A subsidiary of Motorola Mobility, which was acquired in 2014 by...

13.1. The surface of the site for storing materials, structures, products and equipment must be planned and compacted. In case of weak soils, the surface of the site can be compacted with crushed stone or paved with road slabs on a sandy base.

Storage of materials is carried out outside the prism of soil collapse of loose excavations, and their placement within the prism of soil collapse near excavations with fastening is allowed subject to a preliminary check of the stability of the fixed slope according to the fastening passport or calculation taking into account the dynamic load.

Loads (except for ballast unloaded for track work) with a stack height of up to 1.2 m must be at least 2.0 m from the outer edge of the head of the crane rail closest to the load, and at a higher height - at least 2.5 m according to the requirements of GOST 12.3.009-76*.

To drain surface water, a slope of 1-2 ° should be made towards the outer contour of the warehouse with the device, if necessary, ditches.

13.2. Slingers must know the places for storing materials provided for in the PPRk.

13.3. Places for storing materials and structures, as well as places for installing warehouse inventory are marked on construction site according to the example in figure 34.

1 - brick on pallets; 2 - spacer floor slabs - up to 2.5 m; 3 - span slabs - up to 2.5 m; 4 - outer spacer plates - up to 2.5 m; 5 - stiffening walls - up to 2.5 m; 6 - crossbars - up to 2 m; 7 - flights of stairs - up to 2 m; eight - Wall panels in the pyramid - up to 2 m; 9 - stained-glass windows in the pyramid; 10 - partitions in the pyramid with shelter from atmospheric precipitation; 11 - columns - up to 2 m; 12 - platform for tilting structures.

Figure 34 - Approximate plan for the placement of goods in the on-site warehouse

Notes

1. Warehousing is carried out in such a way that the weight of the structures corresponds to the lifting capacity of the crane.

2. Temporary roads are arranged in such a way as to ensure the acceptance of all goods within the capacity of the crane.

3. The scale (may not be shown in the PPRk) will facilitate the layout of goods within the limits of the crane's load characteristics.

4. At the storage site, signs with the name of the goods and their quantity in piles are installed.

13.4. Materials, structures, products and equipment should be placed in accordance with the requirements of standards, intersectoral rules on labor protection during loading and unloading operations and placement of goods, SNiP 12-03-2001 or the technical specifications of manufacturers.

13.5. In the absence of standards and specifications of manufacturers, the following methods of storage of the main types of materials and structures are recommended:

Brick in packages on pallets - no more than two tiers; in containers - in one tier, without containers - no more than 1.7 m high. Brick should be stored according to grades, and facing - according to colors and shades. In autumn and winter, brick stacks are recommended to be covered with sheets of roofing felt or roofing material;

Wall panels - in pyramids or special cassettes in accordance with the passport for the specified equipment, taking into account the geometric dimensions of the products and their stability during storage;

Partition panels - vertically into special cassettes in accordance with the passport for the cassette. Gypsum concrete panels are allowed to be installed in a pyramid with a deviation from the vertical by an angle of not more than 10 °. Gypsum concrete partitions must be covered from atmospheric precipitation;

Wall blocks - in a stack in two tiers on linings and with gaskets;

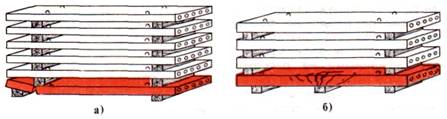

Floor slabs - in a stack with a height of not more than 2.5 m on linings and with gaskets, which are located perpendicular to the voids or the working span;

Crossbars and columns - in a stack up to 2 m high on linings and with gaskets;

Foundation blocks and blocks of basement walls - in a stack with a height of no more than 2.6 m on linings and with gaskets;

Stiffening walls, depending on the type of their transportation from the factory - in pyramids or similarly to floor slabs;

Round wood - in a stack no more than 1.5 m high with spacers between rows and installation of stops against rolling; stack width less than its height is not allowed;

Lumber - in a stack, the height of which, when stacked in rows, is not more than half the width of the stack, and when stacked in cages, not more than the width of the stack. In any case, the height of the stack should not exceed 3 m;

Small-grade metal - in a rack with a height of not more than 1.5 m;

Sanitary and ventilation units - in a stack with a height of not more than 2.0 m on linings and with gaskets;

Large-sized and heavy equipment and its parts - in one tier on linings;

Glass in boxes and rolled materials - vertically in one row on linings;

Bitumen - in a special container, excluding its spreading;

Ferrous rolled metals (sheet steel, channels, I-beams, section steel) - in a stack up to 1.5 m high on linings and with gaskets;

Thermal insulation materials - in a stack up to 1.2 m high, stored in a closed dry room;

Pipes with a diameter of up to 300 mm - in a stack up to 3 m high on linings and with gaskets with end stops;

Pipes with a diameter of more than 300 mm - in a stack up to 3 m high in a saddle without gaskets with end stops.

The lower row of pipes must be laid on linings, reinforced with inventory metal shoes or end stops securely fastened to the lining.

When storing reinforced concrete elements with hinges (slabs, blocks, beams, etc.), the height of the spacers must be at least 20 mm greater than the protruding part of the mounting hinges.

Storage of other materials, structures and products should be carried out in accordance with the requirements of standards and specifications for them.

13.6. Between the stacks (racks) there must be passages with a width of at least 1 m and driveways, the width of which depends on the dimensions of the vehicles and cranes serving the warehouse.

13.7. When storing goods, the factory marking must be visible from the side of the aisles.

13.8. It is advisable to place panels of the same brands in pyramids. The panels must fit snugly against each other over the entire plane. One-sided loading of pyramids is not allowed.

In cassettes, pyramids and other equipment of an on-site warehouse, it is necessary to install products in such a way that both the products themselves and the storage equipment cannot lose stability during storage. Products are installed taking into account their geometric dimensions and shapes.

13.9. Between stacks of structures of the same name, stacked side by side (floor slabs), or between structures in a stack (beams, columns), there must be a distance of at least 200 mm.

13.10. The height of a stack or row of stacks on a common spacer should not exceed one and a half of its width.

13.11. In stacks, gaskets are arranged one vertically. The location of the gaskets depends on the operating conditions of the product in the structure.

13.12. Each stack should store structures and products of one-dimensional length.

13.13. When arranging materials and structures, it is necessary to take into account the requirements of PPB 01-03.

Storage of materials and structures above underground utilities or in a security zone is allowed only with the written permission of their owner.

13.14. When conditions change or in case of production necessity, the person responsible for the safe performance of work with cranes may make additions and changes to the scheme for storing materials and structures provided for in the PPR, in compliance with the requirements of standards, specifications of manufacturers and other regulatory and technical documentation, approved by the State Supervision bodies and taking into account the cargo characteristics of the used cranes, access roads and parking lots; at the same time, the specified person in writing under his signature is obliged to issue to the slingers a modified scheme for storing goods, the second copy of the scheme is attached to the PPRk.

When drawing up a storage scheme, special attention is paid to compliance with the dimensions of the aisles, dimensions and methods of storage, and the inadmissibility of overloading storage places.

13.15. In cramped conditions, in the absence of storage areas, it is allowed to store materials and structures on the ceilings (coverings) of existing and reconstructed buildings with the written permission of the author of the project and the development of the necessary measures to ensure the stability of the building (structure).

Warehouses for the storage of inert materials must be arranged at enterprises that process these materials, since the release of products from factories rarely fully corresponds to the quantity produced daily. The need for large warehouses also arises in cases where stone crushing plants operate year-round, and finished products transported only by water, i.e., sometimes seasonally. Washing and screening plants usually operate only in the warm season, since it is impossible to wash in the cold, and it is not economically feasible to arrange the heating of these plants. The size of factory inert warehouses is set during the design of the plant, depending on the need to temporarily accumulate excess products due to the conditions of transport, seasonality of work, delivery for construction, etc.

Warehouses of inert materials at factories are arranged mainly open; bunkers are arranged only for more convenient loading of materials onto vehicles.

1 - sorting department; 2 - bunkers; 3 - inclined belt conveyor; 4 - distribution belt conveyor; 5 - stacks of materials; 6 - collecting belt conveyor; 7 - vacation department; 8 - collecting belt conveyor in the sorting department; 9 - transfer belt conveyor; 10 - reversible belt conveyor; And - cantilever movable belt conveyor; 12 - loading crane with a grab; 13 rolling stock; 14 unloading trolley; 15 - expansion of the warehouse with a rope scraper; 16 - bucket rope scraper; 17- movable rope scraper tower

Open warehouses are often linearly extended. For the formation of such linear warehouses a high overpass is arranged on wooden or iron supports supporting trusses, along which a belt conveyor or a group of belt conveyors passes, feeding material from the sorting department to the finished product warehouse.

Both the trestle supports and the trusses are made of very light construction in accordance with the light load.

Each type of material has its own stack; the stacks are separated from each other by walls, or are located at such a distance from each other at which their lower parts do not touch. More common is a device with separation of stacks by vertical transverse walls, which are sometimes used as foundations for the support posts of the overpass. With wooden supports, it is possible to sheathe their lower parts on both sides with boards or plates. Be sure to check the stability and strength of the walls for one-sided pressure of the material.

One belt conveyor running along the overpass can be transferred to each this moment only a certain grade of materials (or a certain mixture of them), and therefore it is necessary to have bins in the sorting department, into which materials come from screens and from which one or another grade of material or a certain mixture of materials is alternately unloaded onto a warehouse belt conveyor.

From the belt conveyor, the material is dumped into stacks by a movable unloading trolley 14 . Instead of unloading with the help of this trolley, sometimes a movable reversible belt conveyor 10 is used (i.e., with the movement of the tape in one direction or another - II). The material is unloaded from one or the other end of this conveyor; this conveyor can also move along rails along the overpass so that its shipping end is located above the corresponding stack.

To increase the transverse dimensions of the stacks, it is possible to use mobile cantilever belt conveyors of the so-called "airplane" type ( III), which receive materials from the main belt conveyor through a movable unloading trolley. In some cases, rope scrapers are used ( IV).

A tunnel (usually reinforced concrete) is arranged under the stacks for a collecting belt conveyor, which receives material from the stacks through openings in the tunnel ceiling, equipped with gates.

1 - a cylindrical tower with sector offices adjacent to it; 2 - flat vibrating screens; 3 - belt conveyor feeding material for sorting; 4 - rope scraper with a movable tower; 5 - collecting belt conveyor, feeding material from the warehouse to the holiday bins; 6 - sector warehouses of materials

It is rational to arrange warehouses for inert materials with a sector arrangement of stacks with different fractions. Sector warehouse allows you to place a lot of material in a limited area. In this system, the sorting department of the plant can be located on top of a cylindrical tower. The lower part of the tower is sunk into the ground. Radial walls adjoin the tower, dividing the warehouse into sectors and forming sectoral pockets near the tower itself, which are filled with grades of material entering them directly from the screens through the chutes. Excess material, exceeding the capacity of the pockets, is stretched over the corresponding sector of the warehouse by a rope scraper, forming a spare pile. In the wall of the lower part of the tower, opposite each sector, there is an opening equipped with a gate and a tray through which the material enters the lower end a collecting belt conveyor that feeds material to a concrete plant or to loading bins. Gates allow you to control the flow of material to the belt from each pocket, and therefore you can send from the warehouse not only any particular grade of inert material, but also a mixture different varieties in any proportion.

Scheme of unloading materials and supply to the concrete plant using a rope scraper and a belt conveyor. one - Railway; 2 - trench for material; 3 - belt conveyor to a concrete plant; 4 - bucket rope scraper; 5 - transfer funnel; 6 - inclined plane; 7- mast and winch

Scheme of unloading materials and supply to the concrete plant using a rope scraper and a belt conveyor. one - Railway; 2 - trench for material; 3 - belt conveyor to a concrete plant; 4 - bucket rope scraper; 5 - transfer funnel; 6 - inclined plane; 7- mast and winch

As material is used up from the pocket, the latter is replenished from the spare stack by a rope scraper. The rope scraper winch, together with the block tower, is mounted on a trolley moving along a circular track. On small installations, the winch is mounted on a truck or tractor trailer. Blocks for the return rope move along a circular channel, fixed at the top of the tower at the level of the floor of the sorting department.

The release of materials from warehouses to vehicles is carried out through release bins. When loading onto rail or road transport, transport units are fed under a bunker containing one or another fraction or ready-made mixture of products. For loading onto water transport, bunkers are arranged along the loading line and the contents of the bunkers are dumped immediately into the barge. Usually in this case sand is loaded separately and gravel or crushed stone is separately loaded. Scheme of moving material with the help of a cable-stayed derrick from unloading railroad trenches to piles and to a concrete plant:

1 - cement warehouse; 2 - concrete plant; 3 - unloading trenches; 4 - winch; 6 - sand; 6 - fine gravel - coarse gravel; 8 - winch

This scheme is often used. The material is unloaded from the trains into a trench located along the track. A rope scraper bucket moves along the trench, which pulls up the material and pours it through a funnel onto a conveyor belt that transfers the material to the concrete plant. Sometimes the material is fed by a rope scraper directly to the concrete plant. From railroad trenches, materials can also be reloaded using a cable-stayed derrick into spare piles or directly into the bunkers of a concrete plant. Sometimes trains or trucks transporting material to a construction site are fed onto an overpass and the material is dumped from them into high piles, under which belt conveyors pass.

The figure shows a device used in one of the sections of the construction of the Moscow-Volga canal.

If inert materials are delivered by water, then they can be unloaded by mobile cranes with a clamshell bucket or stationary derricks. The material is loaded into an intermediate hopper, under which a belt conveyor passes, moving the material to the warehouses at the concrete plant, or directly into the hopper of the concrete plant.

When delivering materials to separately located concrete mixers, the stacks are located as close as possible to them.

Onsite warehouse. Materials and structures ordered for construction are delivered to on-site warehouses and placed there in accordance with the project for the production of works and the schemes of on-site warehouses given on the construction general plan.

For each material, a place is allocated, determined in such a way that as little labor and time as possible are spent on transporting the material to workplaces. Places for receiving and reloading the solution are also placed.

The storage areas for materials (by their types) are separated from one another by through passages at least 1 m wide. In each zone, materials and products are stacked according to grades. Stacks of materials are placed at intervals of 0.7 m, so that it is convenient to approach them and sling the load (material). With a large number of the same type of products at the places of storage, they are installed with indexes of series and brands of products.

Reinforced concrete and concrete parts and blocks are positioned so that their factory markings can be read from the aisle or driveway, and the mounting loops of the products stacked in stacks are turned upwards.

Prefabricated parts are stacked in such a way that it is convenient to sling them during loading; the height of the stacks should not exceed for precast concrete products - 2 ... 2.5 m.

Products are positioned so that they do not deform, do not become dirty, do not deteriorate their front surfaces (textures). Laying structures and parts is allowed only on rectangular linings and gaskets; water should not stagnate on the structures, for which they need to be laid with a slight slope.

Through holes in concrete products are closed so that snow does not get there and ice does not form. Reinforced concrete parts are periodically cleaned of snow and ice.

Passports and certificates for products and materials. Suppliers supply the materials and products supplied to the construction site with a passport or certificate. The passport is evidence that the products are manufactured in accordance with the project (working drawings), current GOSTs or technical specifications. Acceptance of prefabricated structures without passports is prohibited.

The passport indicates the name of the products according to GOST or technical specifications and their symbol (index), the number of GOST or technical specifications, the number of products in the batch, the date of manufacture and acceptance of the batch by the technical control department (QCD) and the number of the QCD inspector, concrete grade, tempering strength concrete (as a percentage of design) at the time of acceptance.

For each batch of the same type of prefabricated reinforced concrete structures, the manufacturer submits to the construction organization acts of testing control samples of concrete.

Each product made of prefabricated reinforced concrete and concrete must have a visible marking made with indelible paint, which indicates the brand of the manufacturer, the passport number of the product, index, number of the inspector of the quality control department of the enterprise. On products in which the top is difficult to distinguish from the bottom (slabs, beams), the inscription "Top" is made or the letter B is written in the upper part, and N in the lower part. Stamps on such products are positioned so that the base of the sign faces the lower surface product, which allows you to judge its working position. If there are no loops on the elements, the slinging points are marked in accordance with the project.

Acceptance of structures and products. Upon acceptance of structures submitted for installation, their quality is checked by external inspection. They make sure that the product does not have deformations or other damages (oars), its front surface (textured layer) meets the requirements of the project. Selectively control the compliance of the geometric dimensions of the elements with the design data, the correct location of embedded parts, outlets, grooves, niches, holes, fixing devices, quarters, the safety of the mounted parts of sanitary, electrical and other equipment.

Elements of prefabricated structures that have deviations exceeding the tolerance, or other serious defects, are rejected, about which an act is drawn up.

Storage of materials. Warehousing rules are indicated in flow charts and work process charts.

Bricks are placed according to grades, and face bricks are also placed according to the color of the front surface. If the brick is delivered to the construction site without containers or packages, then it is unloaded manually, stacked in stacks up to 1.6 m high or on pallets. At the same time, bricks with blind voids are laid with voids down so that water does not penetrate into them, which, when frozen, can destroy the brick. The front brick is stacked in regular rows. The height of the stack should not exceed 1.5 m. Packages with bricks are installed in the on-site warehouse in stacks, in one or two tiers.

Ceramic wall and facing stones, as well as stones from other materials, are unloaded and stored, just like facing bricks. Facing products made of ceramic, concrete and other slabs are stored in containers or stacks on wooden spacers, stacked in 2-3 rows on an edge with the front surface to each other.

Prefabricated parts and structures are installed on wooden inventory linings and gaskets, placing them in the places provided for by the working drawings and indicated on the elements.

Platforms for stacks in warehouses are pre-leveled, the soil is compacted to prevent subsidence of linings. Otherwise, the product will not rest on the lining, but on the ground and break due to improper distribution of loads.

Gaskets between products stacked in a stack are placed one above the other, strictly vertically. The thickness of the gaskets is selected so that the overlying elements do not rest on the hinges or protruding parts of the underlying elements. Linings for stacks of products usually have a cross section of at least 100 X 100 mm.

Prefabricated concrete and reinforced concrete elements are stacked according to the following schemes.

Blocks of foundations (Fig. 107, a) and basement walls are stacked with a height of no more than 2.25 m on linings and gaskets, which are installed at a distance of 30 ... 50 cm from the ends of the blocks.

Rice. 107. Stacks of reinforced concrete structures: a - foundation beams, b - crossbars, c - floor slabs, d - flights of stairs

Rectangular crossbars (girders) up to 600 mm high (Fig. 107, b) are stacked on an edge no more than three rows in height, with linings and gaskets located at distances of 0.5 ... 1 m from the ends; crossbars of the upper row in stacks are fastened together by mounting loops.

Hollow-core floor slabs (Fig. 107, c) and floor slabs are stacked in stacks with a height of no more than 2.5 m flat up to 8 ... 10 rows, depending on the strength of the base of the warehouse; gaskets and linings are placed perpendicular to the voids at a distance of 25 ... 40 cm from the edges of the slab. When laying products in stacks, it is necessary to monitor the correct placement of the gaskets and the products themselves - improper storage of precast concrete elements (Fig. 108, a, b) inevitably leads to their destruction.

Rice. 108. Destruction reinforced concrete slabs in case of improper storage: a - pads are located not along one vertical line, 6 - three pads instead of two and not along one vertical line

Flights of stairs (Fig. 107, d) are stored steps up; stack height 5 ... 6 rows. Linings and gaskets are placed along the marches at a distance of 15 ... 20 cm from their edges. Landings are placed in a horizontal position with a height of no more than four rows, linings and gaskets are installed at a distance of 15 ... 20 cm from the ends.

Rice. 109. Storage of wall panels and blocks: a - panels, 6 - textured outdoor blocks, c - horizontal blocks; 1 - pyramid frame, 2 - ladder and railings, 3 - wall panels (partitions), 4 - supporting part

Large-panel partitions, wall panels (Fig. 109, a) and solid flat floor panels the size of a room are recommended to be stored in a vertical or slightly inclined position in cassettes or pyramids. The supporting parts 4 of the pyramids have a slight slope towards the pyramid 1, due to which a right angle is formed between the pyramid and the support. Due to this, the panels 3 installed in the pyramid rest on the flooring of the pyramid supports with the entire area of the face, and not with the edge, which eliminates damage to the edges of the panels. ,

Large concrete blocks of external (Fig. 109, b) and internal walls with a height of more than 1 m are placed in one row vertically in the design position on linings from boards with mounting loops up; when installing two blocks of external walls side by side, they are placed with a textured layer outward (shown by a dotted line).

Horizontal wall blocks (Fig. 109, c) up to 800 mm high are laid in several tiers on linings with an indent from the edges of the block by at least 50 mm (to avoid damage to the textured layer and ice formation) and no more than 1/5 of the length of the element. The total height of the stack should not exceed 2.5 m.

Rice. 110. Warehousing of building frame structures: a - columns, brigels, c - reinforced concrete beams, d - wall panels

Columns (Fig. 110, a) are stored in a warehouse in stacks of 3 ... 4 rows on gaskets, usually at a distance of 1/5 ... 1/6 of the length of the column from the ends. Reinforced concrete crossbars are also stacked (Fig. 110, b).

Trusses and beams (Fig. 110, c) with a height of more than 600 mm are stored in a vertical or slightly inclined position with vertical stops that ensure the stability of structures, and with the installation of vertical spacers between them.

Steel structures are recommended to be laid in the following ways: beams, girders, fachwerk elements (rolled and composite) with a vertical position of the walls - in stacks with a cross arrangement of rows of beams in a stack on two linings; trusses and beams with a height of more than 0.6 m - in a vertical or slightly inclined position with vertical stops that ensure the stability of structures and with the installation of vertical spacers between individual structures. Lantern trusses, window coverings, stairs and other structures are stored in the same position.