition of a sand-cement or sand-slag mixture should be controlled according to SNiP III-40-78 using dispensers in a mixing plant. 8.4. The quality of the prepared sand-cement (sand-slag) mixture should be controlled by producing three samples in each shift and testing them for compressive strength at the age of 28 days. in accordance with the requirements and methods of GOST 23558-79 when added to the slag activator-cement, and at the age of 90 days. when using slag and sludge without additives. Bending strength (split), as well as frost resistance should be determined on samples taken from every 5 thousand m 3 of the prepared mixture, in accordance with the requirements of GOST 23558-79.8.5. When distributing crushed stone and sand-cement or sand-slag mixture, as well as slag and sludge, the thickness and width of the layer of distributed materials for every 100 m of the base should be monitored by measuring rulers and tapes. The thickness of the layer in each diameter must be measured along the axis of the base and at a distance of 1 - 1.5 m from the edges. The quality of mixing crushed stone with sand cement. or sand and slag mixture, as well as with slag and sludge, or the quality of the impregnation should be assessed by the depth of impregnation or by the amount of binder consumed. The amount of sand-cement (sand-slag) mixture in the crushed stone layer is recommended to be determined at least once per shift by taking a sample weighing 10 kg and then sieving it on a sieve with a hole diameter of 5 mm. 8.7. The technological gap between the preparation of the sand-cement mixture and the end of the base compaction, as well as the quality of the seal, should be controlled in accordance with SNiP III-40-78.8.8. Correspondence of the strength of the designed base to the design can be assessed by determining the modulus of elasticity with a deflection meter or other device. The modulus of elasticity must be at least calculated (design) .8.9. After completing the compaction and finishing on every 100 m of the base, you should check the evenness and transverse slopes with a three-meter metal rail and a template with a level of 8.10. After compaction of the base, it is necessary to monitor the timely bottling of film-forming material or water. Lack of maintenance reduces the strength of the substrate by 50%. Reducing the time of care (when watering) up to 21 days. from the moment of compaction of the base reduces strength by 8 - 10%, up to 14 days. - by 20 - 25% and up to 7 days. - 25-30%.

![]()

,

,