Denis Valentinovich Manturov Minister of Industry and Trade of the Russian ...

Gas welding is widely demanded in production and in the household. More and more private traders, who prefer to independently perform various works, do it using sophisticated equipment. This allows them to perform complex tasks and carry out a variety of projects.

For this reason, DIY gas welding is of interest to home craftsmen. But before you pick up the burner, you need to find out how and how it is done.

Gas welding is the process of melting the base and filler metals at the edges of parts as a result of exposure to the flame of a burner. The choice of the chemical composition of the filler rods depends on the physical and chemical characteristics of the base metal.

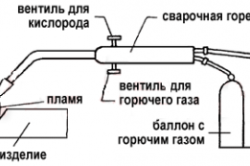

Figure 1. Technology gas welding.

The flame is maintained by supplying gas to the burner together with commercially pure oxygen (Fig. 1). The addition of the latter makes the fire suitable for welding applications. Moreover, the property of fire and its practical application is determined by what proportion is oxygen.

According to the ratio of gases, the flame of gas welding is divided into three types:

The first type of flame (also called normal) contains equal proportions of acetylene and oxygen. Oxidizing fire is formed with an excess of oxygen, and carburizing fire is characterized by an excess of acetylene.

Unlike electric arc welding, gas welding provides smooth heating of metal edges.

With its help at different ways brazing and surfacing, steel parts with a thickness of 0.2-5 mm, various types of tool steels, as well as non-ferrous metals and cast iron are processed. All of these metals must be welded by gentle and slow heating.

The flame of a gas burner is created by the combustion of working gases under the influence of oxygen. The purity of the latter must be at least 98%.

In gas welding, several gaseous gases are used as combustible gases. chemical elements... These are acetylene, methane, hydrogen, propane and propane-butane mixtures, vapors of lighting kerosene and gasoline. All of these substances burn well in the open air.

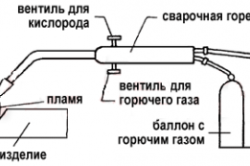

Figure 2. Welding methods - right and left.

A feature of all the gases mentioned is that they themselves do not generate very high temperature necessary for the rapid melting of metal structures. To do this, they require additional oxygen flow.

The most popular among these gaseous substances today is acetylene gas. It is actively formed as a result chemical reaction when combining calcium carbide with ordinary water. Interacting with an oxygen stream, acetylene at the moment of combustion "gives out" a temperature of up to 3200-3400 ° C. To obtain it, special generators are used, which are currently widely produced by industry.

In a gas welding machine, the combination of acetylene with oxygen takes place in a special mixing part of the torch. Both gases are supplied to this chamber through hoses separately: acetylene from the generator, and oxygen from the cylinder, which is traditionally either blue or blue. The oxidizer is contained in the tank under pressure of 3-4 atmospheres.

It should be noted that the constituent components gas mixture are supplied under different pressures (oxygen has more pressure). Therefore, when oxygen enters the central supply channel of the burner, its advance creates a strong vacuum, due to which the acetylene, pumped in at a lower pressure, is sucked into the channel by gravity. Here, in the mixing section, the gases mix, react and pass through the tip to the outside, to the welding point.

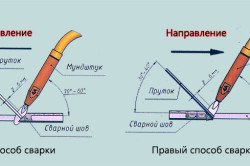

Figure 3. Angles of inclination of the nozzle of the torch when welding different thicknesses.

In order to properly carry out welding work, it is necessary to understand the principles of welding operations and the sequence of actions of the gas welder. The technology of these works includes preparatory operations, including the processing of the welded edges of metal blanks and the choice of the welding method, setting the gas torch to the proper position, as well as determining all the required parameters of the gas welding machine, including the power of the fire jet and the diameter of the wire filler.

In preparation for welding, the metal edges of the workpiece should be cleaned of various contaminants, scale and oil. On a special machine or, if the machine is not available, with the help of an ordinary chisel (you can also use a pneumatic version of this tool), a bevel is made at the edges, which is necessary to fill the future seam with a molten welding filler.

During work, it is very important that the position of the elements to be welded is rigidly fixed. In order to ensure the impossibility of their movement relative to each other, before the main welding, the edges of the blanks are tacked.

If we are talking about thin metal sheets and short seams, then the tacks are made 6-7 mm long each, between them there should be unsecured gaps approximately 70-100 mm long. If parts of thick metal are connected, and the seams are planned to be made long, the length of each tack should be 25-30 mm with intervals between them of 300-500 mm.

Moving on to welding, we note that its quality largely depends on the correct position of the torch in relation to the butt seam and on the direction of the wiring along the seam. Here, right and left variants of the direction of production of welding operations are distinguished (Fig. 2).

When using the movement of the working body of the gas welding unit to the right, the wiring is carried out from left to right. In this case, the torch moves in front of the filler wire, and its flame is directed to the formed weld.

The left-hand method, on the other hand, involves moving the torch from right to left. With this movement, the burner is positioned above the additive. As a result, the fiery jet is directly directed at the metal edges that are not welded to each other. Intensive heating of the edges takes place, which are thus prepared for subsequent high-quality welding.

It is worth noting that using the right method, metal parts with a thickness of more than 5 mm are connected, and ceiling welds are made. At the same time, vertical seams are formed with the left method, if welding is done from the bottom up.

During gas welding, the torch tip and the filler rod must move in relation to each other (Fig. 3) / The mouthpiece is moved along the seam and at the same time cross the seam axis, and the filler rod is gradually advanced towards the movement of the die.

The welding equipment must be in good working order. Otherwise, work is prohibited.

Transportation gas cylinders produced either on a special stretcher or on a specially designed trolley.

When working in closed rooms, it is imperative to provide breaks with exits to fresh air.

When working in containers, the presence of a second employee outside is mandatory.

Safety goggles must be worn by the welder.

Observing all these rules, you can do gas welding at a high level with your own hands.

Oxygen at atmospheric pressure and normal temperature is a colorless and odorless gas, somewhat heavier than air. At atmospheric pressure and a temperature of 20 ° C, the mass of 1 m3 of oxygen is 1.33 kg. Combustion of flammable gases or vapors of flammable liquids in pure oxygen occurs very intensively, a high temperature develops in the combustion zone. To obtain a welding flame with a high temperature required to melt the metal at the point of welding, a combustible gas or vapor of a combustible liquid is burned in a mixture with commercially pure oxygen. If the combustion of gases occurs in air, which contains only 1/5 of oxygen by volume (the remaining 4/5 are nitrogen and other atmospheric gases), then the temperature of the welding flame will be much lower and the combustion process is much slower than in technically pure oxygen. Oxygen itself is non-toxic, non-flammable and non-explosive, however, being the strongest oxidizing agent, it sharply increases the ability of other materials to burn, and at a very high burning rate, to explode. Industrial oxygen is extracted from atmospheric air, which is processed in air separation plants, where it is cleaned of dust, carbon dioxide and dried from moisture. The air processed in the installation is compressed by the compressor to high pressure and cooled in heat exchangers before liquefaction. Liquid air is divided into oxygen and nitrogen. The separation process occurs due to the fact that the boiling point of liquid nitrogen is lower than the temperature of liquid oxygen by 13 ° C. Nitrogen turns out to be a lighter boiling gas and is the first to evaporate, so it is removed from the air separation unit to the atmosphere. Liquid pure oxygen is accumulated in the air separation apparatus. When oxygen evaporates, it is filled into cylinders under pressure generated by a compressor. Technical oxygen is transported in steel cylinders in accordance with the requirements of existing regulatory documents or in autorecipients under a pressure of 15 ± 0.5 MPa (150 ± 5 kgf / cm2) or 20 ± 1.0 MPa (200 ± 10 kgf / cm2) at 20 ° C. When filling cylinders, storing and transporting them in the temperature range from -50 to +30 ° C, the gas pressure in the cylinder must correspond to that given in table. 49.

Table 49

Oxygen pressure in the cylinder depending on the ambient temperature

|

Gas temperature. SS |

Gas pressure in the cylinder, MPa (kgsUsm2) |

Tolerance. MPa (kgf cm :) |

Gava pressure in the cylinder. MPa (kgf cm3) |

Tolerance. MPa (kgf "cm3) |

|

15 MPa (150 kgf / cm5) arn 20 ° С |

20 MPa (200 kgf cm3) prn 20 "C |

|||

For welding and cutting, they produce technical oxygen of the 1st grade with a purity of at least 99.7% and the 2nd grade with a purity of not less than 99.5%. When storing or transporting filled cylinders, the pressure in them must correspond to the ambient temperature. Storage and transportation of filled cylinders at temperatures above 60 ° C is not allowed. Oxygen cylinders must be returned to

filling with a residual pressure of at least 0.05 MPa (0.5 kgf / cm2).

Acetylene (C2H2) is chemical compound carbon with

hydrogen. It is a colorless combustible gas with a sharp characteristic

smell. Long-term inhalation of acetylene causes dizziness, nausea, and sometimes severe general poisoning. Acetylene is lighter than air:

1 m3 of acetylene at 20 ° C and atmospheric pressure has a mass of 1.09 kg. Acetylene is an explosive gas. Temperature

autoignition of acetylene lies in the range of 240-630 ° C and depends on the pressure and the presence of various impurities in the acetylene. At

At atmospheric pressure, a mixture of acetylene with air explodes with an acetylene content of 2.2% or more, and in a mixture with oxygen, with an acetylene content of 2.8% or more. Explosion of air-acetylene or

The oxygen-acetylene mixture can be generated by sparks, flames or strong local heat, therefore handling calcium carbide and acetylene requires care and strict adherence to safety rules. In industry, acetylene is obtained by

decomposition of liquid fuels, such as oil, kerosene, by the action of an electric arc discharge. A method for producing acetylene from natural gas (methane) is also used. A mixture of methane with oxygen is burned in special reactors at a temperature of 1300-1500 ° C. Concentrated acetylene is recovered from the resulting mixture using a solvent. Acetylene production by industrial methods is 30-40% cheaper than from calcium carbide.

Industrial acetylene is pumped into cylinders, where it is dissolved in acetone in the pores of a special mass. In this form, consumers receive bottled industrial acetylene. The properties of acetylene do not depend on the method of its production. The residual pressure in the acetylene cylinder at a temperature of 20 ° C should be 0.05-0.1 MPa (0.5-1.0 kgf / cm2). The working pressure in a filled cylinder should not exceed 1.9 MPa (19 kgf / cm2) at 20 ° C. For the preservation of the filling mass, acetylene cannot be taken from the cylinder at a rate of 1700 dm3 / h. Let us consider in more detail the method of producing acetylene in a calcium carbide generator. Calcium carbide is produced by fusing coke and quicklime in electric arc furnaces at a temperature of 1900-2300 ° C, at which the reaction takes place: CaO + 3C = CaC2 + CO. Molten calcium carbide is poured from the furnace into molds where it cools. Then it is crushed and sorted into pieces ranging in size from 2 to 80 mm. Ready calcium carbide is packed in hermetically sealed drums or cans made of roofing sheet, 40 each; 100; 130 kg. Calcium carbide should not contain more than 3% of particles less than 2 mm in size (dust). According to the relevant standard, the sizes (granulation) of pieces of calcium carbide are set: 2x8; 8x15; 15x25; 25x80 mm. When interacting with water, calcium carbide releases gaseous acetylene and forms slaked lime in the residue, which is a waste. The decomposition of calcium carbide with water proceeds according to the following scheme:

Theoretically, 372 dm3 (liters) of acetylene can be obtained from 1 kg of chemically pure calcium carbide. Practically due to the presence of impurities in calcium carbide, the yield of acetylene is up to 280 dm3 (liters). On average, 4.3-4.5 kg of calcium carbide are consumed to obtain 1000 dm3 (liters) of acetylene. When wetted with water, carbide dust decomposes almost instantly. Carbide dust cannot be used in conventional acetylene generators designed to operate on lumpy calcium carbide. For the decomposition of carbide dust, generators of a special design are used. To cool acetylene during the decomposition of calcium carbide, take from 5 to 20 dm3 (liters) of water per 1 kg of calcium carbide. A "dry" method of decomposition of calcium carbide is also used. For 1 kg of finely crushed calcium carbide, 0.2-1 dm3 (liter) of water is fed into the generator. In this slaking process, lime is obtained, not in the form of liquid lime sludge, but in the form of a dry "fluff", the removal, transportation and disposal of which is greatly simplified. When welding and cutting metals, other flammable gases and vapors of flammable liquids can also be used. For heating and melting the metal during welding, it is necessary that the flame temperature is approximately 2 times higher than the temperature of the metal being welded. Therefore, it is advisable to use gases - substitutes for acetylene only when welding metals with a lower melting point than steel, such as aluminum, its alloys, brass, lead. When cutting scrap metal, propane is used. Propane is a combustible gas that is produced during production natural gases or when refining oil. Usually, not pure propane is obtained, but with an admixture of butane up to 5-30%. This mixture is called propane-butane. For work, the propane-butane mixture is delivered to the consumer in a liquefied state in special cylinders. The transition of the mixture from a liquid to a gaseous state occurs spontaneously in the upper part of the cylinder due to the lower specific gravity of the gas in comparison with the liquefied mixture. Technical propane is heavier than air and has an unpleasant specific odor. Natural gas is composed mainly of methane (98% purity), the rest is contaminated with small amounts of butane and propane. The gas has a faint odor, so special odors are added to detect the leak. Methane is most commonly used in metal cutting. To form a gas flame, other gases (hydrogen, coke oven and oil gases), flammable liquids (gasoline, kerosene, acetone, etc.) can also be used as fuel. Liquid fuels are less scarce, but require special containers for storage. For welding, cutting and brazing, the flammable liquid is converted to vapor by the flame of the torch or torch tip. The characteristics of various flammable gases and liquids used in various branches of mechanical engineering and in the jewelry industry are given in table. 50.

Table 50

Characterization of flammable gases and liquids, expressed in terms of the acetylene coefficient

|

Name fuel |

Flame temperature ;! during combustion in oxygen, ° С |

Weight of I and 'fuel at 20 ° C and dalen; w 7 £ 0 mm Hg_ st .. kg |

The coefficient of substitution of an apartment for |

The amount of oxygen supplied to the burner for 1 Lg1 of fuel, m1 |

|

Basics: acetylene |

||||

|

pyrolysis |

||||

|

nef_yanoy |

||||

|

technical |

||||

|

natural |

||||

|

coke |

||||

|

shale |

||||

|

Vapors of kerosene |

March 22, 2017

The possibility of semi-automatic welding of materials in an environment of carbon dioxide was discussed in the middle of the twentieth century. This technique was developed by N.M. Novozhilov. and Lyubavsky K.V. - Soviet researchers. This welding method, due to the low cost of carbon dioxide, due to the high degree of productivity, has become quite popular in the construction, manufacturing industry, and, of course, in everyday life.

According to this technique, carbon dioxide, which provides protection at the joining site, is divided into O 2, carbon monoxide, under the influence of the high temperature of the arc. As a result, the flow of the resulting gas mixture protects the welding zone of the material from the negative effects of ambient air, interacts with carbon and iron.

To prevent the oxidation of CO 2, manganese, silicon, which are more chemically active than iron, are introduced into the rod for gas welding, they are oxidized first. Therefore, while Mn, Si are present at the site of joining metal products, carbon, iron will not be oxidized.

To obtain high quality welds when welding carbon steels, the ratio of manganese / silicon is taken as 1/2. The resulting oxides of manganese and silicon do not dissolve in the weld pool during work, they form a low-melting compound after reacting with each other. This connection easily removed from liquid metal.

Semi-automatic welding in carbon dioxide environment is performed with direct current with reverse polarity, since the current of direct polarity negatively affects the stability of the arc (the weld will have defects).

The straight polarity current is used in the case of welding, but not welding, since it has a deposition rate 1.7 times higher than that of a current having reverse polarity.

Welding can also be performed on alternating current, but then an oscillator must be used in the circuit.

There are several types of welding. They differ from each other in the technology of education, which has a high temperature, the purpose of which is the connection, cutting of metals and their alloys. This can be done with a gas flame, ultrasound, or an electric arc. The principle of joining metals is based on melting the edges of individual metal structures for their further joining together, as a result of which a weld is obtained.

Depending on the gas used for welding, the temperature will differ. For example, when interacting with calcium carbide H 2 O, acetylene is released. During the reaction of this element with oxygen, the flame temperature can reach more than 3000 ° C.

Welding gases are all butanes, propanes, benzene, MAF, kerosene, etc. When any gases are used for welding, oxygen must be present - this is a combustion catalyst. O 2 must be clean and high quality. The maximum temperature indicator will depend on this.

In the gas composition, the presence of pure oxygen is mandatory, which makes it possible to obtain maximum temperature combustion, important indicators of the flame. The completeness of combustion of combustible components will depend on the quality of this component, and the oxidizing, reducing characteristics obtained by the flame will depend on its quantity.

Special requirements are imposed on the storage conditions for gases. The use of special containers (cylinders) is mandatory, since:

If you use atmospheric oxygen, the welds will not be straight. In this case, after melting and subsequent joining, the metal will lose its original qualities. The use of standard oxygen, which is contained in the atmosphere, is not effective enough. It contains a variety of impurities that significantly reduce the combustion rate of the components, and this accordingly affects the temperature of the burner flame.

Important! The proportions of gas mixtures must be respected when using any type of gas. The choice itself will depend on the material to be welded. For example, to join steel samples, the gas composition must contain 18% carbon dioxide, and to join stainless steel materials, the mixture must consist of 98% argon.

Gas-shielded mechanized welding involves the use of active, inert gases. They do not dissolve in metals, are not poisonous.

Varieties of gases:

Active gases protect the welding area from air. They react, dissolve in metals.

The most popular gas mixtures, which improve the quality of the seam, improve the joining process itself:

Gas-shielded welding is characterized by melting of the material. The process itself is based on the connection of individual elements of the pre-heated metal before melting. For this, a high-temperature burner flame is taken, which is formed during the combustion of a gas composition with oxygen. The gap between the samples is filled with pre-melted metal wire.

Advantages:

Disadvantages:

Despite some drawbacks, welding in shielded gases allows an experienced welder, with the correct power of the torch flame, the concentration of the gas mixture, to produce high quality joints of the welded structures.

With a relatively slow heating of a metal sample, an insignificant concentration of heat during the heating process, the productivity of gas welding significantly decreases with an increase in the thickness of the metal products that are connected.

Example: if the thickness of the welded steel sheet 0.1 cm, the speed of gas welding is approximately 10.0 m / h, if the thickness of the material is 1 cm, the speed is not more than 2.0 m / h.

Gas shielded welding of steel products thicker than 0.6 cm is less effective when compared to arc welding. In such cases, it is rarely used.

The price of gas together with oxygen is higher when compared with the price of electricity used when using resistance arc welding.

Gas welding is more difficult to automatic and mechanical processes than electric welding. Therefore, automated gas welding with multi-flame torches is used only when connecting thin metal pipes, shells.

Welding in a shielded gas environment makes it possible to weld almost any metal that is used in technical equipment. For example, lead, copper, cast iron lend themselves better to gas welding than electric arc welding. And due to the simplicity of the design, gas welding equipment is quite in demand in agriculture, at machine-building enterprises, when performing repair and construction work, in other areas of activity.

When choosing a welding gas for an individual situation, it is recommended to consider the following criteria:

Gas welding will cost an order of magnitude higher than arc, contact electric welding, since gas with oxygen is much more expensive than electricity.

This method of joining metal parts, such as gas welding, is more than a hundred years old. During this time, this technology has continued to be successfully improved, although other welding methods using an electric arc are developing more actively and are replacing welding using a gas torch.

A method of joining metals, such as gas welding, involves the melting of the materials to be joined, resulting in the formation of a homogeneous structure. The combustion of the gas, due to which the heating and melting of the metal is carried out, is ensured by introducing pure oxygen into the gas mixture. This method of joining metals has a number of advantages.

This method also has disadvantages.

Gas welding technology involves the use of various types of gases, the choice of which depends on a number of factors.

One of the gases used for welding is oxygen. This gas is characterized by the absence of color and odor, it acts as a catalyst, activating the processes of melting of the material to be joined or cut.

In order to store and transport oxygen, special cylinders are used in which it is contained under constant pressure. Oxygen can ignite on contact with technical oil, therefore, the very possibility of such contact should be excluded. Oxygen cylinders must be stored in rooms protected from sources of heat and sunlight.

Welding oxygen is obtained by separating it from ordinary air, for which special devices are used. Depending on the degree of its purity, oxygen is of three types: the highest (99.5%), the first (99.2%) and the second (98.5%) grade.

For various manipulations with metals (welding and cutting), the colorless gas acetylene C2H2 is also used. Under certain conditions (pressure exceeding 1.5 kg / cm2 and temperatures above 400 degrees), this gas can explode spontaneously. Acetylene is obtained by the interaction of calcium carbide and water.

The advantage of using acetylene in metal welding is that its combustion temperature allows this process to be carried out without problems. Meanwhile, the use of cheaper gases (hydrogen, methane, propane, kerosene vapors) does not make it possible to obtain such a high combustion temperature.

To carry out welding of metals, in addition to gas, are also needed. It is due to these materials that the weld is created, all of its characteristics are formed. The wire used for welding must be clean, free from corrosion and paint on its surface. In some cases, a strip of the same metal that is being welded can be used as such a wire. In order to protect the weld pool from external factors, it is necessary to use a special flux. Boric acid and borax are often used as such flux, which are applied directly to the surface of the metal to be welded or to the wire used for welding. Gas can be performed without flux, and when joining parts made of aluminum, copper, magnesium and their alloys, such protection is necessary.

Gas welding technology involves the use of certain equipment.

Water seal

A water seal is necessary to ensure the protection of all elements of the equipment (acetylene generator, pipes) from the back draft of the fire from the burner. Such a seal, in which the water must be at a certain level, is placed between the gas burner and the acetylene generator.

Cylinder containing gasSuch cylinders are painted with different paints, depending on what kind of gas is planned to be stored in them. Meanwhile, the upper part of the can is not painted in order to exclude contact of the gas with the paint components. It should also be borne in mind that copper valves must not be installed on cylinders in which acetylene is stored, as this can lead to a gas explosion.

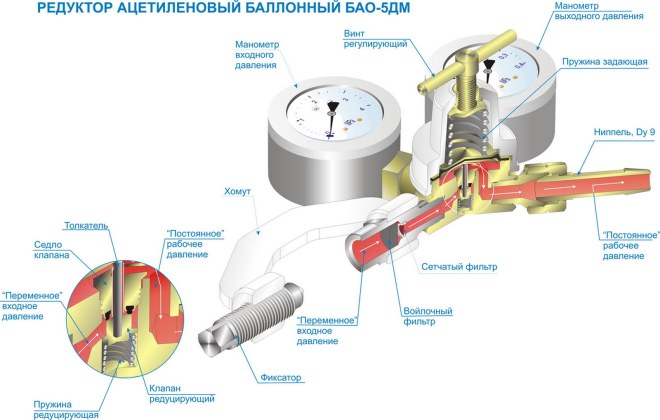

ReducerIt is used to reduce the pressure of the gas leaving the cylinder. Reducers can be of direct or reverse action, and for liquefied gas, models with ribbing are used, which exclude its freezing at the exit.

Special hosesGas welding cannot be performed without the use of special hoses, through which both gas and flammable liquids can be supplied. Such hoses are divided into three categories, marked with 1) a red stripe (operate at pressures up to 6 atmospheres), 2) a yellow stripe (for supplying flammable liquids), 3) a blue stripe (operate at pressures up to 20 atm).

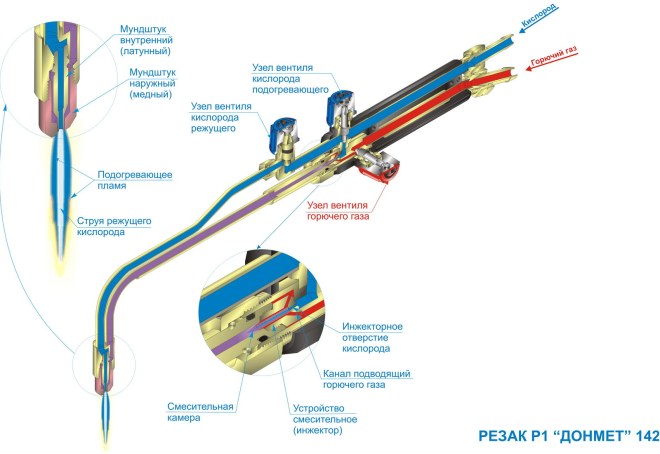

Mixing of gases and their combustion is ensured through the use of a burner, which can be injector or non-injector type. Burners are also classified according to their power, which characterizes the amount of gas passed per unit of time. So, there are burners of large, medium, small and micro-low power.

Special tableGas welding is carried out at a specially equipped place, which is called a post. In fact, such a place is a table, which can be with a swivel or fixed table top. This table, equipped with exhaust ventilation and everything necessary for storing auxiliary tools, greatly facilitates the work of the welder.

The flame parameters are adjusted using a reducer, which allows you to change the composition of the gas mixture. With the help of a reducer, three main types of flame can be obtained: reducing (used for welding almost all metals), oxidizing and with an increased amount of combustible gas. When welding metals in a molten pool, two processes occur simultaneously - oxidation and reduction. At the same time, when welding aluminum and magnesium, oxidation processes are more active.

The welding seam itself and the area adjacent to it are characterized by different parameters. So, the section of metal adjacent to the seam is characterized by minimal strength, it is he who is most prone to destruction. The metal adjacent to this zone has a structure with large grains.

To improve the quality of the seam and the area that adjoins it, additional heating or the so-called thermal forging of the metal is performed.

Welding technologies for various metals have their own nuances.

Do not enter into chemical interaction with metals and practically do not dissolve in metals

Argon (Ar)- colorless, odorless, non-flammable, non-toxic gas, almost 1.5 times heavier than air. It is insoluble in metals both in liquid and solid states. Produced (-79) two grades: the highest and the first.

The premium gas contains 99.993% argon, no more than 0.006% nitrogen and no more than 0.0007% oxygen. Recommended for welding critical metal structures from active and rare metals and alloys, non-ferrous metals.

The first grade gas contains 99.98% argon, up to 0.01% nitrogen and no more than 0.002% oxygen. Recommended for welding steel and pure aluminum.

Helium (Not)- a colorless gas, odorless, non-toxic, much lighter than air and argon. Produced (-75) of two grades: high purity (up to 99.985%) and technical (99.8%).

It is used less frequently than argon due to its scarcity and high cost. However, at the same current value, the arc in helium releases 1.5 - 2 times more energy than in argon. This contributes to a deeper penetration of the metal and a significant increase in the welding speed.

Helium is used in welding of chemically pure and active materials, as well as alloys based on aluminum and magnesium.

Nitrogen (N 2)- gas without color, odor and taste, non-toxic. It is used only for welding copper and its alloys, in relation to which nitrogen is an inert gas. Produced (-74) four grades: the highest - 99.9% nitrogen; 1st - 99.5%; 2nd - 99.0%; 3rd - 97.0%.

They protect the welding zone from air, but they themselves dissolve in the liquid metal or enter into chemical interaction with it

Oxygen (O 2)- colorless, odorless and tasteless gas. Non-flammable, but actively supporting combustion. Technical gaseous oxygen (GOST5583-78) is produced in three grades: 1st grade - 99.7% oxygen; 2nd - 99.5%; 3rd - 99.2%. It is used only as an additive to inert and active gases.

Carbon dioxide (CO 2)- colorless, with a weak odor, with pronounced oxidizing properties, well soluble in water. Heavier than air by 1.5 times, it can accumulate in poorly ventilated rooms, in wells, pits. Produced (-85) of three grades: the highest - 99.8% СО 2, 1st - 99.5% and 2nd - 98.8%. It is not recommended to use grade 2 carbon dioxide. To reduce the CO2 humidity, it is recommended to install the cylinder with the valve downward and after 1-2 hours open the valve for 8-10 seconds to remove water. Before welding, a small amount of gas is released from a normally installed cylinder to remove trapped air.

In carbon dioxide, cast iron, low and medium carbon, low-alloy structural corrosion-resistant steels are welded.

Serve to improve the welding process and the quality of the weld

A mixture of argon and helium. Optimal composition: 50% + 50% or 40% argon and 60% helium. Suitable for welding aluminum and titanium alloys.

A mixture of argon and oxygen at an oxygen content of 1-5%, it stabilizes the welding process, increases the fluidity of the weld pool, the transfer of the electrode metal becomes fine-droplet. The mixture is recommended for welding carbon and stainless steels.

A mixture of argon and carbon dioxide. The rational ratio is 75-80% argon and 20-25% carbon dioxide. At the same time, minimal spattering, high-quality formation of a seam, an increase in productivity, good properties welded joint. Used for welding low carbon and low alloy structural steels.

A mixture of carbon dioxide and oxygen. Optimal composition: 60-80% carbon dioxide and 20-40% oxygen. Increases the oxidizing properties of the protective environment and the temperature of the liquid metal. With this mixture, electrode wires with a high content of deoxidizers are used, for example Sv-08G2SC. The weld is formed slightly better than when welding in pure carbon dioxide. The mixture is used for welding carbon, alloyed and some high-alloyed structural steels.

A mixture of argon, carbon dioxide and oxygen- a three-component mixture provides high process stability and avoids porosity of the joints. Optimal composition: 75% argon, 20% carbon dioxide and 5% oxygen. It is used for welding carbon, stainless and high-alloy structural steels.