Today, science has established that 80% of all human diseases are associated with poor water quality. Moreover, if at waterworks the water after purification has indicators that meet the requirements of GOST for drinking water, then serious tests await it in the future. The inner surfaces of metal pipelines, through which water flows, are a mixture of rust, chlorinated carbons, carbonate salts, heavy metals and bacteria, which cannot but affect the quality of water. Recently, serious claims have been made to drinking tap water - both for excessive chlorination and for a high concentration of rust and scale. The population cope with this problem by its own methods: some advocate drinking water, others use filters, the choice of which is huge. But there is another category of people who, due to their ignorance or neglect of their health, exacerbates the problem, that is, not only does not purify the water, but turns it into dead water, dangerous to life. It is to this problem that the article is devoted. But first things first.

Visitors to construction markets witness an unprecedented variety of sanitary valves with the ITALY, SPAIN marks. Today the brass ball valve is a shut-off valve widely used in the world. The world leaders in the production of ball valves are Italians.

The same (at first glance) ball valves that overflow the counters of specialized markets and stores, with complete external similarity, differ significantly in cost: some of them can be bought for 35-40 rubles. apiece, and the other part of the "twins" stubbornly holds at 60 rubles. Having not received a convincing explanation of the reason for the existence of a serious "gap" in the cost of cranes at any outlet, we decided to conduct an independent investigation. It is no secret that, with complete external similarity of products, the decisive role in determining their value should be played by the composition of the metal used to manufacture the product.

In terms of their operational characteristics, ball valves are distinguished by their reliability and durability. However, during operation after installation, the branded product sometimes begins to leak, and sometimes even completely collapses, causing catastrophic flooding of the premises with all the ensuing consequences. The fact is that at present the Russian market is literally flooded with counterfeit goods. Their nomenclature is so extensive that it is difficult to name a product range that would not be affected by such a phenomenon. From CDs, clothes and groceries to drugs, counterfeits are everywhere.

But back to the sanitary fittings. The desire of manufacturers to get big profits in the shortest possible time pushes them to produce fakes of well-known European, mainly Italian, brands. At the same time, many owners of registered popular brands suffer huge annual losses, measured in hundreds of millions of dollars.

We purchased all the presented types of ball valves at various retail outlets in Moscow and carried out a chemical analysis of the metal of their constituent parts. It is well known that high quality brass is the most wear-resistant, durable and safe material in plumbing systems. The content of copper, lead, iron in brass, which is used to manufacture ball valves, is strictly controlled by European standards. The data obtained as a result of the analysis allowed us to classify all ball valves according to the quality of body alloys and ball locks into two groups.

I group we conditionally named "The firm guarantees"... This group includes ball valves with a nickel-plated brass body, a chrome-plated brass ball.

This group includes ball valves of Italian firms GIACOMINI, STC, RASTELLI and a number of others. These firms are constantly improving the quality of their products. For example, until now, STC has produced one model of a ball valve - STC, which was the basic and only one. The introduction of new technologies resulted in two subsequent models: STC-IDRO and STC-VALVEX. The quality of the brass of these taps is high, complying with European standards. STC-IDRO cranes are superior in performance to previous models. Instead of rubber, a new heat-resistant material Viton was used as one of the seals on the stem, which made it possible to increase the temperature of the medium to 1500C, the wall thickness of the valve to 2 mm. Note that the wall thickness of GIACOMINI ball valves - one of the leading Italian manufacturers of ball valves - is also 2 mm.

II group received a conditional name "No guarantees"... To this group we attributed ball valves having:

Zinc taps are the most vulnerable in terms of safety. Even if the zinc housing does not burst due to the increased water pressure in Moscow water supply systems, it is highly likely that after a year of contact with chlorinated Moscow water, it will simply crumble. The fact is that hyperchlorinated water intensively flushes out zinc and, consequently, the body of the tap becomes thinner. Zinc reacts with chlorine, as a result of which a solution of zinc chloride is formed - the same "dead" water that kills healthy cells in the body and causes a whole bunch of cancers.

We would like to draw your attention to the fact that ball valves with the same marking V or FM come across in different versions: brass body - brass ball, brass body - iron ball, zinc body - iron ball. Almost all ball valves are declared as Italian products, although dedicated people know which ones are actually Chinese. Thus, we made sure that the counterfeit fittings have only an external resemblance to the original. The material of the body and the ball, wall thickness, tolerances and other parameters of fakes do not meet European requirements, and the installation of such fittings is fraught with big troubles both for health and for the family budget.

In an unprecedented dominance of counterfeit goods, education is the best way to combat them. It is for this purpose that we began our story. Finally, take some practical advice.

N. KISELEVA, expert analyst

A pipeline element such as a Bugatti ball valve is highly reliable. Any consumer pays attention to the quality and functional reliability of the valves. It is for this reason that Bugatti ball valves are in the field of vision of most consumers. The products of this manufacturer are the leader in popularity.

At the moment, the manufacturer has developed 25 design lines of ball locking devices, which have significant differences in both design and purpose. The company produces separate series of Bugatti ball valves, which are designed for the installation of pipelines for heating systems and water supply systems.

At the moment, the manufacturer has developed 25 design lines of ball locking devices

At the initial stage, a design line of conventional standard Bugatti ball valves was developed - the 600 series, called Arizona. Subsequently, the engineers of the manufacturing company developed a line of reinforced Bugatti ball valves - the 300 series, which was named Oregon.

After the appearance of these two design lines on the market of valves, the consumer got the opportunity to choose valves depending on cost, quality and purpose.

For the assembly and further operation of pipelines of heating systems, shut-off valves belonging to the 300 series are used. For the installation of pipelines of cold and hot water supply systems, valves belonging to the 600 series are used.

When connecting radiators to the heating system, it is recommended to use shut-off valves of the 300 series, which are completed with a detachable special American coupling. These valves are 1/2 "and 3/4".

For the assembly and further operation of pipelines of heating systems, shut-off valves belonging to the 300 series are used

After developing a range of heavy-duty cranes, the engineers developed a series of heavy-duty cranes, numbered 400 and named Nevada. This type of product is designed to work in high stress conditions.

The 400 series has a special design. In the valves of this line, the use of an inner stem is introduced. The use of this element in the design made it possible to make the shut-off valves more reliable in operation and prevent the stem from jumping out, even in cases when the gland special nut is unscrewed, which ensures the pressing of the seal.

Bugatti ball valves are certified on the territory of the Russian Federation to work with media of different physical parameters. These environments are:

Currently, the manufacturer produces Bugatti ball valve models with thread sizes from 1/8 to 4 inches

Many consumers use the equipment of this company for the operation of systems transporting soft and alcoholic beverages, liquid hydrocarbons. Cases of reliable functioning of this shut-off valve when used in systems transporting slightly acidic or slightly alkaline solutions have also been recorded.

Currently, the manufacturer produces Bugatti ball valve models that have thread sizes from 1/8 to 4 inches. In addition, the company offers the consumer the following types of cranes:

In addition, special models are produced that have a drain connection or filter.

The operating temperature at which the operation of the Bugatti branded valves is allowed reaches +150 degrees Celsius, the operating pressure is 64 atmospheres. In the manufacture of products, the manufacturer uses brass, fluoroplastic and rubber.

At the moment, shut-off equipment is being produced, which is equipped with an electric drive for controlling a ball lock, and shut-off valves with devices that block the operation of taps. The operation of such a device is resumed only when a special key is used to unlock the system. The Green Line taps are absolutely environmentally friendly, which allows them to be used in drinking water supply systems.

High ecological the safety of products belonging to the Green Line is achieved by the fact that brass is used as a material for the manufacture of product bodies, in which the surface layer of the metal contains a minimum amount of lead. This layer does not release lead in contact with water. In addition, the ball insert used in the valves of this series of products has special grooves that provide additional circulation of water in the product cavity, which allows automatic cleaning of the device cavities from mechanical deposits. The use of special grooves on the ball insert prevents the destruction of the taps in case of freezing of water in their inner cavity. This design makes it possible to implement the "anti-frost" function in practice.

Modern Bugatti taps of the Bugatti Waterworks special series allow you to connect to existing water supply networks without complex installation operations. This shut-off valve has a blocking function and has the ability to connect pipelines made using polymer raw materials to it.

There are many manufacturers on the Russian market: there are European, Chinese, Russian ball valves, which differ in technical characteristics, purpose, assortment, cost. We invite you to familiarize yourself with several brands, whose products have been in our product line for many years.

Bugatti is an Italian company that has been known worldwide for its excellent for over 60 years. The family-owned company has always paid the utmost attention to product quality and has invested in the most innovative and reliable technology solutions. All this has made it one of the recognized leaders in the niche of valve manufacturers.

Based on the changing demand, the Italian manufacturer is constantly expanding its range of finished products - weighted valves, cheap ball valves, etc. A notable feature of the Bugatti brand with th, and - maintainability, which is very important for those who wish to buy. The finished product includes a nut for adjusting the packing gland. It is enough to turn the nut for the PTFE ring to take its place. Only due to this design feature, the life of the ball valve reaches 20 thousand openings and closings. All products are made of brass exclusively by hot stamping.

Multi-stage production has a quality control system at any technological stage. This allowed the Bugatti brand to obtain ISO 9000/2000 certification. Today, the company's customers include dealers from 85 countries, and thanks to the Randstroy company, it has been possible to buy in Moscow for more than 20 years. In the nomenclature, as well as for plumbing.

ARCO is a Spanish corporation dating back to 1973. ARCO is well known all over the world as a manufacturer of valves for heating and plumbing (). Following the changing consumer demands, the Spanish factory recommends to its customers simple and safe, innovative and rational turnkey solutions, both for residential buildings and for industrial scale industries. The company does not have production facilities in Asia and for many buyers this is an indisputable proof of product quality.

Each of the shops of the brand's plant is equipped with the most modern equipment:Since all technological processes are concentrated entirely in the production workshops of the plant, the ARCO brand exercises sole control over the quality of products at all stages of their manufacture. At the moment, the Spanish brand is deservedly recognized as the leader in its field and has the high status of the largest supplier, not only nationally, but also international. You can buy at fairly attractive prices - this allows the company's pricing policy. Factories are located in Tunisia and Valencia. The annual volume of supplies is estimated at 40 million units of finished products. To use is to rely on quality.

In an effort to strengthen its position as a recognized leader, the company is continuously increasing the share of its international supplies. Today you can easily find an ARCO office on all 5 continents than in 100 countries. The concept of brand development is high-quality work and proximity to our customers so that anyone can buy in the right quantity and performance. This goal is served by 500 specialists who make up a team of professionals working on the solution of the main task: to make ARCO products even more durable and safer.

NT Corporation is a brand owned by the NT Corporation GmbH group. The appearance of the Corporation on the market was predetermined by the need to provide Russian consumers with an alternative to low-quality Chinese-made products and the opportunity to buy the best quality in Moscow. The development became possible thanks to the participation of specialists from Russia, Spain, Italy, Germany. The result was a product oriented towards operation in Russian conditions, but at the same time meeting European quality standards. It is quite possible to buy a quality ball valve. When creating products, the wishes of the largest consumers of fittings for pipelines and sanitary products were taken into account. The entire assortment is provided with a guarantee, service support and the most modern sales service, which allows you to buy in Moscow on the most attractive terms.

The Corporation brand specializes in the development of new technological processes and finished products, including a selection of design solutions, the creation of innovative materials. All products are subject to technical specifications and approval is carried out in the relevant regulatory authorities. The ball valve can be purchased with all accompanying documentation from NT Corporation. Product tests for compliance with quality standards are carried out at the company's enterprises, which is confirmed by the protocols provided when you need to buy ball valves in Moscow. A ready-made and coordinated solution is placed in the form of an order at factories of world leaders with an impeccable business reputation. As a result, NT Corporation products end up on Russian shelves, you can buy ball valves fully adapted for operation in local conditions, but at the same time meeting international standards. All items have the widest scope of application, and are produced in a wide variety of modifications, differing in individual design, as well as throughput rates and the applied flow shut-off method.

It is possible to buy a ball valve in Moscow of the highest quality. The main parameters of valves:Any locking device is made so that the main condition is met: installation takes a minimum of time and effort. Careful selection of materials allows ensuring the durability of the product. The technological process of manufacturing the product, carefully controlled by the manufacturer, is responsible for the quality. you can buy high quality only from a reputable manufacturer. Only if these conditions are met, you can get a high-quality, durable and reliable product of shut-off valves and buy ball valves at a profit. Such products are used in water supply, gas supply, sewerage, air conditioning and other engineering networks. Installation and operation of a wide variety of household and industrial equipment is unthinkable without the use of valves, however, if necessary, buy ball valves in Moscow - pay close attention to their brand. It is better to buy a ball valve in a specialized store.

In the body of the ball valve there is a through passage and a flow of liquid or gas is directed through it. By turning the knob, the shutter blocks the flow or frees its way. Ball valves can be purchased in the desired design. There are two types of ball valves design: floating ball or bearing ball. You can buy a ball valve in Moscow of any design.

The shutter (ball plug) is not rigidly connected to the spindle. This allows it to move freely in relation to the spindle. Under the pressure of liquid or gas, the blockage is pressed against the O-ring (seat), which allows the ball valve to remain tight.

Ball valves can be bought with large diameters and high operating pressures for operation under high pressure on O-rings. The design features of such a ball valve initially complicate its operation, so it is better to buy a ball valve with a ball in the supports. For this reason, this category of products is used exclusively for the installation of pipelines with working diameters up to 200 mm.

The ball valve shutter rotates and is installed in the support. This support is at the bottom equipped with a trunnion (axial protrusion), which goes into a specially designed recess. The fluid presses the O-rings against the valve. As a result, much less effort is required to turn the bolt. If you need to buy a ball valve in Moscow and at the same time equip it with a drive device, then you need a unit less powerful than for devices with a floating ball. The increasing complexity of the design makes the ball valve more expensive.

There are 4 types of ball valves. A ball valve can be bought by the type of its installation in the pipeline:It is very easy to buy ball valves in Moscow, since they are extremely demanded for the installation of oil pipelines, gas pipelines, as well as other transportation lines for chemical products. Coupling ball valve is most in demand in heating and water supply city networks. Flanged ball valves are used in the oil and gas industry, so it is profitable to buy a ball valve in a large batch.

The nomenclature of finished shut-off products includes special purpose ball valves:Ball valves are widely used for laying water and gas networks, installing heating equipment, plumbing, etc. The main buyers who often need to buy a ball valve are private companies, developers, utilities. Oil and gas companies and manufacturers of related industries of the national economic complex are also the largest consumers of valves, it is profitable for them to buy ball valves at a discount. Products of Bugatti, NT Corporation, ARCO meet all quality requirements, are made of brass and are characterized by the highest performance indicators - up to 20 thousand cycles. Everyone can buy these ball valves in Moscow. The ball valve is very simple and has only 2 positions: open or closed. If the product is used for other purposes (to regulate the fluid flow), this entails a multiple acceleration of its wear and contributes to an early breakdown. You can buy ball valves and then mount them on site in any direction. Installation should be carried out in accordance with the manufacturer's recommendations, in particular, it is prohibited to use "gas" adjustable wrenches, as this leads to crushing of the outer casing of the product. Ball valves must be purchased together with mounting equipment.

NT Corporation brand liquid ball valves are designed for use in heating and plumbing, hydraulic and pneumatic networks. They are referred to the category of heavy series couplings. During production, special materials are used that guarantee extremely high tightness of the product, when the consumer needs to buy ball valves of the highest quality. Therefore, they are chosen for the installation of air supply systems, oil products, natural gas, oxygen, solvents, etc. Today it is easy and affordable to buy a ball valve in Moscow from NT Corporation.

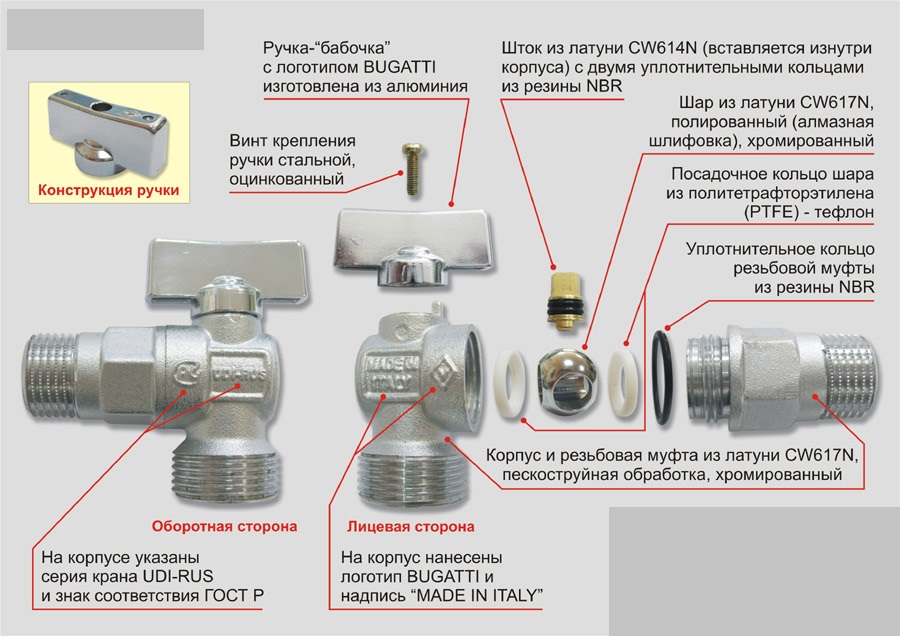

The housings are manufactured from CW617N forged brass. Ready-made ball valves can be bought in Moscow with a nickel-plated body or without nickel-plating. The valve ball is made of the same material on a hot stamping machine, after which it is polished with diamond discs and chrome plated. You can buy ball valves chrome and ordinary. This production method allows achieving high strength characteristics, resistance to heat and high pressure, resistance to mechanical wear and assembly loads. Brass does not rust, so a ball valve can be bought for a very long time. A PTFE-grade 4 / PTFE sealing gasket is responsible for the tightness. When you need to buy ball valves in Moscow, you can choose from products with handles: "butterfly" and "lever". Test reports of Russian and foreign NT Corporation ball valves confirm that they can be operated in the operating temperature range from -200 to +1500 degrees Celsius, at a maximum operating pressure of 64 bar. The ball valve can be purchased with any required strength.

The nomenclature includes the following popular articles with internal and / or external threads:All NT Corporation ball valve part numbers include a wide range of sizes. The scope of application of Bugatti brand ball valves for liquid pipelines is the same as for NT Corporation products: plumbing, heating, pneumatic, hydraulic systems. Ball valves can be purchased for a wide variety of tasks. A very wide range of coupling valves allows you to buy a ball valve for any application. Ball valves to buy in Moscow are available in the design required for specific conditions. For the ball valve body, CW617N (forged) brass was selected. The finished case is sandblasted and then nickel plated. The shutter is also made of brass of the same brand, polished and chrome plated. The choice in favor of forged brass when you need to buy ball valves is due to the strength characteristics of the metal and its resistance to heat and high pressure. Brass is resistant to mechanical stress, which inevitably appears during the installation of the product. A huge advantage of the metal is its corrosion resistance, which allows you to buy a ball valve for a long time.

Two types of gaskets are responsible for the tightness of the products, made of nitrile butadiene rubber (NBR) and fluoroplastic 4 / PTFE. The handle can be of any type: "lever", "globe", "". Handles can be painted with special paints, coated with polymer or chrome. A ball valve can be purchased with the desired handle. The operating temperature range is within -200 / + 1200C, and the highest operating pressure varies, depending on the model, from 4 to 64 bar.

Since ball valves can be bought from Bugatti for use in a wide variety of areas, they are distinguished by a wide variety of design solutions, and the number of series is also very large:

* ISO 228/1 for leaky threads.

** ISO 7: 2000 for sealed threads.

*** The diameter of the hole in the ball is less than the inner diameter of the pipe.

Within the series of ball valves there is a size range, as well as an additional subdivision by type of thread (internal or external), can be supplied with different handles. Additional articles (523, 525, 516, 521) of three-way valves are available in the Virginia series and it is also possible to buy these ball valves in Moscow.

ARCO's products - coupling-type ball valves can be used in hydraulic, pneumatic, heating, water supply systems. A ball valve can be purchased with the required characteristics. The main difference from the products of the Bugatti and NT Corporation brands is that the brass used is UNI 5705-65. Both the shutter and the body for the ARCO ball valve are made by hot stamping of brass, so it is better to buy ball valves of this kind. After that, the forged workpieces are sandblasted and coated with nickel. The gates are chrome plated and polished on diamond machines.

This production technology makes it possible to manufacture products with high strength and resistance to heat and high pressure, which makes it possible to buy a ball valve with the required characteristics. He is not afraid of mechanical stresses inevitable during installation. The choice in favor of brass, when it is necessary to buy ball valves in Moscow profitably, is due to its resistance to corrosion. Elastomer O-rings (NBR) and fluoroplastic rings (PTFE) are used to ensure tightness of the product. The range of handles is represented by the butterfly and lever models, coated with a special paint or polymer. Operating temperature range -300 / + 2200C, maximum withstand operating pressure 10-50 bar, depending on the model.

The ball valve can be purchased from any of the following series:All products are marked by standard sizes, threads (BP or HP), supplied with different handles, so you can always buy a ball valve in the required configuration, and you can buy a ball valve in Moscow from the best manufacturers.

The ball valve is today at the peak of its well-deserved popularity. Pipeline and stop valves from manufacturers from different European countries, as well as from Eastern countries, deserve serious attention, but Italian products are in greatest demand, and this is not surprising: in Italy, more than two thousand companies produce ball valves for gas and water. Top brands have excellent specifications and are appropriately certified in Russia. Here are some examples of the most famous ball valve companies.

Tiemme manufactures ball valves of various types, valves of this brand are of high quality and reliability. Tiemme ball valves are distinguished by the fact that they have a nut for adjusting the stuffing box packing, through which leaks usually occur in case of valve wear. This nut makes it possible to eliminate the leakage and increase the service life of the ball valve. The company's products have certificates for ball valves for water, steam and gas, they are recommended by the Fuel and Energy Industry of Moscow.

Giacomini ball valves have a special cube-shaped shutter with the DADO lettering on it. A distinctive feature of Giacomini products is the holographic sticker on each ball valve and the date of manufacture on the handle, which is applied in a special way so that it will not be erased during the entire service life.

The most popular are ball valves and pipeline accessories Italian firm Bugatti (Bugatti). This is one of the sales leaders who managed to prove the quality and reliability of their products in practice. Since 2001, the stem of the ball valve has been placed outside the body, which has dramatically improved product safety. This technology for the production of ball valves eliminates stem overhang with a sharp increase in pressure in the pipes.

A similar technology is used in production by Enolgas, which also mounts the stem on the outside of the ball valve body. Also, Enolgas ball valves have Teflon washers that act as a seal and antifriction component. Like most Italian manufacturers, Enolgas ball valves perform well in plumbing, gas, steam systems, as well as for oils, compressed air and hydrocarbons.

The Itap company manufactures ball valves of various types, in the assortment there are semi-bore and full bore valves, ball valves for gas and ball valves for water with handles of lever and throttle systems, corner valves and other products of this company are distinguished by a long service life and reliability.

Other world famous brands include Italian brands Remer, Valtec, STC, Ferrero, Bossini, F.I.V., Rastelli, RBM, German Oventrop sanitary ware and Chinese Ser faucets.

But, as you know, the fame gained by labor, modern developments and high-quality materials does not give rest to counterfeiters. On the market of our country, about half of the plumbing products are fake, this fully applies to ball valves. Manufacturers of fake cranes set themselves only one task - to achieve external similarity and make a profit by investing a minimum of funds in production. Fake ball valves cannot be compared with the original ones either in terms of safety parameters or in terms of service life. Before buying ball valves wholesale or retail, you should pay attention to the distinctive features of the product, by which you can recognize a fake.

Each original ball valve is marked accordingly. The company logo, its name and other elements must be written clearly and without errors. To know exactly how a ball valve is marked, it is worthwhile to find information in advance on the company's official website. The ball valve must have a flat surface, without cracks and sagging. If this is not the case, then the casting method was used in the production, which does not allow obtaining high-quality products, such as the method of stamping and forging. Also the use of the casting method is indicated by the increased wall thickness of the crane. The ball valve mirror should not be cloudy or dull. Real ball valves from leading manufacturers have a diamond ground ball. The counterfeiters do not have the means for such a thorough and expensive processing, hence the uneven, cloudy surface of the ball.

A high-quality ball valve should be made of brass, and the chemical composition of the alloy is determined by state standards. Counterfeits often contain increased amounts of lead, hazardous to human health, or are made from zinc. It is not uncommon for unscrupulous manufacturers to use non-ferrous scrap or make a ball from steel, which is prone to corrosion, to manufacture ball valves. Sometimes a simple scratching of the faucet surface helps to distinguish a fake: if a metal of a different color appears under the nickel layer, then the ball valve is made by counterfeiters. You should also pay attention to the thickness of the walls of the faucet: if it is thinner than it should be, the faucet will not last long and cannot withstand a pressure surge.

It is not always possible to distinguish a fake. An entire chemical laboratory is needed to study the chemical composition of the alloy. To be sure of the quality of the purchased products, you need to contact the official representatives of companies that have proven themselves in the plumbing market. Do not be deceived, use the services of reliable and trusted suppliers of plumbing.

Choosing valves can be quite simple if you are well versed in this area, know reliable manufacturers and use your buyer's right to provide information about products. We offer you to understand the points of how to choose a ball valve from the brands presented on the domestic market.

One of the reliable firms is the company Bugatti ball craneswhich have been supplied from Italy since 1996. The products have all the necessary certificates to guarantee safe and long-term operation.

It just so happened that the Italians take the first places in the ratings of high-quality plumbing, they do not lag behind in the manufacture of valves. No system can do without such an important element, be it water or gas supply.

Fast and, most importantly, complete and reliable shut-off of the liquid flow is a very important task, therefore professionals take the choice of such valves seriously.

For example, let's take a look at the Italian company Bugatti, which produces ball valves in a variety of designs. In addition to this company, Danish Ballomax ball valves can be found on the market, there are also other brands offering products of similar quality. But much more important than the name on the box will be the next item - the place of purchase.

There is nothing easier and worse than buying a Bugatti ball valve on the local market, where the chance of acquiring a fake is catastrophically high. In addition, if this low-quality part breaks down, no one will even return the money, because, as a rule, no checks are provided on the market. It is better to purchase valves in a certified store, if one is not available, then in building hypermarkets with a good reputation. But in order to completely remove all doubts, take an interest in the certificate, which must necessarily come with a blue seal, even if it is a copy.

In addition to the papers from the manufacturer, you can take the Bugatti ball valve in your hands and carefully examine it. A quality product will not have any sags or irregularities. Pay great attention to the inscriptions: it is advisable to look through the catalog in advance and write out a number of a specific model (for example, a ball valve coupling 11b27p1), and already in the store check with the markings on the product. Look at the quality of the inscriptions themselves, which should be easy to read, the letters should be even, clearly distinguishable. Note also the brass mark on the tap - Bugatti makes its products from CW617N forged brass.

In addition to the papers from the manufacturer, you can take the Bugatti ball valve in your hands and carefully examine it. A quality product will not have any sags or irregularities. Pay great attention to the inscriptions: it is advisable to look through the catalog in advance and write out a number of a specific model (for example, a ball valve coupling 11b27p1), and already in the store check with the markings on the product. Look at the quality of the inscriptions themselves, which should be easy to read, the letters should be even, clearly distinguishable. Note also the brass mark on the tap - Bugatti makes its products from CW617N forged brass.

The thickness of the walls of the case should not only be 2 mm or more, but also be uniform. Look inside, look at the ball - it should be mirrored. If the ball is not polished, then it is not Bugatti ball valves in front of you, but a fake. The case can be scratched a little - the metal will appear yellowish, which means brass, while all fakes are usually made of silumin.

The thickness of the walls of the case should not only be 2 mm or more, but also be uniform. Look inside, look at the ball - it should be mirrored. If the ball is not polished, then it is not Bugatti ball valves in front of you, but a fake. The case can be scratched a little - the metal will appear yellowish, which means brass, while all fakes are usually made of silumin.

In addition, unscrupulous manufacturers, saving materials, make the case itself too thin. So, in some samples, the thickness was only 0.6 mm, which is too small for reliable operation. It is better to buy an inexpensive but branded Marshall ball valve than a fake of a well-known brand.

One last thing: check if the ball is magnetised. If so, do not take such a copy, since the ball must also be made of brass. These simple tips will help you when you urgently need a crane, and you can go far to the nearest 100% reliable seller.

To buy a fake or just a low-quality tap is not only a chance to flood the neighbors from below, but also to go to a hospital with serious illnesses. It's all about the metals used in the manufacture. So, the quality of brass, more precisely, its chemical composition, is of serious importance. As for the elements made of zinc, there is nothing to talk about: using such shut-off valves for the water supply system, you run a great risk. Zinc + chlorinated water \u003d gradual destruction of both the tap itself and the human body, into which compounds hazardous to health enter. Any Naval ball valves or the same Bugatti certified ones guarantee health safety.

To install correctly, you need to know the structure of any device or element, otherwise it can be damaged during installation. Actually, the ball valve is named because of the shape of the performing part. Despite the fact that in the post-Soviet countries this type of shut-off valves has become widespread relatively recently, the designs have been for more than a century. It's all about the gaskets, which, until the recent appearance of fluoroplastic and synthetic rubber, quickly failed. In addition to the performing movable element, there is a housing in which the cut-off sphere is fixed by means of O-rings. The ball itself has a hole through which water flows.

To install correctly, you need to know the structure of any device or element, otherwise it can be damaged during installation. Actually, the ball valve is named because of the shape of the performing part. Despite the fact that in the post-Soviet countries this type of shut-off valves has become widespread relatively recently, the designs have been for more than a century. It's all about the gaskets, which, until the recent appearance of fluoroplastic and synthetic rubber, quickly failed. In addition to the performing movable element, there is a housing in which the cut-off sphere is fixed by means of O-rings. The ball itself has a hole through which water flows.

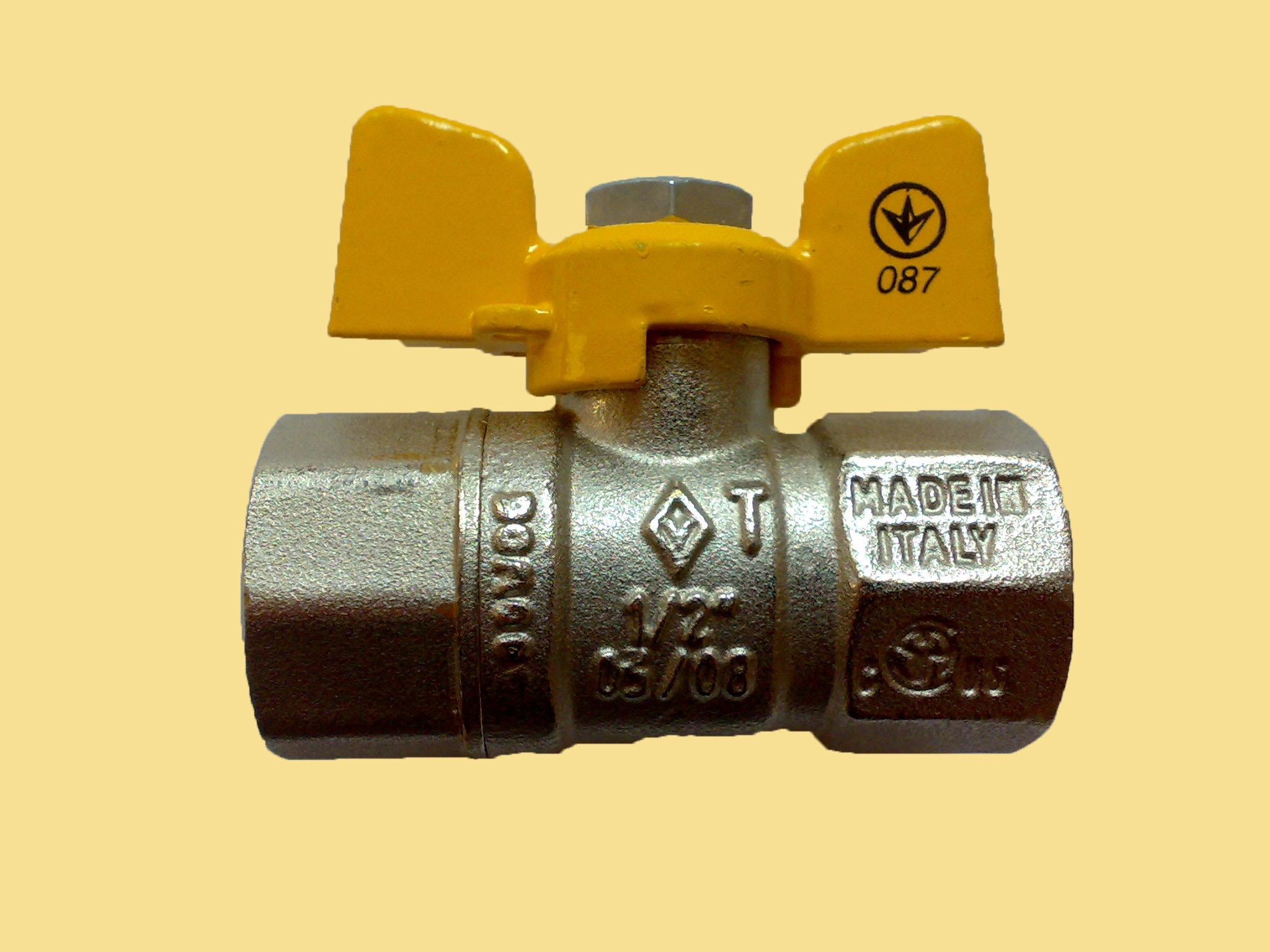

Opening and closing is done by turning the ball by means of the handle, gas ball valves have yellow handles, plumbing handles red and blue. The body has 90 degree stops for two positions: fully open and fully closed. Also, there may be a screw-on part on the body, such models are called collapsible and must be repaired. More often you can find non-separable structures, but they, provided the use of high-quality materials, can serve for a long time.

In addition to simple checkpoints, a ball valve is often used, which is not a shut-off valve, but only redistributes the flow, having one inlet and two outlets, or vice versa.

They are distinguished by the method of attachment to welded, coupling and flanged. The latter are rarely found in everyday life, they are more often used on highways where the diameter exceeds 60 mm. The ld marking also indicates flanged ball valves. They also use models with special automatic closing systems, for example, a ball valve with an electric drive or with a pneumatic drive. Welded ones at the moment have practically disappeared from the market, they were replaced by coupling ones, which are fastened with a thread.

- before installing, remove the handle so that it does not interfere with gripping the product with a key;

- do not use a gas wrench for installation, as excessive compression force can deform and thereby damage the part;

- when connecting, use the nearest hexagonal neck for gripping with a key;

- for a tight connection, use tow or fum. tape.

To start repairing a ball valve, you should decide on a breakdown. The most common failure is the wear of the O-rings, as a result of which the element begins to leak. To replace, remove the handle by unscrewing the fastening nut, then unscrew the threaded ring with a screwdriver and hammer. Using pliers, we carefully take out the chrome-plated dome-shaped part and change the O-rings. Then we take out the ball and change the ring under it, do not forget to clean the seats for the rings. After completing the procedure, carefully assemble the product in the reverse order. If you do not have new rings available, the old ones can be cleaned in any acidic solution, such as citric acid or vinegar, and replaced. Often the tap is missed due to contamination and calcium salt deposits on the rings.