Female infidelity is a rather complex phenomenon. First, with the social ...

The formation of conductive closed circuits around the main magnetic flux or part of it causes local heating, and in some cases, sparks.

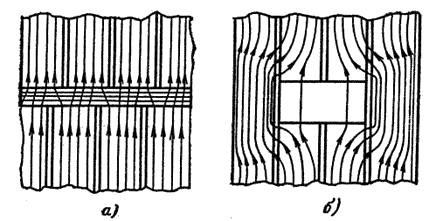

If the inter-sheet insulation of the magnetic core plates is broken, as well as when these plates are closed by conductive particles or objects, a short-circuited circuit for eddy currents arises in the magnetic core. These currents cause local heating of the magnetic circuit, which accelerates further destruction of the insulation of the plates. The development of the process can lead to “ fire in steel " and damage to the transformer (Figure 6.1).

Rice. 6.1. "Fire in steel" magnetic circuit

In case of violation of the insulation of the metal elements of the fastening of the active part of the transformer and (or) improper grounding of the elements of the transformer, a closed current-conducting loop appears around the main magnetic flux. In this case, in places of loose contact between the elements of this circuit, local heating and sparking may occur.

A short circuit between the turns of the windings, if it is short, causes an intense release of thermal energy and a quick operation of the protection of the transformer, acting on its disconnection. When the wires are bridged in multi-parallel windings, as well as when the windings are closed between the turns of the windings through an increased contact resistance, local heating of the windings is observed, which over time leads to the destruction of the insulation and, ultimately, to a short turn circuit.

All of the above defects associated with the formation of conductive closed circuits around the main magnetic flux or its part cause an increase in XX losses.

In a three-phase transformer, when measuring losses XX, three experiments are carried out with bringing a three-phase transformer to a single-phase one by short-circuiting one of its phases and exciting the other two. Short-circuiting one of its phases (or, which is the same, short-circuiting one of its windings) is done in order not to have a magnetic flux in this phase, and therefore not to have any losses in it.

For example, if you short-circuit the phase c and apply voltage to the phases a and b LV windings, the measured losses will characterize the energy loss for the excitation of the phases a and b(Figure 6.2). Let us designate these losses, taking into account the closed phase, as P C. In the absence of defects in the transformer, the losses Р А and Р С, measured at successive short-circuiting of the extreme phases a and c, will be practically the same (the difference is not more than 2 - 3%), and the losses Р В, measured when the middle phase is closed b, will exceed the loss of Р А or Р С by 35 - 40% [L.1]. This is due to the different length of the path of the closure of the magnetic flux when the transformer is excited according to the indicated measurement schemes. Knowing the losses in different phases, you can compare them and make sure that the transformer has the correct loss ratio and is free from defects.

If any short-circuited loop occurs around the main magnetic flux of one of the cores of the magnetic circuit, the ratio of losses measured according to these schemes will change, and the appearance of a short-circuited loop causes an increase in losses, therefore, the defective phase will be that phase, when short-circuited, the smallest losses will be measured. This pattern is used to identify the defective phase [L.2].

The above defects may occur during installation or overhaul transformer. Therefore, in the normative documents [L.3], it is proposed to measure the losses of XX during acceptance tests and after major repairs.

For three-phase transformers during commissioning and overhaul, the ratio of losses in different phases should not differ from the ratios given in the factory test report (passport) by more than 5%.

For single-phase transformers, during commissioning, the difference between the measured loss values and the original ones should not exceed 10%.

Rice. 6. 2. Measurement of losses XX at low excitation with series short-circuiting of phases

Measurements during operation are carried out during complex tests of the transformer. The difference between the measured values and the initial data should not exceed 30%.

Assumptions about a defect are rejected if the following conditions are met [L.2]:

The transformer must be reliably grounded before testing.

Short-circuiting one phase can be done on any winding of the transformer, i.e. on the winding to which voltage is applied during experiment XX, or on another, open winding (Figure 6.2); in this case, they are guided by the actual connection diagram of the transformer windings.

When measuring, voltage is usually applied to two phases of the LV winding, and the third is short-circuited, thus achieving greater excitation of the magnetic system. The no-load test is usually carried out from the side of the LV winding, since it is easier to measure voltage, current and power at a lower voltage.

Before measurements at low voltage, GOST 3484-77 provides for the need to remove the residual magnetization of the magnetic system of the transformer, if before these measurements, work was carried out related to the flow of DC or AC windings, and also if the excitation of the transformer is significant (2 times or more) exceeded the voltage at which the measurements were made. Methods for removing residual magnetization are established by GOST 3484-77.

Voltmeter and wattmeter for measurements, if possible, should be used class 0.2.

During the test, the applied voltage and the total power consumed by the tested transformer and measuring instruments are measured. Then the power consumed by the measuring devices (P pr) is determined by measurement or calculation. Measurement of losses in devices is carried out according to the same scheme as when measuring total losses (P meas), but with the transformer disconnected (Figure 6.3), with the same voltmeter reading (V).

Rice. 6. 3. Scheme for measuring losses in devices

The consumption of appliances can also be determined by the formula

![]() ,

,

Losses in the tested transformer are calculated by the formula:

The losses reduced to the rated voltage are determined by the formulas:

In the case of connecting the excited winding in a delta

In the case of connecting the excited winding into a star

Usually n has the following approximate values when the transformer is excited with a voltage of 5-10% of the nominal:

The value of n can be determined by the formula [A4]

If the applied voltage is less than 5% of the nominal, then to reduce the loss, the exponent n should be determined using this formula.

With phase-by-phase measurement, each phase participates in the measurements twice, therefore the total transformer losses will be:

![]()

The magnetic core of the transformer is made of hot-rolled steel sheet 0.35 mm thick. Measurements were made in phases.

The results are given in table. 7.1.

Table 7.1

| Voltage applied to phases | Phase closed | Voltage, V | Current, A | Losses, W | Reduced losses, kW |

| a - b | c | 525 | 3,5 | 428 | 89,64 |

| b - c | a | 525 | 3,5 | 428 | 89,64 |

| a - c | b | 525 | 4,8 | 574 | 121,7 |

The voltage (525 V) is 5% of the nominal.

The losses in the devices were 20 W.

Losses reduced to the rated voltage of the LV winding:

P drive C = P drive A = (428 - 20) (10500/525) 1.8 = 89.64 kW

P priv. B = (554 - 20) (10500/525) 1.8 = 121.7 kW

P 0 drive = (P drive C + P drive B + P drive A) / 2 = (89.64 + 89.64 + 121.7) / 2 = 150.5 kW,

which is 0.5% more than the factory idle losses.

Losses P pre C and P pre A are equal to each other, and P priv. B more losses P pref. C and P pref. A:

![]()

All this indicates that the transformer is in good working order and has no defects.

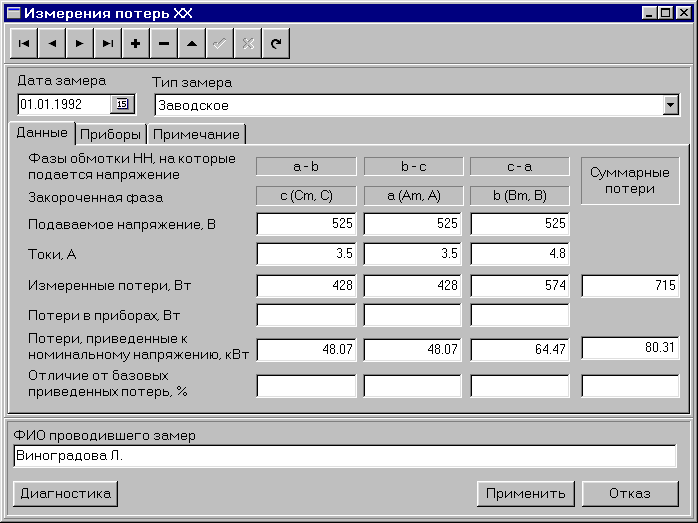

It is imperative to enter the "Test date" and indicate the "Test type".

The form has three tabs: "P O teri "," p R ibory "and" Pr and marking ". You can go to the desired tab by pointing it with the mouse.

In the first tab, the user enters "Voltages", "Currents" and "Measured losses" for each of the three experiments. For single-phase transformers, only the first column of the table is filled in. If the power consumed by the devices was measured during the experiments, then its values are also entered in the form fields, and if their resistances are known from the device passports, then the losses in the devices will be calculated during the examination and the results are entered into the form fields.

The examination also calculates the "Losses reduced to rated voltage" and "Differences of the reduced losses from the base values" for each experiment. In addition, "Total no-load losses in all phases of the transformer at a given voltage", "Total no-load losses in all phases of the transformer reduced to rated voltage" and "Difference of total reduced no-load losses from basic no-load losses at rated voltage" are calculated.

The base values are taken from the earliest measured no-load loss for this transformer.

In the second tab, the numbers of the devices used are entered and if it is necessary to calculate the losses in the devices, then "Resistance of the voltmeter" and "Resistance of the voltage winding of the wattmeter".

You can enter any text in notes.

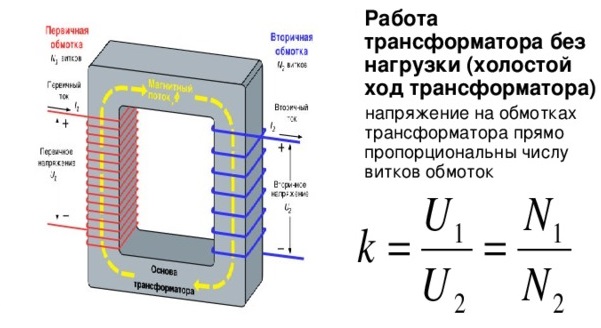

The operating mode of the transformer when one of its windings is powered from an alternating voltage source with the other windings open is called the idle mode. The losses occurring in the transformer in no-load mode at the nominal sinusoidal voltage on the primary winding and the nominal frequency are called no-load losses.

No-load losses of the transformer P x are composed of magnetic losses, i.e. losses in the active material (steel of the magnetic system, losses in the steel elements of the transformer frame caused by the partial branching of the main magnetic flux, basic losses in the primary winding caused by the no-load current, and dielectric losses in the insulation.

Dielectric losses in insulation can play a significant role only in transformers operating at increased frequency, and in power transformers designed for a frequency of 50 Hz, even with voltage classes of 500 and 750 kV, they are usually small and may not be taken into account. Also, the main losses in the primary winding are not taken into account in power transformers, which are usually less than 1% of the no-load losses. Losses in the elements of the transformer structure during no-load operation are relatively small and are taken into account together with other additional losses.

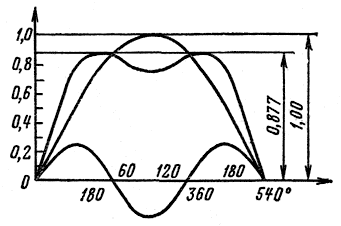

Magnetic losses - losses in the active steel of a magnetic system - constitute the bulk of no-load losses and can be divided into losses from hysteresis and eddy currents. For modern cold-rolled electrical steel with a thickness of 0.35 and 0.30 mm, the first of them amount to 25-35 and the second to 75-65% of the total losses.

In practice, at a frequency of 50 Hz, magnetic losses are usually determined without dividing them, and the experimentally established relationship between induction and specific losses in steel is used. Since, at a given frequency and uniform distribution of induction, the losses per unit mass of steel are uniquely determined by induction, this dependence is expressed in the form of losses per unit mass of steel p, W / kg, at a given induction. The data of the experimental study of steel are tabulated or depicted by the specific loss curve p = f (B). Specific, as well as total losses in steel change with a change in induction B and frequency f. If it is necessary to carry out approximate recalculations of losses with a change in frequency or induction, you can use the approximate formula

where for cold rolled steel n = l, 25; m = 2 at B = 1.0 ÷ 1.5 T and m = 3 at B = 1.5 ÷ 1.8 T. For hot rolled steel n = l, 3; m = 2 at B = 1.0 ÷ 1.5 T.

It should be remembered that the quality of electrical steel from different origins may vary. Therefore, when calculating, always use tables or curves referring to the actual steel used.

Specific losses in cold-rolled steel grades 3404, 3405, М6Х and М4Х are shown in Table 8.10. When using steel grade 3406 with a thickness of 0.27 mm, you can use the data for steel grade M4X with a thickness of 0.28 mm in this table, as well as table. 8.11, 8.13 and 8.14.

The magnetic induction in the rods and yokes of a flat laminated magnetic system is determined for the calculated voltage of the winding turn and the finally established values of the active sections of the bar P c and the yoke P i,

The no-load losses of a transformer, a flat laminated magnetic system of which is assembled from plates, is determined by its design, the mass of steel of individual sections of the system, induction in each of these sections, the quality of steel, thickness of the plates and the technology of manufacturing and processing the plates.

No-load losses in a magnetic system assembled from hot-rolled steel plates,

![]() (8.30)

(8.30)

where p c and p i are the specific losses in 1 kg of steel of the rod and yoke, depending on the inductions B c and B i, the grade and thickness of steel sheets, given for steel grades 1512 and 1513 according to GOST 21427-83 in table. 8.9; k d is a coefficient that takes into account additional losses arising from the uneven distribution of the induction of mechanical effects on steel during the preparation of plates and assembly of the skeleton, losses in fasteners, etc.

When calculating losses in a flat laminated magnetic system assembled from plates of cold-rolled textured anisotropic steel, it is necessary to take into account the properties of the steel itself and design and technological factors.

Table 8.9. Specific losses in steel r and in the zone of the laminated joint rz for hot-rolled steel grades 1512 and 1513 and cold-rolled steel grades 3411, 3412 and

3413 0.35 mm thick at various inductions and f = 50 Hz

Note. Additional losses in the area of the laminated joint for hot-rolled steel are not taken into account.

The design factors include: the shape of the joints of the plates in the corners of the system, the shape of the cross-section of the yoke, the method of pressing the rods and yokes. Of the technological factors, the greatest influence on losses in the magnetic system is exerted by: cutting steel coils into plates, removing burrs formed during cutting, annealing the plates, coating them with varnish, pressing the magnetic system during assembly and re-aligning the upper yoke when installing windings.

Specific losses in 1 kg of steel at a frequency of 50 Hz and induction from 0.2 to 2.0 T for modern grades of cold-rolled anisotropic steel in accordance with GOST 21427-83 are given in table. 8.10 and partially in table. 8.9. It should be borne in mind that these data are valid for the case when the direction of the magnetic field induction vector coincides with the direction of steel rolling. When the magnetic flux deviates from the rolling direction, one should take into account the increase in specific losses, which depends on the angle α between these directions. The degree of increase in losses at induction of 0.5-1.5 T at different angles for one of the grades of cold-rolled steel is shown in Fig. 2.14, a. As the angle changes, only the hysteresis loss changes. Eddy current losses are independent of this angle. Therefore, in steel with a thickness of 0.35 mm, for which losses from hysteresis make up a smaller part of the total losses, the total losses with a change in angle α change to a lesser extent than in steel with a thickness of 0.30 and 0.28 mm.

Plates for rods and yokes are cut so that the longitudinal axis of the plate is parallel to the side edge of the coil strip, i.e. coincides with the direction of rolling of the steel. In this case, in the rods and most of the yokes, the direction of the magnetic field induction vector will coincide with the direction of rolling (Figure 8.8, b).

Table 8.10. Specific losses in steel p and in the area of the laminated joint pz for cold-rolled steel grades 3404 and 3405 in accordance with GOST 21427-83 and for foreign-made steel grades M6X and M4X with a thickness of 0.35, 0.30 and 0.28 mm at various inductions and f = 50 Hz

Note: 1. Specific losses for steel grade 3405 with a thickness of 0.35 mm should be taken according to the column for steel 3404 with a thickness of 0.30 mm.

2. Specific losses for steel М6Х with a thickness of 0.35 mm should be taken according to the graph for steel 3404 of the same thickness.

(3) The last two columns show the specific losses pz, W / m 2, in the zone of the charge joint when mixing in layers in one and two plates, the same for all brands.

When assembling a magnetic system from rectangular plates with straight joints according to Fig. 8.8, a, b in the corners of the magnetic system, that is, in the parts of the yokes shaded in this figure, the angle α between the magnetic induction vector and the direction of rolling will vary from 0 to 900. The general increase in specific losses throughout the volume of shaded parts in the corners magnetic system can be estimated by the coefficient k p, y, depending on the shape of the joint, steel grade, plate thickness and induction. For oblique joints according to Fig. 8.8, additional losses also occur in the corners of the magnetic system, which are smaller than at straight joints. In this case, the zone of non-coincidence of the direction of the induction lines with the direction of rolling is limited by a smaller volume of steel adjacent to the joint of the plates. For an induction range of 0.9-1.9 T, the coefficient k p, y for straight and oblique joints can be taken from table. 8.11.

Table 8.11. Coefficient kп, y, taking into account the increase in losses in the corners of the magnetic system, for steel of different grades with oblique and straight joints for the range of inductions B = 0.9 ÷ 1.7 T at f = 50 Hz.

Note: 1. With an induction B = 1.8 T, the coefficient obtained from the table should be multiplied by 0.96 at an oblique joint, and by 0.93 at a straight one; at B = 1.9 T - by 0.85 and 0.67, respectively.

2.With a combined joint on the middle bar according to Fig. 2.17, c take k p, y = (k "p, y + k" "p, y) / 2

Directly in the joint zone in the laminated magnetic system, an increase in induction occurs and some of the induction lines from one plate to another pass perpendicular to the surface of the plates (Fig. 8.9). As a result, additional losses occur directly in the joint zone, which are determined by the total joint surface (gap) and specific losses per 1 m 2 of the surface.

Rice. 8.8 Parts of the magnetic system in which increased

losses in cold rolled steel with straight and oblique joints.

These specific losses RH for cold-rolled steel are given in table. 8.10 and partially 8.9. Induction for determining pz at straight joints is taken to be equal to the induction in the rod for joints perpendicular to the axis of the rod, and induction in the yoke for joints perpendicular to the axis of the yoke. For oblique joints, one should take B s = B s / √2, where B s is the induction in the rod.

Rice. 8.9. Non-magnetic gap: a - in the butt magnetic

system; b - in the charge magnetic system.

The area of the gap (joint) P z is taken for straight joints equal to the active section of the Ps rod or yoke Pya, for oblique joints P z = √2Ps.

The cross-sectional shape of the yoke can influence the distribution of the induction over the cross-section of the yoke and the bar (see § 2.3). If the number of steps in the yoke section is equal to or differs by one or two steps from the number of steps in the rod section, then the distribution of induction in the yoke and the rod can be considered uniform and the coefficient of increase in losses, depending on the shape of the yoke section, k p, i = 1, 0. For a yoke with a ratio of the number of steps of the rod and yoke equal to three, k p, i = 1.04; equal to six, k p, i = 1.06 and for a yoke of rectangular section k p, i = 1.07.

For pressing rods and yokes when assembling the transformer core, its various structural details are used. Depending on the power of the transformer, the pressing method can be selected in accordance with the recommendations of table. 8.12. The same table shows the coefficients k p, n and k t, n to take into account the effect of pressing on losses and no-load current.

Table 8.12. Methods for pressing the rod and yoke and the coefficients k p, p and k t, p to take into account the effect of pressing on losses and no-load current.

Several technological factors also influence idle losses. Longitudinal cutting of a strip of a steel coil into strips and transverse cutting of a strip into plates lead to the occurrence of internal mechanical stresses in the plates and an increase in specific losses in steel. This increase can be taken into account by introducing the coefficient k p, p, which for annealed steel grades 3404 and 3405 can be taken equal to 1.05 and for unannealed 1.11. For annealed steel grades М4Х and МбХ k p = 1.025 and for unannealed 1.05.

When cutting plates from a strip of a roll, burrs are formed at the cut line. Removing these burrs with knives leads to an increase in specific losses, which can be taken into account by the coefficient k p, s: k p, s = 1 for annealed plates and 1.02 for unannealed plates. If the burrs are not removed, then k p, z = 1.02 and 1.05, respectively. For plates with a width of more than 0.3-0.4 m k p, z = 1.

Coating the plates with an insulating lacquer film increases the losses by a factor of k p, l = 1 times with air cooling of the plates and by a factor of k p, l = 1.04 times for water cooling.

Rearrangement of the upper pit of the frame when installing the windings leads to an increase in losses, taken into account by the coefficient kp, w. With a transformer power up to 250 kVA k p, w = 1.01, at 400-630 kVA - 1.02, at 1000-6300 kVA - 1.04-1.08 and at 10,000 kVA and more - 1.09. Blending the magnetic system into one or two plates in a layer affects the specific losses and is taken into account in table. 8.10. Due to the need to take into account the increase in losses in cold-rolled steel at the corners of the yokes, i.e., in the parts of the yokes shaded in Fig. 8.8, b, in this case it is convenient to determine the mass of steel and losses in the magnetic system in the following order.

The mass of the rods is determined by (8.11) (for a yoke with a rectangular cross-section G c "" = 0), and the losses in them are calculated, as usual, from the induction of the rod and tabular data of specific losses pc for the steel of the grade used.

The weight of the yokes is divided into two parts. The mass of the steel of the parts shaded in Fig. 8.8, for a three-phase transformer is equal to six times and for a single-phase transformer - four times the mass of the angle G y, determined by (8.5), (8.6) or (8.7). The mass of steel of unshaded parts is determined as the difference G "i - 4Gy for a three-phase transformer and G" "i - 2G y for a single-phase transformer. Therefore, the total mass of steel of two yokes can be represented for a three-phase transformer as

![]() (8.31)

(8.31)

for single-phase - in the form

![]() (8.31a)

(8.31a)

In that part of the mass of the yoke steel, which is determined by the difference, on the right side of (8.31), losses occur, determined in the usual way by the induction in the yoke and the specific losses p i. In the mass of steel of the corners, in addition to losses determined in the same way, additional losses arise, depending on the straight or oblique shape of the joints of the plates of the rods and yokes.

For a flat three-phase laminated magnetic system of a modern three-rod design with mutual arrangement rods and yokes according to Fig. 2.5, d, assembled from plates of cold-rolled anisotropic steel, with pressing of rods by wedging with internal winding or bandages, and yokes with yoke beams or beams with half-bands, which do not have through studs in the rods and yokes, idle speed losses can be calculated according to (8.32). Such a magnetic system has four corners on the extreme and two on the middle rods.

The coefficient of increasing losses in the corners can be found by the formula

It depends on the shape of the joints in the corners of the extreme k p, y, cr and average k p, y, cp of the rods of the magnetic system, the coefficients for which are determined from Table. 8.11. The values of k n, y calculated for various combinations of the shape of the joints are given in table. 8.13.

Table 8.13. The values of the coefficient kп, у for different numbers angles with oblique and straight joints of plates of a flat laminated magnetic system for steel of different grades at B = 0.9 ÷ 1.7 T and f = 50 Hz.

* Combined joint according to Figure 2.17, c.

Expression 8.10 and partially 8.9.

For a single-phase transformer with a bar magnetic system according to Fig, 2.5, and the formula. (8.32) turns into the formula, (8.32a)

where k p, y = 4k p, y, cr and can be taken from table. 8.13. When carrying out a preliminary calculation according to the generalized method of Ch. 3, it is desirable to have a more convenient, but rather accurate, formula for determining no-load losses at this stage of the calculation. The product of the coefficients in (8.32), taking into account the fact that the losses in the gap zone, defined as with the previous instructions of this paragraph and is replaced by one coefficient k p, d. In this case, by (8.32), we obtain

where k p, d is a coefficient that takes into account the additional losses caused by cutting steel, deburring, pressing the magnetic system and repacking the upper yoke, as well as losses in the gap zone, can be taken from Table. 8.14.

Table 8.14. Coefficient of additional losses kp, d in (8.33) for steel grades 3404 and 3405.

Notes: 1. For steel grades M4X and M6X, the same coefficients can be taken.

2. For a rectangular yoke cross-section, multiply the coefficient obtained from the table by 1.07.

It should be noted that the thickness of the electrical steel from which the magnetic system will be assembled, according to GOST 21427-83, may differ from the calculated one within ± (6.5 ÷ 8.5)% for cold-rolled steel and ± (8.5 ÷ 10)% for hot rolled steel. These deviations can cause some change in the fill factor and induction in the magnetic system, which in turn will lead to a deviation of the actual no-load losses from the calculated ones.

The deviation of the actual losses in the finished transformer from the calculated ones can also be a consequence of the instability of the steel quality, a greater or lesser increase in losses due to mechanical influences during the preparation of plates and assembly of the system, and other reasons. The influence of these factors can be added or subtracted, but, as a rule, in a correctly calculated transformer, the deviation of the actual losses from the calculated ones is, on average, no more than ± (5 ÷ 8)%. Taking into account these deviations, in cases where the maximum value of the no-load losses of the transformer is set, the calculated losses should be maintained within the limits of the GOST standard or technical conditions plus half the tolerance.

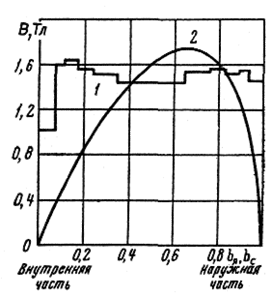

Rice. 8.10. Distribution of induction in the butt

spatial magnetic system: 1 - by

rod packages; 2 - by ring packages

(layers) of the yoke.

According to GOST 11677-85, a tolerance of + 15% is set for no-load losses in the finished transformer. Thus, in the calculation, no-load losses should be maintained within the limits of the corresponding GOST plus 7.5%.

Spatial magnetic system according to Fig. 2.6, a, has its own peculiarities in the distribution of magnetic flux in the rods and yokes, which should be taken into account when calculating losses and no-load current. Due to the fact that the yoke of this system has a rectangular cross-section with a multi-stage cross-section of the rod, as well as due to the unusual joining of the end surfaces of rectangular rod packages with different annular yoke packages (layers) (Fig. 8.5), an uneven distribution of induction over the cross section of the rod and yoke occurs (fig. 8.10). The resulting additional losses, as studies have shown, can be taken into account when calculating losses by multiplying the losses in the rods by k p, n, s = 1.04 and losses in the yokes by k p, n, i = 1.26.

When the primary winding (HV winding) is connected to a star without a neutral wire, the 3rd harmonic no-load current cannot flow in the primary winding, which leads to the appearance of the 3rd harmonic magnetic flux in the magnetic system.

Rice. 8.11. Yoke magnetic flux shape

spatial magnetic system (1st and 3rd

harmonic, resulting curve)

This component of the magnetic flux is displaced from the parallel-connected rods into the annular yokes, where its initial phase coincides with the initial phase of the 1st harmonic. As a result, the maximum value of the magnetic flux and induction in the yokes decreases by 1.14 times (Fig. 8.11), which leads to a decrease in the specific losses in the steel of the yoke and is taken into account in the calculation by a decrease in the induction in the yokes.

In this case, the induction in the rods is calculated according to (8.28). The first harmonic induction in straight sections of the yoke can be found by

![]() (8.34)

(8.34)

The maximum induction in the straight sections of the yoke, taking into account the 3rd harmonic B, is determined as

![]() (8.35)

(8.35)

The calculated induction in the corners of the magnetic system В у is found taking into account the induction of the rods and straight sections of the yokes

![]() (8.36)

(8.36)

The appearance of the 3rd harmonic magnetic flux in the yokes also leads to a distortion of the shape of the curve Ф = f (t), an increase in specific losses in steel and overall losses in the yokes. This increase in losses is taken into account by introducing the coefficient k p, and to the losses in the yokes, which for spatial magnetic systems according to Fig. 2.6 you can take k p, u = 1.33.

The manufacture of yokes by winding from a cold-rolled strip is associated with mechanical effects on the material and significant residual deformations of the strip, which leads to a significant deterioration in its magnetic properties. Therefore, recovery annealing of wound yokes in long-term furnaces is absolutely necessary. In the absence of annealing of the wound yokes, one should consider a possible increase in losses up to two times and with a significantly larger increase in the no-load current. Rod plates must be annealed in continuous roller conveyor furnaces.

When calculating no-load losses, the technological factor should also be taken into account, i.e., an increase in losses due to mechanical effects on steel plates after annealing during assembly of the core and the entire transformer, imperfection of recovery annealing, etc. This factor can be taken into account by introducing the coefficient kp , t, depending on various reasons, including the level of production culture of a particular plant. This coefficient can be taken as k p, t = 1.0b.

Taking into account the remarks made, the formula for calculating the no-load losses in the spatial magnetic system can be represented in the form

Specific losses in steel of rods, straight sections of yokes and angles of the magnetic system p c, p i and p y are determined from Table. 8.10 for steel of the corresponding grade according to the inductions B c, B i and B y. Coefficient k "n, y is selected according to Table 8.1 1 for the same steel with a straight joint.

When carrying out a preliminary calculation according to the generalized method of Ch. 3 you can use the formula (8.37) in the transformed form

![]() (8.38)

(8.38)

where the coefficients k "c, k" i, k "y, calculated according to (8.37) for steel 3404, the induction in the bar B from 1.5 to 1.65 T and for the 1st harmonic induction in the straight sections of the yoke B i = (1.0 ÷ 0.9) V s, can be taken from Table 8.15. For other steels, these coefficients can be calculated on the basis of (8.37). In the coefficients k "c, k" i, k "y, in tab. 8.15 included, respectively, the specific losses p s, p i, p y.

Table 8.15. Values of the coefficient k "c, k" i and k "y in (8.38) for the spatial magnetic system Steel grade 3404.

When calculating no-load losses in the spatial magnetic system according to Fig. 2.6, b, consisting of three wound rings, it should be borne in mind that with the calculated induction in the rod B with the 1st harmonic induction in individual rings B k1 is 2√3 = 1.15 times higher (see § 2.1), i.e. e. B k1 = 1.15 V s. In this case, in each of the wound rings, a harmonic magnetic flux arises according to Figure 8.12 and the maximum value of the induction decreases by 1.14 times. Thus, the maximum induction, which determines the specific losses in steel, in such a magnetic system can be taken equal to the calculated induction В к = В с.

The distortion of the shape of the curve of the magnetic flux and induction in this case can be taken into account by introducing the coefficient k p, u = 1.33.

To take into account the technological factor, you can enter the coefficient k p, t = 1.06.

Since in the considered magnetic system the concept of an angle does not exist and the homogeneity of each ring when calculating losses makes it possible not to divide it into rods and yokes, the formula for calculating losses in the final and preliminary calculation takes the form

![]() (8.39)

(8.39)

where the mass of the steel of the magnetic system G st is determined by (8.26).

i 0a = (P x / S) 100%,

Or, expressing the rated power S v kva,

i 0a = (P x / 10S)%,

Regarding the magnetizing current i op, then its value at a certain value of induction, as well as no-load losses, depends primarily on the type of steel used and the design of the magnetic circuit. The calculation of the magnetizing power consumed by the steel of the magnetic circuit is carried out in the same way as the calculation of losses. Specific magnetizing power values q are taken from the table compiled for each steel grade based on experimental data. But since the main magnetic flux Ф on its way must also pass through the joints (gaps) between the plates, then to overcome the resistance of the joints, additional magnetizing power is required, which will depend on the design of the magnetic circuit - butt or laminated, the size of the gap, the layout of the mixture, and, induction, of course. In the domestic transformer industry, exclusively laminated magnetic circuits are used, therefore the tables contain the values of the specific magnetizing power at the joint (gap) ( var / cm 2 ) precisely for such magnetic circuits. Thus, the magnetizing current

i 0P = (q CT G CT + q I G I + n CT q CT.3 F CT + n I q I F I) / 10S%

Where q CT and q I AM- specific magnetizing powers, respectively, for rods and yokes, var / kg; G CT and G I AM- weight of rods and yokes, kg;n CT and n I AM- the number of joints along the sections of the rod and yoke; q CT.3 and q I. 3- specific magnetizing power per joint, var / cm 2 ; Fst.z and F I AM- cross-sections of the bar and yokes (without taking into account the filling factor), cm 2 ... The number of joints for a three-phase magnetic circuit will be n ST = 3, n I AM= 4 (fig.4.2). In large transformers, in which the magnetic core plates are made composite due to their long length, the number of joints increases accordingly. Specific magnetizing power values q for cold rolled steel can be taken from table. 4.1. To the value of the magnetizing current in the magnetic circuit obtained from formula (4.7), assembled from plates of cold-rolled steel with straight joints, a correction factor is introduced to increase the magnetizing power in the corners of the magnetic circuit in the same way as it is done when calculating losses in steel. An increase in magnetizing power is caused by a decrease in the magnetic permeability of cold-rolled steel in those parts of the magnetic circuit where the direction of the magnetic flux does not coincide with the direction of rolled sheets. For induction in the range of 1.5-1.7 tl the coefficient of increasing the magnetizing power in the corners of the magnetic circuit is approximately 3 ÷ 3.5.

Fig 4.2. The position of the joints of the plates in a three-phase magnetic circuit.

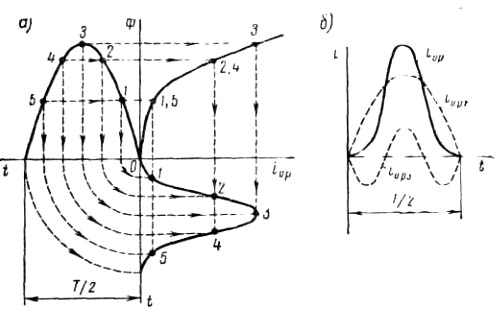

The curve of the dependence of the magnetizing current r op on the magnitude of the induction (the curve of the initial magnetization shown in Fig. 4.3, a) has a so-called inflection point, in the vicinity of which saturation of steel occurs. An increase in induction by sharpening the bend in the curve causes a sharp increase in the magnetizing current, which is the main reason for limiting the maximum value of induction to 1.4-1.45 tl for hot rolled steel and 1.6-1.7 tl for cold rolled steel. In addition, an increase in induction strongly distorts

Rice. 4.3. Curve of magnetizing current: a - construction of a curve at a given saturation point (3); b - decomposition of a non-sinusoidal curve into sinusoidal components of the first harmonic (i op1) and third harmonic (i op3)

The shape of the curve of the magnetizing current, which becomes non-sinusoidal (Fig. 4.3, b). As a result, conditions are created for the appearance of magnetic fluxes of higher harmonics, of which the magnetic flux of the third harmonic is especially unpleasant. With a star-star winding connection scheme (without a zero point output), this flux, being in phase in all three rods, is forced to close in the steel parts of the transformer structure (yoke beams, tank, etc.), causing additional, difficult to take into account losses in them.

i 0 = √ i 2 0P + i 2 0a

For a three-phase transformer, the resulting no-load current will be the average of the three phases. The actual value of the no-load current of the finished transformer for the middle leg will be less than for the outer ones. This is due to the asymmetry of the magnetic system for different phases. The average length of the magnetic line of the middle phase B will be less than that of the extreme phases A and C. Since the active component goa is relatively small, it can be assumed without much error that i 0 = i 0P .

Rice. 4.4. Curves of specific losses and magnetizing power in EZZO steel

But in real transformers, this dependence in the range of applied induction values is expressed more sharply, approximately proportional to the third degree of induction, i.e., no-load losses strongly depend on the value of the primary voltage supplied to the transformer. The curve of changes in specific losses in steel, according to table. 4.1 is shown in Fig. 4.4. The magnitude of the magnetizing current depends on the induction to an even stronger degree. Since, in order to save active materials, power transformers are designed with as high induction values as possible, close to the saturation of steel, a further increase in induction with increasing voltage causes a sharp increase in the magnetizing current. This can be seen in Fig. 4.4, which shows the dependence of the specific magnetizing power q and q 3 from induction V.

|

![]()

Rice. 4 5 Vector diagram of transformer no-load

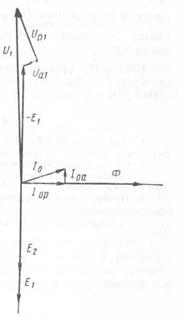

According to Kirchhoff's second law, the geometric sum of e. etc. with. is equal to the sum of the voltage drop in the resistance of the circuit, i.e.

Ú 1 + Q 1 + Q p1 = Ú a1

Since the applied primary voltage Ú 1 must be balanced by the e. with and voltage drops, then the equation of equilibrium (balance) e. etc. with. usually written as follows:

Ú 1 = - Q 1 - Q p1 + Ú a1

E. d. With. Scattering - É p1 can be thought of as reactive voltage drop Ú p1 taken with the opposite sign. The equilibrium equation can be visually represented in the form of a vector diagram of an idle transformer, shown in Fig. 4.5. In this diagram, the e vectors are plotted along the vertical axis. with, and along the horizontal - the vector of the amplitude of the main magnetic flux F. Since e. etc. with. E 1 and E 2 lag behind the flux Ф by a quarter of the period, then their vectors with a positive value are directed downward. The same diagram shows the vectors of the no-load current İ O and its active İ oa and reactive İ op components. Active voltage drop vector Ů a1 coincides in direction with the vector İ O and the vector Ů p1 jet fall ahead of vector İ O for a quarter period (90 °). Vector Ů 1 defined as closing the sum of vectors - Ė 1 , Ů p1 and Ů a1 .

I 2 = U 2 / Z 2

Where Z 2 is the total resistance of the circuit. Secondary current I 2 creates a magnetizing force (ampere-turns) I 2 ω 2 , which should excite some magnetic flux Fn in the magnetic circuit. According to Lenz's rule, this flux in the surrounding primary winding will cause the primary magnetizing force I ' 1 ω 1 equal in size I 2 ω 2 ... The magnetizing force, according to the same rule, creates a magnetic flux - Ф n, i.e. flow equal to and directed opposite to the flow of F n. Magnetic fluxes are mutually canceled, but a load current appears in the primary winding

I 1 = I 2 ω 2 / ω 1

Thus, when the load transformer is switched on from the secondary side, load currents appear in both of its windings, directed opposite to each other. In power transformers, without a large error, it is believed that the primary and secondary voltages are proportional to the number of turns of the windings, therefore

I ’1 = I 2 ω 2 / ω 1 = I 2 U 2 / U 1 or U 1 I’ 1 = U 2 I 2

Hence it follows that the primary and secondary powers are equal, and this is consistent with the law of conservation of energy. Transformer, consuming electrical energy of the same voltage from the primary side U 1 gives the same energy (minus losses) from the secondary side, but only at a different voltage U 2 ... Since there is also no-load current in the primary winding I 0 , then the total primary current I 1 when the transformer is loaded, it must be equal to the sum (in the general case of geometric) of the load current I ' 1 and no-load current I 0 , i.e.

İ 1 = İ "1 + İ 0

But since the no-load current is only a few percent of the rated load current and, in addition, both currents are added at some angle to each other, then the no-load current is usually neglected and it is assumed that I 1 ≈ I ' 1 ... Load currents I 1 and I 2 , passing through the windings of the transformer, cause active voltage drops in them U a1 = I 1 r 1 and U a2 = I 2 r 2 and inductive voltage drops P k1 and P k2... Active voltage drops arise due to electrical (Joule) losses in the windings, equal to P K1 = I 2 1 r 1 and R k2 = I 2 2 r 2 ... Losses in windings R k1 and R k2 add up to the bulk of short circuit losses R To transformer. Inductive voltage drops arise due to the presence of stray magnetic fluxes covering each of the windings separately. Inductive voltage drops compensate for em. etc. with. scattering E p1 and E p2, i.e. U p1 = - E p1 and U p2 = - E p2... In the given transformer, the total active voltage drop is equal to the sum of the active voltage drops in both windings, i.e.

U a = U a1 + U a2

Likewise, the total inductive voltage drop is equal to the sum of the inductive voltage drops, i.e.

U p = U p1 + U p2

In the vector diagram of the reduced transformer, the geometric sum of the active and inductive voltage drops, the vectors of which are at an angle of 90 ° to each other, is the total voltage drop, called the short-circuit voltage U K of the transformer, therefore,

U k = √U 2 a + U 2 p (5.1)

Losses and short-circuit voltage are important operational parameters (characteristics) of transformers, therefore they are standardized by GOSTs. Their values are given above, in table. 2.1 and 2.2. The magnitude of the efficiency and the change in the voltage of the transformer depend on the magnitude of losses and short-circuit voltage, the calculation of which is given below.

P = I 2 r.

In factory practice, a converted formula is often used, which includes the current density δ and the weight of the winding wire G o ,

P K = I 2 r = δ 2 s 2 P ρ (1 / s P) = ρδs P l.

Because G 0 = γs NS l 10 -3 and s NS l = G 0 10 -3 /γ , then

P K = (ρ / γ) δ 2 G 0 10 3 = K P δ 2 G 0, W (5.2)

Where s NS- wire cross-section, mm 2 ; l- wire length, m; ρ - resistivity of copper (or aluminum), Ohm mm 2 / m; γ - specific gravity, kg / dm 3 ; G o- the weight of the winding wire, kg... Coefficient value TO NS is taken from table. 5.1.

Table 5.1

Since the current density and the weight of the wire in the primary and secondary windings differ from each other, the losses in the windings are calculated for each of the windings separately and then summed up.К Ф = 1 + [(m 2 -0.2) / 9] (a ") 4, (5.3)

Where m- the number of layers of the coil; a"- reduced radial wire size, equal to

a "= (a / 1.03) √ (b / b FROM) (f / 50) K P

a- the radial size of the wire, cm ; b- the axial dimension of the bare wire, cm ; b FROM- the same, insulated wire, cm ; TO R is the Rogowski coefficient ( cm ... § 5.4); f- frequency, Hz... For windings from a round wire of diameter d K Ф = 1 + [(m 2 -0.2) / 15.25] (d ") 4, (5.4) where d "- reduced wire diameter equal tod "= (d / 1.03) √ (d / d FROM) (f / 50) K P

d FROM- the diameter of the insulated wire, cm ... With a wire diameter up to 3.5 mm(large diameters are rarely used, usually in such cases they switch to a rectangular wire) the percentage of additional losses is relatively small, therefore, with round wires, additional losses are neglected. When calculating additional losses, it should be taken into account that their value in the layer of wires adjacent to the main scattering channel is approximately 3 times greater than the average value determined by the above formulas, which can lead to increased heating of this layer. In addition, due to the curvature of the magnetic leakage flux at the exit from the winding, local overheating can occur with a large axial size of the wire, which must be taken into account when calculating the losses of high-power transformers. From the consideration of the above formulas, it can be seen that the amount of additional losses very strongly (to the fourth power) depends on the radial size of the wire. Therefore, the use of too thick, massive wires should be avoided, and if this is required because of the need to have a large total cross-section of the winding wire, then several parallel wires with their transposition (movement) should be used ( cm ... further screw windings). In addition to additional losses in the winding wires, leakage fluxes also cause additional losses in the walls of the tank, pressing yoke beams and other massive parts of the transformer structure. These losses arise from both eddy currents and magnetization reversal. The theoretical calculation of these losses is also very difficult, since the exact direction of the stray magnetic field and its configuration are usually unknown. For power transformers of size 1, additional losses in the tank walls R b due to their relatively small size, they are usually not taken into account. For transformers of higher power, there are several proposed empirical formulas for their calculation. For transformers of sizes II and III, the simplest formula isP 6 = 0.007 S 1.5 W (5.5)

Losses in taps between windings and bushings (bushings) are part of the short-circuit losses and must be taken into account when calculating the latter. Losses in the taps can be accurately determined after the design of the transformer, i.e. when the length and cross-section of the taps are known. However, it is advisable to know the magnitude of these losses at least approximately in advance, so as not to make adjustments to the calculation of the windings after the design is developed. The data of the taps of already made serial designs of power transformers of the same type in terms of losses do not differ significantly from each other. Therefore, the preliminary value of losses in the bends R otv three-phase transformer with sufficient approximation can be determined by the empirical formula

P hole = 0.05I 4 √S W, (5.6)

Where I- line current of the winding, a... As can be seen from the above formula, the quantity R otv at a current not exceeding 100-200 a, is relatively small, therefore, the losses in the taps of power transformers of sizes II and III are practically sufficient to determine only for LV windings.

Power dissipation power transformer consists of the so-called copper losses and steel losses. The first are associated with the flow of load current through the conductors of the windings, which have a certain electrical resistance. Losses in steel are due to eddy currents, magnetizing currents arising in the magnetic circuit.

When conducting idle experience voltage is connected to one winding, the other remains open. The power consumed by the transformer from the network is spent to a greater extent on magnetizing the steel of the magnetic circuit, to a lesser extent - on heating the winding conductors, which can be neglected. Therefore, this experience makes it possible to measure the power losses in steel, called no-load losses.

Additionally, by connecting to the remaining open winding, you can measure the voltage across it, and from the readings of the two, calculate the transformation ratio. But this measurement does not apply to the very experience of idling.

Experience XX during commissioning are subject to:

All dry transformers, as well as those having a liquid non-combustible dielectric as an insulating and cooling medium.

- Oil-filled transformers with a capacity of more than 1600 kVA.

- Transformers for auxiliary needs of power plants, regardless of their capacity.

In operation, such measurements are carried out only for transformers with a capacity of 1000 kVA or more, and only after major repairs associated with the change of windings or repair of the magnetic circuit. According to the network rules, it is possible to carry out measurements by order of the technical manager of the enterprise after the chromatographic analysis of gases dissolved in oil has given alarming results. But this only applies to power transformers with windings of 110 kV and above.

Measurement procedure and scheme

Before the experiment, the process of demagnetizing the magnetic circuit of the transformer under test is carried out. For this, a direct current is used, which is passed through one of the windings on the low voltage side. The current is connected repeatedly, each subsequent connection occurs with a change in polarity and a decrease in value. The initial value should not be less than twice the expected no-load current. With each subsequent switch on, the value decreases by 30-40%. The process ends at a current lower than the no-load current value.

To conduct a direct open-circuit experiment, a rated voltage is applied to the secondary winding of the transformer, with a deviation of ± 5% from the norm. The neutral terminal, if any, is not used. In this case, the voltage is strictly sinusoidal, with the nominal frequency of the network.

To carry out measurements, you will need three laboratory instruments, with an accuracy class of at least 0.5. These are ammeters and wattmeters. connected to each phase in series. are connected to the line voltage of all three phases. The current windings of the wattmeters are connected in series with the ammeters. The voltage windings of the wattmeters are connected according to the diagrams shown. Voltage is applied, readings are taken from the devices.

Strictly speaking, the measurement is carried out according to the same schemes that were used at the manufacturer's plant for the experiment. After all, the data obtained will need to be compared with the factory data. But, if a three-phase voltage source is not available, three measurements can be made by applying voltage to two phases of the transformer winding, short-circuiting the third that remains free.

In this case, only line voltage is used, since the distortion of the curve shape due to non-linear loads in the network has a minimal effect on it. According to the same schemes, an open-circuit experiment is carried out at a reduced (low) voltage.

Analysis of measurement results

During acceptance tests and overhauls, the data obtained are compared with the corresponding test report carried out in the factory after the transformer was manufactured. A discrepancy of more than 5% is not allowed.

For single-phase transformers, in the same cases, the power losses should not differ from the initial value by more than 10%.

In operation, only the no-load current is measured based on experience with rated voltage or power loss at reduced voltage. At the same time, PTEEP does not normalize deviations from the norm.

However, if a transformer damage is suspected, the loss measurement method using three successive experiments gives a very valuable result. Since the windings of the transformer phases are in unequal conditions, it is possible not only to calculate whether there is a defect there, but also to determine the defective phase.

The path of the magnetic flux when the terminals AB and BC are excited is the same. Therefore, the power losses for experiments in these phases will not differ. When the AC phases are excited, the path traversed by the magnetic flux is longer, so the power losses will be 25-50% higher than the previous ones. Comparing these indicators, it is possible to identify at which phase there is a defect.

|

transformer |

Voltage |

Power |

making |

No-load losses |

|

|

catalog |

measured |

||||

Let us give, for example, the total losses in large block and network transformers for different voltages (according to data from Renzmann & Gruenewald GmbH, Germany) (Table 2).

As a result of measures taken in European transformer engineering on the basis of improving the design and materials, no-load losses for a conventional 220 kV transformer with a capacity of 200 MVA have decreased over the past 50 years by more than three times, and load losses have been halved.

Table 2.

|

Block transformers |

Mains transformers |

|||||

|

Power, |

Voltage, |

Power, |

Voltage, | |||

No-load losses cause damage several times greater than load losses, accounting for the bulk of capitalized losses. The damage to no-load losses is especially significant for lower power transformers. So, if for a modern 500 kV transformer with a capacity of 1000 MVA, losses are about 0.035% of the total power, then for an 11 kV transformer with a capacity of 1 MVA this is already 0.35%. Distribution transformers bring the main damage to the energy sector in terms of losses. Significant efforts of foreign firms are directed at their improvement, reduction of idling losses. For high-power transformers, the generation of heat losses creates big problems due to the high degree of use of active materials and the desire to reduce the size. Heat generation complicates the cooling system and largely determines the design of the transformer.

The main reason idle losses stroke are losses in steel from magnetization reversal, losses from eddy currents in steel plates, from leakage fluxes in other parts of the transformer. Load losses include losses in copper windings, losses from eddy currents arising in massive parts of the transformer lying next to live parts, losses from leakage fluxes.

Reducing no-load losses can be achieved by:

use of a material for the core with significantly reduced losses for magnetization reversal and eddy currents;

optimization of the core design and technology of its manufacture;

designing a transformer core for low induction operation.

The quality of electrical steel is constantly being improved. For widely used grades of cold-rolled, oriented, high magnetic permeability steel with a high silicon content abroad, 10-15 years ago, a level of specific losses of about 1.05-1.10 W / kg at 50 Hz and 1.7 T. The best steel grades have specific losses of about 0.85 W / kg. The use of thinner sheets also reduces losses. Thus, steel with a thickness of 0.23 mm, which is increasingly used abroad, has a specific loss by 20% less than steel with a thickness of 0.3 mm.

An effective technology for processing steel is laser scribing with a reduction in the length of oriented crystals. In this way, in combination with the use of plates of reduced thickness, a specific loss level of 0.5 W / kg was obtained. With a decrease in sheet thickness to 0.18 mm, a decrease in specific losses to 0.3 W / kg is predicted.

Amorphous steels are being actively developed. Compared to conventional steel, the loss in them is 3-4 times less. The main producer of such materials is AlliedCorp. (USA), producing amorphous steel Metglas.

For Hitachi transformers with Metglas cores, no-load losses are 20% less than usual. Such transformers are most widely used in the USA and Great Britain.

The use of amorphous steels has not yet replaced oriented electrical steel. Extreme brittleness, tape thickness not higher than 20-30 microns, high sensitivity to mechanical influences during processing interfere.

Noise reduction requirements limit the use of steels with high magnetostriction. Steel with a silicon content above 6.5% is unacceptable for this reason, and at 4% it is difficult to roll steel due to its high brittleness. Only fast-cooled steel has less brittleness, but its processing at high temperatures does not allow obtaining structures with such high magnetic characteristics as normal steel with an oriented structure. According to recent studies, the optimal thickness of the plates is 0.1 mm (at 1.8 T).

Recent developments in the field of transformer construction are based on steel with a silicon content of 3%, which has low magnetostriction and allowable losses. The use of reduced induction in the core allows not only to reduce losses in it. but also significantly reduce the noise level from the transformer. The decision is made on the basis of technical and economic considerations.

Design and technological measures to reduce core losses:

the use of a tape tie of cores and a yoke with the help of fiberglass ties, eliminating the need for holes for tie bolts - places of concentration of losses;

mixing of cores with a shift (oblique joint), which became possible with the use of a computer to control the cutting of steel, a combined mixture with a partially oblique joint is also used;

careful fabrication of individual steel sheets;

assembly, lamination of the core, excluding rough mechanical effects on steel plates.

Load losses are determined by the currents flowing through the windings and include losses on the active resistance of the conductors of the windings, losses on eddy currents in conductors, losses on eddy currents in massive parts of the transformer lying near current-carrying parts.

In foreign practice, copper has almost completely replaced aluminum due to its low resistance and high strength - this reduces losses and increases the reliability of the transformer.

Since the eddy current losses in a conductor are proportional to the square of its cross-section, reducing its cross-section by 33% reduces losses by more than 50%. This is successfully used to reduce the load losses in the transformer. Reducing the cross-section of conductors is achieved by using ribbon cables, which are twisted from several thin conductors. Improving the filling of the magnetic circuit window when using a ribbon cable for a series of 141-500 kV transformers developed in the USA with a capacity of 25-250 MBA allowed to reduce the weight by 6-15% , no-load losses by 8-15%, load losses by 3-22%. The winding is made of a ribbon cable, which is a bundle of foil tapes isolated from each other.

Reduction of eddy current losses gives the use of a wire with continuous transposition. To increase their mechanical strength, an epoxy coating of elementary conductors in the rod is used and the rod is baked during the drying of the winding.

In the LV windings, they try to use a transposed wire without additional insulation for better cooling.

The desire to reduce losses makes us improve the methods of their calculation and optimization of the transformer design. Calculation of losses is a difficult task due to the need to determine the fields in active and passive nodes of complex configuration and the eddy currents caused by them.

An example of such work is the research of a transformer manufacturer in Egypt (ELMACO factories) and a number of universities in this country. The direction of work is to improve the accuracy of methods for calculating losses due to eddy currents in the transformer windings and in its tank from leakage fluxes.

On the basis of three-dimensional analysis of the field using the finite element method, a set of programs has been developed for calculating the optimal design of transformers.

When calculating winding losses, the dimensions of the core window, the induction in the core, and the thickness of the conductors in the windings are taken into account. The losses in the tank determine the magnetic load of the core, the thickness and configuration of the tank walls, the distance from the tank to the active parts, and the magnetic and electrical properties of the tank material.

Superconducting Winding Transformers. A fundamentally new way to reduce losses in a transformer is the use of superconducting materials for the winding.

Low-temperature superconductors, on which the first prototypes of transformers were made, are not competitive with high-temperature superconductors (HTSC). The progress in the creation of HTSC materials allows us to consider the economic prospects of such developments as undoubted. 1992 to 2000 the price of HTSC materials has decreased 20 times!

Advantages of HTSC transformers: reduction of load losses by 90%, weight reduction up to 40% , limitation of short-circuit currents, reduction of reactance, overload capacity - 100% for a long time, low noise level. With mastered production, such a transformer is 20% cheaper than a conventional one of the same power.

According to calculations, a 30 MB A HTSC transformer will have a mass of 20 tons and will not have oil, while a conventional transformer has a mass of 45 tons, including 23 tons of oil, "es": ["W5G2KbNw1LU"], "pt": ["vmwyCKACUuc", "PZCvCTpeTsU", "PZCvCTpeTsU"], "fr": ["vgkE_nFia3o", "vgkE_nFia3o"], "la": ["GjdTrDOLKQg", "elRTbJaj" ])